目录

The Invisible Thread Binding the Modern World

Picture this: a team of scientists from three continents collaborating in real time to develop life-saving vaccines. A student in a rural village attends a virtual lecture from one of the world’s top universities. A family spread across multiple time zones comes together for a video call, celebrating a loved one’s milestone. These moments, so integral to our modern existence, are made possible by something we rarely think about – the vast and intricate web of telecommunications infrastructure and comms conduit that spans the globe.

At the heart of this infrastructure lies the 通信管道, the physical channels that enable data to flow seamlessly between individuals, businesses, and nations. Whether buried beneath city streets, stretched across oceans, or threaded through towering buildings, these conduits are the unsung heroes of our hyper-connected age.

In this post, we will explore the transformative role of communication conduits in shaping how we live, work, and interact. From powering global business operations to bridging cultural divides and fostering innovation, telecom network infrastructure has redefined the possibilities of connection. We’ll uncover its importance in today’s society and examine how this infrastructure will continue to evolve to meet the demands of a rapidly digitizing world.

What Is a Communication Conduit?

At its core, a communication conduit, often referred to as a comms conduit or telecommunications conduit, is a physical pathway used to house and protect the cables and wiring that transmit data across vast networks. These conduits are essential components of telecom network infrastructure, enabling the reliable and efficient flow of information. Typically constructed from durable materials like PVC, HDPE, or metal, communication conduits shield their contents from environmental elements, physical damage, and interference, ensuring the seamless transfer of data that modern life depends on.

Communication conduits are used across a range of applications, from urban fiber optic networks to rural broadband installations, and even in the deep-sea infrastructure that connects continents. These conduits can be buried underground, run along buildings, or even suspended on poles, forming the backbone of our telecommunications infrastructure.

To fully appreciate the role of communication conduits, it’s essential to understand the related industry terms and the key components that work in tandem to support global connectivity.

If you would like to learn more details, you can read our last post about the types and purposes of communication conduit.

5 Key Components of Telecommunications Infrastructure

Fiber Optic Cables

Fiber optic cables are the lifeblood of modern telecom networks. They use strands of glass or plastic fibers to transmit data as pulses of light, offering unparalleled speed and capacity compared to traditional copper cables.

Fiber optic cables are typically encased within communication conduits to protect them from physical damage, weather conditions, and electromagnetic interference. This combination of fiber optics and conduits forms the high-speed highways for data transmission.

Cell Towers

Cell towers serve as critical hubs for wireless communication. They transmit and receive radio signals to and from mobile devices, enabling voice calls, text messages, and mobile internet access.

These towers often rely on fiber optic cables running through communication conduits to connect them to the broader telecom network, ensuring high-speed data transfer between the tower and the core network.

Undersea Cables

Undersea cables are the hidden giants of global connectivity. Stretching across oceans and seas, these cables form the backbone of international telecommunications, carrying around 99% of all transoceanic internet data.

Protected by layers of armor and often laid within specialized conduits on the ocean floor, undersea cables connect countries and continents, enabling everything from video calls to e-commerce.

Satellites

While undersea cables dominate long-distance data transmission, satellites play a crucial role in areas where physical infrastructure is challenging to deploy, such as remote regions, mountainous terrains, and disaster-stricken zones.

Satellites rely on ground stations, connected through communication conduits, to receive and transmit data, creating a bridge between orbiting networks and terrestrial systems.

Routers

Routers are the traffic directors of telecom networks. They manage data flow between devices and networks, ensuring that information reaches its intended destination.

Positioned at key network nodes, routers connect to fiber optic cables housed in communication conduits, forming the critical intersections in data transmission pathways.

The Role of Communication Conduits in Telecom Infrastructure

Communication conduits serve as the protective channels for these components, ensuring their optimal functionality. By housing fiber optic cables, linking cell towers, and forming pathways for other network equipment, conduits enable the seamless operation of telecom systems. Their importance lies in their ability to adapt to diverse environments—be it urban, rural, or underwater—and provide the durability and scalability needed to support the increasing demands of digital connectivity.

As we move further into the digital age, the demand for robust and expansive telecom infrastructure will only grow, and communication conduits will remain a cornerstone of this evolution.

Exploring the Types and Uses of Communication Conduits

Communication conduits, or ducts, are the structural backbone of modern telecom infrastructure, facilitating the secure and efficient transfer of data across vast networks. Their designs and materials vary significantly depending on regional standards, environmental conditions, and intended applications. This section delves into the classifications and uses of communication conduits in three major regions—America, Canada, and Australia—highlighting their unique requirements, material preferences, and industry-specific applications.

1. American Standard Communication Conduits

In the United States, communication conduits are classified by Direct Burial (DB) and Encased Burial (EB) standards, as well as by the materials used. These conduits play a critical role in protecting telecom cables in both underground and encased installations, offering solutions for diverse environmental and mechanical stress conditions.

EB (Encased Burial) Comms Conduit:

- EB20 and EB35 Duct are commonly used in projects where conduits are encased in concrete.

- EB20 has thinner walls and is used for lighter-duty applications.

- EB35 has thicker walls for high-stress environments, such as beneath roadways and heavily trafficked areas.

DB (Direct Burial) Comms Conduit:

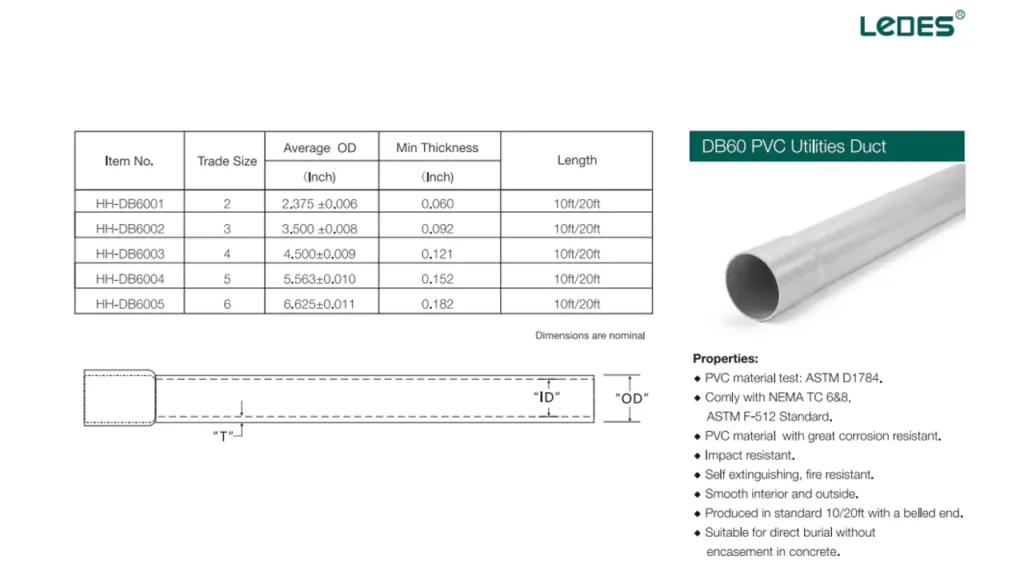

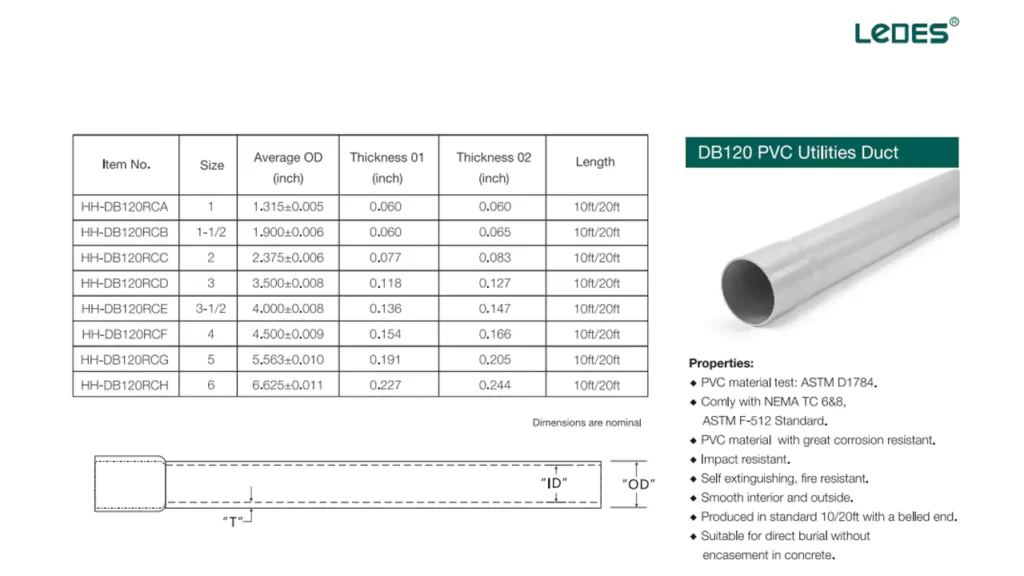

- DB60 Duct: A medium-duty conduit used for shallow burial in residential or commercial applications.

- DB120 Duct: A heavy-duty conduit with thicker walls, suitable for deeper burial or under areas subject to heavy loads, such as highways.

PVC Communication Conduit:

Widely used due to its resistance to corrosion and chemicals, cost-efficiency, and ease of installation.

HDPE Communication Duct:

Flexible and impact-resistant, it is commonly used for long-distance fiber optic networks and trenchless installations.

Steel Communication Conduit:

Durable and highly protective, steel conduits are used in industrial or high-risk environments where maximum mechanical strength is required.

Comm Applications in the United States

Urban Infrastructure: EB ducts like EB35 are used in high-traffic areas where concrete encasement provides added protection.

Long-Distance Telecom Networks: HDPE conduits are preferred for flexible underground deployments, especially in trenchless applications.

Industrial Settings: Steel conduits are used where exposure to mechanical stress or potential damage is high.

2. Canadian Communication Conduits

In Canada, communication conduit standards are tailored to the country’s challenging environmental conditions, such as extreme cold and frost heave. The DB series dominates Canadian telecom conduit standards, providing reliable protection in both urban and remote applications.

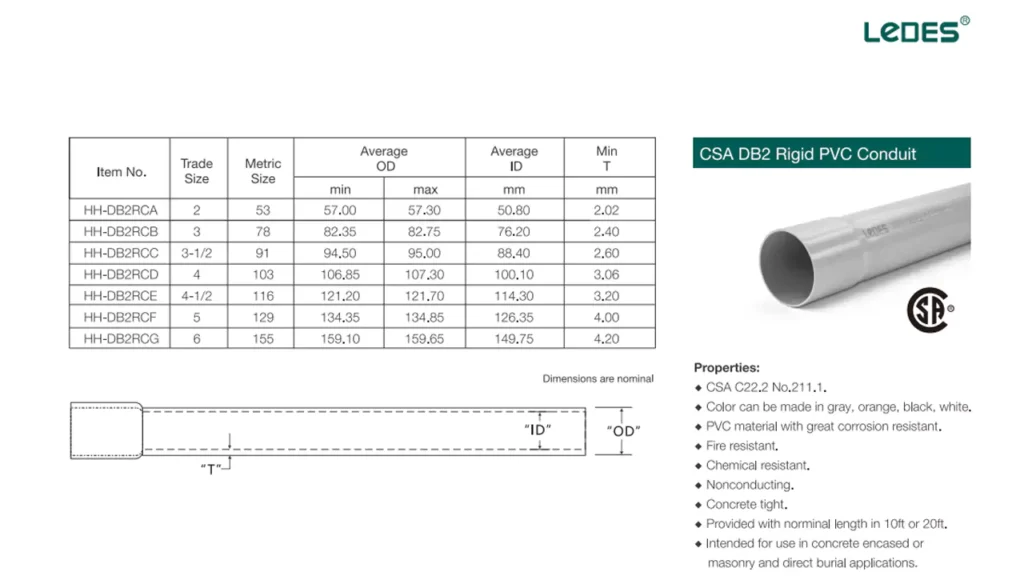

DB2 conduit is a lighter-duty conduit used for shallow burial and residential applications.

Steel Communication Conduits

Steel conduits are also used in Canada for environments requiring additional mechanical protection, particularly in industrial applications.

Common Applications in Canada

Underground Telecom Networks: DB-rated conduits like DB2 are used for direct burial to protect fiber optic and data cables.

Cold-Climate Installations: Conduits are engineered to resist frost heave and temperature fluctuations, ensuring durability in harsh conditions.

Industrial Environments: Steel conduits are used in heavy-duty or high-risk areas, ensuring maximum protection against physical damage.

3. Australian Communication Conduits

Australia’s vast geography and diverse environmental conditions, ranging from urban centers to remote deserts, require communication conduits that can withstand UV exposure, soil movement, and other challenges. Australian communication conduits adhere to AS/NZS standards, focusing on durability and adaptability.

PVC Comms Conduits

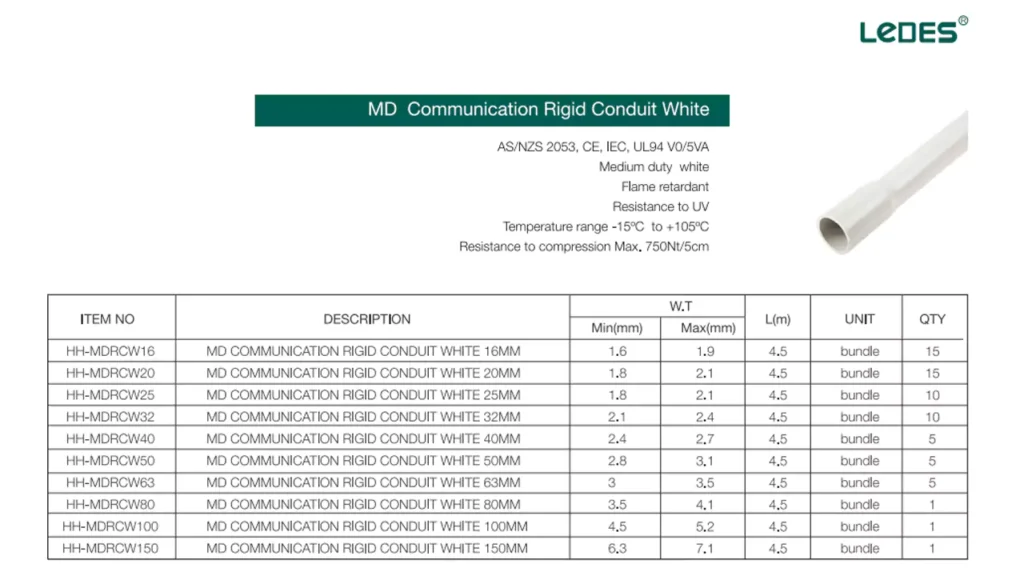

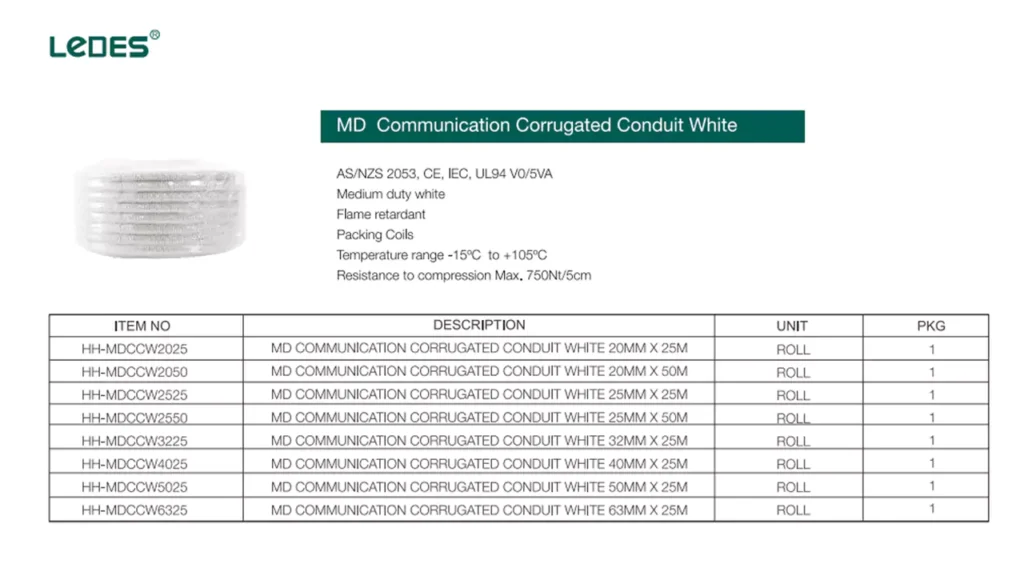

MD Communocation Conduit, including rigid conduit and 波纹管 are widely used for their UV resistance and durability in outdoor and above-ground installations.

HDPE Comms Conduits

Used in underground installations, providing flexibility for trenchless methods and protection in shifting soils.

Steel Comms Conduits

Deployed in industrial settings or for projects requiring extreme mechanical protection.

颜色

In Australia, the color of communication conduits is often standardized to aid in identification during installation and maintenance. According to guidelines referenced in AS/NZS 2053 and AS 1345, different colors are associated with specific uses:

White: Data and telecommunications conduits.

Grey: Electrical conduits installed above ground.

Orange: Electrical conduits installed below ground.

These color codes simplify the identification of conduits in various environments, ensuring that the appropriate pipes are used for their intended purpose. For example, white conduits are explicitly used for data and telecom purposes, making it easier to distinguish them from electrical conduits in mixed-use installations.

While the AS/NZS 2053 standard does not explicitly mandate color specifications for electrical and communication conduits, other guidelines, such as AS 1345 and PIPA Guideline POP203, offer practical recommendations for color coding based on the location and type of installation.

Why Comms Conduit important in Telecom Infrastructure?

At their core, comms conduits serve a straightforward yet critical purpose: to protect and organize telecom cables. Whether they are buried underground, mounted above ground, or installed within buildings, these conduits shield cables from physical damage, environmental stress, and interference.

Without comms conduits, telecom infrastructure would face frequent failures, increased maintenance costs, and reduced efficiency. The reliability of high-speed internet, uninterrupted mobile services, and robust data centers depends significantly on the proper deployment of communication conduits.

The Role of Comms Conduits in Telecom Infrastructure

The comms conduits play important roles in telecom infrastructure running,

- Protection and Durability:

Conduits protect sensitive fiber optic cables, coaxial lines, and power cables from physical damage, moisture, and environmental wear. Whether buried underground, laid undersea, or installed in urban areas, conduits safeguard the integrity of telecom systems.

- 电缆管理:

Efficient cable organization is essential for modern networks. Communication conduits streamline installations, allow for future upgrades, and minimize network disruptions during maintenance or repairs.

- Scalability and Growth:

Telecom networks must evolve to meet growing demands. Conduits enable easy expansion of networks by providing a structured system for adding or replacing cables.

- Versatility in Application:

Whether made of PVC, HDPE, or steel, communication conduits are designed to meet diverse requirements. They can handle high-traffic urban environments, extreme weather conditions, or long-distance data transfers via undersea cables.

Industry Impact of Communication Conduits

Beyond their physical role, communication conduits influence the telecom industry in transformative ways.

- Supporting Business Growth:

For businesses, reliable telecom infrastructure is essential for operations. Conduits enable fast data transmission, facilitating secure e-commerce transactions, seamless video conferencing, and cloud-based services. They empower companies to adopt remote work models, access global talent pools, and enhance productivity.

- Driving Innovation in the Digital Economy:

Communication conduits underpin the digital economy, enabling online platforms, fintech services, and e-learning systems. By supporting fast and secure connectivity, conduits allow startups and enterprises to innovate, expand, and thrive in a highly competitive market.

- Fostering Global Connectivity:

Communication conduits bridge distances, allowing individuals and businesses to connect across the globe. This fosters economic collaboration, cultural exchange, and the sharing of ideas, driving social and economic progress.

- Addressing the Digital Divide:

In underserved areas, where connectivity is limited, conduits play a crucial role in bringing reliable internet and telecom services. Governments and private sectors use these conduits to expand networks, providing more people with access to education, jobs, and healthcare.

- Enabling Emerging Technologies:

Communication conduits are crucial for accommodating the infrastructure needs of 5G networks, smart cities, and the Internet of Things (IoT). These innovations rely on high-speed, low-latency connections, made possible by the protection and efficiency that conduits provide.

- Improving Network Security:

In a world where data breaches are a growing threat, conduits add a layer of physical protection to critical telecom lines. They guard against tampering, environmental hazards, and accidental damage, ensuring secure and reliable data transfer.

The Difference Between Power and Communication Conduits

While power conduits and communication conduits may appear similar in structure and materials, their purposes, designs, and requirements differ significantly. Both play crucial roles in modern infrastructure, but understanding their distinctions is essential for selecting the right solution for specific applications.

1. Purpose and Function

Power Conduits:

Power conduits are designed to house and protect electrical wiring that transmits electricity. They are primarily used in residential, commercial, and industrial settings to ensure safe and efficient electrical distribution. The Schedule 40 conduit is a typical power conduit, for example.

Example Applications:

Power supply to buildings, machinery, and streetlights

Electrical systems in factories and large facilities

Communication Conduits:

Communication conduits protect low-voltage cables used for transmitting data, signals, and communication. These conduits ensure the integrity of fiber optic, coaxial, or Ethernet cables in telecom networks. The types EB, DB (USA and Canada) and medium-duty white PVC conduit (Australia) are typical communication conduits.

Example Applications:

Fiber optic networks for high-speed internet

Telephone, television, and data transmission systems

Undersea data cables

2. Voltage and Signal Types

Power Conduits:

Power conduits handle high-voltage electrical wires, typically carrying alternating current (AC) or direct current (DC). These voltages range from low residential power (120-240V) to industrial levels exceeding 10kV.

Communication Conduits:

Communication conduits carry low-voltage signals or optical data pulses, typically below 60V. These signals are more sensitive to interference, making proper shielding and separation essential.

3. Design and Installation Standards

Power Conduits:

Governed by electrical codes such as the National Electrical Code (NEC) in the U.S. and Canadian Electrical Code (CEC) in Canada.

Must meet specific safety standards for voltage capacity, grounding, and insulation.

Communication Conduits:

Governed by telecommunications standards like ANSI/TIA or specific guidelines for fiber optic and data cabling.

Often installed in separate pathways from power conduits to reduce electromagnetic interference (EMI).

4. Separation and Shielding

Power Conduits:

Since they carry high voltage, power conduits require insulation and must be placed at safe distances from sensitive electronic equipment to prevent electrical hazards.

Communication Conduits:

Because data signals are sensitive to interference, communication conduits are typically installed away from power conduits. Shielding and grounding are used to reduce EMI and maintain signal quality.

5. Typical Applications in Modern Infrastructure

The common applications of power and communication conduits are different,

Different Application Between Power and Communication Conduits

Feature | Power Conduits | Communication Conduits |

Primary Purpose | Transmitting electrical power | Transmitting data and communication signals |

Common Locations | Buildings, factories, outdoor power lines | Data centers, telecom towers, undersea cables |

材料 | PVC, steel, aluminum | PVC, HDPE, composite polymers |

Key Standards | NEC, CEC, IEC | ANSI/TIA, ISO/IEC for telecom systems |

Voltage Levels | High-voltage | Low-voltage or data signals |

6. Importance of Keeping Them Separate

To ensure safety and performance, power and communication conduits are kept separate during installation:

Safety Concerns:

High-voltage cables in power conduits can cause electrical hazards if not properly isolated. Separation prevents accidents and equipment failures.

Signal Quality:

Power lines can generate electromagnetic fields, causing interference with low-voltage communication cables. Dedicated communication conduits maintain the integrity of data signals.

守则合规性:

Electrical and telecom codes mandate separation distances and shielding to ensure compliance and operational efficiency.

Comms Conduit Code and Installation Requirements

Understanding the codes and standards for communication conduits is essential for ensuring compliance, safety, and optimal performance in telecom infrastructure. These regulations govern everything from the materials used to the installation techniques, ensuring the protection and efficiency of the telecom network. Here, we will explore the key standards and codes for communication conduits in Australia, the United States, and Canada, focusing on some of the most significant ones, including the NEMA TC-10, NEC, and other relevant national standards.

Australian Standards Comms Conduit

Australia’s communication conduit standards are outlined in several key documents that provide guidelines for the construction, installation, and use of conduits in telecom and data applications. Key Australian standards include:

AS/NZS 2053: This standard covers the installation of communication cables and provides specifications for telecommunication conduit systems, ensuring their safety, durability, and effective operation. The AS/NZS 2053 series includes guidelines on the installation of both indoor and outdoor conduit systems and defines their compatibility with various cable types.

AS/NZS 4296: This standard is concerned with the installation of telecommunications cabling and the physical protection of cables, including the use of conduits. It provides requirements for pathways, supports, and conduit systems to ensure safe operation and long-term reliability of telecommunication installations.

AS/NZS 5033: This standard primarily addresses the installation of photovoltaic (solar) systems, including the requirements for communication cables that may be part of the solar power systems. The conduits used in these installations must meet both safety standards and compatibility with the electrical systems.

AS 4702: This standard defines the requirements for communication cables used in optical fiber installations, including conduit protection against external forces. It ensures that cables are properly shielded from mechanical damage.

American Standards Comms Conduit

In the United States, a comprehensive set of codes and standards governs telecommunication conduit systems. These standards define the physical requirements, performance specifications, and installation methods for communication conduits to ensure safety, reliability, and effectiveness. Key standards include:

NEMA TC-6 & TC-8: The National Electrical Manufacturers Association (NEMA) provides these standards for telecommunication conduits. NEMA TC-6 is for non-metallic conduits such as PVC and HDPE, while NEMA TC-8 is for corrugated conduit systems. These standards focus on the material, design, and performance of the conduits used in the telecom industry.

NEMA TC-10: This standard, issued by NEMA, is widely used in telecommunications conduit installations. NEMA TC-10 focuses on underground conduit systems that need to provide extra protection for cables and communications equipment. The standard covers the design, construction, and testing methods for communication conduit, with an emphasis on reducing electromagnetic interference (EMI) and providing mechanical protection. It also addresses fire resistance and moisture resistance, ensuring that installations are safe and durable over time.

UL Standards (e.g., UL 651A): Underwriters Laboratories (UL) provides certifications for conduits that meet certain fire-resistance and safety criteria. For example, UL 651A covers the requirements for rigid HDPE conduit used in telecommunication applications, ensuring that the conduit material and design comply with safety standards.

ASTM F-512: This ASTM standard specifies the requirements for non-metallic electrical and telecommunication conduit, mainly PVC and HDPE. It establishes the minimum performance criteria, including mechanical strength, resistance to environmental factors, and the installation practices for safe, efficient operation.

NEC(国家电气规范): Chapter 8 of the NEC governs the installation of telecommunications wiring and communication conduit systems. It includes rules for conduit routing, grounding, bonding, and separation from power lines to minimize risk of fire or electrical interference. This chapter also defines the safety measures necessary for telecommunication wiring in commercial, industrial, and residential applications.

EIA/TIA 569: The Electronics Industries Alliance (EIA) and the Telecommunications Industry Association (TIA) provide guidelines for the design and installation of telecommunications pathways and spaces, including conduits. TIA 569 covers both the physical installation and environmental factors that affect conduit performance, ensuring that data cabling systems are safe and efficient.

Canadian Standards Comms Conduit

In Canada, telecommunication conduits are regulated by a combination of CSA standards and national codes that ensure safety and functionality. Key Canadian standards include:

CSA C22.2 NO. 211.1: This standard defines the construction and performance requirements for direct burial conduit that used for underground communication installation. The CSA standard includes specifications for both metallic and non-metallic conduits, addressing their ability to withstand environmental stresses and ensuring they provide safe pathways for communication cables. This standard ensures that conduits meet strict performance criteria for:

Material composition to resist chemical corrosion and degradation.

Mechanical properties such as impact resistance and crush strength.

Temperature tolerance for both high and low extremes.

Flammability to reduce risks in fire-prone environments.

Canadian Electrical Code (CEC):

The CEC establishes the foundational rules for designing, installing, and maintaining electrical and communication systems. Among its many sections, Section 12 (Wiring Methods) and Section 60 (Electrical Communication Systems) provide critical guidance for communication conduit installations, ensuring safety, reliability, and compliance. Together, these sections offer a comprehensive framework for protecting communication cables and enabling modern connectivity.

- Section 12 – Wiring Methods: Section 12 of the CEC is dedicated to wiring methods, covering the installation of conductors, cables, and raceways in diverse applications. It emphasizes versatility and safety, offering detailed rules for everything from exposed wiring on building exteriors to specialized raceways like conduits. The overarching goal of Section 12 is to ensure that wiring systems are durable, efficient, and adaptable to future needs.

When it comes to communication conduits, Section 12 highlights:

Material Requirements: Conduits must meet high standards for durability, with specific attention to resisting environmental and mechanical stress.

Compatibility with Cables: Properly sized conduits are essential to house cables securely, allowing for smooth installation and future upgrades.

Separation and Routing: Ensures that communication conduits are installed with adequate separation from power wiring to minimize electromagnetic interference (EMI).

This section underscores that raceways, including rigid and flexible conduits, are not merely protective pathways but integral components of a safe and efficient electrical infrastructure.

- Section 60 – Electrical Communication Systems: Section 60 focuses exclusively on communication systems, addressing the unique challenges of routing and protecting cables used for data, voice, and signaling. With the increasing reliance on fast and reliable connectivity in residential, commercial, and industrial settings, this section ensures that communication conduits meet modern performance and safety demands.

Key aspects of Section 60 include:

Tailored Protection: Communication conduits must shield cables from physical damage, environmental exposure, and signal interference.

Adaptability for Emerging Technologies: Recognizing the growth of high-speed internet and IoT systems, Section 60 ensures that communication conduits are suitable for advanced applications.

Compliance with Installation Standards: From underground to aerial installations, this section ensures that conduits maintain long-term performance and safety under various environmental conditions.

Section 60 builds on the principles of Section 12, applying them specifically to communication systems. It ensures that these systems are not only functional but also future-ready and aligned with Canada’s growing demand for digital infrastructure.

Conduit or Direct-Buried Cable for Fiber Optic Systems?

When it comes to installing fiber optic systems, choosing between conduit and direct-buried cables involves weighing factors like protection, scalability, installation, and maintenance requirements. Each method has its advantages, but conduit offers notable benefits in terms of longevity, flexibility, and reduced operational complexity.

Installation and Maintenance

Direct-buried fiber cables typically require metallic armor for physical protection and detection, as well as grounding and bonding to guard against electrical hazards. These steps can add complexity, time, and cost to the installation process. Additionally, when it’s time to terminate the cable, removing the armor introduces further challenges.

By contrast, conduit eliminates the need for metallic armor and its associated grounding requirements. Conduits provide a permanent protective pathway for fiber cables, simplifying the overall installation process. Maintenance also becomes more manageable, as technicians can easily access the conduit to repair or replace damaged cables without disturbing the surrounding environment.

Durability and Risk Mitigation

The risk of damage to communication cables during construction or ground disturbances is significant, particularly in urban or high-traffic areas. Conduits act as a robust protective barrier, safeguarding cables from environmental stresses like moisture, soil shifts, and external mechanical forces, including accidental strikes during excavation.

Direct-buried cables, while equipped with durable outer sheaths, are inherently more vulnerable to such risks. Repairing these cables is not only costly but also time-sensitive, particularly when service disruptions lead to penalties under service-level agreements. Conduits mitigate these risks by physically separating cables from potential hazards, offering peace of mind in high-stakes installations.

Scalability and Future-Readiness

One of the most significant advantages of conduit systems is their inherent scalability. Installing conduits creates a protected pathway that can accommodate additional fiber cables as network demand grows. This flexibility eliminates the need for repeated excavation or new permits, saving both time and resources. Conduits also allow for the possibility of leasing spare capacity to other service providers, offering a secondary revenue stream for operators.

In contrast, upgrading a direct-buried fiber network requires reopening trenches and laying new cables—a costly and time-intensive process. As technologies like 5G and Fiber-to-the-Home (FTTH) drive the need for expanded bandwidth, conduit systems provide the adaptability needed to meet evolving demands efficiently.

Innovative Approaches: Compact Conduit Solutions

Advancements in conduit technology, such as microduct systems, have further enhanced the appeal of using conduits. Microducts are smaller-diameter conduits designed to optimize space and allow for multiple fiber pathways within a single protective structure. These systems offer:

Space Optimization: More cables in a smaller footprint, ideal for dense urban networks.

Ease of Routing: Simplified installation for distributed applications like 5G backhaul.

Cost-Effective Upgrades: The ability to add or replace cables without disturbing the overall infrastructure.

Conduit Vs. Direct-Buried Cable

Aspect | 导管 | Direct-Buried Cable |

Installation | Structured and streamlined | Simpler initial setup but with added steps |

Protection | High level of mechanical and environmental safety | Moderate, relying on cable construction |

Repair Accessibility | Accessible without excavation | Requires trenching for repairs |

Scalability | Future-ready, supporting additional capacity | Limited and costly to upgrade |

Environmental Conditions | Ideal for unstable or high-risk areas | Suitable for stable, low-risk environments |

Cost | Higher upfront cost; lower long-term expenses | Lower initial cost; higher maintenance and repair costs |

Installation Requirements and Considerations

The installation of communication conduit systems must adhere to various requirements that ensure both safety and reliable performance. Here are the primary considerations and installation guidelines drawn from NEC, ASTM, and other standards:

Material Compatibility: The conduit must be compatible with the type of cable being used, ensuring protection against physical damage, moisture, and electromagnetic interference.

Separation from Power Lines: In many codes, such as the NEC Chapter 8, conduits carrying communication cables must be installed separately from high-voltage power lines to reduce the risk of electrical hazards and signal interference.

Grounding and Bonding: Communication conduit systems must be properly grounded and bonded to avoid electrical shock hazards and to ensure signal integrity.

Temperature and Environmental Resistance: Communication conduits must be able to withstand environmental factors such as temperature fluctuations, moisture, and UV exposure. This is particularly important in outdoor or underground installations, as per standards like NEMA TC-10.

Fire Resistance: Conduits must meet specific fire-resistance standards, such as those outlined in UL 651A and other relevant fire codes, to prevent the spread of fire and protect telecom infrastructure.

The Evolution of the Comms Conduit

这是测试文本,单击 “编辑” 按钮更改此文本。

The telecom industry has always been in a state of constant evolution, adapting to the increasing demand for faster, more reliable connections and the emergence of new technologies. As the backbone of global communications, communication conduits have undergone significant transformations to meet the ever-growing needs of both consumers and businesses. From the early days of copper wire and basic protection systems to today’s advanced fiber optic networks and smart conduits, the evolution of the comms conduit is closely tied to the technological advances shaping the world.

Rising Demands: A New Era for Connectivity

The demand for faster internet speeds, low-latency communication, and the ability to handle massive amounts of data is at an all-time high. This is due in part to the expansion of 5G networks, which promise to revolutionize connectivity. With ultra-fast speeds and minimal delay, 5G technology is expected to support cutting-edge applications such as autonomous vehicles, virtual reality, and real-time data analytics. As these technologies require more advanced communication systems, the role of comms conduit systems in enabling them becomes even more critical.

Similarly, the expansion of fiber optic networks continues to provide the bandwidth needed for applications like seamless cloud computing, streaming, and the proliferation of the Internet of Things (IoT). Fiber optic cables, which use light to transmit data, require specialized conduits that protect the delicate fibers while maintaining high performance. Over time, fiber optic conduits have evolved to offer enhanced durability, flexibility, and easy installation, helping telecom networks keep pace with the demand for high-speed data transfer.

New Frontiers: Expanding the Reach of Connectivity

One of the most promising developments in the telecom world is the rise of satellite internet solutions. These networks are bridging the digital divide by providing internet access to remote and underserved areas. Through the use of advanced satellite technology, communication conduits are extending their reach far beyond urban centers, ensuring that even the most geographically isolated communities can benefit from reliable internet connections. This is particularly important for rural areas and developing nations, where traditional cable-based infrastructure may be cost-prohibitive or impractical.

Smart Conduits: The Future of Telecom Infrastructure

The future of communication conduits goes beyond physical protection to include smart technology. Smart conduits integrate sensors and monitoring systems that can detect issues such as cable damage, temperature fluctuations, or moisture ingress in real time. This allows telecom companies to proactively maintain their networks, preventing outages and minimizing downtime. As telecom systems become more complex and interconnected, the role of smart conduits in maintaining the integrity of the network becomes increasingly important.

These innovations not only improve the efficiency and longevity of telecom infrastructure but also align with the growing demand for sustainability. The push for environmentally friendly materials is driving the development of more sustainable conduits made from recycled plastics or biodegradable materials. As the world becomes more conscious of its environmental impact, the materials used in telecom conduit systems are evolving to reflect these concerns.

A Connected Future

The evolution of the comms conduit is a testament to the rapidly changing telecom landscape. From simple protective tubes to advanced systems capable of supporting cutting-edge technologies like 5G, fiber optics, and satellite internet, communication conduits are more critical than ever. As we move toward a future where information flows seamlessly across the globe, the role of these conduits will only grow, ensuring that our networks remain fast, reliable, and capable of supporting the innovations of tomorrow

结论

The comms conduit plays a crucial role in our modern world, providing the connections that make everything from video calls to online shopping possible. Although it’s often hidden, it is essential to the way we communicate, do business, and innovate. This network of communication conduits is what connects people, powers economies, and helps new technologies thrive.

We’ve discussed how communication conduits come in different types, like fiber optic cables, HDPE ducts, and steel conduits, each serving specific needs. These conduits ensure fast, reliable connections that support the growth of industries, especially with the rise of 5G networks and satellite internet bringing connectivity to remote areas.

Looking to the future, advancements in smart conduits and sustainable materials will continue to improve telecom infrastructure, enabling new technologies like IoT and AI. As these systems grow, it’s important that everyone has access to the benefits they bring.

We’d love to hear your thoughts on the future of comms conduits and how they might impact your life. And if you have any questions or requirements for communication conduit, contact us at any time.