Índice

Selecting the right conduit for electrical installations is crucial for ensuring safety, durability, and long-term performance. With various materials available, understanding their strengths and limitations helps electricians, engineers, and contractors make informed decisions that balance cost-effectiveness with compliance to safety standards.

Among the most commonly used conduit materials, PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) stand out for their widespread applications in electrical systems. While both materials share similarities, their differences in temperature resistance, chemical composition, and mechanical properties make them suitable for distinct environments and applications.

This article aims to provide a detailed comparison of CPVC and PVC conduits, exploring their technical specifications, benefits, limitations, and best-use scenarios. By the end, you’ll have a clear understanding of which conduit type is the right fit for your specific electrical project.

When it comes to electrical conduit systems, PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) are two widely used materials due to their durability, non-metallic properties, and cost-effectiveness. However, despite their similarities, these materials have distinct differences in temperature resistance, chemical properties, and application suitability.

Polyvinyl Chloride (PVC) is a widely used rigid thermoplastic known for its strength, lightweight structure, and affordability. Conduíte de PVC is specifically designed to protect and route electrical wiring, providing insulation, moisture resistance, and protection against mechanical damage.

- Temperature Resistance: Can withstand temperatures up to 140°F (60°C).

- Resistência química: Offers good protection against acids, alkalis, and moisture, making it suitable for various environments.

- Acessibilidade: One of the most cost-effective conduit options.

- Facilidade de instalação: Lightweight, easy to cut, join, and bend with heating techniques or factory-manufactured fittings.

PVC conduit is the go-to choice for many standard electrical installations due to its low cost and reliable performance. It is commonly used in:

- Residential and commercial buildings, where standard temperature and environmental conditions exist.

- Outdoor and underground electrical installations, as it resists moisture and soil chemicals.

- Industrial settings with moderate environmental exposure, where corrosion resistance is needed but high-temperature resistance is not a concern.

Chlorinated Polyvinyl Chloride (CPVC) is a modified version of PVC, with an increased chlorine content (63-69%). This structural enhancement significantly improves CPVC’s heat resistance, chemical stability, and durability compared to standard PVC. As a result, CPVC conduit can withstand higher temperatures and is better suited for extreme environments.

- Higher Temperature Resistance: Can handle temperatures up to 200°F (93°C) without softening or deforming.

- Improved Mechanical Strength: Offers better flexibility and pressure tolerance than standard PVC.

- Superior Chemical Resistance: More resistant to corrosive substances, industrial chemicals, and soil acids, making it ideal for harsh environments.

Due to its high-performance characteristics, CPVC conduit is used in:

- High-temperature environments, such as industrial facilities, power plants, and manufacturing plants.

- Chemical processing plants, where exposure to harsh chemicals and corrosive substances is common.

- Outdoor applications in extreme climates, where high temperatures and prolonged sun exposure could degrade standard PVC.

- Specialized electrical installations requiring enhanced durability and longevity.

When selecting electrical conduits, understanding the differences between PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) is crucial for ensuring safety, durability, and cost-effectiveness. While both materials are widely used in electrical installations, their distinct chemical compositions, temperature tolerances, and resistance properties influence their performance in various environments.

CPVC and PVC are both derived from polyvinyl chloride, but CPVC undergoes an additional chlorination process, increasing its chlorine content to 63–69%, compared to PVC’s 56%. This modification enhances CPVC’s thermal stability, fire resistance, and mechanical durability.

- Conduíte de PVC: Limited to a maximum temperature of 140°F (60°C), making it suitable for standard electrical applications in residential and commercial settings.

- CPVC Conduit: Withstands temperatures up to 200°F (93°C), making it ideal for high-heat environments such as industrial plants, commercial buildings, and areas with high ambient temperatures.

CPVC offers superior resistance to chemicals, including acids, alkalis, and industrial solvents, making it a preferred choice in chemical plants, wastewater treatment facilities, and corrosive environments.

Conduíte de PVC: Vulnerable to degradation when exposed to chlorine-reactive chemicals or ammonia. While cost-effective for general use, it may fail in settings with frequent chemical exposure.

CPVC Conduit: Resistant to soil acids, aggressive chemicals, and corrosive industrial environments, ensuring greater durability in extreme conditions.

Industrial reports highlight PVC conduit degradation in chemical plants, whereas CPVC conduits remain structurally intact, reducing failure risks and maintenance costs.

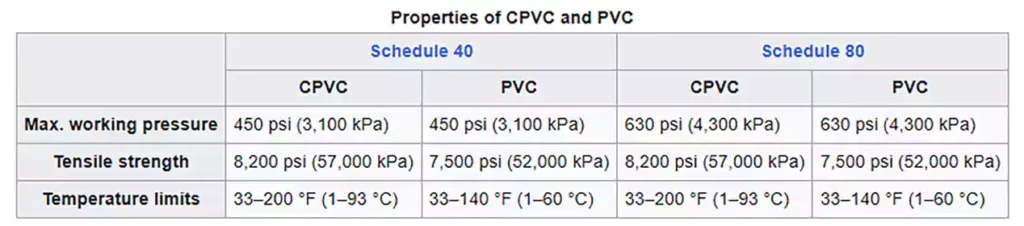

One of the main mechanical differences between CPVC and PVC is ductility. CPVC is more ductile than PVC, offering greater flexure and crush resistance, which makes it significantly more flexible, reducing installation complexity and allowing better crush resistance in underground or confined-space installations. Here are the mechanical properties outlined in wikipedia that you can refer to.

CPVC Conduit:

More ductile and crush-resistant, reducing wiring complexity.

Easier to install with fewer fittings, reducing labor costs.

Less prone to cracking under mechanical stress.

Conduíte de PVC:

More rigid, requiring additional bends and connectors.

Can be more challenging to install in complex routing paths.

Standard choice for general electrical conduit installations.

CPVC is more expensive due to its advanced processing and enhanced performance capabilities.

Conduíte de PVC: 2 to 3 times cheaper than CPVC, making it the economical choice for non-demanding environments.

CPVC Conduit: Higher initial cost but offers long-term savings due to lower maintenance, longer lifespan, and reduced failure risks in harsh environments.

PVC and CPVC conduits cannot be directly joined due to differences in material composition and sizing standards.

PVC and CPVC each require specific solvent cement adhesives.

CPVC connections demand CPVC-specific cement, while PVC uses standard PVC cement.

CPVC: Excels in high-temperature, chemically aggressive, or high-pressure environments. Third-party studies confirm its superior UV resistance and wear tolerance compared to PVC, making it more reliable for outdoor applications.

PVC: Performs well in moderate conditions but may degrade faster under prolonged UV exposure or mechanical stress.

Both CPVC and PVC conduits must comply with NEC (National Electrical Code) regulations and relevant safety standards.

CPVC Conduit: Often meets higher fire resistance ratings.

Used in applications where additional safety compliance is required.

Conduíte de PVC: Complies with standard NEC regulations but may not be suitable for high-temperature or chemically aggressive environments.

CPVC conduits require a specialized solvent cement due to their unique chemical composition.

CPVC Cement: Must meet ASTM F493 standards and provides high-strength bonding.

Cimento PVC: Must adhere to ASTM D2564 standards but cannot be used for CPVC.

Using incorrect adhesives can lead to bond failure and compromised conduit integrity.

Both PVC and CPVC exhibit fire resistance and self-extinguishing properties, but their combustion byproducts differ significantly.

Conduíte de PVC: When burned, releases hydrogen chloride (HCl) and carbon dioxide, which can pose environmental and health risks.

CPVC Conduit: Similar to PVC in fire resistance but can generate chlorinated dioxins and polychlorinated dibenzofurans when incinerated.

Fire Safety Considerations: In environments requiring minimal smoke and halogen emissions, CPVC still poses some combustion risks.

While CPVC and PVC conduits have their advantages, LSZH (Low-Smoke Halogen-Free) conduits offer superior fire safety by reducing hazardous emissions during combustion. Ledes low smoke halogen free conduits offer:

Minimal Smoke and Toxic Fumes: LSZH conduits do not release harmful halogens or dense smoke, improving air quality and safety in fire situations.

Ideal for enclosed spaces: Used in hospitals, data centers, tunnels, and public buildings, where fire safety is a priority.

Environmental Benefits: LSZH conduits align with green building initiatives by eliminating toxic emissions.

CPVC Conduit Vs. PVC Conduit

Recurso | Conduíte de PVC | CPVC Conduit |

Max Temperature | 140°F (60°C) | 200°F (93°C) |

Resistência química | Moderado | Superior |

Flexibilidade | Rígido | Mais flexível |

Custo | Mais baixo | Mais alto |

Durabilidade | Vida útil moderada | Mais duradouro |

Resistência ao fogo | Padrão | Classificação mais alta |

Adesivo | Cimento PVC | CPVC – cimento específico |

Resistência UV | Propenso à degradação | Mais resistente |

Tanto os conduítes de PVC (Policloreto de Vinila) quanto os de CPVC (Policloreto de Vinila Clorado) são usados em aplicações elétricas e mecânicas, mas são regidos por padrões distintos com base em suas propriedades e uso pretendido. Abaixo está uma análise detalhada dos principais padrões e códigos que regulam os conduítes de PVC e CPVC, juntamente com seus principais requisitos.

O Artigo 352 do NEC descreve os requisitos de instalação, usos permitidos e diretrizes de segurança para conduítes de PVC rígido.

- Ele especifica que o conduíte de PVC deve ser resistente à umidade, não condutor e retardante de chamas para garantir instalações elétricas seguras.

- Define profundidades mínimas de enterramento, espaçamento de suporte de conduíte e limitações de temperatura para diferentes ambientes.

- Fornece orientação sobre a transição entre PVC e outros tipos de conduíte (por exemplo, conduíte metálico).

Pontas: Você pode ler nosso último post sobre o Requisito do código NEC para conduíte de PVC.

- A norma UL 651 define critérios de desempenho para conduítes de PVC, abrangendo aspectos como resistência ao impacto, durabilidade mecânica, resistência à luz solar e isolamento elétrico.

- Requer testes de resistência ao fogo, garantindo que o conduíte não propague chamas além dos limites permitidos.

Notas: Você pode ler nosso guia definitivo para Norma UL 651 para conduítes Schedule 40 e 80 para mais detalhes.

- A UL1653 trata principalmente do ENT, que é um tipo de conduíte de PVC flexível e leve.

- Exige conformidade com padrões de resistência a chamas, resistência a esmagamento e resistência ao impacto para aplicações internas e internas de paredes.

- Ao contrário dos conduítes rígidos de PVC, o ENT é mais flexível e fácil de instalar, sendo comumente usado em edifícios residenciais e comerciais leves.

Pontas: Saiba mais sobre conformidade com o código elétrico para conduíte ENT para nossa última postagem.

- Esta norma classifica os materiais de PVC com base em suas propriedades, incluindo resistência ao impacto, temperatura de deflexão, resistência à tração, inflamabilidade e composição principal.

- Requer resistência à tração mínima, módulo de elasticidade e gravidade específica para materiais de conduíte para garantir durabilidade a longo prazo.

- O conduíte de PVC normalmente usa classificação de células igual ou superior a 12123 conforme especificado em UL651.

Enquanto os conduítes CPVC são aplicados para eletrodutos, eles são usados principalmente em aplicações de tubulação. Os padrões relevantes para CPVC incluem:

- Assim como para o PVC, a ASTM D1784 estabelece a classificação e as propriedades do material para conduítes e tubos de CPVC.

- O CPVC deve atender a requisitos mais elevados de resistência à temperatura em comparação ao PVC padrão.

- Garante que o material CPVC mantenha a integridade mecânica em temperaturas elevadas, normalmente até 200°F (93°C), em comparação com o limite do PVC de 140°F (60°C).

- Os materiais CPVC se enquadram na Classificação de Células 23447, o que exige resistência ao calor e resistência à tração superiores em comparação ao PVC.

- Especifica classificações de pressão, dimensões e critérios de desempenho para tubos de CPVC usados em sistemas hidráulicos e mecânicos.

- Requer tubos de CPVC para suportar fluxo de água de alta pressão e temperaturas elevadas sem deformação.

- Abrange tubos de CPVC fabricados nos tamanhos Schedule 40 e 80 e com classificação de pressão para água, suas dimensões e requisitos de espessura de parede para diferentes aplicações.

- Requer testes de resistência à pressão hidrostática, resistência química e desempenho a longo prazo.

- Um padrão canadense que a maioria dos fabricantes dos EUA pode testar para avaliar a propagação de chamas e o desenvolvimento de fumaça de CPVC e outros materiais não metálicos para instalações em espaços plenos.

- O CPVC deve passar por rigorosos testes de desempenho contra incêndio, com propagação limitada de chamas e baixas emissões de fumaça.

- Este código rege aplicações mecânicas e hidráulicas de CPVC em ambientes de alta temperatura.

- Define as limitações de uso de conduítes e tubos de CPVC com base na exposição ao calor e no estresse mecânico.

- Inclui requisitos adicionais de proteção contra incêndio e resistência térmica para sistemas CPVC.

O conduíte de PVC continua sendo a escolha dominante para eletrodutos devido à sua clara conformidade com NEC e UL. O CPVC, embora ofereça maior resistência à temperatura e melhor desempenho contra incêndio, é usado principalmente em aplicações mecânicas e de encanamento, em vez de instalações elétricas. Entender os padrões aplicáveis ajuda a garantir a conformidade com os códigos de segurança e o desempenho ideal para ambos os materiais.

Conformidade com o código de eletrodutos CPVC e PVC

Recurso | Conduíte de PVC | Conduíte e tubo de CPVC |

Uso primário | Pistas elétricas | Aplicações primárias de encanamento e mecânicas; algumas canaletas elétricas |

Principais Padrões | Artigo 352 do NEC, UL651, UL1653, ASTM D1784-20 | ASTM D1784-20, ASTM F442/F442M-23, ASTM F441, CAN/ULC S102.2 |

Resistência à temperatura | Até 40°F (60°C) | Até 200°F (93°C) |

Padrões de inflamabilidade e incêndio | Padrões de inflamabilidade e incêndio | Maior resistência ao fogo, testado de acordo com CAN/ULC S102.2 |

Propriedades mecânicas | Resistente a impactos, não condutivo, resistente a UV conforme UL 651 | Maior resistência à tração e ao calor |

Profundidade e suporte do enterro | Definido no artigo 352 do NEC | Regulamentado principalmente para resistência à pressão e ao calor |

Aplicações comuns | Instalações elétricas residenciais, comerciais e industriais | Encanamento, HVAC, proteção contra incêndio e alguns usos de conduítes elétricos |

Desenvolvimento de fogo e fumaça | Deve atender aos requisitos de resistência ao fogo da NEC e UL | Deve passar por testes rigorosos de propagação de chamas e desenvolvimento de fumaça (CAN/ULC S102.2) |

Classificação de células | Mínimo 12123 por UL 651 | 23447 conforme ASTM D1784-20 (maior resistência ao calor e à tração) |

Instalação de espaço plenum | Uso limitado devido a preocupações com o desenvolvimento de fumaça | Mais adequado devido às menores emissões de fumaça conforme CAN/ULC S102.2 |

Classificação de pressão | Não classificado para pressão | Classificado para uso em alta pressão e alta temperatura (ASTM F442) |

Tanto os conduítes CPVC (cloreto de polivinila clorado) quanto os PVC (cloreto de polivinila) desempenham papéis importantes na proteção da fiação elétrica, mas suas aplicações diferem devido às suas propriedades distintas de material, resistência à temperatura e resistência mecânica. Abaixo está uma análise de onde cada tipo de conduíte é mais adequado para uso.

O conduíte de PVC é o conduíte não metálico mais comumente usado para aplicações de fiação elétrica devido à sua relação custo-benefício, facilidade de instalação e durabilidade geral. É mais adequado para:

O conduíte de PVC é amplamente utilizado em residências, escritórios e edifícios comerciais para rotear fiação elétrica em paredes, tetos e instalações expostas.

Ele oferece excelente isolamento e resistência à corrosão, o que o torna ideal para aplicações internas e externas onde a exposição aos raios UV não é excessiva.

O Artigo 352 do NEC permite seu uso em locais expostos e ocultos, desde que esteja devidamente protegido e apoiado.

O conduíte de PVC mantém a integridade estrutural em temperaturas mais baixas, mas pode se tornar quebradiço em frio extremo (abaixo de -10°F ou -23°C).

É ideal para aplicações em climas moderados ou espaços internos onde temperaturas congelantes não são uma grande preocupação.

O conduíte de PVC Schedule 80 é frequentemente preferido em regiões mais frias devido às suas paredes mais espessas e maior resistência ao impacto.

O conduíte de PVC é mais acessível que o CPVC, o que o torna a escolha preferida para projetos onde a eficiência de custos é uma prioridade.

É leve e fácil de instalar, reduzindo os custos de mão de obra e as despesas gerais do projeto.

Comumente usado em construções residenciais, pequenos projetos comerciais e instalações temporárias onde não é necessária resistência a altas temperaturas.

O conduíte CPVC, embora menos comum que o PVC em aplicações elétricas, oferece isolamento superior, maior resistência mecânica e melhor resistência a temperaturas extremas e exposição química. É particularmente adequado para:

O conduíte de CPVC é uma escolha melhor para aplicações de enterramento direto, pois resiste a:

Penetração de umidade e erosão do solo melhores que o PVC.

Acúmulo de condensação, que pode causar falhas elétricas em conduítes enterrados.

Deformação sob pressão do solo, devido à sua maior resistência à compressão.

Ele permanece estruturalmente estável ao longo do tempo, o que o torna ideal para instalações subterrâneas de longo prazo em ambientes residenciais, comerciais e industriais.

O conduíte CPVC pode suportar temperaturas operacionais mais altas (até 200°F / 93°C) cem comparação com PVC (140°F / 60°C).

É adequado para:

Fábricas, instalações de processamento químico e refinarias onde os conduítes elétricos podem ser expostos a altas temperaturas ou produtos químicos corrosivos.

Usinas de energia e instalações de energia renovável onde os sistemas de fiação exigem dresistência à expansão térmica e ao estresse mecânico.

As propriedades superiores de isolamento do CPVC reduzem o acúmulo de calor dentro do conduíte, protegendo a fiação elétrica das flutuações de temperatura.

CPVC conduit performs better than PVC in both extremely hot and extremely cold environments.

It is ideal for:

Desert regions, high-temperature industrial sites, and tropical climates, where standard PVC may soften or deform.

Cold storage facilities and sub-zero environments, where PVC may become brittle.

Its higher flexibility and impact resistance allow it to maintain structural integrity in harsh conditions.

While PVC conduit remains the go-to choice for general electrical installations, CPVC conduit provides advantages in underground, high-temperature, and chemically aggressive environments. Choosing the right conduit type depends on project-specific requirements, including temperature conditions, moisture exposure, and mechanical stress factors.

Selecting the appropriate electrical conduit for an electrical installation requires careful consideration of several factors, including environmental conditions, budget constraints, and compliance with relevant standards. Below are key aspects to evaluate when deciding between PVC and CPVC conduits for your project.

PVC: Works well in most environments but may soften in extreme heat and become brittle in very cold temperatures.

CPVC: Handles higher temperatures, making it better for industrial or high-heat applications.

PVC: Suitable for general use but may degrade in harsh chemical environments.

CPVC: More resistant to chemicals and moisture, making it ideal for underground and industrial settings.

PVC: Commonly used for above-ground and residential installations.

CPVC: Better for underground installations because it resists condensation and pressure from soil.

The cost of conduit materials should be weighed against long-term performance:

PVC conduit is more cost-effective upfront, making it the preferred choice for budget-conscious projects such as residential wiring and commercial electrical systems.

CPVC conduit is more expensive due to its enhanced material properties, but it offers greater durability in harsh conditions.

PVC may require replacement sooner in environments with high temperatures or chemical exposure.

CPVC lasts longer in demanding applications, leading to lower maintenance costs and fewer replacements over time.

For PVC conduit, must comply with NEC and other UL, ASTM standards as required.

Regions with extreme climates may enforce stricter requirements for UV resistance or thermal stability, and CPVC conduit would be a better choice. But no matter it is PVC conduit or CPVC conduit, all need to meet the local safety standard requirements

Selecting a reliable PVC or CPVC conduit manufacturer is crucial for ensuring quality, compliance, and durability. Here are the key factors to consider:

To ensure quality, compliance, and long-term reliability, one of the first things to check is whether the manufacturer adheres to recognized industry standards, such as NEC, UL, and ASTM for PVC conduits and ASTM, CAN/ULC, and local mechanical codes for CPVC. Compliance with these regulations guarantees that the conduit meets essential safety and performance requirements.

Beyond certifications, the overall quality and durability of the conduit should be assessed. This includes material composition, resistance to mechanical stress, and the ability to withstand environmental factors such as heat, moisture, or chemical exposure. Reliable manufacturers will have strict quality control processes and conduct rigorous testing to ensure their products meet industry benchmarks.

Experience and reputation also play a key role. Established manufacturers with years of expertise tend to offer better product consistency and technical support. Checking customer feedback, case studies, or real-world applications can provide insight into how well their conduits perform over time. A manufacturer with a solid reputation is more likely to produce reliable products that meet project needs.

Availability and supply chain efficiency are equally important. Delays in product delivery can disrupt project timelines, so it’s essential to choose a manufacturer with a stable supply chain and an efficient distribution network. Some manufacturers also offer customization options for conduit size, wall thickness, or special requirements, which can be beneficial for specific installations.

Lastly, cost considerations should go beyond just the initial price. While PVC is generally more affordable, CPVC offers better performance in high-temperature and underground applications, potentially reducing long-term maintenance costs. Comparing pricing, warranty policies, and bulk purchase options can help balance affordability with quality and longevity.

By evaluating compliance, product quality, reputation, availability, and overall value, selecting the right manufacturer ensures that electrical installations remain safe, durable, and code-compliant for years to come.

CPVC and PVC conduits each offer distinct advantages depending on the project requirements. CPVC stands out for its superior heat resistance, chemical stability, and durability, making it ideal for high-temperature, corrosive, or underground applications. On the other hand, PVC remains a cost-effective and widely used option for general electrical installations, particularly in residential and low-risk environments.

When selecting the right conduit, it’s essential to consider factors like temperature exposure, installation conditions, and compliance with electrical codes. If you’re unsure which material best suits your needs, consult Ledes team to ensure optimal safety, performance, and cost efficiency for your electrical project.

CPVC e PVC podem ser usados juntos?

While CPVC and PVC share similarities, they are not typically used interchangeably in the same system due to differences in material properties and installation requirements. Both materials are made from polyvinyl chloride, but CPVC undergoes additional chlorination, giving it enhanced heat resistance, chemical durability, and mechanical strength compared to standard PVC.

One of the main challenges in combining CPVC and PVC is their differing temperature tolerances and pressure ratings. CPVC can withstand higher temperatures, making it more suitable for industrial or underground applications, whereas PVC is preferred for general-purpose electrical conduit systems in residential and commercial settings.

Another important consideration is the type of solvent cement or adhesive used for joining. PVC and CPVC require different solvent cements, as CPVC’s chemical structure demands a stronger bonding agent that can handle higher temperatures and pressures. Using the wrong adhesive could lead to weak joints or failures in the conduit system.

However, there are situations where PVC and CPVC can be connected using transition fittings, designed specifically to accommodate both materials. These fittings ensure a secure and leak-proof connection while maintaining the integrity of each conduit type.

CPVC vs. PVC: Qual dura mais?

When comparing longevity, CPVC generally outlasts PVC due to its superior material properties. CPVC conduits can last over 50 years, while PVC conduits typically have a lifespan of 25 to 40 years, depending on environmental conditions and usage.

CPVC’s extended lifespan is mainly due to its higher heat resistance, better chemical durability, and greater mechanical strength, making it more suitable for demanding applications such as industrial environments, underground installations, and high-temperature areas. It resists cracking, warping, and chemical degradation better than PVC, ensuring a longer service life in extreme conditions.

PVC, while still durable and long-lasting, is more susceptible to UV exposure, freezing temperatures, and chemical wear over time. It remains a reliable and cost-effective choice for above-ground electrical installations, residential wiring, and general-purpose conduit systems, but may degrade faster in harsher environments.

O CPVC vale o custo extra?

CPVC is typically more expensive than PVC, but its enhanced durability and performance make it a worthwhile investment for certain applications. If your project involves high temperatures, corrosive environments, or underground installations, CPVC is the better choice due to its higher heat resistance, chemical stability, and superior mechanical strength.

In industrial settings or areas with harsh environmental conditions, CPVC’s longer lifespan and lower maintenance needs can offset the initial cost, providing better long-term value. However, for general electrical installations, residential wiring, and budget-conscious projects, PVC remains a cost-effective and reliable option.

The decision ultimately depends on the specific project requirements—if extreme conditions are a concern, the extra investment in CPVC can lead to greater durability, safety, and longevity.