Índice

Schedule 40 PVC conduit is a mainstay in the world of electrical installation. Often working behind the scenes, this versatile and reliable solution plays a crucial role in ensuring the safety and longevity of your wiring systems. From protecting delicate cables from physical damage to safeguarding against environmental hazards, Schedule 40 PVC conduit is an unsung hero of construction projects both big and small.

The sch 40 conduit materials are covers metal, plastic, fiber, fired clay, etc. Appearance forms include rigid pipes and corrugated pipes, and corrugated pipes are generally used for specific purposes.

What is Schedule 40 PVC Conduit?

Conduíte de PVC Schedule 40 is a rigid PVC pipe designed to protect and route electrical wiring in a building or construction. ‘Schedule 40’ or ‘sch 40’ is the North American nominal pipe size (NPS), which has been replaced by ASTM and other standards over time.

6 Types of Schedule 40 PVC Conduit

Metal

Eletroduto metálico rígido (RMC)

Schedule 40 Rigid Metal Conduit is a type of galvanized steel conduit with standardized wall thickness, used for protecting wiring in various applications.

Eletroduto rígido galvanizado (GRC)

Schedule 40 Galvanized Rigid Conduit is a type of galvanized steel electrical conduit with standardized wall thickness, offering enhanced protection against corrosion.

Conduíte de alumínio

Schedule 40 Aluminum Conduit is a type of aluminum electrical conduit with standardized wall thickness, offering a cost-effective and durable option for various applications.

Non-metallic

Conduíte de PVC

Sch 40 PVC conduit is the most common wire conduit now. Compared with metal conduits, it has the advantages of being lightweight and lower cost, and its hardness is not weaker than metal conduits. That’s why schedule 40 & 80 conduits belong to this type.

PVC conduit has been developed for many years. So the manufacturing and process are stable, and the fittings family is almost complete. Smart designers use various innovative designs to make quick installation and removal accessories, which can greatly improve installation efficiency and save huge labor costs.

Specifically, it can be listed in the following categories,

Conduíte de resina termoendurecível reforçado (RTRC)

Also known as a fiberglass conduit, its biggest advantage is lightweight. And the fiberglass conduit is also installed in placements that require high corrosion resistance of wire conduits, such as seaside buildings.

Conduíte rígido não metálico (RNC)

It is still a rigid conduit but has no threads and is very smooth inside, which is suitable for protecting wires. The well-known Schedule 40 & 80 PVC Conduit belongs to this type;

8 Benefits of Schedule 40 PVC Conduit?

The benefits of Sch 40 PVC conduit are,

1. Cost-Effectiveness

Conduíte do Anexo 40 is generally less expensive than metal conduits like steel or aluminum, making it a budget-friendly choice for many projects.

2. Lightweight & Easy to Work With

PVC’s lightweight nature simplifies installation and handling, reducing labor costs and making it ideal for DIY projects. It’s also easy to cut and thread with standard tools.

3. Excellent Corrosion Resistance:

PVC conduit is highly resistant to corrosion from moisture, chemicals, and even soil, ensuring long-lasting performance in demanding environments.

4. Durability & Impact Strength

Despite its lightweight nature, Schedule 40 PVC offers good impact resistance, able to withstand bumps and accidental damage.

5. Electrical Insulation

PVC itself acts as an insulator, providing a layer of protection against electrical shocks.

6. Flame Retardant Properties

Most Schedule 40 conduits are flame retardant, reducing the risk of fire spread in case of an electrical hazard.

7. Simple Installation

Sch 40 conduit can be easily joined using solvent cement, creating secure and watertight connections.

8. Wide Range of Applications

Schedule 40 PVC is suitable for both indoor and outdoor installations in residential, commercial, and industrial settings.

6 Benefits of Sch 40 Metal Conduit

Here are the key benefits of using Schedule 40 metal conduit (often steel or aluminum).

1. Superior Strength & Durability

Sch 40 metal conduits offer significantly higher strength and durability compared to PVC, making them ideal for demanding applications where impact resistance is crucial.

2. Long-Lasting Performance

Metal resists corrosion exceptionally well, especially when galvanized (coated with zinc), ensuring longevity even in harsh environments.

3. Fire Resistance

Schedule 40 metal conduit offers excellent fire resistance, limiting the spread of flames and providing additional safety in case of electrical hazards.

4. Electromagnetic Interference (EMI) Shielding

Metal acts as a Faraday cage, effectively shielding sensitive electronic equipment from electromagnetic interference.

5. Grounding Capability

Schedule 40 Metal conduits provide an inherent grounding path, enhancing electrical safety by facilitating the safe dissipation of fault currents.

6. Flexibility in Installation

While heavier than PVC, sch 40 metal conduit comes in various sizes and configurations (e.g., threaded or grooved), allowing for adaptability in different installation scenarios.

So you can choose the right conduit now based on the above comparison.

Here are common Schedule 40 PVC conduit fittings and their uses:

Basic Fittings

Elbows (90° & 45°): Change the direction of conduit runs.

Acoplamentos: Join two lengths of conduit together.

Corpos de Conduíte: Used to house connections within a conduit run, allowing for branching or cable terminations.

Reducers: Connect conduits of different diameters.

Specialized Fittings

Tee Fittings: Create a branch point in the conduit run.

Cross Fittings: Similar to a tee but with four branches, often used for complex wiring setups.

Wyes: Provide a junction point where one main conduit splits into two smaller ones.

Street Ell (also known as Lateral): Used to connect a horizontal run of conduit to a vertical run (common in outdoor installations).

Pull Boxes: Large boxes designed to facilitate pulling wires through the conduit system.

End Fittings:

Conduit Cap: Seals the end of a conduit run, protecting it from moisture and debris.

Hubs: Used for entering or exiting a building structure with conduit (e.g., passing through walls).

Remember: Always choose fittings that are compatible with Schedule 40 PVC conduit and use appropriate adhesives (solvent cement) for secure connections.

What is Sch 40 PVC pipe used for?

The purpose of sch 40 PVC pipes is water supply and drainage.

Some competitors do not clearly describe this point but only mention that it can be drained, which is only one-sided.

From UL’s physical performance requirements for Schedule 40 PVC pipe, we know that it can take a temperature of 140°F for better sealing by installing accessories or using glue at the connection, so there is no problem with the water supply at this temperature. The most common applications are agricultural irrigation, etc.

Another question is: what is the purpose of schedule 40 PVC conduits?

Many people don’t know the difference between pipe and conduit. In a word, the purpose of schedule 40 PVC pipe is plumbing and other pressurized systems, but the purpose of schedule 40 PVC conduit is single electrical systems.

However, the easiest way to distinguish whether it is for consumers or professionals in the electrical industry is to check the printing on the pipes. If it’s the pipe, it’s obviously for plumbing. Conversely, if printing is a conduit, it is only used for electrical systems, not for water supply and drainage.

So is it possible to install the electrical wires with sch 40 PVC pipe? The answer is NO.

From the design goals, schedule 40 PVC pipe mainly targets water supply and drainage, so the strength requirements are slightly lower, and the main consideration is the speed of water flow. So it does not have the characteristics of anti-sunlight exposure. It will be damaged quickly if used on the ground for a long time compared with sch 40 PVC conduit.

The schedule 40 PVC conduit is mainly operated to protect electrical cable wires because the wires are very fragile, so the strength of the conduit must be high enough. That’s why it has a thicker wall and stronger sunlight exposure performance. Not only can it be installed directly on the ground, but it can also be buried in the ground.

Schedule 40 PVC Conduit Application

Schedule 40 PVC conduit finds a wide range of applications due to its cost-effectiveness, durability, and ease of installation:

residencial

Wiring electrical circuits: Commonly used for running wiring in walls, ceilings, and under floors for lighting fixtures, outlets, appliances, etc.

Outdoor installations: Suitable for underground runs, landscaping lighting, and exterior wiring due to its corrosion resistance.

Plumbing: Can be used for drain-waste-vent (DWV) systems where it meets local building codes. (for Schedule 40 PVC Pipe Only)

Commercial & Industrial:

Wiring Control Panels: Used in industrial settings to house and protect electrical connections within control panels.

Telecommunications: Employed for running cables in communication infrastructure.

Security Systems: Protects wiring for alarm systems, surveillance cameras, and access control systems.

Other Applications

Solar Installations: Conduit runs can channel wiring from solar panels to inverters and storage systems.

Agricultural Settings: Used for irrigation systems, electrical wiring in barns or greenhouses. (for Schedule 40 PVC Pipe Only)

Schedule 40 PVC’s versatility, combined with its cost-effectiveness and resistance to corrosion, makes it a popular choice across many industries and applications.

What's the Difference Between Schedule 40 and Schedule 80 PVC Conduit?

In our opinion, the 2 biggest differences between Schedule 40 PVC and Schedule 80 PVC Conduit are wall thickness and price.

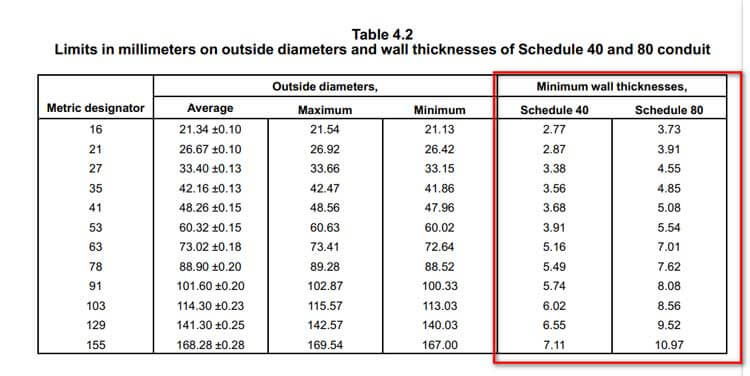

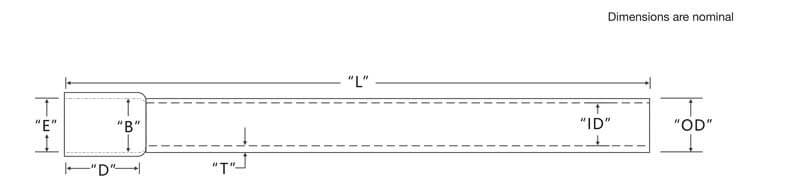

First, let’s talk about wall thickness. The wall thickness is the thickness of the single-side conduit wall. Whether it is Sch 40 or Sch 80 PVC conduit, their out diameters are kept the same, but the tube wall is not. Please see the following diagram.

Moreover, the wall thickness requirements of these 2 pipes are different based on UL651 documents Chapter 4.3. We can easily see that the minimum wall thickness of Sch 80 PVC conduit is much higher than that of Sch 40 PVC conduit.

So what does this mean? The impact resistance and tensile strength of the Schedule 80 PVC conduit are much better than the Schedule 40 PVC conduit, so the former is harder.

However, we can plan at the beginning of the project and install Schedule 80 PVC conduit in necessary places or places with higher requirements for the conduit to improve safety, such as outdoor installation projects that are directly exposed to sunlight.

Then the second difference is easy to understand because Schedule 80 PVC conduit has a thicker wall and better physical performance, so its price is higher than Schedule 40 PVC conduit year-on-year. Then it means that the purchased cost of the former is higher, so as we mentioned above, you can make a plan in the early stage of your project and use it reasonably to save costs.

Where and how can PVC electrical conduit be used?

We have talked about schedule 40 PVC pipes used for plumbing situations and generally only buried in the ground and not exposed to direct sunlight. So, where is the schedule 40 PVC conduit used and installed?

We list the following 3 keywords, and you can learn where they are installed, Wiring cable, wet, sunlight.

Concealed Place

For example, walls, floors, ceilings, etc., can be directly buried or threaded through wire conduits. We’ve already said that having exposed wire conduits outside is not a good idea.

Easier Corrosive Place

Because schedule 40 & 80 PVC conduit has stable physical performance, it is not easy to be corrupted by common chemical components and why it works in such places. The most common example is a chemical plant.

BTW, if we live by the sea, it is also recommended that you use PVC conduit because the salt in seawater is also corrosive, especially for metal conduits. It is a complete disaster and will quickly rust the metal conduit and risk the wires.

Wet Locations

There are many such places in your home, such as your bathroom. And there are also many public places such as car washes, dairy plants, laundromats, etc.

The main component of schedule 40 & 80 PVC conduit is PVC plastic, and in UL651 related standards, there are strict requirements for the water absorption of schedule 40 & 80 PVC conduit, so you can understand that they can be sealed and waterproof. Therefore, it is better to use in wet places than metal conduits.

Exposed Sunlight

The sun’s ultraviolet rays are the most damaging to schedule 40 & 80 PVC conduit, which can accelerate aging and make the plastic lose its elasticity and eventually crack.

If there is no special formula, such as schedule 40 & 80 PVC pipe, it cannot be used directly in sunlight because it will quickly age and fail. But the schedule 40 & 80 PVC conduit is different because a special formula is counted during the production process, which greatly enhances the anti-UV performance and works directly in the sun.

Subterrâneo

It is similar to the wet place, but if we use the direct burial schedule 40 & 80 PVC conduit, the moisture penetrates the conduit and the influence of bacteria in the ground. We will also add a special formula to prevent these bacteria from eroding the catheter in the design.

We want to tell you that almost all Schedule 40 & 80 PVC conduits support direct burial purposes except for those with bad-quality conduits. Because schedule 40 & 80 PVC conduit is specified in the relevant UL standards, it must meet the requirements of normal use on the ground and underground and don’t be tricked by some unscrupulous businessmen and lose money.

Quanto tempo o tubo de PVC Schedule 40 dura no sol?

This is an interesting question. Because of the time, it takes for Schedule 40 & 80 PVC conduit to be completely unusable after being exposed to sunlight for a long time, or just talking about when the damage due to prolonged exposure to sunlight? But if we would like to answer the question here, the degradation of PVC materials needs to be concerned.

According to the description on Wikipedia, if biodegradation generally takes decades to complete, that means the PVC material is a raw material degrades very slowly. Generally, in the industry, we use UV test equipment to imitate sunlight exposure, and the test time is as long as 300 hours. According to the test results, it is inferred that the theoretical life of schedule 40 & 80 PVC conduit produced by adding special anti-direct sunlight formula can reach 80- 100 years. So the Schedule 40 PVC conduit can normally work for 80-100 years in direct sunlight.

Of course, the Sch 40 & 80 PVC conduit lifespan will shorten if the environment is too harsh (such as a place that is extremely cold or extremely hot all the year round). Since this is inappropriate for most of us, we will not discuss it here.

Does an electrical PVC conduit need to be glued?

The US National Electrical Code (NEC) requires all conduit connections to be “made up tight,” meaning all the PVC conduit must be glued.

It’s quite simple to glue the conduit, but here are our tips.

Pro Tip 1,

Choose the same size tube and fittings

We do not recommend using tubes and fittings with incorrect sizes and then connecting them with glue. That’s wrong.

Glue doesn’t fill in overly large dimensional differences. If the connection between the conduit and the fittings becomes loose, water will enter the conduit, and the protection will fail.

Pro Tip 2,

Use the correct glue

Don’t try to find random or bad-quality glue to connect your conduits and fittings. The biggest function of glue is not to stick it firmly but to fill the gap at the joint of the conduit and improve the sealing.

Poor quality glue not only fails to seal the connection of the conduit but also easily fails in the future. It’s not just water that gets in; microbes or bacteria in the ground can corrupt your wires.

Pro Tip 3,

After connecting, you can place the conduit flat and wait a moment for the glue to dry. Although we are currently using quick-drying glue, if we can place them in the installation position smoothly after applying the glue and wait for the glue to dry, the sealing effect will be better.

Once again, the function of glue is mainly to seal the gaps and enhance the performance of waterproof and dustproof. Especially for wire pipes buried directly underground, if the glue is not used to connect the interface, bacteria and moisture may enter the wire pipe from the gap of the interface, causing internal water to enter or corrode the wire, resulting in line failure.

How can I find dealers for PVC conduit pipes?

We think this issue should be discussed from 3 views: cost, quality, and service.

It is more cost-effective to directly source manufacturers than to buy scheduled 40 & 80 PVC conduits from local distributors or wholesalers because trading companies or wholesalers will always earn money. It may not have been a big problem before, but with the global attack by COVID-19, the cost savings plan should be scheduled in your company.

However, the quality is acceptable if the manufacturer you find has UL or related qualifications. As the first company in China to obtain UL certification, Ledes has no doubts top schedule 40 & 80 PVC conduit suppliers. At least, our products are no different from those claimed ‘Made in USA’ companions.

As for services, if you buy products from brands, there will be corresponding quality assurance services. On the contrary, if you find a supplier with a low price, it usually means that it will not provide or can only provide basic technical or after-sales service. Once a problem happens, your procurement cost will increase significantly. So it is not a smart choice.

So we recommend that if you are only buying small quantities, you can buy from your local dealer. If you want to expand your business locally or source a better product, you can try buying from the manufacturer.

What is the standard length of a rigid nonmetallic conduit?

Available in schedule 40 & 80 PVC conduit sizes are 10 feet and 20 feet for rigid conduit and up to 1,500 feet for flexible conduit reels.

The conduit dimensions are 1/2 to 6 for rigid and 1/2 to 2-1/2 inch for flexible conduit pipe based on UL651 & UL1653.

All Ledes electrical conduit pipes can be fully customized, not only in the color and size but the design and even the mold creation.

É possível colocar um conduíte de PVC no concreto?

Schedule 40 & 80 PVC conduit is fully concrete-ready, mentioned in UL’s relevant documents, and needs to be tested.

As we mentioned before, PVC material is difficult to degrade and has excellent anti-corrosion properties. It can be used for 80-100 years or even longer, not only in sun-exposed conditions but even buried in the ground or concrete.

The key is whether schedule 40 & 80 PVC conduit has strong impact resistance and tensile strength. If the wire conduit is of bad quality, it is likely to crack or be damaged once it bears the pressure, resulting in the wire not being protected.

Schedule 40 & 80 PVC conduit works well in concrete because it usually needs to be installed in a concealed place, so it has to overcome the problems of moisture, microorganisms, water absorption, and so on.

So you don’t have to worry about this issue as long as your products are qualified.

Contato

That’s it. Feel free to contact us if you have any questions or requests, and our business manager will contact you in 1 working day.