Índice

Compartilhe esta imagem em seu site

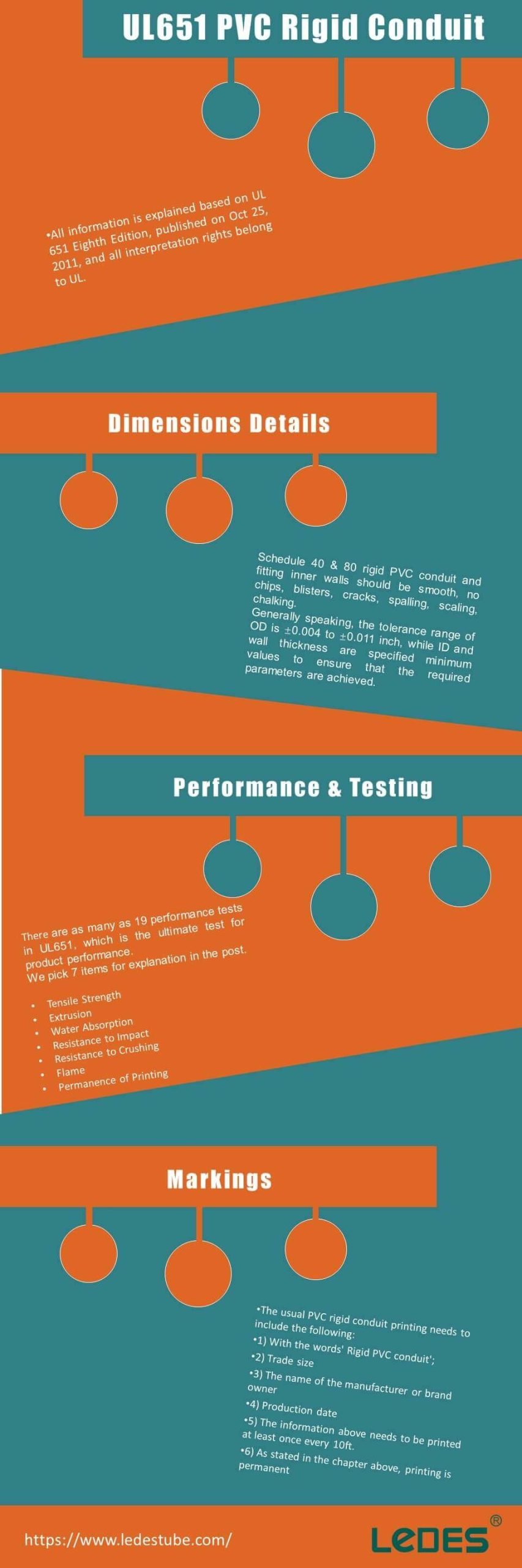

Todas as informações são explicadas com base na UL 651 Oitava Edição, publicada em 25 de outubro de 2011 e todos os direitos de interpretação pertencem à UL.

Conduíte e conexões de PVC rígido extrudado tipo EB e A, Schedule 40 e 80. UL651 se aplica a conexões relacionadas, incluindo cotovelos, acoplamentos, adaptadores, juntas de expansão, expansão-deflexão, deflexão e conexões de tubos rígidos para construção. No entanto, o material UPVC deve atender aos requisitos relevantes da ASTM 1784.

Os padrões relevantes da UL 651 cobriram os padrões relevantes no NEC (National Electrical Code) e NFPA 70. O conduíte e o encaixe de PVC rígido Schedule 40 e 80 podem ser usados para acabamento interno e externo ou uso externo. Eles devem ser protegidos da luz solar e dos efeitos do clima inclemente e podem ser usados diretamente no concreto.

Conduíte e conexão de PVC rígido Schedule 40 e 80 pode ser usado de 50°C (122°F) a 75°C (167°F)

Funciona bem e pode ser usado para necessidades de fiação de 90°C (194°F).

Para materiais reciclados limpos ou materiais mistos, os fabricantes devem garantir que os padrões relevantes sejam atendidos, como UL746D e padrões relacionados à UL.

Aqui queremos expressar nossas opiniões. Embora, para o bem da proteção ambiental, o uso de materiais reciclados ou produção mista possa reduzir o desperdício de matérias-primas, a desvantagem é que isso leva a uma diminuição no desempenho.

Então haverá uma situação em que muitos produtos no mercado alegam ser certificados por padrões UL relevantes. De fato, eles também têm certificados de conformidade. Mas em termos de desempenho, há de fato um declínio, como resistência ao estiramento.

Os conduítes e conexões de PVC rígido Schedule 40 e 80 são resistentes a influências corrosivas comuns, incluindo vapores e névoas de ácido alcalino, fluorídrico e crômico, bem como decapagem e galvanoplastia, e atendem às necessidades dos usuários nesses cenários industriais.

As paredes internas do conduíte e encaixe de PVC rígido Schedule 40 e 80 devem ser lisas, e não deve haver risco de rebarbas causando danos aos fios. Além disso, não deve haver lascas, bolhas, rachaduras, lascas, escamações, calcário ou outros defeitos na superfície externa do tubo.

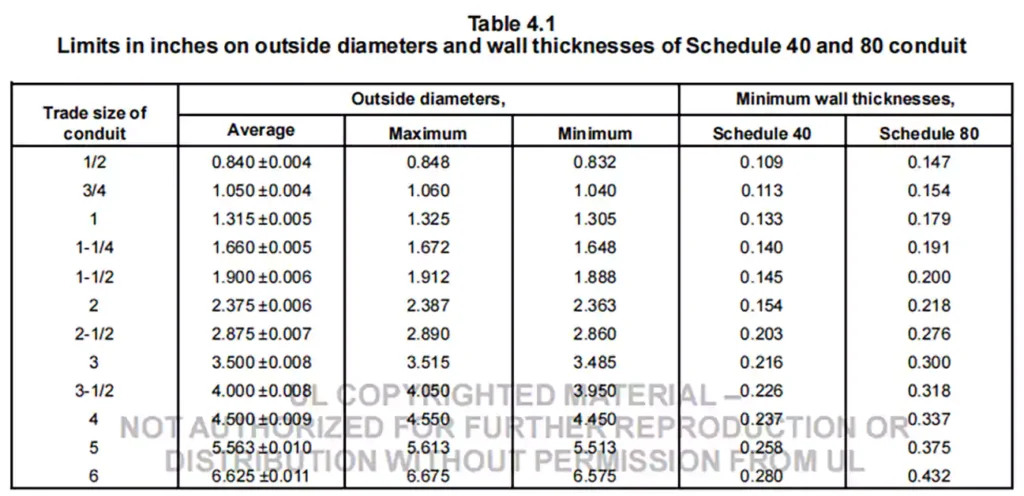

O corpo do tubo deve manter a ordenada vertical e não ter roscas. Use um micrômetro ou um medidor de manga cônica para medir, a escala precisa ser precisa para 0,001 polegadas ou 0,01 mm, e o desvio de precisão da medição não deve exceder ±1%. As dimensões medidas precisam estar em conformidade com as dimensões especificadas relevantes. Os dados relevantes já incluem a faixa de tolerância. As dimensões a serem atendidas incluem espessura externa, interna e de parede. Além disso, como acoplamentos, você precisa medir o comprimento, a profundidade do soquete, etc.

Os requisitos de tamanho para conduítes de PVC rígido Schedule 40 e 80 são claramente descritos na Tabela 4.1. Em termos gerais, a faixa de tolerância de OD é de ±0,004 a ±0,011 polegada, enquanto ID e espessura de parede são valores mínimos especificados para garantir que os parâmetros necessários sejam alcançados.

Para o Tipo A e EB, o método básico é similar. A diferença é que nesta versão, o OD e a espessura da parede do Tipo EB, a descrição oficial é que “Requisitos adicionais serão adicionados conforme esses tamanhos forem determinados como aceitáveis.”

Para os requisitos de qualidade dos acessórios, a UL651 também tem algumas regulamentações, como uma parede interna lisa sem rebarbas, que não pode afetar o movimento dos fios. Não permite detritos, bolhas, rachaduras, descamação, escamação, pulverização ou outros defeitos.

A UL 651 também especifica os valores máximos e mínimos de comprimento, espessura de parede, diâmetro do soquete e outros parâmetros para todos os acessórios para combinar com conduítes rígidos. Por exemplo, para acoplamento para conduítes tipo EB e A, sob a condição de tamanho comercial de 1/2 a 6 polegadas, a tolerância média do diâmetro interno na extremidade interna do soquete é de ± 0,008 a ± 0,014 polegadas, enquanto a tolerância média do diâmetro interno na entrada do soquete é de ± 0,015 a ± 0,023 polegadas, e os requisitos de tamanho são especificados na tabela relevante.

Há também alguns especiais, que listaremos brevemente aqui. Por exemplo, em um adaptador rosqueado adequado para fio e tubo de PVC rosqueado, a rosca deve ser clara e limpa, e o tamanho precisa atender aos requisitos da ASME B1.20.1-1983. Ao mesmo tempo, a porta rosqueada deve ter campo suficiente e atender ao teste de flexão.

Como há muitos acessórios, não os listaremos aqui.

Existem até 19 testes de desempenho no UL651, que é o teste definitivo para desempenho do produto. Selecionamos os seguintes itens para alguma explicação,

- Resistência à tracção

- Extrusão

- Absorção de água

- Resistência ao Impacto

- Resistência ao esmagamento

- Chama

- Resistência à luz solar

- Programação 40 e 80 para uso com fio de 90°C

- Permanência da impressão

O objetivo principal deste ensaio é determinar a resistência à tração de amostras envelhecidas e não envelhecidas de conduítes rígidos de PVC. As amostras envelhecidas devem manter pelo menos 95% da resistência à tração de suas contrapartes não envelhecidas para atender aos requisitos de conformidade.

- Seis espécimes são cortados do conduíte acabado, com dimensões específicas baseadas no tipo de conduíte.

- As medições, incluindo espessura de parede e diâmetro, são feitas usando paquímetros micrométricos de precisão com precisão mínima de 0,0001 polegada (0,001 mm).

- O conduíte deve estar limpo e a uma temperatura controlada de 23,0 ±2,0°C (73,4 ±3,6°F) antes do teste.

- Processo de envelhecimento: Três espécimes são submetidos a 168 horas em um forno de ar circulante a 113,0 ±1,0°C (235,4 ±1,8°F) e depois resfriados em ar parado.

- Teste de tração:

- Os seis espécimes (três envelhecidos e três não envelhecidos) são testados dentro de 16 a 96 horas após o envelhecimento.

- Um tampão de metal é inserido para evitar esmagamento durante o teste.

- Cada espécime é submetido à força de tração em uma máquina acionada mecanicamente, com garras separando-se a uma taxa controlada de 1/2 ±1/8 polegada (10,0 ±2,5 mm) por minuto.

- A carga máxima antes da falha é registrada.

- A resistência à tração é calculada dividindo-se a carga máxima pela área da seção transversal.

- A resistência à tração média de espécimes envelhecidos e não envelhecidos é comparada para garantir a conformidade com os requisitos da UL651:

Anexo 40 e 80: Mínimo 5.000 psi (34,5 MN/m²).

Tipo A e EB: Mínimo 4.000 psi (27,6 MN/m²).

- Os espécimes envelhecidos devem manter pelo menos 95% da resistência à tração dos espécimes não envelhecidos.

Simule a extrusão de tubos de PVC usando acetona anidra para observar e testar a fusão incompleta. Em geral, se houver uma grande área de descascamento, rachaduras e outros problemas após a imersão, teste se o produto atende aos requisitos padrão. É um ótimo teste para a qualidade da matéria-prima e do processo de produção de cateteres de PVC.

A UL651 exige que após o acabamento Conduíte de PVC é embebido em água destilada por 24 horas, a taxa de absorção de água não deve exceder 0,50% de seu peso. É muito fácil de entender. Se enterrarmos tubos de PVC no solo, eles serão inevitavelmente afetados pela umidade do solo. Se o conduíte de PVC absorver muita água e inchar, isso fará com que a junção do conduíte inche e se deforme, resultando em uma vedação ruim, e o resultado é que os fios não são protegidos como deveriam ser.

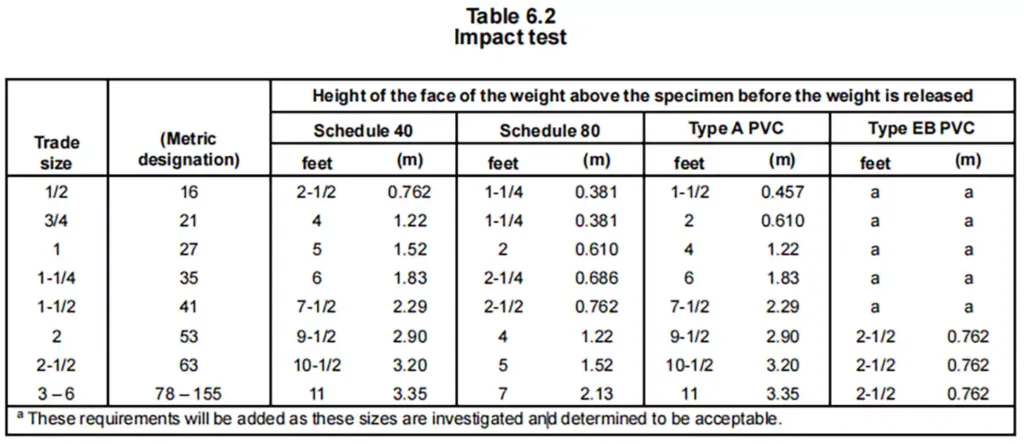

O Teste de Resistência ao Impacto descrito na norma UL 651 avalia a capacidade do conduíte rígido de PVC de suportar impactos físicos sem rachar ou rasgar além de um limite aceitável. Este teste é crucial para avaliar a durabilidade e a resistência mecânica do conduíte em condições reais, garantindo que ele permaneça intacto e funcional mesmo quando submetido a força ou impacto repentino.

- Dez Espécimes de 6 polegadas (150 mm) são cortados de comprimentos acabados de cada tamanho comercial de conduíte rígido de PVC.

- Os espécimes devem ser livre de rachaduras, rasgos ou outras imperfeições antes do teste.

- Os espécimes são condicionados ao ar a uma temperatura de 23,0 ±2,0°C (73,4 ±3,6°F) por pelo menos 4 horas para garantir condições de teste uniformes.

- Cada espécime é colocado em um chapa de aço sólida e plana isso é pelo menos 1/2 polegada (13 mm) de espessura e firmemente ancorado em uma posição horizontal.

- UM peso de aço, em forma de um cilindro sólido, circular reto, com uma face de impacto plana e bordas arredondadas, é solto sobre o espécime de uma altura especificada.

- As condições de impacto dependem do tipo de conduíte:

Anexo 40, Tipo A e Tipo EB:

Peso: 20 libras (9,1 kg)

Diâmetro do cilindro: 2 polegadas (51 mm)

Anexo 80:

Peso: 75 libras (34 kg)

Diâmetro do cilindro: 6 polegadas (150 mm)

- O face plana do peso atinge o centro do espécime ao longo do diâmetro e ao longo do eixo longitudinal, garantindo uma força de impacto padronizada.

- Existe um mecanismo para garantir o peso só ataca uma vez por teste.

- O conduíte rígido de PVC falha no teste se mais de três em cada dez espécimes desenvolvem uma rachadura ou rasgo maior que 1/32 polegada (0,8 mm) ao longo da superfície externa.

- Se sete ou mais os espécimes permanecem intactos ou desenvolvem rachaduras/rasgos dentro do limite permitido, o conduíte passa no teste.

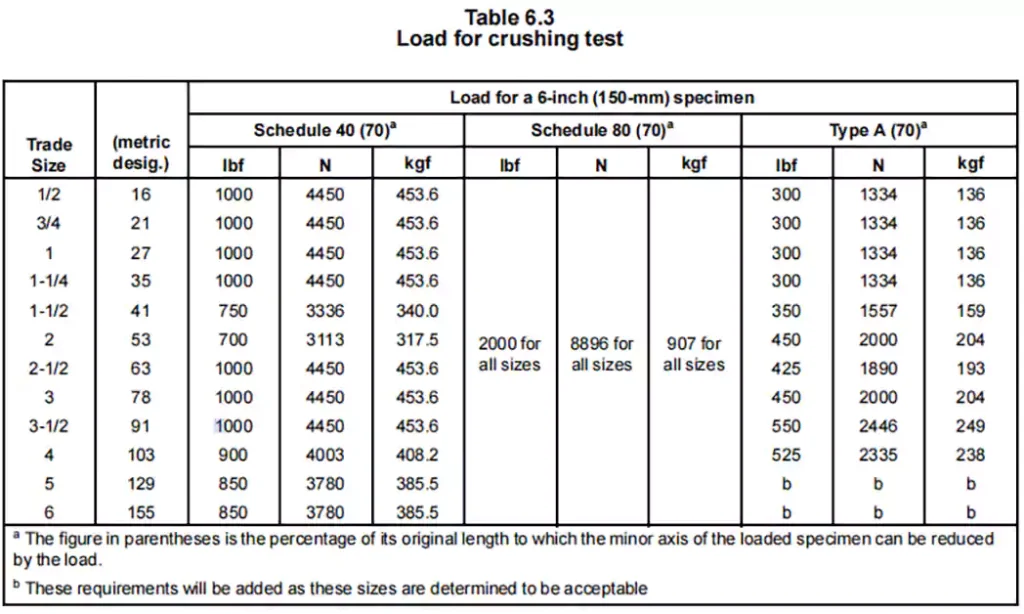

O Ensaio de Resistência ao Esmagamento avalia a capacidade do conduíte rígido de PVC de suportar pressão externa sem deformação significativa ou falha estrutural. Este ensaio garante que o conduíte mantenha sua integridade sob forças de compressão, o que é essencial para seu desempenho em instalações subterrâneas, enclausuradas ou expostas, onde pode ser submetido a cargas pesadas.

Ao simular condições reais, o teste verifica se o conduíte não encurva ou se deforma excessivamente sob cargas especificadas. Um critério fundamental para a aprovação no teste é que o eixo menor do diâmetro interno não deve ser reduzido a menos de 70% de sua medida original antes do carregamento.

Este teste é diferente do teste de resistência ao impacto porque o conduíte de PVC é embutido no solo ou na parede e fica sob pressão por um longo tempo. Este teste experimenta a capacidade compressiva do conduíte de PVC sob a ação da pressão, o que também a afeta. Fatores de longevidade.

O Teste de Chama da norma UL 651 avalia a resistência ao fogo de conduítes rígidos de PVC (Tabela 40 e Tabela 80) para garantir que eles não sustentem ou espalhem chamas em caso de incêndio. Este teste foi desenvolvido para confirmar que o conduíte se autoextingue rapidamente e não contribui para a ignição de materiais combustíveis próximos.

Durante o teste, o conduíte é exposto a uma Aplicação de chama de 60 segundos, repetido três vezes, com um intervalo de 30 segundos entre cada exposição. O conduto deve cessar a chama em 5 segundos após cada aplicação de chama e não deve liberar partículas em chamas que possam incendiar os materiais ao redor. Se o conduíte não atender a esses critérios, ele será considerado inadequado para aplicações onde a segurança contra incêndio seja uma preocupação.

Este teste simula se o conduíte de PVC Schedule 40 e 80 pode fornecer proteção máxima quando ameaçado por fogo. Se o conduíte tiver excelente retardância de chama, ele pode garantir que os fios no conduíte estejam intactos quando a chama aberta for extinta para não causar um acidente mais sério.

O Teste de Resistência à Luz Solar da norma UL 651 avalia a capacidade dos conduítes de PVC rígido Schedule 40 e Schedule 80 de suportar exposição prolongada à radiação UV sem degradação significativa. Como as instalações elétricas externas frequentemente expõem os conduítes à luz solar direta, este teste garante que o material mantenha sua integridade mecânica e resistência ao impacto ao longo do tempo.

O teste envolve Medições de resistência ao impacto Izod em espécimes entalhados preparados a partir de amostras de conduítes não envelhecidas e condicionadas por UV. Essas amostras são expostas à radiação UV por até 1440 horas, após o qual sua resistência ao impacto é testada de acordo com as normas ASTM D 256. Para passar no teste, o conduíte deve manter um nível aceitável de resistência ao impacto, conforme especificado na norma UL 651.

Este processo de teste garante que os conduítes rígidos de PVC permaneçam duráveis e confiáveis em aplicações externas, proporcionando desempenho e proteção de longo prazo contra fatores ambientais, como exposição a raios UV e intempéries.

Entre os requisitos da UL651, uma especificação fundamental é a capacidade de suportar fios com classificação de 90 °C, que indica a temperatura máxima de operação dos condutores dentro do conduíte.

A classificação de 90 °C refere-se à temperatura máxima que o isolamento do fio pode suportar sem se degradar ao longo do tempo. Conduítes de PVC com certificação UL 651 são normalmente classificados para condutores de 75 °C, mas muitas especificações elétricas agora exigem conduítes com classificação de 90 °C para acomodar fiação de alta temperatura sem exigir redução da capacidade do sistema. Essa maior tolerância à temperatura garante que o sistema elétrico opere com eficiência total, mantendo a segurança e a confiabilidade.

Para atingir a classificação de 90 °C, o conduíte de PVC deve passar por testes adicionais de longo prazo, além dos requisitos padrão para conduítes de 75 °C. O processo de teste descrito na norma UL 651 se estende por 360 dias, expondo o conduíte a diversas tensões ambientais, incluindo altas temperaturas prolongadas, para avaliar sua resistência à degradação térmica, integridade mecânica e desempenho geral.

O teste envolve o envelhecimento acelerado pela colocação de amostras de conduíte em um forno de circulação de ar a 80°C (176°F) por até 360 dias. Em intervalos específicos, são realizados testes de impacto usando um método de queda de cilindro de aço para determinar retenção de resistência ao impacto ao longo do tempo. Uma curva de degradação suave é traçada e o conduíte deve manter pelo menos 50% de sua resistência ao impacto inicial após exposição prolongada.

Essa avaliação rigorosa garante que os conduítes de PVC Schedule 40 e 80 permaneçam confiáveis e estruturalmente sólidos quando usados com fiação de alta temperatura, proporcionando segurança e desempenho de longo prazo em aplicações elétricas exigentes.

Conduítes com classificação de 90°C também devem incluir marcações permanentes que indiquem explicitamente "fio com temperatura máxima de 90°C" ou "fio com temperatura máxima de 90°C". Agências de certificação como UL e ETL exigem essas marcações para confirmar que o conduíte atende à norma.

Se um conduíte não possuir essa marcação obrigatória, ele não está em conformidade com a especificação de 90 °C, independentemente das alegações do fabricante. O uso de conduítes não conformes em sistemas projetados para condutores de 90 °C pode levar a consequências graves, incluindo inspeções malsucedidas, rejeição do sistema, substituições dispendiosas e responsabilidades legais.

Este teste requer que a amostra seja submetida a um teste de envelhecimento por 168 horas de antecedência, embebida em água da torneira por 24 horas e, em seguida, esfregada com óleo IRM902 para iniciar o teste. O teste usará um dispositivo automático simples para permitir que a fita entre em contato com a parte impressa do cateter em um ciclo fixo, com um movimento de vai e vem para cada ciclo, para um total de 50 ciclos.

Após os testes acima, os caracteres impressos devem ficar claramente visíveis para produtos qualificados.

Como a maioria dos fabricantes agora está gravando a laser, esse teste não é muito severo. Seu propósito é principalmente reter a impressão do cateter, que pode rastrear o fabricante, a data de produção, etc.

A impressão usual em tubo rígido de PVC precisa incluir o seguinte:

1) Com as palavras 'Conduíte de PVC rígido';

2) Tamanho do comércio

3) O nome do fabricante ou proprietário da marca

4) Data de produção

5) As informações acima precisam ser impressas pelo menos uma vez a cada 10 pés.

6) Conforme dito no capítulo acima, a impressão é permanente

Além disso, há alguns requisitos detalhados para conduítes de PVC Schedule 40 e 80. Por exemplo, a impressão deve ser atualizada para conduítes de PVC rígido Schedule 40 ou Schedule 80 para esses dois conduítes.

Alguns são adequados para fios de 90°C (194°F), então o “fio máximo de 90°C” deve ser marcado na impressão. Existem também alguns requisitos especiais. Por exemplo, se Conduíte rígido Schedule 40 é adequado apenas para uso subterrâneo, então “Somente uso subterrâneo” deve ser impresso.

Quanto à impressão de produtos acessórios, como a maioria deles é produzida por tecnologia de moldagem por injeção, ela só precisa ser feita durante o projeto do molde e precisa atender aos requisitos permanentes. O conteúdo impresso geralmente é o nome do fabricante ou da marca e o modelo do produto. Semelhante ao conduíte de PVC rígido Schedule 40 ou Schedule 80, se ele só puder ser usado em cenários limitados, precisa ser observado, como enterrado no solo ou é adequado apenas para fios de 90 °C.

O NEC (Código Elétrico Nacional) define os requisitos de instalação e uso de eletrodutos de PVC para garantir a conformidade com os padrões de segurança elétrica. O Artigo 352 do NEC especifica as principais aplicações, limitações e requisitos de instalação. A seguir, algumas informações importantes:

Aplicações para Eletrodutos de PVC:

Usos permitidos | Usos não permitidos |

Instalações ocultas em paredes, pisos ou tetos | Em locais perigosos (classificados), a menos que seja especificamente permitido |

Locais úmidos e secos | Como meio de suporte para luminárias (luminárias) |

Ambientes corrosivos onde os conduítes metálicos podem se deteriorar | Onde sujeito a danos físicos graves |

Instalações subterrâneas, incluindo enterramento direto | Em áreas onde as temperaturas excedem 50°C (122°F) |

Aplicações expostas, desde que o conduíte seja classificado para resistência à luz solar | Where it may be used as a grounding conductor |

Conduit Fill: The number of conductors must comply with NEC Chapter 9.

Conduit Fill Size Chart for PVC Conduit

Número de condutores | Cross-Sectional Area (%) |

1 | 53 |

2 | 31 |

Mais de 2 | 40 |

Support Requirements: Must be secured within 3 feet (900mm) of terminations and supported per NEC Table 352.30.

Expansion Fittings: Required when thermal expansions is expected to exceed 1/4 inch (6mm).

Aterramento: PVC conduit does not provide an equipment grounding path; a separate grounding conductor is required.

Composição do material: Must be made from non-plasticized PVC, resistant to moisture, chemicals, impact, and fire, and UV-resistant for above ground use.

Ledes is a trusted manufacturer in high-quality electrical conduit solutions, committed to delivering safe, durable, and high-performance products that meet industry standards. Our extensive range of UL-listed PVC conduits and fittings ensures compliance with the UL standard, offering superior reliability for a variety of electrical applications.

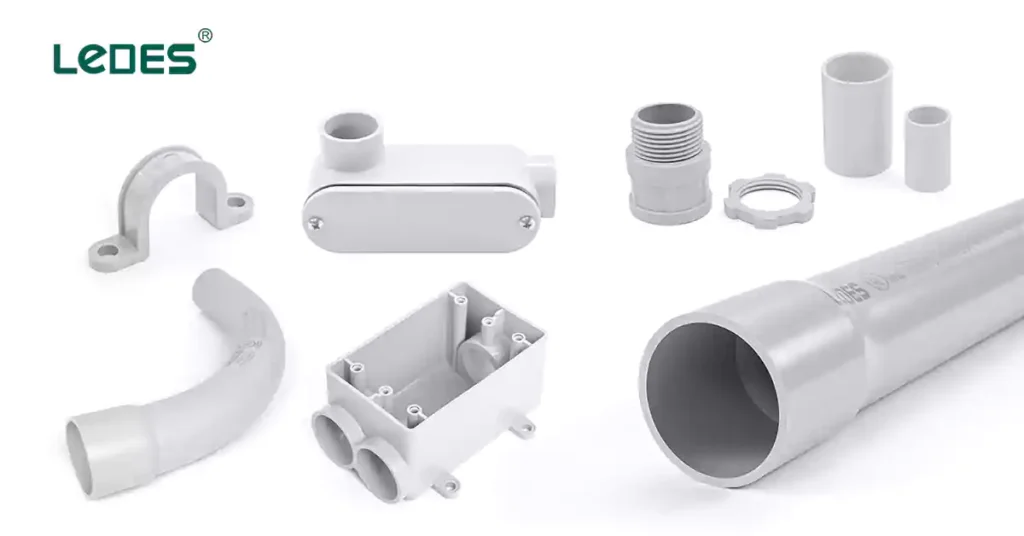

Ledes provides UL-listed PVC conduits and fittings that for use with the conduits, including:

- Conduíte de PVC Anexo 40 – A versatile, lightweight option suitable for general-purpose electrical installations, both aboveground and underground.

- Conduíte de PVC Schedule 80 – Features a thicker wall for enhanced impact resistance, ideal for high-traffic or demanding environments.

- Elbows – Available in 45°, 90°, and other custom angles of standard elbows and special radius elbows, these elbows allow smooth directional changes in conduit runs without compromising wiring integrity.

- Acoplamentos – Essential for joining conduit sections, ensuring a seamless and secure connection for continuous wiring runs.

- Adaptadores – Including Male Terminal Adapters and Female Adapters, enabling smooth transitions between different conduit types, boxes, or enclosures.

- Pipe Straps – Strong and reliable conduit supports that securely fasten Schedule 40 and 80 conduits to walls, ceilings, or other structures.

- Caixas de gangue – Designed for secure mounting of electrical devices and wiring connections.

- Corpos de conduíte – Ideal for providing pull points, splicing spaces, and directional changes, available in multiple styles such as Type LB, LL, LR, T, and C to suit different installation needs.

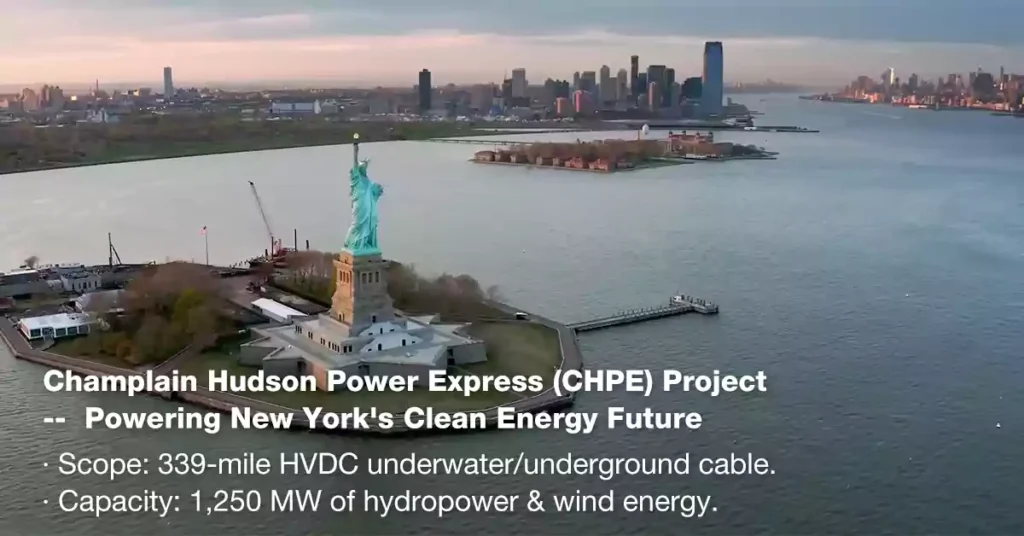

The Champlain Hudson Power Express (CHPE) is a landmark high-voltage direct current (HVDC) transmission project, spanning 339 miles from Quebec, Canada, to New York City. This project is critical for:

- Delivering clean, renewable hydroelectric power to New York.

- Reducing carbon emissions and enhancing grid reliability.

- Creating thousands of jobs and modernizing the region’s energy infrastructure.

For this massive underground and underwater transmission line, Ledes’ UL-listed PVC conduits and fittings were selected due to their superior durability, corrosion resistance, and electrical safety. Our Schedule 40 and 80 PVC conduits provide secure cable protection over long distances, ensuring efficient energy transmission while withstanding underground conditions.

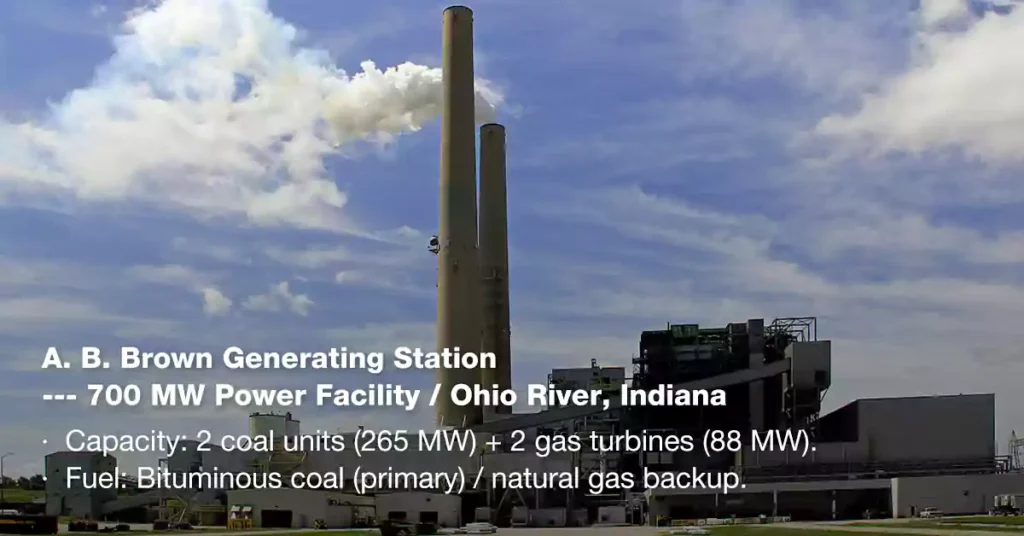

The A.B. Brown Generating Station is a 700-megawatt (MW) power plant located along the Ohio River in Indiana, just southwest of Evansville. This facility, owned by CenterPoint Energy (formerly Vectren), consists of:

- Two coal-fired units, each with a 265.2 MW nameplate capacity, primarily using bituminous coal with the capability to substitute natural gas.

- Two gas turbine units, each providing 88.2 MW of capacity for additional power generation.

As part of CenterPoint Energy’s modernization plan, there are ongoing infrastructure improvements and grid enhancements to support future energy needs. The company previously announced plans to retire the coal-fired units and transition to natural gas-powered generation, pending approval from the Indiana Utility Regulatory Commission.

To ensure a secure and reliable electrical system, Ledes’ UL-listed PVC conduits and fittings were selected for various electrical installations and upgrades within the A.B. Brown facility.

Listado pela UL – Ensuring compliance with safety and performance standards.

Durable & Corrosion-Resistant – Made from high-quality PVC for long-lasting performance in harsh environments.

Instalação fácil – Lightweight and designed for quick assembly.

Aplicações Versáteis – Suitable for residential, commercial, and industrial electrical installations.

Ledes is proud to be a supplier for critical infrastructure projects that shape the future of energy. Our innovative, high-performance conduit solutions ensure safe and efficient electrical installations in the most demanding environments.

UL (Underwriters Laboratories) and CSA (Canadian Standards Association) are two leading organizations establishing safety and performance benchmarks for electrical conduits. Their standards ensure products meet rigorous requirements for durability, fire resistance, and environmental adaptability, with distinct regional and technical emphases.

- UL Standards: Primarily recognized in the United States, UL standards focus on ensuring that electrical products, including PVC conduits, are safe to use within the U.S. infrastructure. The UL standard for PVC conduit (e.g., UL 651) addresses fire safety, impact resistance, temperature ratings, and more.

- CSA Standards: These are focused on ensuring that products are safe for use within Canada. CSA standards often align with international guidelines but may have specific adjustments to reflect local safety and regulatory needs. CSA C22.2 No. 211.2 is the standard for PVC conduit in Canada, outlining similar requirements to UL but tailored for Canadian safety regulations.

Performance Requirements UL651 and CSA C22.2:

Aspects | UL651 | CSA C22.2 Nº 211.2 |

Temperature | Use at 50° C(122°F) or lower ambient temperatures; Use with 75° C (or maybe 90° C) wiring. | Use at a continuous operating temperature of 75° C.

|

Resistência ao impacto | Test at 23.0 ±2.0° C, with 20lbs (9.1 kg) weight for Schedule 40. | Test at –34 ± 2 °C, with 12 J impact energy for rigid conduit.

|

Resistência à tracção | 5,000 psi for Schedule 40 conduit | Não especificado |

Resistant to Crushing | Detail required in section 6.9 | Não especificado |

Compressão | Não especificado | No cracks and decrease no more than 25% when subjected to certain forces. |

Chama | 3 times of 60-seconds flame application, no more than 5s flame after each application. No flaming drops. | Not burn than 30 seconds, no flaming or glowing particles. |

Resistência à luz solar | Same requirements with CSA | Same requirements with UL |

- Código Elétrico Nacional (NEC): UL-certified PVC conduits are recognized for compliance with the U.S. National Electrical Code (NEC), which is the standard governing electrical installations across the United States.

- Código Elétrico Canadense (CEC): CSA-certified PVC conduits are recognized for compliance with the Canadian Electrical Code (CEC), ensuring that products meet the specific safety and installation standards for electrical systems in Canada.

- UL Mark: PVC conduit that is UL-listed typically displays the UL mark, which indicates that it meets the specific UL safety standards and is approved for use in the United States.

- CSA Mark: Similarly, PVC conduit that meets CSA standards is marked with the CSA logo, indicating that it is compliant with Canadian requirements.

Both UL and CSA standards are crucial for ensuring that PVC conduits meet the necessary safety, performance, and regulatory requirements in their respective regions. While there are similarities in the testing protocols and requirements, the key difference lies in their geographic applicability and specific regulations. For projects in the United States, UL-listed PVC conduit is the ideal choice, while CSA-certified conduit is essential for Canadian installations.

As we’ve explored throughout this guide, UL 651 PVC conduit plays a crucial role in modern electrical installations by offering a combination of durability, fire resistance, corrosion resistance, and compliance with NEC requirements. Its classification into Schedule 40 and Schedule 80 allows for flexibility in different applications, ensuring that electricians and contractors can choose the right type based on mechanical protection needs and environmental conditions.

Whether you’re working on an underground installation, a commercial building, or an industrial facility, using UL 651-compliant PVC conduit ensures that your electrical system meets safety standards and performs reliably over time. By selecting certified conduit from reputable manufacturers, you can guarantee long-term performance while ensuring compliance with industry regulations.

As the demand for sustainable, cost-effective, and reliable electrical solutions continues to grow, UL 651 PVC conduit remains a key component in safe and efficient wiring infrastructure. Now that you have a thorough understanding of UL 651, you can confidently choose the right conduit for your next project.

Se você tiver alguma dúvida ou estiver interessado em nossa série de produtos UL, você pode entre em contato conosco por e-mail ou mesmo What’s app, e geralmente responderemos a você dentro de 1 dia útil.