목차

이 이미지를 귀하의 사이트에 공유하세요

개요

All information is explained based on UL 651 Eighth Edition, published on Oct 25, 2011, and all interpretation rights belong to UL.

적용범위

일정 40 및 80, EB 및 A형 압출 강성 PVC 도관 및 피팅. UL651은 엘보, 커플링, 어댑터, 팽창, 팽창-편향, 편향 조인트 및 건설용 강성 파이프 피팅을 포함한 관련 피팅에 적용됩니다. 그러나 UPVC 소재는 ASTM 1784의 관련 요구 사항을 충족해야 합니다.

UL 651의 관련 표준은 NEC(National Electrical Code) 및 NFPA 70의 관련 표준을 포괄합니다. 일정 40 및 80 강성 PVC 도관 및 피팅은 실내 및 실외 마감 또는 실외 사용에 사용할 수 있습니다. 햇빛과 악천후의 영향으로부터 보호해야 하며 콘크리트에 직접 사용할 수 있습니다.

스케줄 40 및 80 강성 PVC 도관 및 피팅 50°C(122°F) ~ 75°C(167°F)에서 사용 가능

잘 작동하며 90°C(194°F) 배선 요구 사항에 사용할 수 있습니다.

치수 세부 정보

깨끗한 재활용 소재나 혼합 소재의 경우, 제조업체는 UL746D 및 UL 관련 표준 등 관련 표준이 충족되는지 확인해야 합니다.

여기서 우리는 우리의 의견을 표현하고자 합니다. 환경 보호를 위해 재활용 소재를 사용하거나 혼합 생산하면 원자재 낭비를 줄일 수 있지만, 단점은 성능이 저하된다는 것입니다.

그러면 시중에 나와 있는 많은 제품들이 관련 UL 표준 인증을 받았다고 주장하는 상황이 생길 것입니다. 사실, 그들은 또한 준수 인증서도 가지고 있습니다. 하지만 성능 면에서는 실제로 감소가 있는데, 예를 들어 스트레치 저항성입니다.

일정 40 및 80 강성 PVC 도관과 피팅은 알칼리, 불산, 크롬산 증기와 안개를 비롯한 일반적인 부식성 영향뿐만 아니라 산세척 및 전기 도금에도 강하며 이러한 산업 현장에서 사용자의 요구를 충족합니다.

일정 40 및 80 강성 PVC 도관 및 피팅 내부 벽은 매끄러워야 하며, 버로 인해 전선이 손상될 위험이 없어야 합니다. 또한 튜브 외부 표면에 칩, 물집, 균열, 박리, 스케일링, 백킹 또는 기타 결함이 없어야 합니다.

파이프 본체는 세로좌표를 수직으로 유지해야 하며 나사산이 없어야 합니다. 마이크로미터 또는 테이퍼 슬리브 게이지를 사용하여 측정하고, 눈금은 0.001인치 또는 0.01mm까지 정확해야 하며 측정 정확도 편차는 ±1%를 초과해서는 안 됩니다. 측정된 치수는 관련 지정 치수와 일치해야 합니다. 관련 데이터에는 이미 허용 오차 범위가 포함되어 있습니다. 충족해야 할 치수에는 외측, 내측 및 벽 두께가 포함됩니다. 또한 커플링과 마찬가지로 길이, 소켓 깊이 등을 측정해야 합니다.

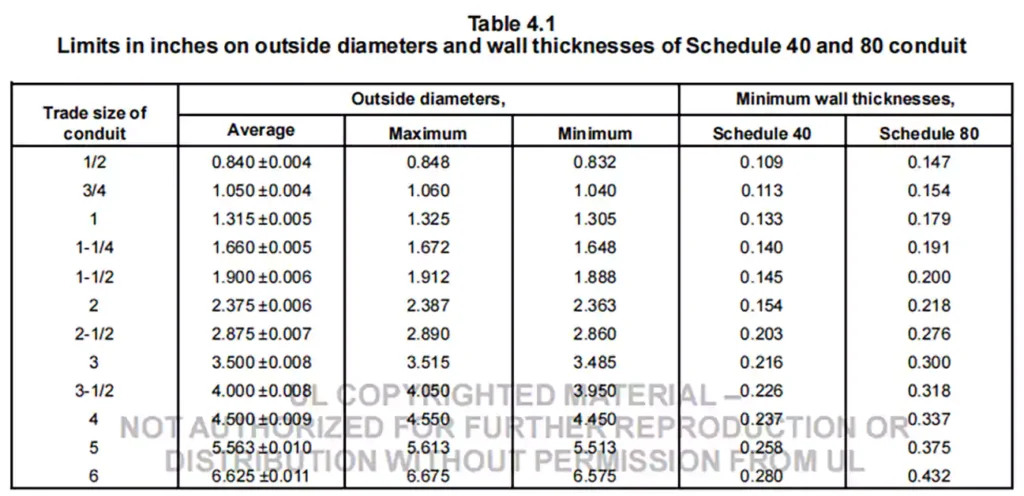

일정 40 및 80 강성 PVC 도관의 크기 요구 사항은 표 4.1에 명확하게 설명되어 있습니다. 일반적으로 OD의 허용 범위는 ±0.004~±0.011인치이고 ID와 벽 두께는 필요한 매개변수가 달성되도록 하기 위해 지정된 최소값입니다.

Type A 및 EB의 경우 기본 방법은 비슷합니다. 차이점은 이 버전에서 Type EB의 OD 및 벽 두께에 대한 공식 설명은 "이러한 크기가 허용 가능한 것으로 결정되면 추가 요구 사항이 추가됩니다."라는 것입니다.

부속품의 품질 요구 사항에 대해 UL651에는 와이어의 이동에 영향을 줄 수 없는 버가 없는 매끄러운 내부 벽과 같은 몇 가지 규정도 있습니다. 파편, 물집, 균열, 벗겨짐, 스케일링, 분쇄 또는 기타 결함을 허용하지 않습니다.

UL 651은 또한 모든 부속품에 대한 길이, 벽 두께, 소켓 직경 및 기타 매개변수의 최대 및 최소값을 지정하여 강성 도관과 일치시킵니다. 예를 들어, EB 및 A형 도관 커플링의 경우 1/2~6인치 무역 크기 조건에서 소켓 내부 끝의 내경 평균 허용 오차는 ±0.008~±0.014인치이고 소켓 입구의 내경 평균 허용 오차는 ±0.015~±0.023인치이며 크기 요구 사항은 관련 표에 지정되어 있습니다.

특별한 것도 몇 가지 있는데, 여기서 간단히 나열해 보겠습니다. 예를 들어, 나사산 PVC 와이어와 튜브에 적합한 나사산 어댑터에서 나사산은 깨끗하고 투명해야 하며, 크기는 ASME B1.20.1-1983의 요구 사항을 충족해야 합니다. 동시에 나사산 포트는 충분한 필드가 있어야 하고 굽힘 시험을 충족해야 합니다.

액세서리가 너무 많으므로 여기서는 나열하지 않겠습니다.

성능 및 테스트

제품 성능에 대한 궁극적인 테스트인 UL651에는 무려 19개의 성능 테스트가 있습니다. 설명을 위해 다음 항목을 선택합니다.

- 인장 강도

- 압출

- 물 흡수

- 충격에 대한 저항성

- 파쇄 저항성

- 불꽃

- 햇빛 저항성

- Schedule 40 and 80 for use with 90°C wire

- 인쇄의 영구성

인장 강도

The primary goal of this test is to determine the tensile strength of both aged and unaged specimens of rigid PVC conduit. The aged specimens must retain at least 95% of the tensile strength of their unaged counterparts to meet compliance requirements.

Specimen Preparation

- Six specimens are cut from finished conduit, with specific dimensions based on the conduit type.

- Measurements, including wall thickness and diameter, are taken using precision micrometer calipers with a minimum accuracy of 0.0001 inches (0.001 mm).

- The conduit must be clean and at a controlled temperature of 23.0 ±2.0°C (73.4 ±3.6°F) before testing.

Test Procedure

- Aging Process: Three specimens are subjected to 168 hours in a circulating-air oven at 113.0 ±1.0°C (235.4 ±1.8°F), then cooled in still air.

- Tensile Testing:

- The six specimens (three aged and three unaged) are tested within 16 to 96 hours after aging.

- A metal plug is inserted to prevent crushing during testing.

- Each specimen is subjected to tensile force on a power-driven machine, with grips separating at a controlled rate of 1/2 ±1/8 inch (10.0 ±2.5 mm) per minute.

- The maximum load before failure is recorded.

Results & Evaluation

- Tensile strength is calculated by dividing the maximum load by the cross-sectional area.

- The average tensile strength of aged and unaged specimens is compared to ensure compliance with UL651 requirements:

Schedule 40 & 80: Minimum 5,000 psi (34.5 MN/m²).

Type A & EB: Minimum 4,000 psi (27.6 MN/m²).

- The aged specimens must maintain at least 95% of the unaged specimens’ tensile strength.

압출

Simulate extruding PVC pipes using anhydrous acetone to observe and test for incomplete fusion. In general, whether there is a large area of peeling, cracking, and other problems after soaking, test whether the product meets the standard requirements. It is a great test for PVC catheters’ raw material quality and production process.

물 흡수

UL651은 완성된 후에 다음을 요구합니다. PVC 도관 24시간 동안 증류수에 담가두면 물 흡수율은 무게의 0.50%를 초과해서는 안 됩니다. 이해하기 매우 쉽습니다. PVC 파이프를 땅에 묻으면 필연적으로 토양의 수분에 영향을 받습니다. PVC 도관이 너무 많은 물을 흡수하여 부풀면 도관 접합부가 부풀어 변형되어 밀봉이 제대로 되지 않아 전선이 제대로 보호되지 않습니다.

충격에 대한 저항성

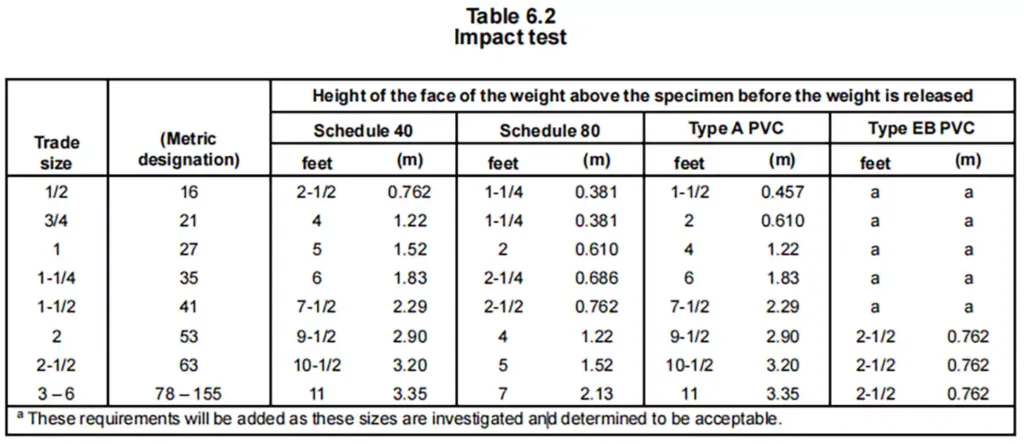

The Resistance to Impact Test outlined in UL 651 evaluates the ability of rigid PVC conduit to withstand physical impact without cracking or tearing beyond an acceptable limit. This test is crucial in assessing the durability and mechanical strength of conduit under real-world conditions, ensuring that it remains intact and functional even when subjected to sudden force or impact.

Specimen

- Ten 6-inch (150 mm) specimens are cut from finished lengths of each trade size of rigid PVC conduit.

- The specimens must be free from cracks, tears, or other imperfections before testing.

Conditioning

- The specimens are conditioned in air at a temperature of 23.0 ±2.0°C (73.4 ±3.6°F) for at least 4 hours to ensure uniform testing conditions.

Impact Setup

- Each specimen is placed on a solid, flat, steel plate that is at least 1/2 inch (13 mm) thick and firmly anchored in a horizontal position.

Impact Mechanism

- 에이 steel weight, shaped as a solid, right-circular cylinder with a flat impact face and rounded edges, is dropped onto the specimen from a specified height.

- The impact conditions depend on the conduit type:

Schedule 40, Type A, and Type EB:

무게: 20 lbs (9.1 kg)

Cylinder diameter: 2 inches (51 mm)

Schedule 80:

무게: 75 lbs (34 kg)

Cylinder diameter: 6 inches (150 mm)

- 그만큼 flat face of the weight strikes the center of the specimen across the diameter and along the longitudinal axis, ensuring a standardized impact force.

- A mechanism is in place to ensure the weight only strikes once per test.

Pass/Fail Criteria

- The rigid PVC conduit fails the test if more than three out of ten specimens develop a crack or tear longer than 1/32 inch (0.8 mm) along the outer surface.

- If seven or more specimens remain intact or develop cracks/tears within the allowable limit, the conduit passes the test.

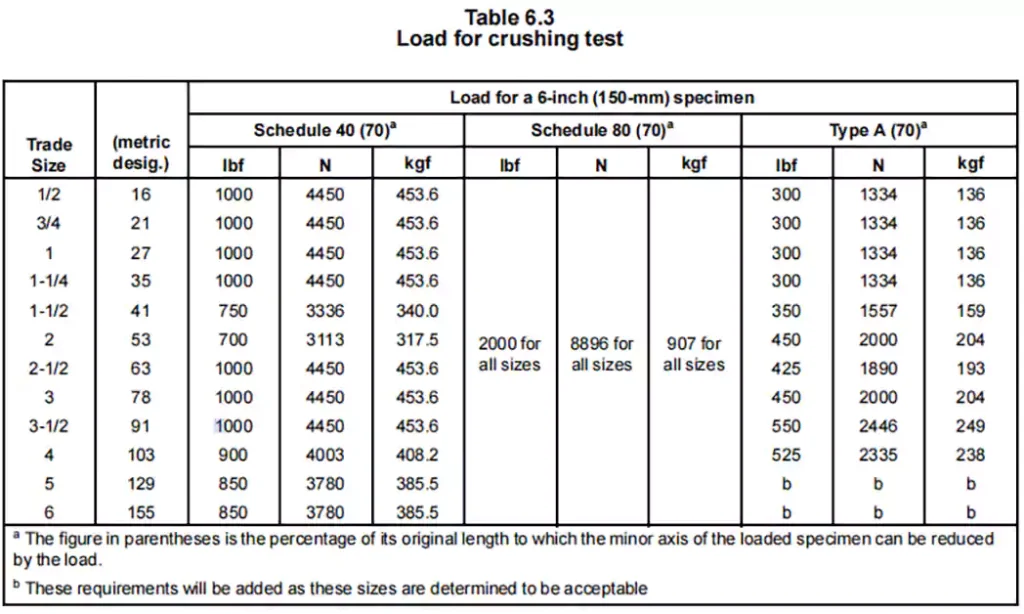

파쇄 저항성

The Resistance to Crushing Test evaluates the ability of rigid PVC conduit to withstand external pressure without significant deformation or structural failure. This test ensures that the conduit maintains its integrity under compressive forces, which is essential for its performance in underground, encased, or exposed installations where it may be subjected to heavy loads.

By simulating real-world conditions, the test verifies that the conduit does not buckle or excessively deform under specified loads. A key criterion for passing the test is that the minor axis of the inner diameter must not be reduced to less than 70% of its original measurement before loading.

이 시험은 PVC 도관이 땅이나 벽에 묻혀 있고 장시간 압력을 받고 있기 때문에 충격 저항 시험과 다릅니다. 이 시험은 압력의 작용 하에서 PVC 도관의 압축 용량을 실험하는데, 이는 또한 그것에 영향을 미칩니다. 수명의 요인.

불꽃

The Flame Test in UL 651 evaluates the fire resistance of Schedule 40 and Schedule 80 rigid PVC conduit to ensure it does not sustain or spread flames in the event of a fire. This test is designed to confirm that the conduit self-extinguishes quickly and does not contribute to igniting nearby combustible materials.

During the test, the conduit is exposed to a 60-second flame application, repeated three times, with a 30-second interval between each exposure. The conduit must cease flaming within 5 seconds after each flame application and must not release flaming particles that could ignite surrounding materials. If the conduit fails to meet these criteria, it is considered unsuitable for applications where fire safety is a concern.

이 테스트는 일정 40 및 80 PVC 도관이 화재 위협을 받을 때 최대한의 보호를 제공할 수 있는지 시뮬레이션합니다. 도관이 우수한 난연성을 가지고 있다면, 화염이 꺼질 때 도관의 전선이 손상되지 않아 더 심각한 사고가 발생하지 않도록 할 수 있습니다.

햇빛 저항성

The Sunlight Resistance Test in UL 651 evaluates the ability of Schedule 40 and Schedule 80 rigid PVC conduit to withstand prolonged exposure to UV radiation without significant degradation. Since outdoor electrical installations often expose conduits to direct sunlight, this test ensures that the material maintains its mechanical integrity and impact resistance over time.

The test involves Izod impact strength measurements on notched specimens prepared from both unaged and UV-conditioned conduit samples. These samples are exposed to UV radiation for up to 1440 hours, after which their impact strength is tested according to ASTM D 256 standards. To pass the test, the conduit must retain an acceptable level of impact resistance as specified in UL 651.

This testing process ensures that rigid PVC conduits remain durable and reliable in outdoor applications, providing long-term performance and protection against environmental factors such as UV exposure and weathering.

Conduit for Use with 90°C Wire

Among UL651 requirements, one key specification is the ability to support 90°C-rated wire, which indicates the maximum operating temperature of the conductors inside the conduit.

What Does 90°C Wire Mean and Why It Matters?

The 90°C rating refers to the maximum temperature the wire’s insulation can withstand without degrading over time. UL 651-certified PVC conduit is typically rated for 75°C conductors, but many electrical specifications now demand 90°C-rated conduit to accommodate higher-temperature wiring without requiring system derating. This higher temperature tolerance ensures that the electrical system operates at full efficiency while maintaining safety and reliability.

To achieve a 90°C rating, PVC conduit must pass additional long-term testing beyond the standard requirements for 75°C conduit. The testing process outlined in UL 651 extends over 360 days, exposing the conduit to various environmental stresses, including prolonged high temperatures, to evaluate its resistance to thermal degradation, mechanical integrity, and overall performance.

Testing Requirements

The test involves accelerated aging by placing conduit specimens in a circulating-air oven at 80°C (176°F) for up to 360 days. At specific intervals, impact tests are conducted using a steel cylinder drop method to determine impact strength retention over time. A smooth degradation curve is plotted, and the conduit must maintain at least 50% of its initial impact strength after prolonged exposure.

This rigorous evaluation ensures that Schedule 40 and 80 PVC conduits remain reliable and structurally sound when used with high-temperature wiring, providing long-term safety and performance in demanding electrical applications.

How to Tell If the PVC Conduit is Listed to the 90°C Requirements?

Compliant 90°C-rated conduit must also include permanent markings that explicitly state “maximum 90°C wire” or “max 90°C wire”. Listing agencies such as UL, ETL require these markings to confirm the conduit meets the standard.

If a conduit does not have this mandatory marking, it is not compliant with the 90°C specification, regardless of manufacturer claims. Using non-compliant conduits in systems designed for 90°C conductors can lead to serious consequences, including failed inspections, system rejection, costly replacements, and legal liabilities.

인쇄의 영구성

이 테스트는 샘플을 168시간 동안 노화 테스트를 거친 후, 24시간 동안 수돗물에 담가둔 다음 IRM902 오일로 문질러서 테스트를 시작해야 합니다. 이 테스트는 간단한 자동 장치를 사용하여 테이프가 카테터의 인쇄된 부분에 고정된 주기로 접촉하도록 하며, 각 주기마다 앞뒤로 움직여 총 50회 주기를 수행합니다.

위의 테스트를 거친 후, 인쇄된 문자는 합격한 제품의 경우 선명하게 보여야 합니다.

대부분 제조업체가 이제 레이저로 각인하고 있기 때문에 이 테스트는 너무 가혹하지 않습니다. 그 목적은 주로 제조업체, 생산 날짜 등을 추적할 수 있는 카테터 인쇄를 유지하는 것입니다.

표시

일반적인 PVC 강성 튜브 인쇄에는 다음 사항이 포함되어야 합니다.

1) '강성 PVC 도관'이라는 단어가 있습니다.

2) 거래 규모

3) 제조사 또는 브랜드 소유자의 이름

4) 생산일자

5) 위 정보는 최소한 10피트마다 한 번씩 인쇄해야 합니다.

6) 위 장에서 언급했듯이 인쇄는 영구적입니다.

또한, 일정 40 및 80 PVC 도관에 대한 몇 가지 세부 요구 사항이 있습니다. 예를 들어, 이 두 도관에 대해 인쇄를 일정 40 또는 일정 80 강성 PVC 도관으로 업데이트해야 합니다.

일부는 90°C(194°F) 와이어에 적합하므로 인쇄물에 "최대 90°C 와이어"를 표시해야 합니다. 또한 몇 가지 특수 요구 사항도 있습니다. 예를 들어, 스케줄 40 강성 도관 지하 사용에만 적합한 경우 "지하 사용 전용"이라고 인쇄해야 합니다.

부속 제품의 인쇄는 대부분이 사출 성형 기술로 생산되기 때문에 금형 설계 중에만 하면 되고 영구적인 요구 사항을 충족해야 합니다. 인쇄된 내용은 일반적으로 제조업체 또는 브랜드 이름과 제품 모델입니다. 일정 40 또는 일정 80 강성 PVC 도관과 유사하게 제한된 시나리오에서만 사용할 수 있는 경우 땅에 묻거나 90°C 와이어에만 적합한지 확인해야 합니다.

Conduit Applications and Installation - NEC Article 352

NEC (National Electrical Code) has outlined the installation and usage requirements of PVC conduit, to ensure compliance with electrical safety standards. Article 352 of NEC specifies the key applications, limitations, and installation requirements, follow are some key information:

Applications for PVC Conduit:

Applications for PVC Conduit:

Uses Permitted | Uses Not Permitted |

Concealed installations within walls, floors, or ceilings | In hazardous (classified) locations unless specifically permitted |

Wet and dry locations | As a means of support for luminaries (light fixtures) |

Corrosive environments where metal conduits could deteriorate | Where subject to severe physical damage |

Underground installations, including direct burial | In areas where temperatures exceed 50°C (122°F) |

Exposed applications, provided the conduit is rated for sunlight resistance | Where it may be used as a grounding conductor |

Some Installation Considerations:

Conduit Fill: The number of conductors must comply with NEC Chapter 9.

Conduit Fill Size Chart for PVC Conduit

도체 수 | Cross-Sectional Area (%) |

1 | 53 |

2 | 31 |

2개 이상 | 40 |

Support Requirements: Must be secured within 3 feet (900mm) of terminations and supported per NEC Table 352.30.

Expansion Fittings: Required when thermal expansions is expected to exceed 1/4 inch (6mm).

접지: PVC conduit does not provide an equipment grounding path; a separate grounding conductor is required.

재료 구성: Must be made from non-plasticized PVC, resistant to moisture, chemicals, impact, and fire, and UV-resistant for above ground use.

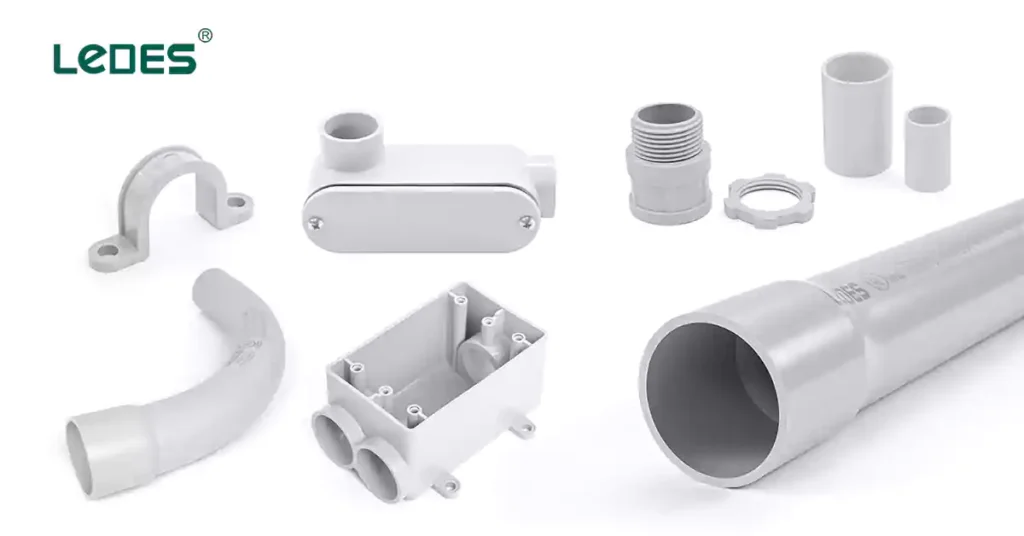

Your Reliable Electrical Solution – Ledes

Ledes is a trusted manufacturer in high-quality electrical conduit solutions, committed to delivering safe, durable, and high-performance products that meet industry standards. Our extensive range of UL-listed PVC conduits and fittings ensures compliance with the UL standard, offering superior reliability for a variety of electrical applications.

Ledes provides UL-listed PVC conduits and fittings that for use with the conduits, including:

- 스케줄 40 PVC 도관 – A versatile, lightweight option suitable for general-purpose electrical installations, both aboveground and underground.

- Schedule 80 PVC Conduit – Features a thicker wall for enhanced impact resistance, ideal for high-traffic or demanding environments.

- Elbows – Available in 45°, 90°, and other custom angles of standard elbows and special radius elbows, these elbows allow smooth directional changes in conduit runs without compromising wiring integrity.

- Couplings – Essential for joining conduit sections, ensuring a seamless and secure connection for continuous wiring runs.

- Adapters – Including Male Terminal Adapters and Female Adapters, enabling smooth transitions between different conduit types, boxes, or enclosures.

- Pipe Straps – Strong and reliable conduit supports that securely fasten Schedule 40 and 80 conduits to walls, ceilings, or other structures.

- Gang Boxes – Designed for secure mounting of electrical devices and wiring connections.

- Conduit Bodies – Ideal for providing pull points, splicing spaces, and directional changes, available in multiple styles such as Type LB, LL, LR, T, and C to suit different installation needs.

Trusted by Major Infrastructure Projects

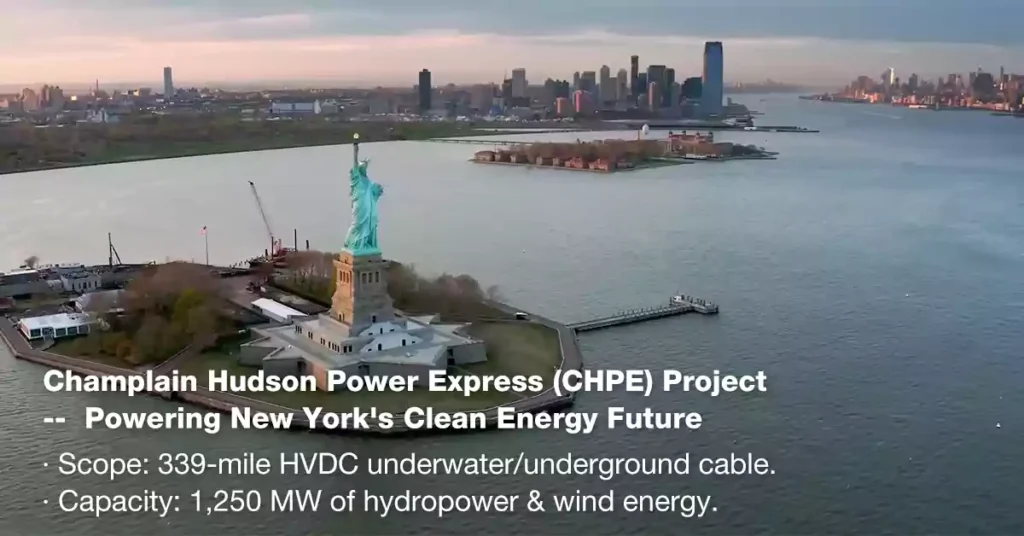

Champlain Hudson Power Express (CHPE) Project

The Champlain Hudson Power Express (CHPE) is a landmark high-voltage direct current (HVDC) transmission project, spanning 339 miles from Quebec, Canada, to New York City. This project is critical for:

- Delivering clean, renewable hydroelectric power to New York.

- Reducing carbon emissions and enhancing grid reliability.

- Creating thousands of jobs and modernizing the region’s energy infrastructure.

For this massive underground and underwater transmission line, Ledes’ UL-listed PVC conduits and fittings were selected due to their superior durability, corrosion resistance, and electrical safety. Our Schedule 40 and 80 PVC conduits provide secure cable protection over long distances, ensuring efficient energy transmission while withstanding underground conditions.

A.B. Brown Power Station Project

The A.B. Brown Generating Station is a 700-megawatt (MW) power plant located along the Ohio River in Indiana, just southwest of Evansville. This facility, owned by CenterPoint Energy (formerly Vectren), consists of:

- Two coal-fired units, each with a 265.2 MW nameplate capacity, primarily using bituminous coal with the capability to substitute natural gas.

- Two gas turbine units, each providing 88.2 MW of capacity for additional power generation.

As part of CenterPoint Energy’s modernization plan, there are ongoing infrastructure improvements and grid enhancements to support future energy needs. The company previously announced plans to retire the coal-fired units and transition to natural gas-powered generation, pending approval from the Indiana Utility Regulatory Commission.

To ensure a secure and reliable electrical system, Ledes’ UL-listed PVC conduits and fittings were selected for various electrical installations and upgrades within the A.B. Brown facility.

왜 Ledes를 선택하시나요?

UL 인증 – Ensuring compliance with safety and performance standards.

Durable & Corrosion-Resistant – Made from high-quality PVC for long-lasting performance in harsh environments.

쉬운 설치 – Lightweight and designed for quick assembly.

Versatile Applications – Suitable for residential, commercial, and industrial electrical installations.

Ledes is proud to be a supplier for critical infrastructure projects that shape the future of energy. Our innovative, high-performance conduit solutions ensure safe and efficient electrical installations in the most demanding environments.

UL vs. CSA Standard PVC Conduits

UL (Underwriters Laboratories) and CSA (Canadian Standards Association) are two leading organizations establishing safety and performance benchmarks for electrical conduits. Their standards ensure products meet rigorous requirements for durability, fire resistance, and environmental adaptability, with distinct regional and technical emphases.

- UL Standards: Primarily recognized in the United States, UL standards focus on ensuring that electrical products, including PVC conduits, are safe to use within the U.S. infrastructure. The UL standard for PVC conduit (e.g., UL 651) addresses fire safety, impact resistance, temperature ratings, and more.

- CSA Standards: These are focused on ensuring that products are safe for use within Canada. CSA standards often align with international guidelines but may have specific adjustments to reflect local safety and regulatory needs. CSA C22.2 No. 211.2 is the standard for PVC conduit in Canada, outlining similar requirements to UL but tailored for Canadian safety regulations.

Performance Requirements for UL and CSA

Performance Requirements UL651 and CSA C22.2:

Aspects | UL651 | CSA C22.2 No.211.2 |

Temperature | Use at 50° C(122°F) or lower ambient temperatures; Use with 75° C (or maybe 90° C) wiring. | Use at a continuous operating temperature of 75° C.

|

충격 저항성 | Test at 23.0 ±2.0° C, with 20lbs (9.1 kg) weight for Schedule 40. | Test at –34 ± 2 °C, with 12 J impact energy for rigid conduit.

|

인장 강도 | 5,000 psi for Schedule 40 conduit | Not specified |

Resistant to Crushing | Detail required in section 6.9 | Not specified |

압축 | Not specified | No cracks and decrease no more than 25% when subjected to certain forces. |

불꽃 | 3 times of 60-seconds flame application, no more than 5s flame after each application. No flaming drops. | Not burn than 30 seconds, no flaming or glowing particles. |

햇빛 저항성 | Same requirements with CSA | Same requirements with UL |

코드 준수

- 국가 전기 규정 (NEC): UL-certified PVC conduits are recognized for compliance with the U.S. National Electrical Code (NEC), which is the standard governing electrical installations across the United States.

- 캐나다 전기 규정(CEC): CSA-certified PVC conduits are recognized for compliance with the Canadian Electrical Code (CEC), ensuring that products meet the specific safety and installation standards for electrical systems in Canada.

Marking and Labeling

- UL Mark: PVC conduit that is UL-listed typically displays the UL mark, which indicates that it meets the specific UL safety standards and is approved for use in the United States.

- CSA Mark: Similarly, PVC conduit that meets CSA standards is marked with the CSA logo, indicating that it is compliant with Canadian requirements.

Both UL and CSA standards are crucial for ensuring that PVC conduits meet the necessary safety, performance, and regulatory requirements in their respective regions. While there are similarities in the testing protocols and requirements, the key difference lies in their geographic applicability and specific regulations. For projects in the United States, UL-listed PVC conduit is the ideal choice, while CSA-certified conduit is essential for Canadian installations.

결론

As we’ve explored throughout this guide, UL 651 PVC conduit plays a crucial role in modern electrical installations by offering a combination of durability, fire resistance, corrosion resistance, and compliance with NEC requirements. Its classification into Schedule 40 and Schedule 80 allows for flexibility in different applications, ensuring that electricians and contractors can choose the right type based on mechanical protection needs and environmental conditions.

Whether you’re working on an underground installation, a commercial building, or an industrial facility, using UL 651-compliant PVC conduit ensures that your electrical system meets safety standards and performs reliably over time. By selecting certified conduit from reputable manufacturers, you can guarantee long-term performance while ensuring compliance with industry regulations.

As the demand for sustainable, cost-effective, and reliable electrical solutions continues to grow, UL 651 PVC conduit remains a key component in safe and efficient wiring infrastructure. Now that you have a thorough understanding of UL 651, you can confidently choose the right conduit for your next project.

UL 제품 시리즈에 대해 궁금한 사항이 있거나 관심이 있으시면 이메일로 문의하세요 아니면 심지어 What’s app, 일반적으로 영업일 기준 1일 이내에 답변해 드리겠습니다.