目录

电气导管在保护电线免受损坏、确保电气系统安全可靠运行方面起着至关重要的作用。无论是在住宅、商业还是工业应用中,电气导管都能保护电线免受物理伤害、潮湿、火灾和其他环境危害。管理电气导管使用和安装的最重要标准之一 澳大利亚和新西兰的电气导管 是 AS/NZS 2053。该标准提供了有关各种导管系统的类型、材料和安装实践的详细指南,确保它们满足必要的安全和性能标准。

在此综合指南中,我们将深入探讨三个主要的 AS/NZS 2053 标准:

AS/NZS 2053.2–电气设备用导管和配件–绝缘材料制成的刚性普通导管。

AS/NZS 2053.6–电气设备用导管和配件– 绝缘材料制成的异型壁光滑内孔导管和配件。

AS/NZS2053.5 – 电气设备用导管和配件第 5 部分绝缘材料波纹导管和配件

我们将详细分析其范围、主要规定以及它如何适用于不同类型的电气导管,包括硬质 PVC 导管、柔性 PVC 导管和波纹导管。了解这项标准对于在这些地区设计、安装或维护电气系统的电工、承包商和工程师来说至关重要。

通过阅读本文,您将获得以下方面的宝贵见解:

- AS/NZS 2053 标准的范围及其与各种类型的导管系统的相关性。

- 该标准涵盖的不同类型的电气导管,例如硬质 PVC 导管、PVC 导管、柔性 PVC 导管和波纹导管。

- 导管材料必须经过的测试程序,以满足所需的安全和性能标准。

- AS/NZS 2053 在不同电气装置和环境中的应用。

- 遵守 AS/NZS 2053 规范对于确保电气系统安全耐用的重要性。

注:本文所有内容均基于 AS/NZS 2053 2001 版本,并 归澳大利亚标准局所有.

了解澳大利亚标准

澳大利亚标准协会在电气管道法规中的作用

澳大利亚标准协会是澳大利亚全国性标准组织,负责制定和发布澳大利亚各行各业的标准。该组织在确保产品和服务(包括电气系统)的安全、质量和性能方面发挥着重要作用。通过制定和更新行业标准,澳大利亚标准协会确保电气设备达到最高安全性和可靠性水平,从而降低电气危险风险。

AS/NZS 2053 标准是澳大利亚标准协会和新西兰标准协会共同努力的成果。它是一套更广泛的指导方针的一部分,旨在确保两国电气系统安装的统一性和一致性。AS/NZS 2053 不仅对澳大利亚电工和工程师至关重要,而且也是新西兰电气安装的重要参考。该标准适用于各种类型的电气导管,为其构造、安装和测试提供指导,以确保它们符合安全和性能要求。

AS/NZS 2053 等电气标准的制定符合国际最佳实践,同时也满足了澳大利亚和新西兰市场的独特需求和条件。遵守这些标准对于遵守国家建筑规范和法规至关重要,从而确保电气系统和与之合作的人员的安全。

AS/NZS 2053 的范围

AS/NZS 2053 标准为电气导管系统(包括金属和非金属导管和配件)提供了全面的指导方针,确保它们满足安全性、耐用性和性能要求。该标准的范围涵盖导管系统的各个方面,包括材料、安装实践和测试程序。其主要目标是保护电线免受外部因素的影响,例如物理损坏、潮湿、火灾和化学暴露。

AS/NZS 2053 中定义的导管类型

1. AS/NZS 2053.2 – 绝缘材料刚性平面导管

本节重点介绍用于为固定安装中的电线提供强大保护的刚性普通导管。

涵盖的导管类型:

PVC 硬管: 由于其重量轻、耐腐蚀、阻燃和易于安装,因此被广泛使用。这些导管适用于外露、嵌入式或地下布线系统。

非火焰传播导管: 专门设计的导管可在发生火灾时最大程度地减少火焰蔓延,从而提高安装的整体安全性。

应用:

住宅和商业建筑中的墙壁和天花板安装。

基础设施项目中的地下电缆保护。

暴露的设施需要抗紫外线和防风雨的解决方案。

2. AS/NZS 2053.5 – 绝缘材料波纹管和配件

该标准的这一部分定义了全波纹导管,这种导管重量轻、灵活性高,是需要适应性的动态安装的理想选择。

涵盖的导管类型:

PVC波纹管: 由于其适应性,这些导管被广泛使用,非常适合在狭小空间或频繁移动的区域安装。

紫外线稳定波纹管: 这些导管专为户外使用而设计,可抵抗紫外线辐射和极端天气条件。

应用:

在狭窄或密闭空间内进行电线安装。

频繁运动的动态系统,例如机器人或机械。

需要抵抗环境压力的户外设施。

3. AS/NZS 2053.6 – 绝缘材料异型壁光滑内孔导管和配件

这种导管具有波纹外壁,具有柔韧性和强度,内孔光滑,便于拉动电缆。这些导管非常适合需要兼具适应性和耐用性的安装。

涵盖的导管类型包括:

型壁 PVC 导管: 其外观呈波纹状,可增强灵活性和强度,内表面光滑,可轻松拉动电缆。

应用:

公用事业网络中的地下电缆布线。

灵活的安装需要光滑的内壁以最大限度地减少电缆摩擦。

化学腐蚀环境中的基础设施项目。

AS/NZS 2053 涵盖的关键领域:

AS/NZS 2053 主要与以下国家相关:

澳大利亚: 该标准在全国范围内得到广泛认可和采用,成为许多地方电气法规和合规要求的基础。

新西兰: 该标准在新西兰也得到认可,使两国的做法保持一致,并确保电气装置符合类似的安全和性能标准。

AS/NZS 2053 的主要内容

AS/NZS 2053 系列是澳大利亚和新西兰电气导管标准的基石,为电气安装导管和配件的设计、构造和性能提供全面的指导。这些标准确保了各种应用的安全性、可靠性和兼容性。在本节中,我们将总结前面介绍的三个关键标准涵盖的主要方面:AS/NZS 2053.2、AS/NZS 2053.6 和 AS/NZS 2053.5。

1. AS/NZS 2053.2 – 绝缘材料刚性平面导管

本标准提供了电气设备中使用的刚性普通导管的详细规格。它概述了:

材料要求: PVC 等绝缘材料的标准,确保耐用性、电气安全性和抵抗环境因素的能力。

方面: 刚性导管直径和长度的规格。

机械性能: 强度、抗压和抗冲击性的规格可满足不同的工作分类。

性能测试: 评估耐火性、电气绝缘性和紫外线稳定性的标准。

2. AS/NZS 2053.5 – 绝缘材料波纹管和配件

本系列的这一部分讨论了波纹管的独特特性,重点强调:

设计规范: 罗纹结构增强了灵活性并减轻了结构重量。

方面: 刚性导管直径和长度的规格。

材料要求: PVC 等绝缘材料,具有高灵活性和耐用性。

机械性能: 抵抗冲击、压缩和动态运动的标准。

3. AS/NZS 2053.6 – 异型壁光滑内孔导管和配件

本标准主要针对外部壁呈异形且内孔光滑的导管。它包括:

材质标准: 适用于柔性、轻型导管的绝缘材料。

尺寸要求: 壁面轮廓和钻孔光滑度的规格,以方便拉动电缆。

机械和热性能: 柔韧性、抗冲击性和热稳定性的标准。

AS/NZS 2053 详细介绍

AS/NZS 2053.2 – 刚性普通导管和配件

AS/NZS 2053.2 是 AS/NZS 2053 系列中的重要标准,规定了由绝缘材料制成的刚性普通非螺纹导管和配件的要求。这些导管主要用于保护电气设备中的电缆,确保机械保护和电气安全。本节详细介绍了该标准、其分类、尺寸、机械性能以及相关的测试程序。

范围和总体概述

AS/NZS 2053.2 适用于:

刚性平面导管: 不可螺纹,由 PVC 等绝缘材料制成。

配件: 诸如接头、弯头和适配器等配件专为与这些导管一起使用而设计。

分类

分类依据 机械性能:

- Vert 轻型刚性导管

- 轻型刚性导管

- 中型刚性导管

- 重型刚性导管

- 超重型刚性导管

分类依据 电气特性:

- 具有电绝缘特性

尺寸要求

该标准定义了精确的尺寸要求,以确保安装过程中的兼容性和统一性。

圆形导管尺寸(尺寸表)

公称尺寸 | 外径 | 壁厚 | ||||||||

平均直径 | 非常轻便 | 轻型 | 中型 | 重负 | ||||||

最小。 | 最大限度。 | 最小。 | 最大限度。 | 最小。 | 最大限度。 | 最小。 | 最大限度。 | 最小。 | 最大限度。 | |

16 | 15.7 | 16.0 | / | / | / | / | 1.6 | 1.9 | / | / |

20 | 19.7 | 20.0 | / | / | / | / | 1.8 | 2.1 | 2.3 | 2.6 |

25 | 24.7 | 25.0 | / | / | / | / | 1.8 | 2.1 | 2.5 | 2.8 |

32 | 31.7 | 32.0 | / | / | / | / | 2.1 | 2.4 | 2.7 | 3.0 |

40 | 39.7 | 40.0 | / | / | / | / | 2.4 | 2.7 | 3.1 | 3.4 |

50 | 49.7 | 50.0 | / | / | / | / | 2.8 | 3.1 | 3.4 | 3.9 |

63 | 62.7 | 63.0 | / | / | / | / | 3.0 | 3.5 | 3.9 | 4.5 |

65 | 75.2 | 75.5 | / | / | / | / | 3.0 | 3.5 | 3.9 | 4.5 |

80(新西兰) | 82.3 | 82.7 | / | / | 2.2 | 2.6 | 3.2 | 3.7 | 4.2 | 4.9 |

80(澳大利亚) | 88.7 | 89.1 | 1.8 | 2.2 | 2.4 | 2.8 | 3.5 | 4.1 | 4.6 | 5.3 |

100(新西兰) | 110.0 | 110.4 | 2.2 | 2.6 | 2.9 | 3.4 | 4.3 | 5.0 | 5.7 | 6.5 |

100(澳大利亚) | 114.1 | 114.5 | 2.3 | 2.7 | 3.0 | 3.5 | 4.5 | 5.2 | 5.9 | 6.7 |

125 | 140.0 | 140.4 | 2.8 | 3.3 | 3.7 | 4.3 | 5.5 | 6.3 | 7.2 | 8.1 |

150 | 160.0 | 159.5 | 3.2 | 3.7 | 4.2 | 4.8 | 6.3 | 7.1 | 8.3 | 9.3 |

导管长度表

导管尺寸 | 长度 |

最大至 63 码 | 4 米 + 20, -0 毫米 |

63 码以上 | 6 米 + 50, -0 毫米 |

机械性能

该标准概述了严格的机械性能要求,以确保导管和配件能够承受各种压力:

弯曲强度:

AS/NZS 2053.2 中描述的弯曲测试评估了导管在安装或使用过程中承受弯曲力的机械柔韧性和耐用性。该测试可确保按特定机械应力水平分类的导管能够承受弯曲而不会出现明显损坏,从而保持其功能性和完整性。以下是标准中概述的要求和程序的摘要:

适用性

弯曲测试仅适用于某些类别和尺寸的导管:

适用导管:

直径小于32毫米的导管。

被归类为适合于:

机械应力非常小。

轻微的机械应力。

中等机械应力。

豁免管道:

直径等于或大于 32 毫米的导管。

重型和超重型导管无需经过此项测试。

测试程序

弯曲试验包括以下步骤:

- 放置:

将 500 毫米试件放置在弯曲装置的凹槽中,用夹具轻轻固定。

- 弯曲:

使用弯曲滚轮将试件围绕成型器移动,形成约 180° 的弯曲。

释放后,试件应保持90°的弯曲。

- 移动:

移除弯曲装置,而不会对试件造成额外的损坏。

验收标准

完成测试后:

- 导管不得出现无需放大即可在正常或矫正视力下看到的裂纹。

- 导管的结构完整性必须保持完整,以确保适合电气安装。

抗压强度:

抗压测试可确保导管在安装和操作使用过程中能够承受压缩力,而不会发生明显变形或损害结构完整性。该测试评估导管在承受特定负载时保持其形状和性能的程度。

适用性

该测试适用于 AS/NZS 2053.2 涵盖的所有导管,并参考 AS/NZS 2053 第 1 部分概述的一般抗压测试。导管要通过此测试:

- 初始外径与施加力时测量的直径之差不得超过 10%。

试件

- 测试件由切割成 200 毫米长 的导管段组成。

测试程序

测试在受控环境中按照以下步骤进行:

- 测量和调节:

测量并记录试件的初始外径。

将试件放入20°C±1°C的调节室中至少10小时。

- 压缩力应用:

均匀施加压缩力,确保在 30±3 秒内达到规定值。

维持该力量 60±6 秒。

- 受力期间测量:

在施加力的同时,测量并记录试件压缩部分的外径。

- 压缩后测量:

移除力和中间件。

1分钟后,测量施加力点处试件的外径。

- 计算:

初始直径与施加力后的直径之差。

初始直径与去力后测量的直径之间的差值。

压缩力数据表

导管 | 压缩力N |

非常轻 | 125 |

光 | 320 |

中等的 | 750 |

重的 | 1250 |

很重 | 4000 |

验收标准

如果满足以下条件,则导管通过抗压测试:

- 施加力量时:

试验期间直径的减小不超过标准相应部分规定的最大允许值。

- 压缩后恢复:

撤去力后,初始直径与试验后直径之差不超过10%。

抗坍塌性:

抗塌陷试验评估了电气导管在机械应力和高温下保持结构完整性的能力。该试验对于在高温环境下安装或操作过程中易弯曲的导管尤其重要。它确保导管保持足够的内径,以有效保护和容纳电缆。

适用性

塌陷测试适用于根据 AS/NZS 2053.2 分类的直径小于 32 毫米且设计用于以下用途的导管:

- 机械应力极小

- 轻机械应力

- 中等机械应力

豁免:

直径为 32 毫米或更大的导管以及重型和超重型导管由于其固有的坚固设计和材料特性,无需进行塌陷测试。

试件

试件由根据标准表 C1 准备的导管段组成。

试件长度 AS/NZS 2053.2

公称尺寸 | 样品最小长度 mm |

16 | 340 |

20 | 370 |

25 | 450 |

32 | 590 |

40 | 740 |

50 | 900 |

63 | 1130 |

测试程序

评估抗倒塌能力的程序包括以下步骤:

- 弯曲试件:

在室温下,使用指定的弯曲装置将导管逐渐弯曲 90° 角。

弯曲半径及方法必须符合AS/NZS 2053中的相关要求。

- 调理:

将固定的测试件转移到调节室。

将室保持在制造商建议的最高安装温度 (±2°C) 持续 24 小时。

- 后处理评估:

从调节室中取出刚性支撑和测试件。

测量导管的最小内径,并确保其符合 AS/NZS 2053 系列相关部分中概述的要求。

验收标准

如果满足以下条件,则导管通过抗塌陷测试:

指定的量规经过调节后穿过导管的最小内径,确认内部空间保持畅通无阻。

耐热性:

耐热测试评估导管承受制造商规定的最高使用温度而不发生明显变形的能力。该测试可确保导管和配件在高温条件下保持其结构完整性和保护功能,这对于在受热环境中安装电气设备而言是一个关键考虑因素。

试件

测试在三个准备好的样品上进行:

每个样品长 80 毫米,纵向切成两半,每段长度取一半进行测试。

测试程序

耐热试验包括以下步骤:

- 准备:

将球压装置和钢支架放入加热室内。

将腔室预热至制造商指定的最高使用温度(±5°C),并确保设备和支架达到此温度。

- 定位:

将测试件放置在室内的钢支架上。

使用钢球对试件施加 20±0.2 N 的力,持续时间为 60 分钟±1 分钟。

- 冷却:

试验持续时间结束后,取出试件并将其浸入冷水中。

确保作品在 10 秒内达到室温。

- 测量:

用精密工具测量钢球在试件上留下的压痕直径。

验收标准

如果满足以下条件,则试件通过耐热试验:

球压痕直径不超过2毫米

耐燃性:

耐燃性测试可确保非金属和复合导管及配件具有足够的耐火焰蔓延性。这项评估对于识别能够防止或限制电气设备中火势蔓延的材料至关重要。通过此测试的产品被归类为不燃,可增强火灾敏感环境中的安全性。

关键测试概述

该测试根据 AS/NZS 4695.2.41 使用 1 kW 火焰进行,包括:

- 测量代表性样品的可燃性和火焰传播特性。

- 在等效条件下评估类似材料和设计的配件。

- 由于对火焰行为的影响很小,因此免除小型配件的测试。

所需设备

测试设置包括:

- 测试外壳:

具有开放表面的矩形金属外壳,用于控制环境变量并最大限度地减少气流。

- 安装组件:

金属夹和钢棒用于牢固地定位导管和配件。

- 薄纸和松木板:

在外壳底部的松木板上放置一层白色薄纸(质量为 12-25 克/平方米),以检测落下的熔融物质。

- 1千瓦燃烧器:

以 45 ±2° 角放置,以模拟受控条件下的火焰暴露。

试件

测试针对三个样品进行:

导管:

使用两个间距为 550 ±10 毫米的夹具垂直安装 675 ±10 毫米的长度。

测试程序

测试包括以下步骤:

- 安装:

使用夹具或悬挂装置将样品垂直固定在外壳内。

- 火焰应用:

将燃烧器火焰以 45° 角照射样品 60±1 秒。

根据试件的类型确保火焰在指定的点与样品表面相交。

- 观察:

在测试过程中监测火焰行为和任何物质的沉降。

- 试验后检查:

让样品冷却。

用浸水的布擦拭表面以去除烟灰并评估损坏程度。

验收标准

如果满足以下条件,则样品通过耐燃烧性测试:

- 在火焰作用下它不会点燃。

- 擦拭后上下夹具50mm范围内无燃烧或烧焦现象。

- 火焰移除后 30 秒内燃烧停止。

- 外壳底部的薄纸仍未点燃。

- 样品表面的熔融物质不会导致燃烧或烧焦。

电气特性

绝缘: 导管必须具有较高的电绝缘性能,以保护电缆并防止意外接触导电元件。

外部影响

耐腐蚀性: 材料必须能够抵抗湿气、化学物质和土壤的侵蚀。

电磁兼容性 (EMC)

确保导管不会干扰或受到电磁场的影响。

AS/NZS 2053.5 – 波纹导管和配件

AS/NZS 2053.5 标准定义了 非螺纹波纹管 及其由绝缘材料制成的相关配件。这些导管用于保护安装中的电缆,提供柔韧性、机械保护和抵抗外部影响的能力。该标准与提供通用要求和指南的 AS/NZS 2053.1 紧密相关。

范围和适用性

本标准适用于:

- 绝缘材料制成的非螺纹波纹导管。

- 专门设计用于波纹管的配件。

- 在不同的环境和机械条件下需要电缆保护的电气装置。

分类

波纹管和配件根据以下内容进行分类,这些适用于 AS/NZS 2053.5:

按力学性能分:

轻型

中型

重负

根据火焰传播:

非火焰传播

电气特性:

提供能力 电绝缘 并防止出现连续性问题。

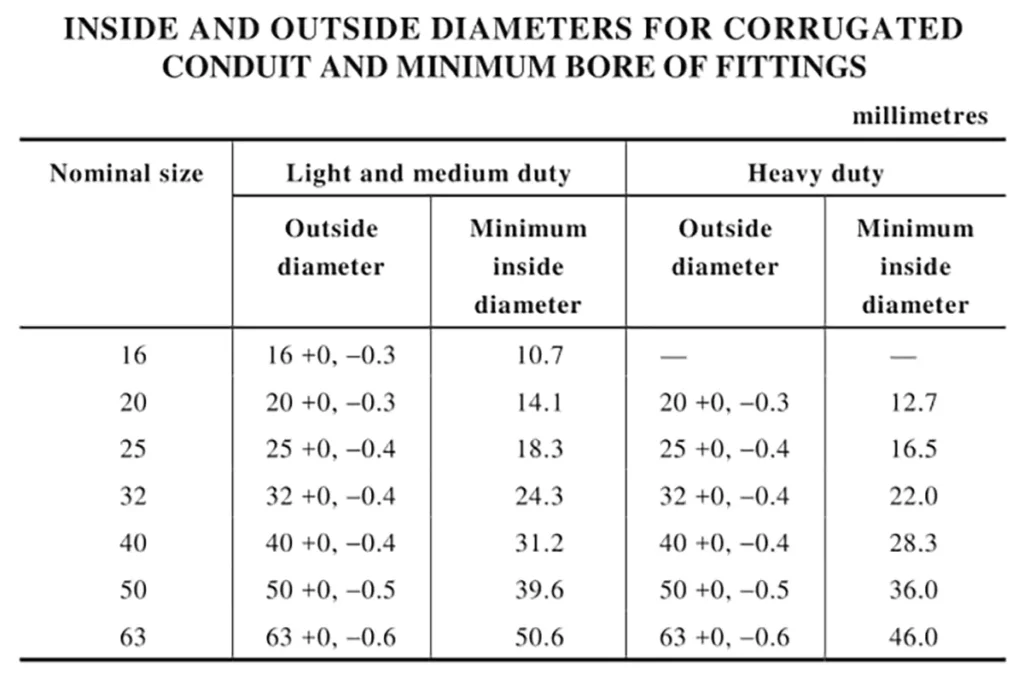

波纹管尺寸

该标准规定了波纹管的公称直径、壁厚和公差。

机械性能

以下机械测试可确保波纹管在压力下的性能:

弯曲测试:

AS/NZS 2053.5 中概述的弯曲测试可确保非螺纹波纹导管在安装和使用过程中能够承受机械应力。该测试评估导管在标准和低温条件下经受重复弯曲运动时保持其结构完整性和功能的能力。

试件

- 需要六个试件,每个试件的长度至少为其外径的 12 倍。

- 三个样品在 20°C 下进行测试,其余三个样品在制造商指定的最低安装温度下进行测试。

测试程序

- 在 20°C 下测试

(a)调理:

将测试件和仪器放入温度为 20°C ±1°C 的调节室中 2 小时。

(b)弯曲工艺:

手动执行以下序列:

将试件向左弯曲90°。

将其恢复到垂直位置。

将试件向右弯曲90°。

将其恢复到垂直位置。

每走一步后保持该姿势 1 分钟。

重复该动作 4 次,但在最后一次循环中,向右转 90° 处停止并保持该姿势 5 分钟。

(c)量规测试:

旋转弯曲装置,使试件的直线部分与垂直方向成 45° 角。

将直径计在自身重量的作用下穿过导管,确保不施加初速度。

- 在最低安装温度下进行测试

(a)调理:

将测试件和设备放入调节室中,在制造商指定的最低安装温度±2°C 下保持 2 小时。

(b)重复弯曲顺序:

遵循 20°C 测试中概述的相同弯曲步骤和规格测试。

验收标准

如果满足以下条件,则导管通过弯曲测试:

压力表无需施加任何力,便可在自身重量的作用下穿过导管。

用正常或矫正视力不经放大观察,试件上无可见裂纹。

抗压强度:

AS/NZS 2053.5 中规定的抗压试验用于评估波纹导管和配件在受到压缩力时抵抗变形的能力。该程序遵循 AS/NZS 2053.2 中针对刚性普通导管概述的相同方法,但验收标准要求有所不同。

对于波纹管: 初始外径与压缩下测量的直径之间的差异 不超过25% 初始直径。

坍塌测试:

波纹管的压溃试验程序与刚性平管相同,均按照 AS/NZS 2053.1 进行测试。

如果满足以下条件,则波纹管通过了抗塌陷测试:

指定的量规经过调节后穿过导管的最小内径,确认内部空间保持畅通无阻。

弯曲测试:

AS/NZS 2053.5 中概述的弯曲测试用于评估波纹导管及其端接配件在反复弯曲运动下的耐久性和机械弹性。该测试旨在确保导管能够承受安装或使用过程中遇到的动态机械应力,而不会损害其结构完整性或功能。

测试程序

安装:

通过终端配件将测试件固定到设备的振动构件上。

对准导管,使得在其行程的中点处,其轴线垂直并且穿过振荡轴线。

弯曲运动:

以每分钟 40 次弯曲的速率对试件进行 5000 次弯曲。

每次弯曲都涉及一个完整的运动周期,从垂直位置开始,向后和向前移动 180° 的角度。

检查:

完成测试后,使用正常或矫正视力检查试件是否有结构损坏,无需放大。

验收标准

使用正常或矫正视力检查时没有发现明显的结构损坏迹象。

耐热性:

测试程序

热调节:

将试件和热试验装置放入调节室。

保持规定的最高安装温度4小时。

加载应用程序:

通过 6 毫米钢棒施加负载,尽可能垂直于导管的轴线,如下图所示。

AS/NZS 2053.5 耐热试验负荷

导管 | 质量kg |

光 | 1.0 |

中等的 | 2.0 |

重的 | 4.0 |

冷却:

24 小时后,从试验箱中取出试件和仪器,让它们冷却至室温。

量规测试:

移除负载并尝试让适当的量规在自身重量的作用下穿过测试件,没有任何初始速度,并且导管处于垂直位置。

验收标准

如果出现以下情况,则测试件通过:

仪表在自身重量的作用下成功穿过管道,无需任何额外的力或速度。

耐燃性:

波纹管的耐燃烧性试验与刚性光管相同,要求也相同。

电气特性

电气连续性: 不适用

绝缘: 与 AS/NZS 2053.2 中的刚性普通导管的要求相同。

外部影响

与 AS/NZS 2053.2 中的刚性普通导管的要求相同。

电磁兼容性

与 AS/NZS 2053.2 中的刚性普通导管相同

AS/NZS 2053.6 - 异型壁、光滑内孔导管和配件

AS/NZS 2053.6 规定了由绝缘材料制成的刚性、非螺纹、异型壁、光滑内孔导管及配件的要求。这些导管用于保护电气设备中的电缆,可提供 90 毫米至 150 毫米的指定尺寸。

定义

异型壁、光滑内孔管道: 导管内表面光滑,便于电缆插入,管壁为异型壁(可能为空心),以增强强度。这类导管通常不适合弯曲。

按机械强度分类:

轻型

中型

重负

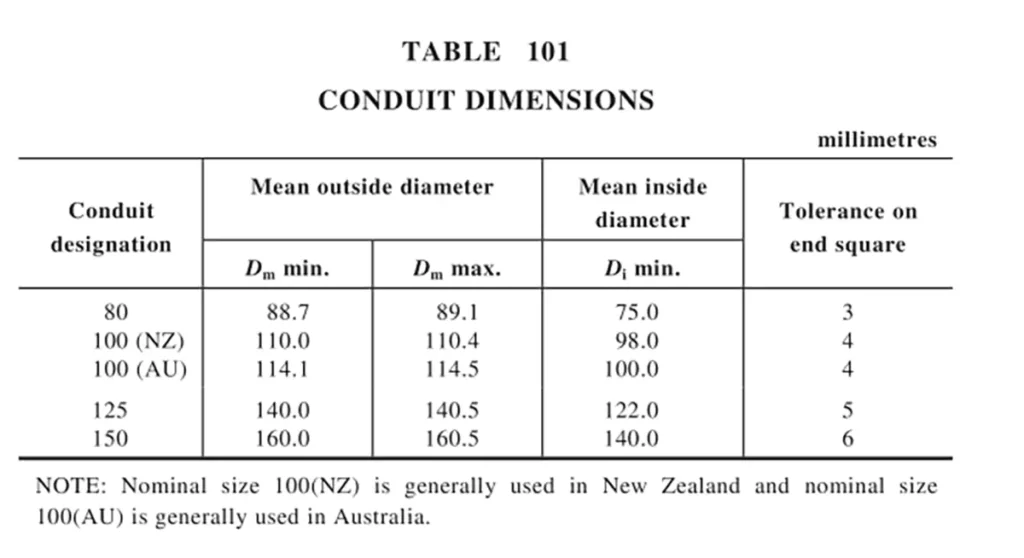

导管尺寸

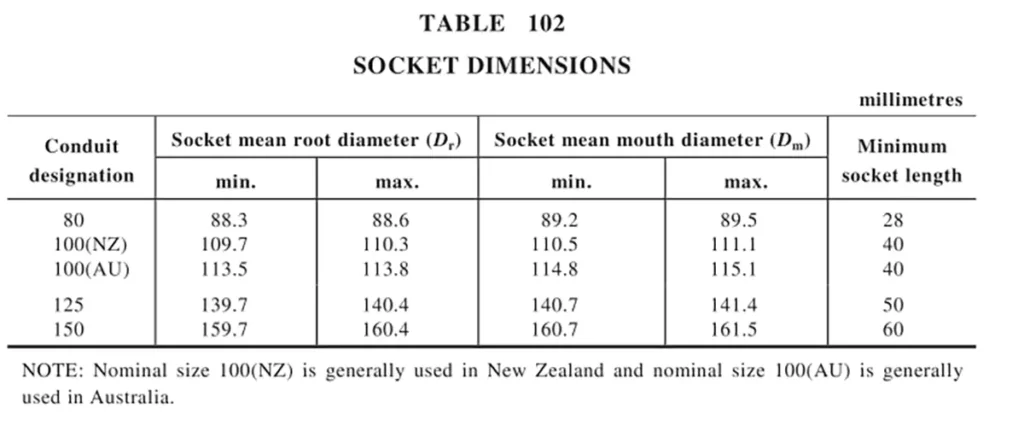

导管尺寸经过严格控制,以确保与相关配件兼容。规定的直径、插座尺寸和公差确保了机械稳定性和电气性能。

机械性能

AS/NZS 3053.6列出了异型壁、光滑内孔导管和配件的机械强度要求,详情如下:

抗压强度:

导管压缩测试和要求与刚性普通导管和波纹导管类似,均根据 AS/NZS 2053.1 进行测试。但对于异型壁、光滑内孔导管,初始外径与施加力时测量的直径之差不应超过 25%。

异型壁、光滑内孔管道的其他机械强度试验不适用,例如:弯曲、压缩、冲击、接头拉拔强度试验。

耐热性

导管经过测试,以确保在制造商指定的最高安装温度下保持结构稳定性。测试包括在指定负载条件下暴露于指定温度 4 小时:

程序:

- 将测试件和仪器放入调节室。

- 将室内温度保持在最高安装温度(±2°C)4 小时。

- 按照表 AA1 中的规定,使用 6 毫米钢棒施加载荷。

- 24小时后,取出试件并让其冷却至室温。

- 测试仪表是否能在自身重量的作用下穿过导管。

验收标准:

如果压力表自由移动且没有阻力,则导管通过。

耐燃性

材料必须具备阻燃性能。测试确保导管具有抗燃性,并在移除火源后自行熄灭。可燃性等级根据 AS/NZS 2053.1 标准确定,与刚性普通导管和波纹导管相同。

电气特性

电气连续性: 不适用

绝缘: 与刚性普通导管和波纹导管相同

外部影响

除了绝缘材料的导管和配件被归类为具有针对腐蚀性和污染物质的高防护(内部和外部)之外,与刚性普通导管和波纹导管相同,并且不需要进行测试。

电磁兼容性

与刚性普通导管和波纹导管相同

案例研究

在Ledes,我们对卓越的承诺体现在澳大利亚标准刚性导管和波纹导管生产过程的每一步。通过符合AS/NZS 2053.2和AS/NZS 2053.5等标准的严格要求,我们确保产品在各种应用中始终如一地提供卓越的性能、耐用性和安全性。

Ledes 澳大利亚标准导管和配件的优势

所有 Ledes 导管和配件均按照 AS/NZS 2053 标准制造,具有以下主要优点:

机械强度: 出色的抗压缩、抗冲击和抗负载变形能力,确保地下和暴露安装的耐用性。

热性能: 在高安装温度下保持稳定,即使长时间暴露在高温下也能保持结构完整性。

阻燃性: 刚性和波纹导管满足阻燃要求,并可选择低烟无卤 (LSZH) 材料,以减少火灾期间的有毒排放。

安装简便: 光滑的孔径可轻松拉动电缆,而异型壁结构可增强强度。

耐环境性: 对紫外线、潮湿和腐蚀性物质具有很强的抵抗力,使其成为户外和工业应用的理想选择。

Ledes的质量控制

在 Ledes,我们相信优质的产品始于每个阶段的严格质量控制措施:

1.原材料选择:

- 仅使用优质 PVC 和绝缘材料,以确保符合机械、热和电气性能标准。

- 原材料经过纯度、成分和一致性的全面测试。

- 低烟无卤 (LSZH) 选项:为了满足地铁系统等对安全要求较高的项目,我们还提供 LSZH 导管和配件,以最大限度地减少火灾期间的烟雾和有毒气体排放。

2.精密制造:

在Ledes,精密制造是我们生产高性能澳大利亚标准导管和配件的基石。我们先进的生产工艺确保每件产品都符合AS/NZS 2053标准的严格要求。我们制造工艺的主要亮点包括:

- 先进的挤压技术

精密挤压:

我们使用先进的挤压机生产具有一致壁厚、尺寸精度和光滑内孔的刚性和波纹导管。

这种精度可确保无缝拉动电缆,并消除安装过程中电缆磨损的风险。

型材墙体结构:

对于波纹管,我们的挤压工艺采用了增强型壁结构。这种结构兼具灵活性和高机械强度,使波纹管适用于动态环境和狭窄的安装空间。

受控冷却系统:

挤压后,导管经过受控冷却槽以固化其结构而无内部应力,确保长期耐用性和抵抗环境因素的能力。

自动化配件生产

配件注塑成型:

我们的配件,包括联轴器、适配器和接线盒,都是使用高精度注塑机制造的。

该工艺保证了严格的公差、光滑的边缘和安全的配合,确保与所有 Ledes 导管兼容并符合 AS/NZS 标准。

- 实时监控与调整

计算机监控系统:

在整个生产过程中,实时监控系统控制温度、压力和挤压速度等变量,以确保所有批次的质量一致。

任何偏差都会立即标记,并进行调整以保持精度。

批次编码和可追溯性:

每批产品都经过编码以便于追溯,从而实现全面的质量保证,并确保交付给客户的每件产品都符合严格的规格。

- 制造后精加工

切割和倒角:

导管经过精密切割,确保端面整洁、长度均匀,方便安装。对于硬质导管,端面会进行倒角处理,以便与配件紧密贴合。

尾钟形成:

对于刚性导管,在挤压过程中会产生端盖结构,以确保快速、安全的连接,而无需额外的配件。

定制长度和包装:

我们提供可定制的长度和专业包装以满足项目的特定要求,减少承包商的浪费和安装时间。

3.严格测试:

我们从每个生产批次中选择样品进行测试,重复 AS/NZS 2053 中概述的程序。这些测试包括:

抗压性

坍塌试验

耐热性

阻燃性

墨尔本隧道项目:一个成功的故事

墨尔本隧道项目 这项具有里程碑意义的基础设施计划旨在通过打造世界一流的地下轨道交通网络,提升墨尔本的城市交通系统。该项目旨在缓解交通拥堵,改善交通连通性,包括建设两条9公里长的隧道、先进的车站以及支持高容量铁路服务的先进系统。该项目遵循严格的安全和环保标准,代表着澳大利亚在可持续高效公共交通建设方面迈出了重要一步。

项目中的 Ledes 管道和配件

Ledes 很荣幸为墨尔本隧道项目提供澳大利亚标准刚性导管、波纹导管和配件。这些组件在确保这一关键基础设施中电气设备的安全性、可靠性和效率方面发挥了关键作用。

该项目选定的关键产品是 Ledes 的 低烟无卤导管和配件由于具有出色的耐火性、低毒性和耐用性,它们在项目中发挥着至关重要的作用,以确保满足电气安全、可靠性和环境性能的严格要求。

这些导管对于保护关键电缆系统免受机械损坏、外部影响和火灾风险至关重要,是这一雄心勃勃的项目的重要组成部分。

如何选择合适的电气导管供应商?

有 8 个专业技巧可以帮助你选择合适的 PVC导管供应商 在澳大利亚和新西兰,

- 符合标准:确保供应商的产品符合澳大利亚标准(例如 AS/NZS 2053、IEC 61386)和当地建筑规范。

- 认证和测试: 验证供应商是否提供符合监管要求的认证和测试报告。

- 已证实的项目经验: 寻找在当地主要基础设施项目中拥有良好记录、可靠性和遵守标准的供应商。

- 质量保证: 评估其质量控制流程,包括原材料采购、生产监控和批量测试,以确保一致的产品质量。

- 产品范围: 选择拥有全面产品组合的供应商,包括刚性和波纹导管、低烟无卤选项和各种配件。

- 技术支援: 考虑提供技术指导、安装支持和定制解决方案以满足项目特定需求的供应商。

- 及时交货: 优先考虑拥有可靠分销网络和能够满足项目期限的供应商。

- 价格与价值: 虽然价格很重要,但也要关注整体价值,包括产品的耐用性、合规性和可靠性。稍高的前期成本从长远来看可以节省更换和维护费用。

结论

AS/NZS 2053 系列为电气导管系统建立了全面的框架,确保其安全性、性能以及符合澳大利亚和新西兰的标准。了解这些标准的要求并选择符合其严格标准的产品,您就能实现可靠且高质量的安装。

在Ledes,我们致力于提供符合澳大利亚标准的导管和配件,这些导管和配件集精密制造、严格质量控制和可靠性能于一身。无论是关键基础设施项目还是日常应用,我们的解决方案都能确保合规性、安全性和耐用性。

如需了解有关我们产品的更多信息或讨论您的项目需求,请立即联系我们。