Índice

In modern electrical installations, conduit and trunking play a vital role in providing a safe and organized pathway for electrical wiring. These components not only protect the wiring from physical damage but also contribute to the overall efficiency and reliability of the electrical system. This article provides a comprehensive overview of conduit and trunking, highlighting their importance and applications in electrical installations.

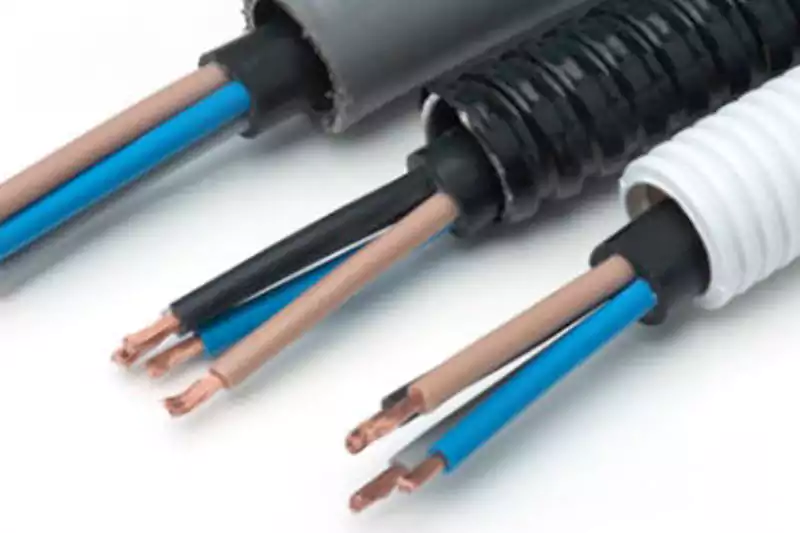

Conduit refers to a protective channel or tubing that encloses electrical cables, providing a shield against external elements and preventing accidental contact with the wires. It is available in various types, such as rigid conduit and flexible conduit. Rigid conduit, typically made of metal or PVC, offers higher mechanical strength and is commonly used in industrial settings. On the other hand, flexible conduit, usually made of PVC or metal-coated materials, provides flexibility and ease of installation in areas with tight bends or vibrations.

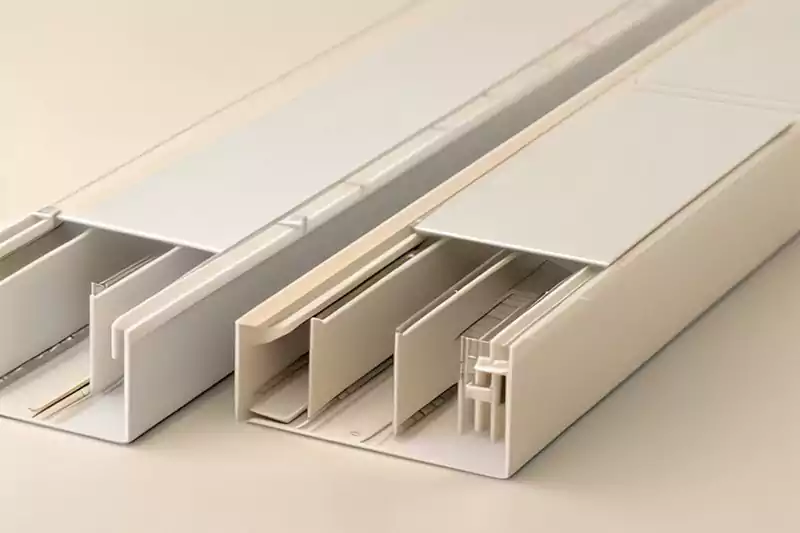

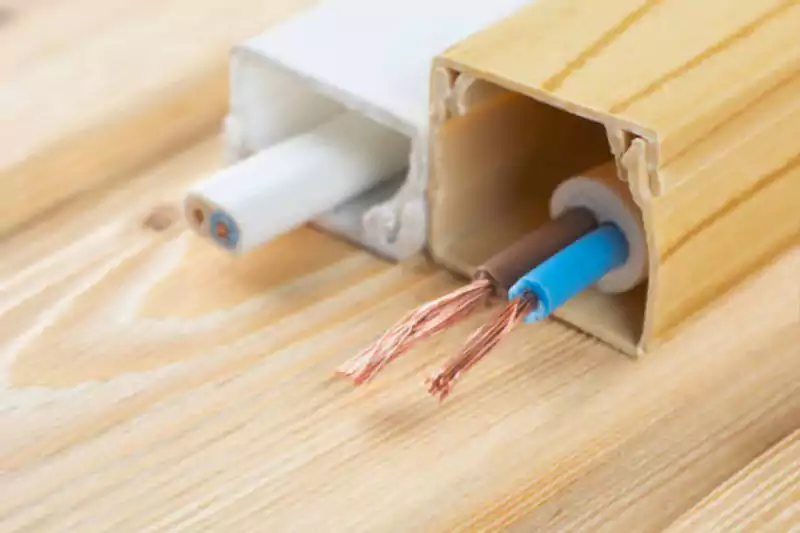

Trunking, also known as cable trunking or wireways, is a system of enclosed pathways that house electrical cables, allowing for organized routing and protection. It consists of a base and a cover, which can be easily opened for cable installation or maintenance. Trunking comes in different sizes and shapes, such as rectangular, square, or circular, to accommodate various cable sizes and quantities. It is commonly made of materials like PVC or metal, providing durability and electrical insulation.

Protection of Wiring: One of the primary purposes of conduit and trunking is to safeguard electrical wiring from physical damage, moisture, chemicals, and other external factors. By enclosing the cables within a protective housing, these components minimize the risk of accidents, such as short circuits or electrical shocks, ensuring the safety of individuals and the integrity of the electrical system.

Organization and Neatness: Conduit and trunking contribute to a well-organized and aesthetically pleasing electrical installation. They allow for the systematic routing of cables, preventing clutter and confusion. This organized approach simplifies future maintenance or troubleshooting activities, saving time and effort.

Conformidade com as Normas: Conduit and trunking play a crucial role in meeting electrical code requirements and industry standards. These standards specify the types, sizes, and installation methods of conduit and trunking, ensuring uniformity and consistency in electrical installations. Adhering to these standards is essential for regulatory compliance and ensuring the safety and reliability of the electrical system.

Flexibility and Adaptability: Conduit and trunking systems offer flexibility in accommodating changes or additions to the electrical system. They allow for easy re-routing or expansion of wiring without the need for extensive modifications. This flexibility makes conduit and trunking suitable for both residential and commercial applications, where modifications and upgrades are common.

Conduit is a protective channel or tubing that is used to enclose electrical cables, providing a secure pathway and insulation. Its primary purpose is to safeguard the electrical wiring from physical damage, moisture, and environmental factors. By containing and shielding the cables, conduit ensures the safety and longevity of the electrical system.

Conduit is available in various materials, each offering different characteristics and suitability for different applications. Common materials include:

Conduíte de metal rígido (RMC): Made of steel, RMC is known for its high mechanical strength and durability. It is commonly used in industrial and commercial applications where robust protection is required.

Tubulação Metálica Elétrica (EMT): EMT is made of galvanized steel or aluminum, providing a lightweight and cost-effective option. It is commonly used in residential and commercial applications.

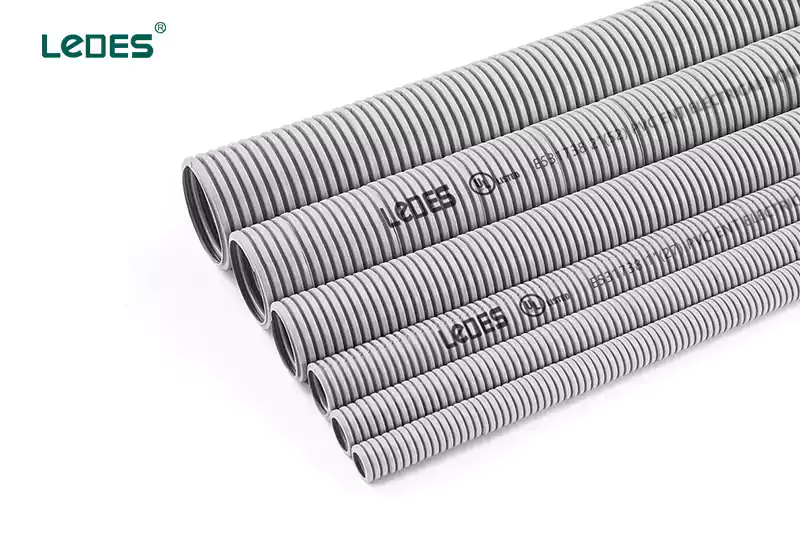

Polyvinyl Chloride (PVC) Conduit: Conduíte de PVC is a popular choice due to its excellent corrosion resistance, affordability, and ease of installation. It is available in different schedules (thickness) and is commonly used in residential, commercial, and industrial applications.

Conduíte metálico flexível (FMC): FMC consists of a spirally wound metal strip with a flexible PVC coating. It offers versatility and ease of installation in areas that require flexibility, such as tight bends or vibrations.

Liquid-tight Flexible Conduit (LFMC): LFMC is a flexible conduit with a liquid-resistant coating, making it suitable for areas where exposure to liquids or moisture is a concern.

Electrical Nonmetallic Tubing: Electrical Nonmetallic Tubing (ENT), made od PVC, also known as conduíte flexivel or plastic conduit, is a type of electrical conduit used to protect and route electrical wiring in buildings.

In the United States and Canada, the installation of conduit, particularly PVC conduit, must adhere to specific standards and regulations. The National Electrical Code (NEC) in the US and the Canadian Electrical Code (CEC) in Canada provide guidelines for conduit installation, covering aspects such as conduit sizing, routing, supports, and grounding requirements. These codes ensure uniformity, safety, and compliance with electrical regulations.

PVC Conduit is the most popular one on the market, and the most used PVC types such as rigid PVC conduit and nonmetallic tubing should complies to:

In the America: UL651, UL1653, NEMA TC-2

In Canada: CSA C22.2 No.211.2, CSA C22.2 No.227.1

Conduit finds applications in various electrical installations, including:

Concealed wiring in walls, ceilings, and floors.

Wiring for lighting fixtures, outlets, and switches.

Outdoor electrical installations, such as landscape lighting.

Wiring for commercial buildings, offices, and retail spaces.

Industrial machinery and equipment wiring.

Hazardous locations, where conduit provides additional protection against flammable or explosive environments.

- Protection against physical damage, moisture, and environmental factors.

- Enhanced safety by reducing the risk of electrical shocks or short circuits.

- Organization and neatness, simplifying maintenance and troubleshooting.

- Flexibility for future modifications or upgrades to the electrical system.

- Compliance with electrical codes and regulations, ensuring safety and regulatory compliance.

Trunking, also known as cable trunking or wireways, is a system of enclosed pathways that serves as a protective conduit for electrical cables. In most cases, it is rectangular or square in shape and has a lid that can be removed. Its primary purpose is to organize and route cables in a neat and efficient manner, ensuring easy installation, maintenance, and troubleshooting of the electrical system. Trunking plays a significant role in providing a safe and organized environment for cables, minimizing the risk of damage, tangling, or accidental contact.

Cable trunking, also known as cable ducting, is a type of trunking specifically designed for protecting and routing electrical cables. It is available in various sizes and materials, such as PVC, metal, or composite, to accommodate different cable capacities and environmental conditions. Cable trunking is commonly used in residential, commercial, and industrial settings to create organized pathways for power, data, or communication cables.

Lighting trunking is specifically designed for the installation of lighting fixtures. It provides a convenient and organized solution for routing power and control cables to multiple lighting points. Lighting trunking often features pre-fabricated sections with integrated mounting options for light fittings, simplifying installation and maintenance. It is commonly used in commercial buildings, retail spaces, and large-scale lighting installations.

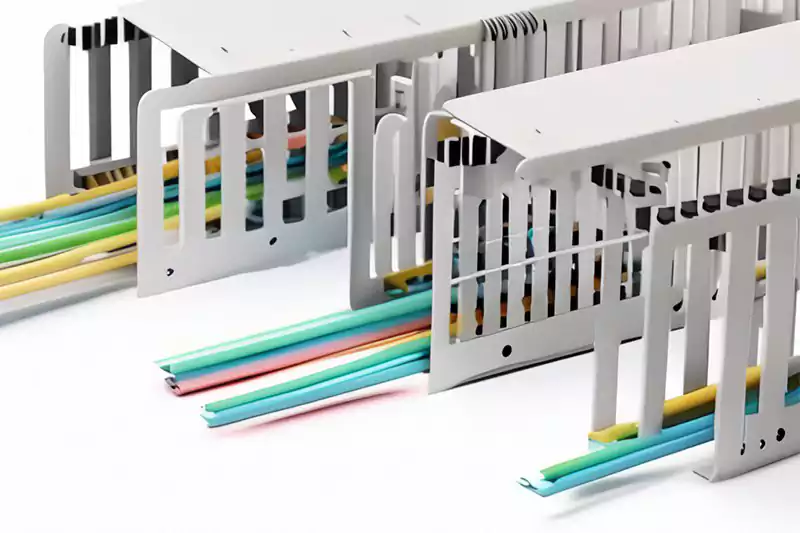

Bus-bar trunking (BBT) is a trunking system used for distributing electrical power in buildings and industrial facilities. It consists of a metal enclosure that houses multiple bus-bars, which are conductors used to transmit electric power. BBT offers a compact and efficient solution for power distribution, reducing the need for long cable runs and individual wiring. It is commonly used in applications where high power loads, such as lighting, machinery, or HVAC systems, need to be supplied.

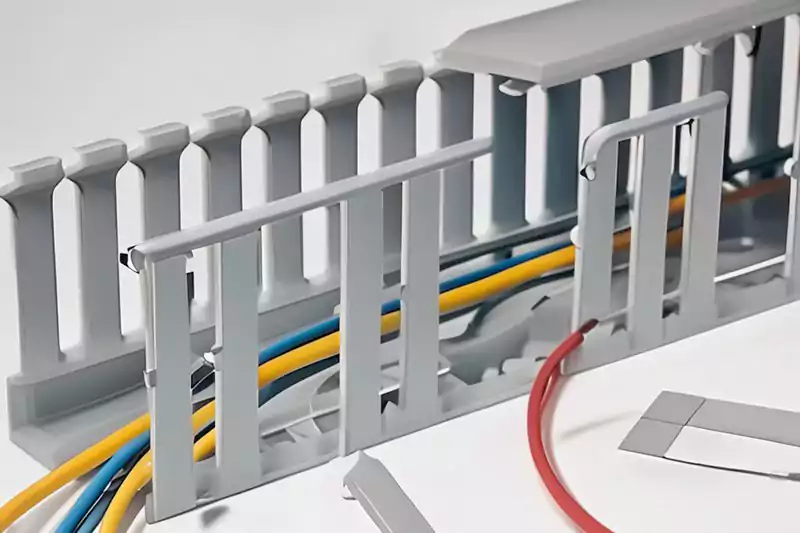

Multi-compartment trunking features separate compartments or channels within a single enclosure. Each compartment is designed to accommodate different types of cables, such as power cables, data cables, or communication cables, while keeping them segregated. This design allows for the separation of various services within a single trunking system, providing a neat and organized solution while reducing the risk of interference or crosstalk between different types of cables. Multi-compartment trunking is commonly used in office buildings, data centers, and installations where multiple services need to be routed and managed efficiently.

In networking, trunking refers to the concept of link aggregation, where multiple physical network connections are combined to increase overall capacity and reliability. This technique allows for higher bandwidth and improved network performance. Trunking enables load balancing, where traffic is distributed across the aggregated links, and redundancy, ensuring uninterrupted network connectivity even if one link fails. It enhances network capacity and provides fault tolerance, making it particularly valuable in high-demand environments, such as data centers or enterprise networks.

Trunking technologies in both electrical and networking contexts often adhere to standards and protocols to ensure compatibility and interoperability. Some common standards and protocols include:

IEEE 802.3ad: This standard defines Link Aggregation Control Protocol (LACP) for Ethernet trunking, enabling the dynamic creation and management of aggregated links.

Virtual Router Redundancy Protocol (VRRP): VRRP is a network protocol that provides automatic failover and redundancy in routing by creating a virtual IP address that multiple routers can share.

IEEE 802.1Q: The IEEE 802.1Q standard, also known as VLAN (Virtual Local Area Network) tagging, is a protocol used in computer networks to implement virtual LANs. It provides a method for identifying and separating different VLANs within a network infrastructure.

Trunking offers numerous benefits across different applications:

Gerenciamento de cabos: Trunking systems provide an organized and structured pathway for cables, minimizing the risk of tangling, damage, or accidental disconnection. This simplifies installation, maintenance, and troubleshooting processes.

Proteção: Trunking shields cables from external elements, such as dust, moisture, or physical impact, ensuring the longevity and reliability of the electrical or network infrastructure.

Scalability: Trunking systems allow for easy expansion and modification of cables, accommodating future growth or changes in the system.

Segurança e conformidade: Trunking ensures compliance with electrical codes and regulations, providing a safe environment for cables and reducing the risk of electrical hazards.

Efficiency: Trunking simplifies cable routing, saves installation time, and enhances system performance through link aggregation and load balancing in networking contexts.

Trunking systems provide efficient cable management, improved organization, and enhanced system performance, making them essential components in electrical and networking installations.

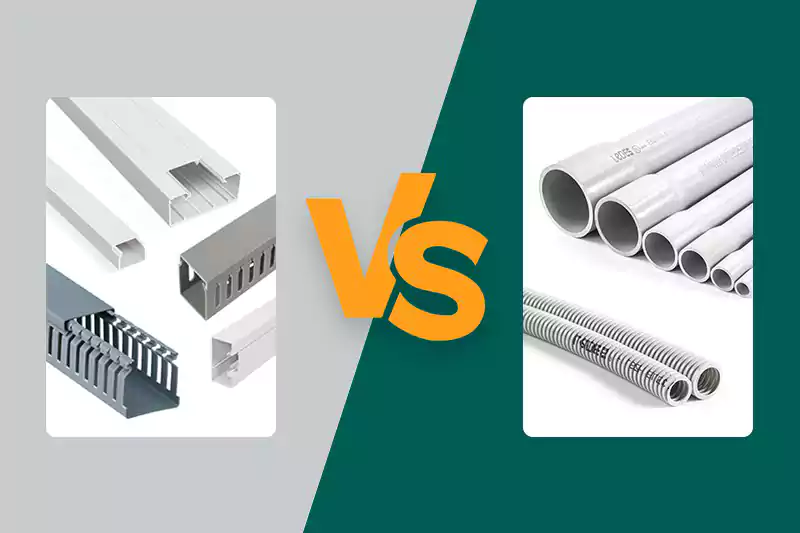

Conduit is a rigid or flexible tube-like structure made of materials such as metal or PVC.

It typically has a circular cross-section, although rectangular or square conduit is also available.

Conduit is designed to enclose and protect individual cables or wire runs.

It can be used for both exposed and concealed installations.

Trunking is an enclosed pathway system that consists of a series of interconnected sections or compartments. It’s usually rectangular or square in shape.

It can be made of materials like PVC, metal, or composite.

Trunking is designed to accommodate multiple cables and provide a pathway for their routing and protection.

Trunking is typically used for surface-mounted or overhead installations.

Conduit installation involves threading individual cables through the conduit or pulling pre-wired cables.

It requires bending and cutting the conduit to fit the desired path.

Conduits may need to be secured with clamps or brackets.

Joining conduit sections often requires fittings, connectors, or couplings.

Trunking installation involves attaching trunking sections to walls, ceilings, or floors using brackets, clips, or screws.

Cables are laid or inserted into the trunking compartments.

Trunking often allows for easy access to cables through removable covers or access points.

Trunking sections can be connected or extended using compatible connectors or couplings.

Conduit is commonly used in both residential and commercial settings.

It is suitable for installations where individual cable protection and segregation are required, such as electrical wiring, telecommunications, or data cabling.

Conduit is often used in concealed installations within walls, floors, or ceilings.

Trunking is widely used in commercial, industrial, and institutional settings.

It is ideal for installations that involve multiple cables or wire runs, such as power distribution, data centers, or audio/video installations.

Trunking is commonly used for surface-mounted installations where cable routing needs to be visible and easily accessible.

Conduit can be more expensive due to the cost of materials, fittings, and labor-intensive installation.

The cost may vary depending on the conduit type (rigid, flexible) and material (metal, PVC).

Trunking is often more cost-effective compared to conduit, especially for installations with multiple cables.

The cost may vary based on the trunking material, size, and complexity of the installation.

Conduit provides limited access to cables once installed, requiring disassembly or cutting for modifications or repairs.

Maintenance or troubleshooting may involve more effort and time due to the enclosed nature of conduit.

Trunking offers easy access to cables through removable covers or access points, simplifying maintenance, modifications, and troubleshooting.

Trunking allows for easier reconfiguration or addition of cables without disrupting the entire system.

Conduit provides better protection against physical damage, moisture, and environmental hazards.

It offers improved fire resistance due to the materials used, such as metal conduit offering higher fire-rated properties.

Trunking also provides cable protection but may offer less resistance to physical damage compared to conduit.

Fire resistance may vary depending on the trunking material used.

It’s important to consider specific project requirements, regulations, and budget when choosing between conduit and trunking. Factors such as cable quantity, installation location, accessibility needs, and fire safety requirements will influence the decision-making process. Consulting with electrical professionals or conducting a thorough analysis of the project’s needs will ensure the appropriate choice between conduit and trunking.

- Planning: Determine the conduit size, type (rigid or flexible), and material based on the application and local electrical codes.

- Route Planning: Map out the desired conduit path, considering obstacles, bends, and required access points.

- Marking: Use a pencil or marker to mark the conduit’s path on the walls, floors, or ceilings.

Mounting: Install conduit clamps or brackets at regular intervals along the marked path to secure the conduit.

- Cutting and Bending: Cut the conduit sections to the required lengths using a hacksaw or conduit cutter. Use a conduit bender to create bends where necessary.

- Threading or Pulling: Thread individual cables through the conduit or use pre-wired cables and pull them through the conduit sections.

- Joining: Use appropriate fittings, connectors, or couplings to join conduit sections together securely.

- Aterramento: Ensure proper grounding of the conduit system by connecting grounding wires to each conduit section and to the grounding system.

- Securing and Fastening: Secure the conduit system firmly in place using clamps, straps, or fasteners.

- Testing: Conduct necessary tests to ensure proper installation, such as continuity, insulation resistance, or voltage drop tests.

- Covering: Install conduit covers or fittings to protect the exposed ends of the conduit and ensure safety.

- Planning: Determine the trunking size, material, and configuration based on the number and types of cables to be accommodated.

- Route Planning: Decide on the trunking path, considering accessibility, cable management, and aesthetics.

- Montagem: Attach trunking brackets, clips, or screws to the walls, ceilings, or floors at suitable intervals along the planned path.

- Cutting: Cut trunking sections to the desired lengths using appropriate cutting tools, following manufacturer guidelines.

- Joining: Connect trunking sections together using compatible connectors or couplings.

- Cable Placement: Lay or insert the cables into the trunking compartments, ensuring proper organization and segregation.

- Covering: Install trunking covers or access points, providing easy access to the cables while ensuring their protection.

- Fixing: Secure the trunking system firmly in place using the provided fasteners or clips.

- Testing: Conduct necessary tests, such as continuity or cable integrity checks, to ensure proper installation.

- Rotulagem: Label the trunking sections or compartments to aid identification and maintenance activities.

- Regular Inspections: Conduct routine inspections of the conduit or trunking system to identify any signs of damage, wear, or loose connections. Check for corrosion, dents, or physical impacts.

- Cleanliness: Keep the conduit or trunking system clean, removing any dust, debris, or obstructions that may accumulate over time.

- Gerenciamento de cabos: Ensure cables are properly organized and secured within the conduit or trunking system, avoiding excessive bending, twisting, or strain.

- Repair and Replacement: Promptly repair or replace damaged conduit or trunking sections, fittings, or covers to maintain system integrity.

- Moisture Protection: Take measures to prevent water or moisture ingress into the conduit or trunking system, such as sealing entry points or using waterproof gaskets.

- Grounding Integrity: Regularly inspect and maintain proper grounding connections within the conduit or trunking system to ensure electrical safety.

- Labeling and Documentation: Maintain accurate labeling of cables and document any changes or additions to the conduit or trunking system for future reference and troubleshooting purposes.

- Conformidade com códigos e normas: Ensure that the installation and maintenance practices adhere to relevant electrical codes, regulations, and industry standards.

Regular maintenance and adherence to proper installation procedures will help ensure the longevity, safety, and performance of both conduit and trunking systems.

Conduit is commonly used in outdoor and damp environments, offering protection against moisture and chemicals. It is ideal for installations that may undergo future changes and can be easily altered or removed. Conduit is also effective in minimizing electromagnetic interference when using metal conduit systems.

Trunking is often used for power distribution in buildings, equipment, and switching yards where multiple electrical cables are involved. It excels in cable management, providing easy accessibility and organization of cables. Trunking systems are suitable for applications that require high current distribution and where aesthetic considerations are important.

Trunking efficiency refers to the effectiveness and utilization of trunking systems in efficiently managing and distributing cables. It measures how well the trunking system optimizes the available space and resources while maintaining effective cable management.

Here are some factors that contribute to trunking efficiency:

Cable Capacity: Trunking efficiency is influenced by the capacity of the trunking system to accommodate the number and size of cables required for a specific application. A well-designed trunking system should have sufficient capacity to handle the current and future cable requirements without overcrowding or excessive cable congestion.

Cable Organization: Efficient trunking systems ensure proper organization and bundling of cables. This includes using appropriate cable management accessories such as cable ties, clips, or trays to neatly arrange and route cables within the trunking. Well-organized cables minimize the risk of tangles, twists, or obstructions, making maintenance and troubleshooting easier.

Utilização do espaço: Trunking efficiency is also related to how effectively the available space is utilized. A well-designed trunking system maximizes the use of available space while considering factors such as cable bend radius, ventilation requirements, and access for maintenance. Efficient use of space ensures that the trunking system can accommodate the required cables without unnecessary wastage or overcrowding.

Scalability and Future Expansion: Trunking efficiency includes the ability of the system to scale and accommodate future cable additions or modifications. A flexible trunking system can easily adapt to changing needs, allowing for the seamless integration of new cables or the removal of obsolete ones. This scalability minimizes disruption and the need for extensive rework in the future.

Accessibility and Maintenance: An efficient trunking system provides easy access to cables, allowing for quick and convenient maintenance, repairs, or modifications. Trunking systems with removable covers or access points simplify the process of adding or removing cables, reducing downtime and minimizing disruption to the overall network or infrastructure.

The choice between cable tray and conduit as a wiring system design depends on various factors and the specific requirements of the project. Both systems have their advantages and considerations. Cable trays are typically more suitable for managing large cable volumes, providing flexibility, and cost-effectiveness. On the other hand, conduit offers superior cable protection, EMI shielding, and compliance with certain regulations. In some cases, a combination of both cable tray and conduit systems may be used, leveraging the strengths of each system for different sections of the installation. It is recommended to consult with electrical professionals and consider the specific requirements and constraints of the project before making a decision.

Conduit and trunking systems play a vital role in managing electrical cables by providing protection, organization, and routing. This article covered key points about these systems. Conduits enclose and safeguard cables, while trunking systems facilitate neatness and easy identification. Both contribute to safety by minimizing electrical hazards. Conduit options include rigid metal, intermediate metal, and flexible conduits, each with specific applications. Trunking systems are typically made of PVC or metal. Factors to consider when choosing between conduit and trunking include required protection levels, environmental factors, ease of installation, cost, and compliance with regulations. Seeking professional advice from electricians or engineers is strongly advised for proper system selection and installation. Professionals ensure adherence to safety standards and regulations, resulting in a reliable and secure electrical infrastructure.

Any more questions about cable or wiring systems, Ledes is here for helping resolving the wiring problems. Send us an email ou submit a filled form at any time.