Table of Contents

PVC (Polyvinyl Chloride) conduit is widely used in electrical installations to protect and route electrical wires and cables. The durability, affordability, and versatility of PVC conduit make it a popular choice for both residential and commercial applications. To ensure efficient identification and organization of electrical systems, color coding is employed to distinguish various types of conduits. In this article, we will explore the color codes commonly used for PVC conduit and their significance in electrical installations.

Burial Depth Requirements for PVC Conduit

PVC electrical conduit is commonly used for underground installations due to its corrosion and moisture resistance. According to the NEC, residential installations require a minimum burial depth of 18 inches, while non-residential installations require 24 inches. However, local codes and special circumstances may dictate different requirements. Consulting local regulations and professionals is essential to ensure compliance and safe installation. Additionally, areas with vehicular traffic may require deeper burial depths for added protection. Always verify the specific burial depth requirements for your project before proceeding.

PVC Conduit Colour Codes

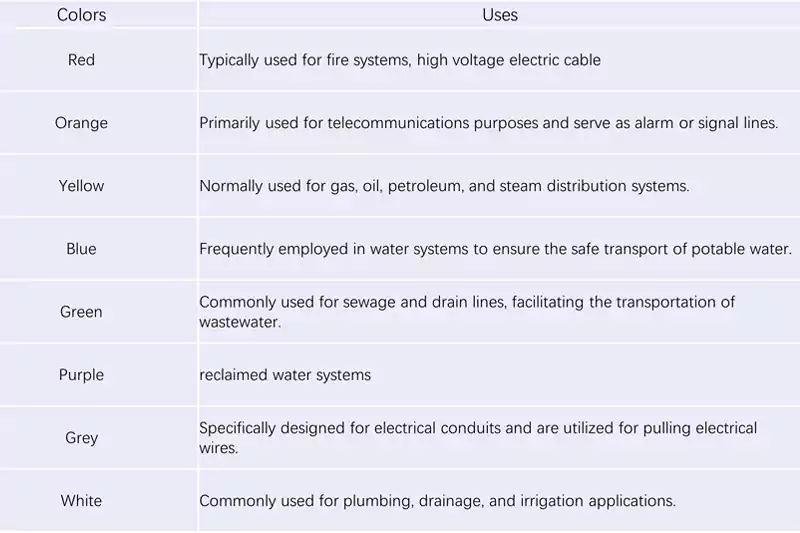

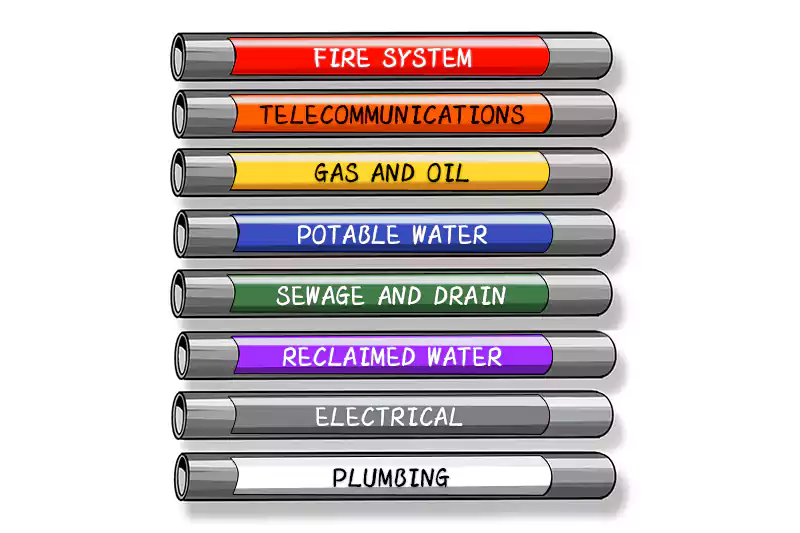

PVC piping color codes serve an important purpose in easily identifying the type of content a pipe can carry, including whether it is hazardous or not. This plays a crucial role in preventing accidents and ensuring worker safety within a facility. Each pipe is designated for a specific purpose and should only be used accordingly.

Here are the commonly recognized PVC piping color codes and their corresponding applications:

PVC Conduit Colour Codes

Why Color Codes is Important?

Compliance

According to the relevant content in NEC Code 200.6, Means of Identifying Grounded Conductors, specific requirements are established for color identification of grounding conductors. This applies to sizes 4 AWG or larger. Therefore, in practical applications, color coding can serve the purpose of quick identification.

However, in the NEC Code and other related documents, there is no explicit specification regarding the actual corresponding uses of each color.

- Sizes 6 AWG or Smaller. An insulated grounded con-

ductor of 6 AWG or smaller shall be identified by one of

the following means:

(1) A continuous white outer finish.

(2) A continuous gray outer finish.

(3) Three continuous white or gray stripes along the con-

ductor’s entire length on other than green insulation.

(4) Wires that have their outer covering finished to show a

white or gray color but have colored tracer threads in

the braid identifying the source of manufacture shall be

considered as meeting the provisions of this section.

Maintenance and Inspection

The significance of PVC piping color codes lies in their ability to facilitate easy identification of the content being transported by the pipes, as well as whether the content is hazardous or not. This plays a crucial role in preventing accidents and ensuring the safety of workers and the facility as a whole. Each pipe is designated for a specific purpose and should be used exclusively for that intended purpose. By adhering to the color coding system, workers can quickly and accurately identify the contents of the pipes, promoting safety and preventing potential risks.

During maintenance and inspection activities, some PVC pipes may be buried underground. Having clear and distinct color markings on these pipes greatly facilitates their differentiation, thereby enhancing maintenance efficiency.

3 Things to Know When Installing PVC Conduit

- Choose the appropriate color based on local regulations or commonly used standards. For example, in Australia, gray PVC conduit is typically used for medium-duty applications, while orange is used for heavy-duty applications, each with specific installation requirements.

- Pay attention to burial depth. Different countries have varying requirements for burying PVC conduit, so it’s important to adhere to the relevant laws and regulations of each specific region. (Provide examples of burial depths in Australia and North America, for instance.)

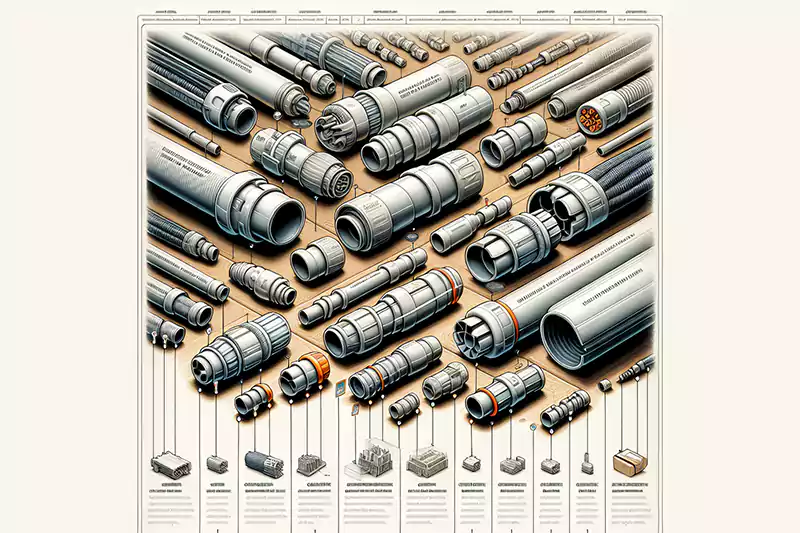

- Consider the installation environment for the conduit. PVC conduit can be used for both buried and surface installations, so it’s essential to select the appropriate fittings based on the specific requirements. For surface installations exposed to sunlight and dust, it is advisable to choose the Solar uPVC Conduit series of conduits and accessories to ensure long-term stability and reliable performance.

How to Choose Right PVC Conduit?

When choosing the right PVC conduit, consider the following factors:

- Application and Usage: Determine the intended application and usage of the PVC conduit. Different conduits are designed for specific purposes, such as electrical wiring, underground installations, or outdoor environments. Select a conduit that is suitable for your specific application.

- Size and Capacity: Determine the size and capacity requirements based on the number and size of wires or cables that will be housed within the conduit. Ensure that the conduit has sufficient space to accommodate the desired wiring configuration.

- Environmental Considerations: Consider the environmental conditions in which the conduit will be installed. If the conduit will be exposed to sunlight, extreme temperatures, or corrosive substances, choose a conduit that is UV-resistant, rated for high temperatures, or chemically resistant, respectively.

- Code Compliance: Ensure that the chosen PVC conduit meets the relevant local electrical codes and regulations. Different regions may have specific requirements for conduit materials, flame resistance, or burial depths. Verify that the conduit you select complies with these regulations.

- Quality and Durability: Select a PVC conduit from a reputable manufacturer or supplier known for producing high-quality products. Look for conduits that are durable, long-lasting, and resistant to impact, moisture, and other environmental factors.

- Ease of Installation: Consider the ease of installation and compatibility with fittings and accessories. Look for conduits that are easy to cut, bend, and join, and ensure that compatible fittings and connectors are readily available.

- Cost: Compare the cost of different PVC conduit options while considering the factors mentioned above. Balance the quality, features, and suitability of the conduit with your budget requirements.

- Brand: Products from reputable brands often undergo multiple certification tests, ensuring higher quality and greater assurance. For example, Ledes’ Schedule 40 PVC conduit and DB2 conduit have been certified according to UL 651 and CSA C22.2 No.211.1-06 standards, respectively, guaranteeing 100% compliance with local construction standards. You can contact us to request free samples.

Consulting with electrical professionals or suppliers in your area can provide further guidance and ensure that you choose the right PVC conduit for your specific needs.

Conclusion

In conclusion, understanding and adhering to the color codes for PVC conduit is of utmost importance in the selection and installation process. The color codes provide valuable information about the contents and purpose of the conduits, allowing for easy identification and ensuring the correct usage. By following the color coding system, potential hazards can be avoided, and the overall safety of both workers and the facility can be enhanced.

If you have any further questions or require assistance in choosing the right PVC conduit for your needs, we are here to help. Please fill out the submission form on our website or reach out to us via email. Our team will be glad to provide you with the necessary information and support your project’s success.