目录

Electrical systems play a vital role in powering our modern world, and ensuring their safety and functionality is of utmost importance. One crucial component that contributes to this is the PVC junction box. PVC (Polyvinyl Chloride) junction boxes are widely used in electrical installations due to their durability, versatility, and ability to provide efficient wire management. In this comprehensive guide, we will delve into everything you need to know about PVC junction boxes, from their construction and features to their applications and benefits.

What are electrical junction boxes?

An electrical junction box is a standard enclosure used to house and protect the connections of two or more circuit cables or wires. It serves as a central meeting point where electrical wires come together before branching out in different directions through conduits or other electrical fittings. These boxes can be made of metal or plastic and are designed to provide insulation, protection, and organization for electrical connections.

Electrical junction boxes can be used in various applications, including surface mounting in ceilings, under floors, or concealed behind access panels in residential or commercial buildings. They can also be buried in plaster walls or cast into concrete, with only the cover visible. Junction boxes are essential for ensuring safety, managing wire connections, and complying with electrical codes and standards.

How do junction boxes function?

Junction boxes function by performing several important tasks in electrical systems:

- Containing and Protecting Connections: Junction boxes are designed to enclose and protect electrical connections. They provide a secure housing that prevents external elements like moisture, dust, or accidental contact from coming into contact with the live wires or terminals. This containment helps to minimize the risk of electrical hazards and ensures the integrity of the wiring system.

- Insulation and Electrical Safety: Junction boxes provide insulation for electrical connections. The box’s construction materials, such as plastic or metal, act as a barrier between the exposed conductors and other conductive surfaces. This insulation helps prevent electrical shocks and short circuits by reducing the chances of accidental contact or stray currents.

- Wire Organization and Management: Junction boxes facilitate the organization and management of electrical wiring. They offer a central location where wires can be neatly arranged and secured. This organization not only enhances the aesthetics of the installation but also simplifies maintenance and troubleshooting. Proper wire management reduces the risk of tangled or loose connections, which can lead to electrical issues.

- Compliance with Electrical Codes: Junction boxes are designed to meet electrical codes and regulations. These codes specify the types of junction boxes to be used, their installation requirements, and their capacity based on the specific application and electrical load. By adhering to these codes, junction boxes ensure that electrical installations meet the required safety standards.

- Access for Maintenance and Modifications: Junction boxes provide easy access to electrical connections for maintenance, repairs, or modifications. They typically have removable covers or panels, allowing electricians or technicians to work on specific connections without disrupting the rest of the wiring system. This accessibility simplifies troubleshooting, facilitates efficient maintenance procedures, and supports future modifications or expansions.

What are junction boxes made of?

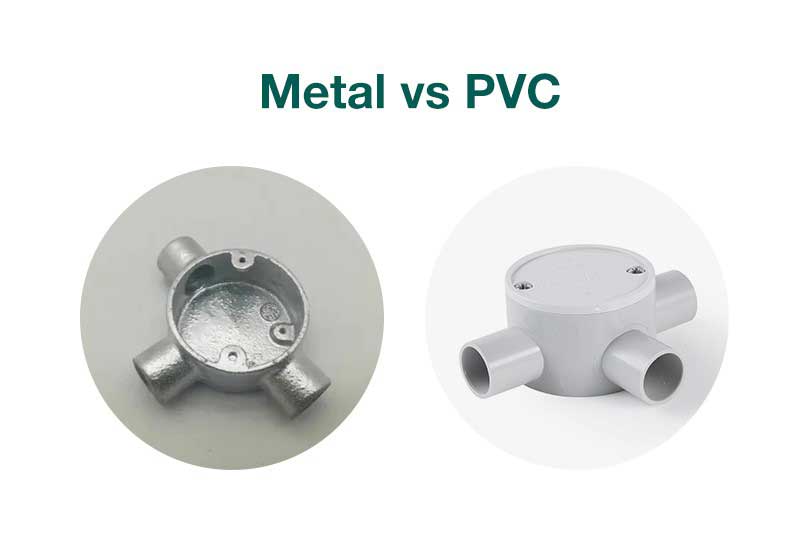

Junction boxes can be made of either metal or plastic, with each material offering distinct characteristics and benefits.

Metal Junction Boxes:

Metal junction boxes are typically constructed from materials such as aluminum, steel, or cast iron. These boxes are known for their durability and strength, making them suitable for demanding environments or areas with high mechanical stress. Metal junction boxes provide excellent protection against impact, crushing, and physical damage. They are also resistant to fire and can withstand high temperatures. Additionally, metal boxes offer good electromagnetic shielding, which can be advantageous in certain applications. However, metal junction boxes tend to be heavier and more expensive compared to their plastic counterparts. They may also require grounding to ensure electrical safety and prevent electrical interference.

Plastic Junction Boxes:

Plastic junction boxes are usually made of materials such as polycarbonate or ABS (Acrylonitrile Butadiene Styrene). These boxes are lightweight, cost-effective, and resistant to corrosion, making them suitable for a wide range of applications. Plastic junction boxes are non-conductive, providing an added level of safety against electrical shocks. They are also easier to handle and install due to their lighter weight. Additionally, plastic boxes are not prone to rust or corrosion, making them suitable for both indoor and outdoor installations. However, plastic junction boxes may not be as durable as metal boxes and can be more susceptible to damage from impact or extreme temperatures.

Metallic vs. Plastic Junction Boxes

When comparing metallic and plastic junction boxes, there are several key factors to consider:

耐用性: Metallic junction boxes, made of materials like aluminum, steel, or cast iron, are known for their durability and ability to withstand harsh conditions. They offer robust protection against impact, crushing, and physical damage, making them suitable for demanding environments. Plastic junction boxes, on the other hand, are lightweight and may not be as durable as metal boxes. They are more prone to damage from impact or extreme temperatures.

耐腐蚀性: Metal junction boxes are generally resistant to corrosion, especially if they are properly coated or made from corrosion-resistant metals. This makes them suitable for both indoor and outdoor installations. Plastic junction boxes, such as those made from polycarbonate or ABS, are inherently corrosion-resistant, making them a preferred choice in environments where moisture or chemical exposure is a concern.

Electrical Conductivity: Metallic junction boxes are conductive, which means they can conduct electricity. This can be advantageous in certain scenarios, as it allows for grounding and helps prevent electrical interference. Plastic junction boxes, being non-conductive, offer an added level of safety against electrical shocks. They do not require grounding and are ideal for situations where electrical insulation is a priority.

Cost and Weight: Plastic junction boxes are generally more cost-effective compared to their metallic counterparts. They are also lighter in weight, making them easier to handle and install. Metal junction boxes, particularly those made of steel or cast iron, tend to be heavier and more expensive.

美学: Plastic junction boxes are available in a variety of colors and finishes, allowing for more design flexibility and aesthetic integration. Metallic junction boxes, although they can be painted, typically have a more industrial appearance.

What Is a Junction Box Used For in Commercial Projects?

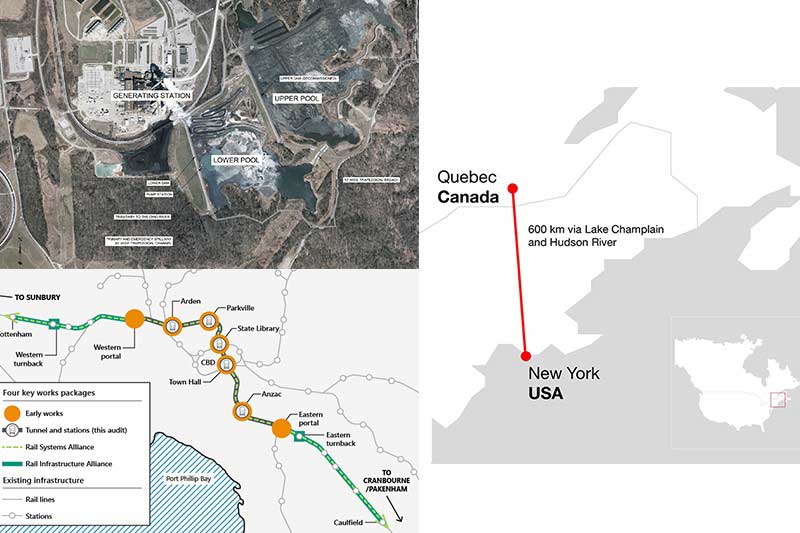

Ledes Massive Building Project – The Champlain Hudson Power Express (CHPE) in USA

In commercial projects, the use of junction boxes holds immense importance as they serve multiple essential functions. These boxes, often overlooked but critical components, play a pivotal role in ensuring the safety, organization, and efficiency of electrical systems. Ledes, renowned for their high-quality PVC electrical conduit and accessories, including fittings such as electrical boxes, junction boxes, elbows, etc., has made significant contributions to notable projects such as the New York CHPE and A. Brown developments.

Junction boxes primarily serve as protective enclosures for electrical connections in commercial settings. Their purpose is to house and secure these connections, creating a centralized location where multiple wires can be safely joined together. By keeping the connections contained and protected, junction boxes prevent accidental contact and minimize the risk of electrical hazards.

Ledes has been a trusted provider of PVC electrical conduit and accessories, offering durable and versatile solutions for commercial projects. Their PVC electrical conduit, known for its robust construction and reliability, provides an ideal pathway for routing and protecting electrical wiring. With a smooth internal surface, it allows for easy wire pulling and reduces friction during installation. Moreover, Ledes’ PVC electrical conduit offers excellent resistance to moisture, corrosion, and physical damage, ensuring the longevity and integrity of the electrical system.

As a part of their product line, Ledes’ junction boxes have been instrumental in numerous commercial projects, including the CHPE Project (A electricity project from Quebec to New York), A.B. Brown Project, Melborne Metro Tunnel Project and so on. These junction boxes not only provide secure enclosures for electrical connections but also comply with the stringent electrical codes and regulations. By adhering to these codes, Ledes ensures that the commercial projects meet the required safety standards.

Furthermore, Ledes offers elbows as part of their product range, which enable smooth directional changes in the electrical conduit. Elbows facilitate efficient routing of wires around corners and bends, maintaining the integrity of the wiring system. By providing precise angles and durability, Ledes’ elbows ensure optimal wire management and minimize the risk of damage or strain on the wires.

In addition to junction boxes and elbows, Ledes’ electrical boxes serve as versatile solutions for mounting switches, outlets, and other electrical devices. Designed specifically for commercial environments, these boxes offer durability, reliability, and seamless integration into the overall electrical system.

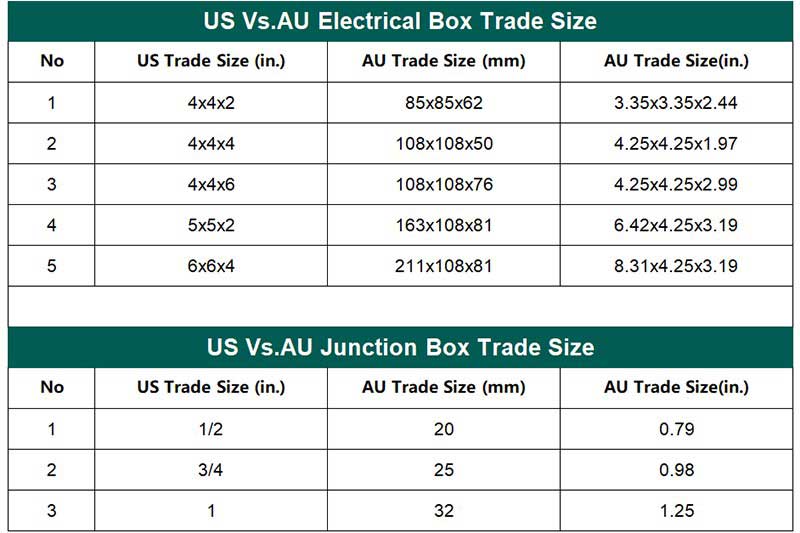

US Vs. AU Junction Box

When it comes to junction boxes, there are notable differences between the United States and Australia in terms of electrical box standards and requirements. The following points summarize the distinctions in appearance, standard references, and requirements for junction boxes in the US and Australia.

Appearance and Size:

- US Junction Boxes: In the United States, junction boxes come in various shapes and sizes to accommodate different electrical installations. They can be made of metal or non-metallic materials, such as steel or plastic. The dimensions of US junction boxes may vary based on specific application and installation requirements.

- Australian Junction Boxes: Australian junction boxes also have different shapes and sizes to meet specific installation needs. They are typically constructed from materials like metal (e.g., steel) or non-metallic materials (e.g., plastic) to comply with Australian electrical installation standards.

US Vs. AU Junction Box Size

Standard References:

- US Junction Boxes: The US follows the National Electrical Code (NEC) and the standards set by the National Electrical Manufacturers Association (NEMA). The NEC provides comprehensive regulations and guidelines for electrical installations, including junction boxes. NEMA offers technical specifications and guidelines for junction boxes, covering aspects such as dimensions, material requirements, protection ratings (e.g., NEMA 1, NEMA 3R), and waterproof performance.

- Australian Junction Boxes: In Australia, junction boxes adhere to the AS/NZS 3000 standard, also known as the Australian/New Zealand Wiring Rules. AS/NZS 3000 covers various aspects of electrical installations, including junction boxes. It specifies requirements for dimensions, material specifications, installation guidelines, and protection ratings.

Standard Requirements

- US Junction Boxes: NEC and NEMA standards for US junction boxes include considerations for wire capacity, fire resistance, grounding, and installation practices. They outline requirements for box size based on the number of wires, accessibility for maintenance, and compliance with safety codes.

- Australian Junction Boxes: AS/NZS 3000 specifies requirements for Australian junction boxes, including dimensions, material properties (e.g., fire resistance), installation guidelines, and protection ratings. It also covers aspects such as insulation, grounding, wire capacity, and compliance with local regulations.

UL and AU Standard Rigid Conduit

Take UL and AS Standard Rigid Conduit as example, their have different reference standards, which make the testing methods and requirements different even for the same performance test.

Flame Test

According to AS/NZS2053.1 PVC Rigid conduit and fittings, it reqiures as bellow (Copyright belongs to AS ):

The burner shall be supported so that its axis is at an angle of 45 ±2° to the vertical.

The flame shall be applied to the sample of conduit so that the distance from the top of the burner tube to the sample, measured along the axis of the flame,shall be 100 ±10 mm,and the axis of the flame shall intersect with the surface of the sample at a point 100 ±5 mm from the upper extremity of the lower clamp,and so that the axis of the flame intersects with the axis of the sample.

The test shall be carried out on three samples.

The flame shall be applied to the samples for a period of 60 ±1 s,and it shall then be removed.During the application of the flame,the sample shall not be moved.

But according to UL651 8日 edition, it describes (Copyright belongs to UL):

- a) A fitting shall not continue to flame for more than 5 seconds after the third application of the test flame;

b) Flaming particles or drops shall not fall from the fitting during or after any application of the test flame;and

c) The fitting shall not be entirely consumed during or after any application of the tes flame.

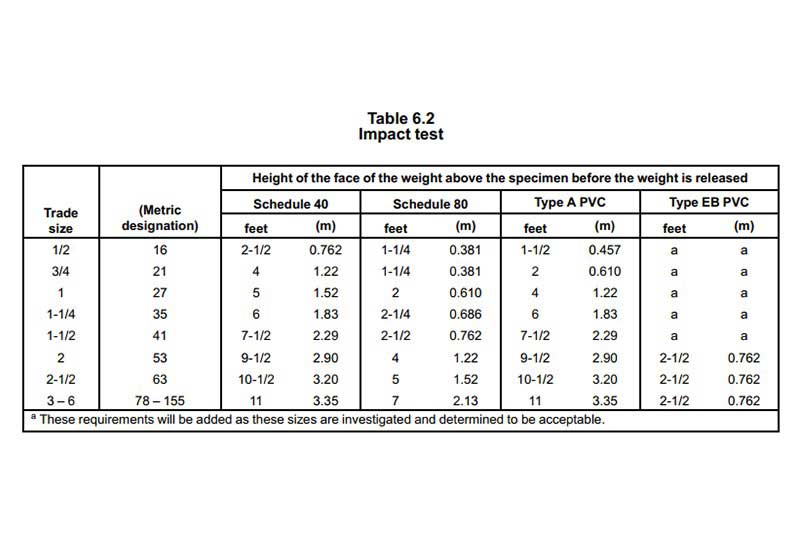

抗冲击性

Another example for rigid conduits’ impact resistance test. AS/NZS 2053.1:2001 requires (Copyright belongs to AS ):

A conditioning chamber capable of maintaining the maximum permanent service temperature ±2C specified by the manufacturer for the conduit or fitting as per Clause 5.5(Chamber 1).

An impact test apparatus as shown in Figure B1.

A conditioning chamber capable of maintaining the minimum permanent service temperature specified by the manufacturer for the conduit or fitting as per Clause 5.5 (Chamber 2).

But UL651 8日 edition reqiures (Copyright belongs to UL):

A crack or tear longer than 1/32 inch (0.8 mm) shall not appear in seven out of ten finished rigid PVC conduit specimens as the result of the impact described in 6.6.2.

UL 651 8th edition reqiures of Impact Resistance performance

How to Install an Electrical Junction Box?

Here are some general guidelines for the installation of junction boxes:

- Location: Choose a suitable location for the junction box that allows easy access for maintenance and inspection. Consider factors such as proximity to electrical connections, structural integrity of the mounting surface, and adherence to local electrical codes and regulations.

- 安装: Securely mount the junction box on a stable surface using appropriate hardware. Ensure that the junction box is securely fastened and does not wobble or move. Follow the manufacturer’s instructions for the specific mounting requirements of the junction box.

- Wiring: Proper wiring practices are essential for a safe and reliable installation. Here are some key considerations:

- Turn off the power: Before working with electrical connections, always turn off the power supply to the circuit at the main electrical panel or disconnecting the relevant circuit breaker.

- Wire sizing: Use the appropriate wire size for the electrical load and ensure the wires are properly stripped and prepared for connection.

- Wire connections: Make sure to follow proper wiring connections, such as using wire nuts, terminal blocks, or other approved connectors. Ensure that all connections are secure and free from loose wires or exposed conductors.

- Grounding: Proper grounding is crucial for electrical safety. Connect the ground wires to the designated grounding terminals or conductors within the junction box, following the applicable electrical codes and regulations.

- 可访问性: It is important to ensure that the junction box remains easily accessible for future maintenance, repairs, or inspections. Avoid burying the junction box behind walls or inaccessible areas. If the junction box needs to be covered or concealed, use appropriate covers or access panels that can be easily removed when required.

- 环境考虑: Consider the environmental conditions of the installation area. For example, if the junction box is installed in a wet or corrosive environment, choose a box that provides appropriate protection against moisture or corrosive substances.

- Seal and Insulate: If necessary, use appropriate sealants or gaskets to provide additional protection against moisture, dust, or other environmental factors. Insulate any exposed electrical connections or conductors to prevent accidental contact or short circuits.

How to Choose the Right Junction Box for Your Project?

Choosing the right junction box is crucial for ensuring a safe and efficient electrical installation. Here are some key steps to help you select the right junction box for your needs:

- Determine your requirements: Understand the specific requirements of your electrical project. Consider factors such as the number of connections, wire sizes, voltage rating, and the intended use of the junction box.

- Size and capacity: Select a junction box that offers enough space to accommodate all the wires, connectors, and devices that need to be housed within it. Overcrowding the box can lead to overheating and potential safety hazards.

- Material and construction: Choose a junction box made of high-quality materials that are appropriate for the environment in which it will be installed. Common options include metal (such as steel or aluminum) or durable plastic. Ensure that the box is capable of withstanding the anticipated conditions, such as moisture, temperature extremes, or corrosive substances.

- Safety ratings and certifications: Look for junction boxes that have undergone testing and certification by reputable organizations, such as UL (Underwriters Laboratories) or an equivalent certification body in your region. These certifications ensure that the box meets recognized safety standards for fire resistance, electrical insulation, and other important safety parameters.

- Environmental protection: Consider the installation environment and choose a junction box with an appropriate IP (Ingress Protection) rating. This rating indicates the box’s ability to protect against dust, water, and other solid or liquid contaminants. Ensure that the IP rating matches the environmental conditions of your installation.

- Mounting options: Determine how you plan to mount the junction box—whether it will be surface-mounted, recessed into a wall, or installed in a specific location. Ensure that the box has the necessary mounting features, such as mounting holes or brackets, to facilitate secure and stable installation.

- 可访问性: Consider the need for future maintenance, inspection, or modifications. Choose a junction box that allows easy access to the internal wiring and connections. If required, select a box with removable covers or access panels to facilitate accessibility.

- Wiring connections: Evaluate the type of wiring connections you will be using—such as screw terminals, push-in connectors, or crimp connectors—and ensure that the junction box provides suitable connection options. Look for boxes with clear labeling and adequate space for proper wire routing and organization.

- Grounding provisions: Verify that the junction box has provisions for proper grounding connections. Adequate grounding is essential for electrical safety and helps protect against electrical faults and potential shocks.

- Consult an expert if needed: If you are uncertain about which junction box to choose or if your project has specific requirements, consider consulting with a qualified electrician or electrical engineer. They can provide expert advice based on their experience and knowledge.

By following these steps and prioritizing safety, you can select the right junction box that meets your specific needs and ensures a reliable and secure electrical installation.

How to make PVC Junction box?

Here are ten steps to make a PVC junction box for the electrical conduit and fittings manufacturer.

(1) Mold Preparation:

Create a mold design and construct the mold using suitable materials and techniques.

(2) Material Mixing:

Thoroughly mix the PVC material with additives and stabilizers to achieve desired properties.

(3) Adjusting Injection Machine Parameters:

Set and adjust the parameters of the injection molding machine, including temperature and pressure, to optimize the molding process.

(4) Mold Closure:

Securely close the mold, ensuring proper alignment and tight sealing.

(5) Injection:

Inject the heated PVC material into the closed mold cavity.

(6) Pressure Maintenance:

Maintain sufficient pressure to ensure complete and uniform filling of the mold.

(7) Cooling and Solidification:

Allow the PVC material to cool and solidify within the mold.

(8) Mold Opening and Ejection:

Open the mold and carefully remove the PVC junction box from the mold.

(9) Post-processing and Finishing:

Trim excess material, smooth rough edges, and perform any additional required steps.

(10) Quality Inspection:

Thoroughly inspect the PVC junction box for defects and ensure it meets the required specifications and standards.

Please note that manufacturing PVC junction boxes using injection molding techniques typically requires specialized equipment and expertise. If you lack experience or access to appropriate equipment, it is advisable to obtain PVC junction boxes from reputable manufacturers or suppliers.

How do you attach a PVC conduit to a junction box?

Here are three steps to connect the PVC conduit to the junction box.

- Here are three steps to connect the PVC conduit to the junction box.Prepare the PVC Conduit: Cut the PVC conduit to the desired length using a hacksaw or PVC pipe cutter. Remove any burrs or rough edges from the cut end using sandpaper or a file.

- Apply PVC Cement: Apply PVC cement (solvent) to the inside of the junction box and the outside of the PVC conduit’s cut end. Use a brush or applicator that comes with the PVC cement to ensure even and thorough coverage.

- Insert the Conduit into the Junction Box: Insert the PVC conduit into the junction box, ensuring a snug fit. Twist the conduit slightly to spread the cement evenly and create a strong bond. Hold the conduit in place for a few seconds to allow the cement to set.

结论

In conclusion, this article has provided comprehensive information about PVC junction boxes, covering their features, applications, installation process, and safety considerations. PVC junction boxes offer a reliable and versatile solution for electrical wiring projects, ensuring protection and organization of electrical connections.

By understanding the key factors when selecting a PVC junction box, such as size, material, and certifications, users can make informed decisions that meet their specific needs. The installation process involves steps like measuring, cutting, fitting, and securing the PVC conduit to the junction box, following North American wiring standards.

It is crucial to adhere to electrical codes and regulations and consider safety precautions when working with PVC junction boxes. This includes proper grounding/earthing, avoiding overloading, and ensuring the compatibility of PVC conduit and fittings. Remember that professional assistance from a licensed electrician is recommended for complex installations or if you are unsure about any aspect of the process.

If you have any further questions or need additional guidance regarding PVC junction boxes, we encourage you to 提交表格 或者 contact us via email. Our team of experts is available to assist you and provide further information to ensure a successful and safe electrical installation.