Índice

In recent years, the rapid growth of solar energy has paved the way for innovative solutions in the field of electrical conduit. As modern society strives for cleaner and more sustainable energy sources, the demand for efficient and reliable solar installations has skyrocketed. This article aims to shed light on the concept of Conduíte Solar by providing an overview of electrical conduit and its specific application in solar energy systems.

Compreendendo o eletroduto:

O conduíte elétrico serve como um caminho de proteção para a fiação elétrica, fornecendo um meio seguro e organizado de roteamento de cabos de energia e comunicação. Ele desempenha um papel vital na proteção de circuitos elétricos contra danos físicos, umidade e fatores ambientais. Os sistemas de conduíte são comumente usados em ambientes residenciais, comerciais e industriais para garantir a integridade e a longevidade das instalações elétricas.

O que é conduíte solar?

Solar Conduit é um tipo especializado de conduíte elétrico projetado especificamente para sistemas solares fotovoltaicos (PV). À medida que as instalações de energia solar continuam a se expandir, os requisitos exclusivos desses sistemas levaram ao desenvolvimento de soluções de conduíte adaptadas às suas necessidades.

Normas e requisitos para conduítes solares:

Para garantir a qualidade, segurança e conformidade do PVC Solar Conduit, vários padrões e requisitos foram estabelecidos. Essas diretrizes ajudam fabricantes, instaladores e órgãos reguladores a manter a uniformidade e a confiabilidade em sistemas de energia solar.

1. Código Elétrico Nacional (NEC):

The NEC is a widely recognized standard in the electrical industry that provides requirements for the safe installation of electrical systems, including conduit. It addresses the sizing, installation methods, and grounding of conduits used in solar energy systems. Compliance with NEC standards is crucial to ensure the proper installation and functionality of PVC Solar Conduit.

2. Normas IEC:

The International Electrotechnical Commission (IEC) has developed several standards relevant to electrical conduit, including those applicable to PVC Solar panel Conduit. IEC 61386-21 provides specifications for rigid conduit systems, while IEC 61386-24 covers the requirements for flexible conduit systems. These standards address factors such as dimensions, mechanical properties, and performance characteristics of conduit systems used in various applications, including solar installations.

3. Normas AS:

A Standards Australia (AS) também desempenha um papel significativo no estabelecimento de padrões para conduítes elétricos. A AS 2053 fornece especificações para conduítes rígidos e flexíveis usados em instalações elétricas. Esses padrões abrangem aspectos como materiais, dimensões, resistência mecânica e resistência a fatores ambientais. A AS 2053 garante que o conduíte solar de PVC atenda aos requisitos necessários para durabilidade e desempenho em sistemas de energia solar.

4. Teste UV:

Considerando a exposição de instalações solares à luz solar e à radiação UV, o PVC Solar Conduit deve passar por testes UV para avaliar sua resistência à degradação. Os testes UV envolvem submeter o conduíte à luz solar simulada e monitorar seu desempenho ao longo do tempo. Os resultados do teste fornecem dados valiosos sobre a capacidade do conduíte de suportar exposição prolongada à radiação UV sem degradação significativa ou perda de propriedades.

Os produtos de conduíte solar Ledes passaram por um teste de envelhecimento por UV de 1.080 horas, sem alteração de cor óbvia e sem degradação de propriedades.

5. Classificações de incêndio:

A segurança contra incêndio é uma consideração crítica para sistemas de conduítes elétricos, incluindo o conduíte solar de PVC. O conduíte com classificação de incêndio é projetado para resistir à propagação do fogo e manter a integridade dos circuitos elétricos durante um evento de incêndio. As classificações de incêndio são normalmente classificadas com base em critérios como resistência à chama, geração de fumaça e toxicidade. O conduíte solar de PVC deve atender aos padrões de classificação de incêndio aplicáveis, como UL 1660 ou AS 3013, para garantir sua conformidade com os requisitos de segurança contra incêndio.

6. Testes de altas e baixas temperaturas:

A instalação do painel solar geralmente ocorre em ambientes externos expostos, como áreas desérticas, a temperatura muda rapidamente. Exposição prolongada a altas e baixas temperaturas, o conduíte pode ser:

Empenamento e rachaduras: conduítes expostos podem se tornar vulneráveis a danos e rachaduras facilmente.

Fragilidade: O conduíte pode se tornar quebradiço e propenso a quebra sob estresse físico. Degradação do desempenho: Temperaturas extremas podem degradar o desempenho dos conduítes ao longo do tempo e comprometer sua capacidade de proteção.

Para essas situações, o conduíte solar deve ser projetado para suportar temperaturas extremas. O conduíte solar LEDES passou nos testes de temperatura de -15℃ a 105℃ e manteve sua integridade funcional. Nenhum sinal de fragilidade ou rachadura.

7. Regional Comparisons:

Em diferentes regiões, como América do Norte e Austrália, pode haver variações nos padrões e requisitos específicos para conduítes solares de PVC. Por exemplo, na América do Norte, o National Electrical Code (NEC) define diretrizes para instalações de conduítes, enquanto os padrões UL certificam a segurança e o desempenho de produtos elétricos. Na Austrália, as Wiring Rules (AS/NZS 3000) e os padrões AS ditam os requisitos para sistemas de conduítes. Comparar esses padrões regionais pode fornecer insights sobre as diferentes abordagens adotadas para garantir a qualidade e a segurança dos conduítes solares de PVC.

Aplicação e Perspectiva do Conduíte Solar:

O conduíte solar de PVC é comumente usado nas seguintes aplicações:

● Projeto Solar Fotovoltaico:

Projetos solares fotovoltaicos envolvem a instalação de painéis solares para gerar eletricidade a partir da luz solar. Esses projetos podem variar de instalações residenciais de pequena escala a grandes fazendas solares que abrangem vários acres.

Os conduítes solares Ledes foram usados em alguns grandes projetos de PV e ganharam bastante reconhecimento. Incluindo o projeto ASB 2.6GW na Arábia Saudita e o projeto PV2 em Abu Dhabi, que são atualmente os dois maiores projetos solares fotovoltaicos do mundo. A aplicação de conduítes solares de PVC em projetos de PV solar é crucial para o roteamento seguro e eficiente de cabos elétricos.

● Fazenda Solar:

Uma fazenda solar é uma instalação em larga escala que compreende vários painéis solares, geralmente dispostos em fileiras ou matrizes, para gerar eletricidade em escala comercial. Essas fazendas aproveitam a energia solar e a convertem em eletricidade utilizável. O conduíte solar de PVC desempenha um papel significativo na conexão e proteção da extensa rede de cabos elétricos dentro de uma fazenda solar. Ele garante o roteamento e a organização adequados dos cabos, mantendo a integridade e a eficiência do sistema elétrico.

● Fazendas e instalações agrícolas modernas:

Fazendas e instalações agrícolas modernas estão cada vez mais integrando automação e sistemas elétricos para tarefas como irrigação automatizada, controle de temperatura e gerenciamento de gado. Esses sistemas exigem instalações elétricas confiáveis e eficientes. Ao utilizar sistemas de energia solar limpos e ecologicamente corretos, os fazendeiros podem reduzir significativamente os custos e aumentar a eficiência da produção. Conduítes solares de PVC e acessórios são componentes essenciais na instalação de sistemas de energia solar em fazendas. Eles fornecem um caminho seguro e organizado para a fiação elétrica, garantindo a estabilidade e a longevidade do sistema elétrico.

● Instalações solares:

Para instalações de processamento de pequena escala e fábricas, incorporar sistemas de energia solar como uma fonte de eletricidade de reserva pode ser vantajoso. Os sistemas de energia solar podem ajudar a reduzir a carga na rede elétrica principal e fornecer economia de custos. Nesses casos, a energia solar pode ser usada para fornecer eletricidade a equipamentos ou áreas específicas, como iluminação, dormitórios de funcionários ou energia de reserva para sistemas críticos como centros de rede. O conduíte solar de PVC é vital para a instalação e conexão desses sistemas de energia solar, garantindo uma distribuição de eletricidade confiável e eficiente.

Perspectivas futuras da conduíte solar:

A perspectiva futura para a Solar Conduit parece promissora à medida que o mundo muda cada vez mais para fontes de energia renováveis, como a energia solar. Aqui estão alguns pontos-chave e referências de dados a serem considerados:

1. Demanda crescente por energia solar:

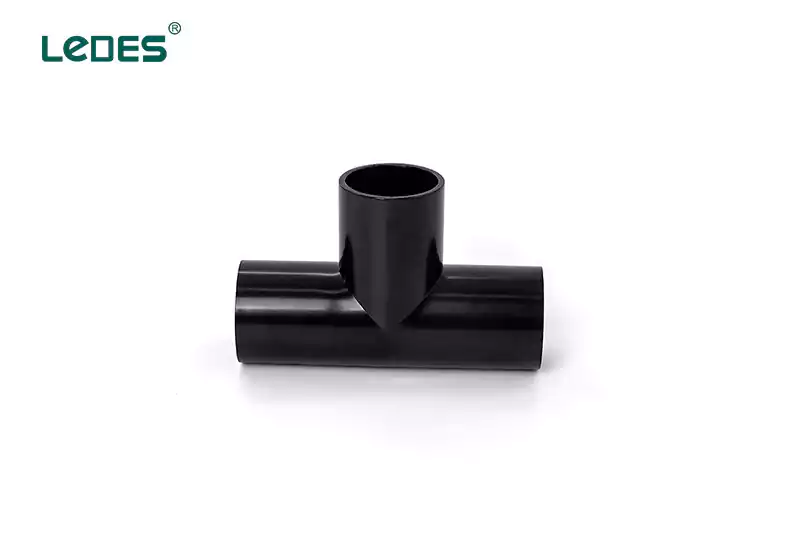

A demanda por energia solar vem aumentando constantemente em todo o mundo. De acordo com dados da Administração de Serviços Gerais dos EUA, novas fontes de energia, como a energia solar, vêm gradualmente ganhando força, com a energia renovável testemunhando um crescimento significativo após 2022. Essa tendência indica uma mudança em direção a opções de energia mais limpas e sustentáveis, incluindo a energia solar.

2. Aumento das instalações solares:

A instalação de painéis solares e sistemas de energia solar está aumentando, tanto nos setores residenciais quanto comerciais. À medida que governos, empresas e indivíduos buscam reduzir sua pegada de carbono e adotar energia renovável, espera-se que a adoção de sistemas de energia solar continue sua trajetória ascendente. Essa atividade de instalação aumentada impulsionará a demanda por Conduíte Solar de PVC como um componente vital nesses sistemas.

3. Políticas e incentivos governamentais favoráveis:

Muitos governos em todo o mundo estão implementando políticas de apoio e incentivos para encorajar a adoção de energia renovável, incluindo energia solar. Essas políticas incluem tarifas feed-in, créditos fiscais, subsídios e outros incentivos financeiros. Essas iniciativas criam um ambiente favorável para o crescimento de projetos de energia solar, o que, por sua vez, alimenta a demanda por PVC Solar Conduit.

4. Avanços na tecnologia solar:

Os avanços contínuos na tecnologia solar, incluindo melhorias na eficiência e acessibilidade dos painéis solares, estão tornando a energia solar mais acessível e economicamente viável. À medida que a tecnologia solar continua a evoluir, espera-se que a demanda por PVC Solar Conduit cresça em conjunto para atender aos requisitos de instalação de sistemas solares avançados.

5. Sustentabilidade e Consciência Ambiental:

A crescente consciência ambiental e as preocupações com as mudanças climáticas estão impulsionando a transição para fontes de energia renováveis. A energia solar é considerada uma das formas de energia mais limpas e sustentáveis, pois não produz emissões de gases de efeito estufa durante a operação. O uso do Solar Conduit se alinha com o objetivo de criar sistemas de energia solar ecologicamente corretos, contribuindo ainda mais para o crescimento da indústria.

conduíte solar desempenha um papel crucial na proteção e segurança de fios e cabos elétricos em sistemas de energia solar. Seu uso garante a transmissão segura e eficiente da eletricidade gerada por painéis solares. Com os avanços tecnológicos contínuos e as preferências do consumidor em mudança em direção a soluções de energia sustentável, espera-se que a demanda por conduíte solar de PVC testemunhe um crescimento substancial.

Tipos de conduíte solar:

Existem vários tipos de conduítes usados em aplicações de energia solar. Esses conduítes podem ser classificados em duas categorias principais com base em sua composição de material: conduítes metálicos e conduítes não metálicos.

Eletrodutos Metálicos:

● Tubulação metálica elétrica (EMT)

Também conhecido como conduíte de parede fina, o EMT é feito de aço galvanizado e é comumente usado em aplicações residenciais e comerciais leves.

– Advantages: Lightweight, easy to bend and install, cost-effective, good corrosion resistance.

– Disadvantages: Less physical protection compared to rigid conduits, not suitable for harsh environments.

● Eletroduto metálico rígido (RMC)

Feito de aço galvanizado de parede espessa, o RMC oferece um alto nível de proteção física para fiação elétrica em aplicações mais exigentes.

– Advantages: Provides excellent physical protection, suitable for demanding environments, high durability.

– Disadvantages: Heavy and rigid, more difficult to install compared to other conduits, higher cost.

● Eletroduto Rígido Galvanizado (GRC)

Semelhante ao RMC, o GRC é um conduíte de parede mais espessa feito de aço galvanizado e é comumente usado em ambientes industriais e comerciais.

– Advantages: Offers superior protection in hazardous locations, high strength, excellent corrosion resistance.

– Disadvantages: Heavy and rigid, more expensive than other metallic conduits.

● Eletroduto metálico flexível estanque (LFMC)

Este conduíte consiste em um núcleo de metal flexível e uma cobertura externa estanque a líquidos, fornecendo proteção em ambientes onde a umidade ou a exposição a líquidos são uma preocupação.

– Advantages: Flexibility for easy installation in tight spaces, provides liquid-tight protection, suitable for outdoor and wet locations.

– Disadvantages: Limited mechanical protection compared to rigid conduits, higher cost compared to non-metallic conduits.

Conduítes não metálicos:

● Conduíte de PVC

O conduíte de PVC (Policloreto de Vinila) é uma escolha popular para instalações elétricas devido à sua durabilidade, acessibilidade e resistência à corrosão. Ele está disponível em vários tamanhos e é comumente usado em aplicações residenciais e comerciais.

– Advantages: Lightweight, low cost, corrosion-resistant, easy to install, available in various sizes and lengths.

– Disadvantages: Lower impact resistance compared to metallic conduits, may degrade under prolonged exposure to sunlight.

ENT é um conduíte flexível e não metálico, tipicamente feito de PVC ou uma mistura de PVC e nylon. É comumente usado em aplicações residenciais e comerciais leves devido à sua facilidade de instalação.

– Advantages: Flexible and easy to install, resistant to corrosion and moisture, suitable for residential applications.

– Disadvantages: Less mechanical protection compared to rigid conduits, limited temperature tolerance.

● Conduíte flexível não metálico estanque a líquidos (LFNC)

LFNC, também conhecido como conduíte de PVC estanque a líquidos, é um conduíte flexível com uma cobertura externa estanque a líquidos. É comumente usado em locais externos e úmidos onde proteção contra umidade e líquidos é necessária.

– Advantages: Provides liquid-tight and flexible protection, suitable for outdoor and wet locations, resistant to corrosion.

– Disadvantages: Limited mechanical protection compared to rigid conduits, higher cost compared to PVC conduit.

● Conduíte de PEAD

O conduíte HDPE (Polietileno de Alta Densidade) é um conduíte durável e flexível, não metálico, comumente usado para instalações subterrâneas. Ele oferece excelente resistência a produtos químicos, exposição UV e estresse ambiental.

– Advantages: Durable and flexible, excellent resistance to chemicals and UV exposure, suitable for underground installations.

– Disadvantages: Limited mechanical protection compared to metallic conduits, higher cost compared to PVC conduit.

Por que Solar Conduit?

O conduíte solar é crucial para sistemas de energia solar pelos seguintes motivos:

Proteção

O conduíte solar fornece proteção essencial para cabos e fiação elétrica em instalações solares, protegendo-os de danos físicos, fatores ambientais, umidade, radiação UV e pragas. Essa proteção garante a confiabilidade e a segurança do sistema a longo prazo.

Conformidade

O conduíte solar ajuda a atender aos requisitos de código elétrico e segurança específicos para instalações solares. Ele garante o gerenciamento de fios, aterramento e isolamento adequados, reduzindo o risco de perigos elétricos e garantindo a conformidade com os regulamentos e padrões locais.

Durabilidade

O conduíte solar é projetado para suportar as duras condições externas tipicamente associadas a instalações solares. Ele é construído para resistir a temperaturas extremas, umidade, exposição à luz solar e produtos químicos, garantindo desempenho duradouro e minimizando as necessidades de manutenção.

Organização

O conduíte solar permite uma fiação organizada e limpa dentro do sistema de energia solar. Ele ajuda a rotear e gerenciar cabos elétricos, reduzindo o risco de emaranhamento, interferência e danos acidentais. A organização adequada simplifica a manutenção do sistema, solução de problemas e futuras expansões ou atualizações.

Comparação: Conduíte Solar de PVC vs. Conduíte Solar Metálico

1. Conduíte solar de PVC:

Vantagens:

Custo-benefício: os conduítes de PVC geralmente são mais baratos quando comparados aos conduítes metálicos, o que os torna uma opção econômica para instalações solares.

Fácil instalação: o conduíte de PVC é leve e fácil de manusear, simplificando os processos de transporte e instalação.

Segurança: O PVC fornece isolamento elétrico confiável, garantindo um sistema elétrico seguro dentro da instalação solar.

Resistência à corrosão: o PVC é inerentemente resistente à corrosão, adequado para diversas condições ambientais.

2. Conduíte solar metálico (por exemplo, EMT, RMC, GRC):

Vantagens:

Proteção superior: conduítes metálicos oferecem excelente proteção física para fiação elétrica em ambientes exigentes e locais perigosos.

Durabilidade: Os conduítes metálicos têm alta durabilidade e resistência, proporcionando desempenho duradouro e proteção contra danos físicos e fatores externos.

Desvantagens (Conduíte Metálico):

Custo mais alto: conduítes metálicos geralmente são mais caros quando comparados aos conduítes de PVC.

Instalação difícil: os conduítes metálicos são mais pesados e rígidos, o que os torna mais desafiadores de instalar em comparação aos conduítes de PVC.

Conexões de conduíte solar:

Os acessórios são essenciais nas instalações elétricas, aqui estão alguns acessórios comumente usados que a Ledes fornece:

Caixas de junção são invólucros elétricos usados para proteger e conectar fios ou cabos elétricos. Elas fornecem um espaço seguro e organizado para emendar fios, fazer conexões.

Curvas de varredura, também conhecidas como cotovelos de varredura, são conexões de conduíte curvas usadas para mudar a direção de um conduíte suavemente. Elas têm um raio maior em comparação aos cotovelos padrão, o que ajuda a reduzir o risco de danificar ou torcer os fios dentro do conduíte durante a curvatura.

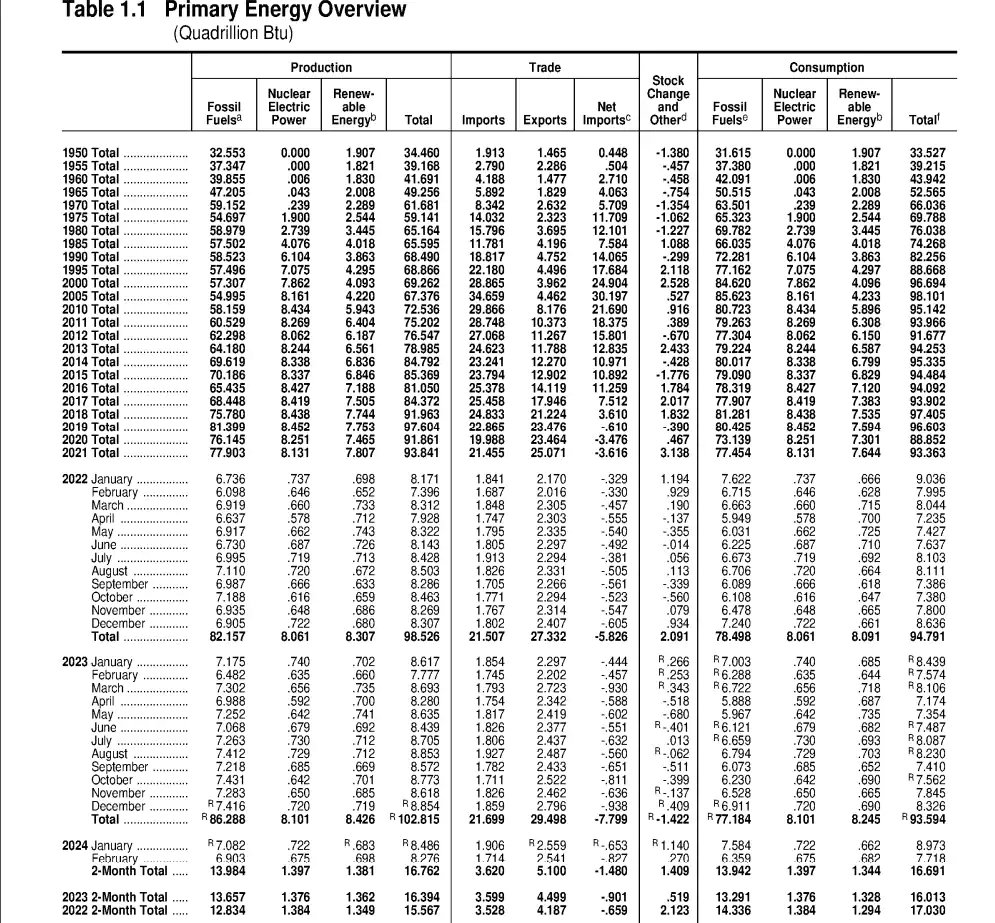

Cotovelos padrão, também chamados de cotovelos rígidos, são encaixes de conduíte usados para mudar a direção de um conduíte em 90 graus. Eles são comumente usados em instalações elétricas para navegar em cantos ou obstáculos, mantendo o alinhamento e a proteção adequados da fiação elétrica.

Cotovelos Sólidos

Cotovelos sólidos são conexões de conduíte padrão que oferecem uma mudança de ângulo de 90 graus ou outro ângulo especificado na direção de um percurso de conduíte. Eles são frequentemente usados para navegar em cantos ou obstáculos, mantendo a integridade e a proteção da fiação elétrica.

Cotovelos de 90 graus

Cotovelos de 90 graus são um tipo específico de cotovelo sólido que fornece uma mudança de ângulo reto na direção de um conduíte. Eles são amplamente usados em instalações elétricas para fazer curvas fechadas ou para conectar seções de conduíte em uma direção perpendicular.

Acoplamentos são conectores usados para unir duas seções de conduíte. Eles são normalmente usados ao estender ou reparar trechos de conduíte, permitindo um caminho seguro e contínuo para a fiação elétrica.

Adaptadores

Adaptadores são usados para conectar conduítes rígidos ou corrugados com caixas elétricas, como caixas adaptáveis e caixas de distribuição.

Tee reto

Um tee reto é um encaixe de conduíte que permite uma conexão de derivação em um percurso de conduíte. Ele tem três aberturas, sendo uma o caminho principal do conduíte e as outras duas fornecendo conexões para seções ou dispositivos adicionais do conduíte.

Clipes U

Clipes em U, também conhecidos como clipes de conduíte ou cintas de conduíte, são dispositivos de fixação usados para prender conduítes a superfícies como paredes, tetos ou vigas. Eles ajudam a manter os conduítes no lugar e evitam que eles cedam ou se movam, garantindo suporte e proteção adequados para a fiação elétrica.

Manutenção e Cuidados com Conduítes Solares

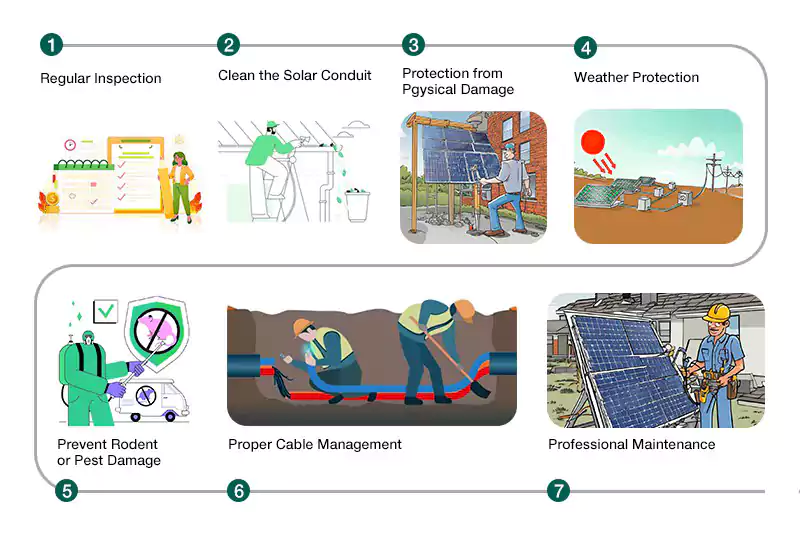

A manutenção adequada e regular de conduítes solares pode ajudar a estender sua vida útil e garantir a segurança do sistema elétrico solar. Aqui estão alguns conselhos e etapas que você pode seguir para uma manutenção adequada de conduítes:

1. Regular Inspections

Conduct regular inspections of the PVC solar conduit to identify any signs of damage, wear, or deterioration. Look for cracks, breaks, sagging, or loose fittings. Promptly address any issues to prevent further damage or potential electrical hazards.

2. Cleanliness

Keep the PVC solar conduit clean by removing any dirt, dust, or debris that may accumulate on or around it. Use a soft cloth or brush to gently wipe the surface. Avoid using abrasive materials or harsh chemicals that could damage the PVC.

3. Protection from Physical Damage

Take precautions to protect the PVC solar conduit from physical damage. Avoid placing heavy objects or applying excessive pressure on the conduit. Keep it clear of sharp objects or potential impact hazards.

4. Weather Protection

PVC conduits are designed to withstand various weather conditions, but extra protection can help prolong their lifespan. Apply a UV-resistant paint or coating to shield the conduit from prolonged exposure to sunlight. Additionally, ensure the conduit is properly sealed to prevent water ingress during heavy rain or storms.

5. Prevent Rodent or Pest Damage

Check for any signs of rodent or pest activity near the PVC solar conduit. Rodents may chew through the conduit, causing damage to the wiring inside. Take necessary measures to prevent access or use rodent-deterrent methods if needed.

6. Proper Cable Management

Ensure that the cables or wires within the PVC solar conduit are properly organized and secured. Avoid excessive bending or overloading of the conduit, as it can lead to damage or poor performance. Use appropriate cable management techniques to maintain a neat and organized system.

7. Professional Maintenance

If you encounter significant damage or suspect any electrical issues, it is advisable to consult a qualified electrician or professional for assessment and repairs. They can provide expert guidance, conduct thorough inspections, and ensure the proper maintenance and safety of the PVC solar conduit.

By following these maintenance practices, you can help extend the lifespan and ensure the optimal performance of PVC solar conduit in your solar energy system. Regular inspections and timely repairs are crucial to maintaining the integrity and safety of the conduit and the electrical wiring within it.

How to Choose A Right Solar Conduit Supplier?

When selecting a solar conduit supplier, it’s important to consider several factors to ensure you choose the right one. Here are some guidelines to help you make an informed decision:

1. Quality and Standards

Look for a solar conduit supplier that offers high-quality products manufactured according to relevant industry standards, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association) certifications. Quality products ensure durability, reliability, and compliance with safety requirements.

2. Range of Products

Consider the supplier’s product range and whether they offer a variety of conduit sizes, types, and fittings to meet your specific project requirements. A supplier with a comprehensive product range can provide you with flexibility and options to suit your installation needs.

3. Material and UV Resistance

Evaluate the materials used in the solar conduits offered by the supplier. PVC (polyvinyl chloride) is a common material choice due to its durability and UV resistance. Ensure that the supplier’s conduits are designed to withstand outdoor conditions and have appropriate UV protection to prevent degradation over time.

4. Supplier Reputation

Research the reputation and track record of the supplier in the industry. Look for reviews, testimonials, or references from other customers to gauge their reliability, customer service, and product quality. A reputable supplier with positive feedback is more likely to provide satisfactory products and support.

5. Warranty and Support

Inquire about the supplier’s warranty policy and customer support services. A reliable supplier should offer warranties that cover defects or failures in their products. Additionally, they should provide responsive customer support for inquiries, technical assistance, and after-sales service.

tetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

6. Pricing and Value

Compare the pricing of different suppliers while considering the overall value they offer. Don’t solely focus on the lowest price; instead, evaluate the quality, reliability, and support provided by the supplier. Choosing a supplier that offers a balance of competitive pricing and value can ensure a cost-effective and reliable solution.

7. After-Sales Service and Support

Consider the supplier’s after-sales service and support offerings. A reliable supplier should provide excellent customer service, technical assistance, and prompt response to inquiries or issues that may arise during or after the installation process. Look for suppliers that have a dedicated support team and clear communication channels to ensure a smooth and efficient experience.

Conclusão

Solar conduits are vital components in the renewable energy industry, particularly in solar power systems. They serve the essential purpose of safely housing and protecting electrical wiring in solar installations. As the world increasingly focuses on the development and importance of renewable energy sources like solar and wind power, the demand for solar conduits has grown significantly.

As the renewable energy sector continues to expand, with increased investment and attention from individuals, businesses, and governments worldwide, the utilization of solar power and other forms of clean energy is on the rise. Consequently, the use of solar conduits has become increasingly prevalent and important in facilitating the growth and success of solar energy systems.

If you have any requirements or questions regarding solar conduits, please don’t hesitate to envie o formulário ou send us a email, we are here to assist you.