목차

Electrical conduit systems play a crucial role in safely housing and protecting electrical wiring in various installations, whether residential, commercial, or industrial. When it comes to designing and implementing these systems, two important factors to consider are impact resistance and tensile strength. These properties determine the conduit’s ability to withstand external forces and maintain structural integrity, ensuring long-term performance and safety.

To ensure consistent and reliable performance, several standards have been established to evaluate the impact resistance and tensile strength of electrical conduits. Among these standards, UL651, CSA C22.2 NO.211.2, UL1653, and AS/NZS 2053 are widely recognized and followed within the industry. In this article, we will focus on the requirements specified in UL651, CSA C22.2 NO.211.2, UL1653, and touch upon AS/NZS 2053, particularly concerning PVC rigid conduit and Nonmetallic Tubing or Corrugated conduit.

Impact resistance and tensile strength are critical considerations in electrical conduit systems, as they ensure the conduit can withstand external forces and environmental conditions, safeguarding the enclosed electrical wiring and minimizing the risk of electrical failures or accidents. Let’s delve deeper into these properties and explore the standards that govern them.

충격 저항성

정의

Impact resistance refers to the ability of electrical conduit systems to withstand physical impacts without sustaining damage or compromising their structural integrity. It is a critical property that ensures the conduit can protect the enclosed electrical wiring from external forces and environmental conditions.

UL651 Standard for Electrical Conduit Impact Resistance

The UL651 standard, established by Underwriters Laboratories, plays a significant role in evaluating the impact resistance of PVC rigid conduit. UL is a globally recognized independent safety science organization that sets rigorous standards for various electrical products and components. Widely accepted in American Countries.

UL651 defines the testing procedures and requirements to assess the impact resistance of PVC rigid conduit. The standard specifies the maximum impact energy levels that the conduit must withstand without cracking, fracturing, or experiencing any significant damage. This ensures that the conduit can endure accidental contact, minor impacts during installation, or external factors without compromising its protective capabilities.

Requirements:

After testing ten conduit samples, no more than 3 samples should have crack longer than 0.8mm on the conduit surface.

Test Method:

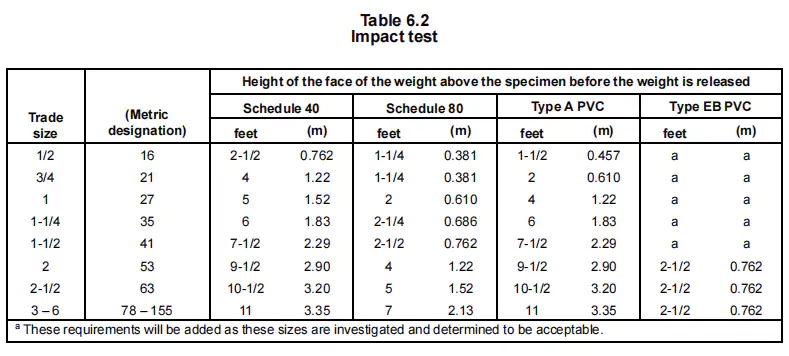

“Ten 6-inch (150-mm) specimens without cracks, tears, or other imperfections are to be cut from

finished lengths of each trade size of rigid PVC conduit. The specimens are to be conditioned in air at a temperature of 23.0 ±2.0° C (73.4 ±3.6° F) for a minimum period of 4 hours before being tested. The specimens are to be tested separately, within 15 seconds after conditioning, while resting on a solid, flat, steel plate that is at least 1/2 inch (13 mm) thick and is firmly anchored with its upper surface horizontal. A protective cage is to surround the plates and specimen to reduce the likelihood of injury from pieces of broken conduit in the event that the conduit flies apart. A steel weight in the form of a solid, right-circular cylinder with a flat impact face having rounded edges is to fall freely through a vertical guide from the height indicated in Table 6.2. For Schedule 40, Type A and EB rigid PVC conduit, the weight shall be 20 lbs (9.1 kg) and the cylinder shall have a diameter of 2 inches (51 mm). For Schedule 80 conduit the weight shall be 75 lb (34 kg) and the cylinder shall have a diameter of 6 inches (150 mm). The flat face of the weight is to strike the center of the specimen across the diameter and along the longitudinal axis once

(provision is to be made for keeping the weight from striking the specimen more than once).” — Quoted from the Eighth Edition of UL651.

CSA Standard for Electrical Conduit Impact Resistance

The Canadian Standards Association (CSA) and its standard CSA C22.2 NO.211.2 also play a crucial role in assessing the impact resistance of PVC rigid conduit. CSA is an internationally recognized organization that develops standards for a wide range of electrical products and systems.

Requirements and Criteria:

After testing 10 conduit samples, no more than 2 samples should have cracks or ruptures on the inside or outside of the conduit.

Test Method:

Ten conduit samples shall be conditioned at -34±2 °C with wood pices in a cold chamber for 4 hours. After conditioning, using a steel hammer to conduct a force of 12J on the conduit samples under -34±2 °C. Each sample is subjected to only one blow from the hammer. — Refering to CSA C22.2 No.211.0 and CSA C22.2 No.211.2

UL1653 is another significant standard established by Underwriters Laboratories, UL651 primarily covers PVC rigid conduit, UL1653 is the standard for Electrical Nonmetallic Tubing. UL1653 and CSA C22.2 No.227.1 share the same tests and requirements for nonmetallic tubing, just slight difference in some specific tests.

Criteria of Acceptance:

After testing ten tubing samples, no more than 2 of samples shloud show cracks, chips, or ruptures on the inside and outside of the samples.

Testing Process:

Conditioning 10 samples in a cold chamber under a temperature of minus 20±1°C for at least 4 hours. Then subject the samples to the impact (2.7J) within 15s of its removal from the chamber with a flat, level steel or aluminum plate. — Refering to Second Edition of UL1653

The standard also specifies the sample and plate requirements, including the lengths and thicknesses.

AS/NZS 2053 Standard for Electrical Conduit Impact Resistance

AS/NZS 2053 is a key standard used in Australia and New Zealand for evaluating the quality and safety of PVC conduit products. It sets parameters for impact energy levels and evaluates the conduit performance under specific conditions.

Criteria of Acceptance:

After testing 12 samples, no more than 3 samples should be no sign of disintegration or cracks.

Apparatus Required:

Two conditioning chambers, an impact apparatus, a pad of sponge rubber.

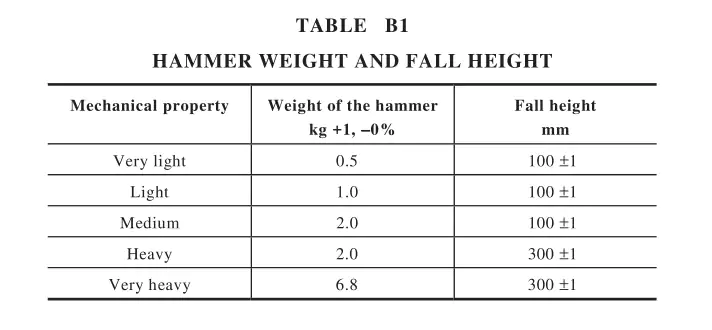

Test Procedure:

“(a) Place a test piece in conditioning Chamber 1, at the maximum permanent service

temperature specified by the manufacturer (with a tolerance of ±2°C), for 240 h.

(b) Place the impact test apparatus on the pad of sponge rubber in conditioning

Chamber 2. Also place the test piece in conditioning Chamber 2.

(c) Maintain the temperature within conditioning Chamber 2 at the lowest installation

temperature specified by the manufacturer (with a tolerance of ±2°C).

(d) When the test piece reaches the temperature of the air within conditioning Chamber 2,

or after 2 h, whichever is the longer period, place the test piece on the steel base.

(e) Rest the intermediate steel piece on the test piece.

(f) Set the weight of the hammer and the fall height in accordance with Table B1 and

then let the hammer fall on the test piece. For fittings, the test is made on the weakest

part of the conduit fitting, except that it is not applied within 5 mm of any socket

mouth.

(g) Using normal or corrected vision, without magnification, examine the test piece for

cracks or disintegration.” — Quoted from AS/NZS 2053.1:2001

인장 강도

정의

Tensile strength refers to the maximum amount of tensile stress a material can withstand before breaking or experiencing permanent deformation. In the context of electrical conduit systems, tensile strength measures the conduit’s ability to resist pulling forces without failure or structural compromise.

UL651 for Tensile Strength Test

Acceptance Criteria:

Six samples of rigid PVC conduit, three aged, three unaged, after subjecting to tensile test, three aged samples’ average tensile strength should be equal or exceed 95 percent of three unaged samples’ average tensile strength.

Test Method:

“Prepare the six specimens according the standard requirements, including the conduit size, length and shape.

Put three specimens in a oven under temperature of 113.0 ±1.0°C for 168 hours. Then take out the samples and cool them in still air at a temperature of 23.0 ±2.0°C for 16 – 96 hours. Then test all six specimens in succession using a tensile machine. Specific requirements for the tensile machine and operation method please refer to the standard.

The tensile strength conducted on the specimens should not less than 5000 psi for Schedule 40 and Schedule 80 rigid PVC conduit.

Calcultion for the tensile strength also specified in the standard.” — Refering to standard UL651, Eighth Edition.

UL1653 for Tension Strength Test

요구 사항:

After the samples withstand for a period of 1 min, the electrical nonmetallic tubing should not break.

Test Method:

“Prepare six samples. For 16 (1 /2) and 21 (3/4) trade sizes, a 90 kg (200 lb) mass resting on the floor shall be clamped to one end of the ENT and shall be used to create a tension force of 889 N (200 lbf) by lifting the mass off the floor by pulling on the other end of the ENT and maintaining the load for 1 min. Similarly, for 27 (1 ) and larger trade sizes, a 1 35 kg (300 lb) mass resting on the floor shall be clamped to one end of the ENT and shall be used to create a tension force of 1 334 N (300 lbf) by lifting the mass off the floor by pulling on the other end of the ENT and maintaining the load for 1 min.

The grip of the test machine shall be separated at a rate of 50 to 75 mm/min (2 to 3 in/min) until the sample reaches the load for each trade size specified above. And this level of tension shall be held for 1 min.” — Quoted and referred from UL1653, Clause 7.8.

Safety First: How an Electrical Conduit Protects Your Project

Conduit is an important part of electrical installation, which ensures the safety of the entire electrical system and personnel. Therefore, the quality and performance of the conduit are crucial.

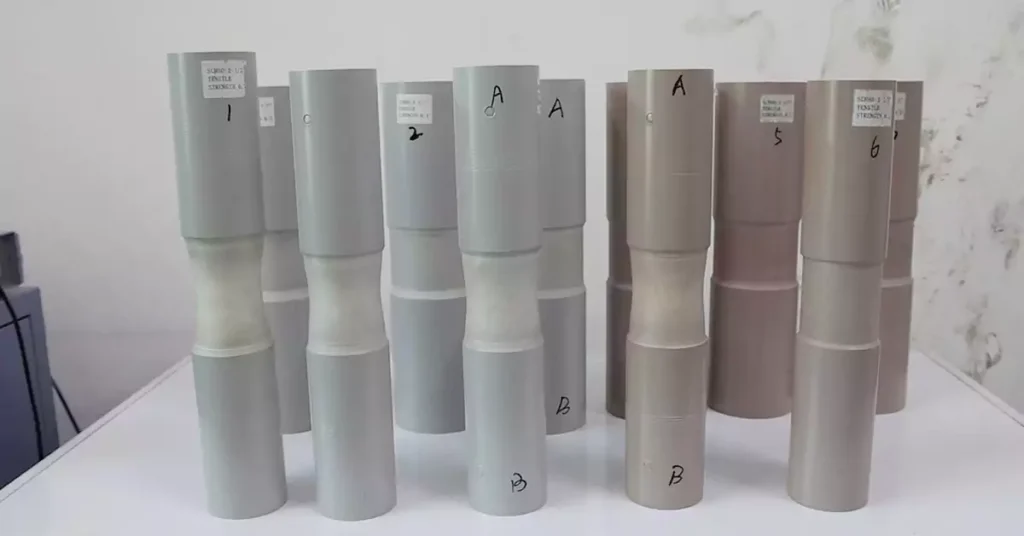

In-House Testing

After the production of electrical conduit systems, it is crucial for manufacturers to perform self-testing to ensure the products meet the required standards and specifications. Self-testing serves as a quality control measure to verify that the conduit systems possess the necessary impact resistance and tensile strength.

By conducting rigorous testing, manufacturers can identify any potential issues or defects in the conduit systems before they reach the end users. This proactive approach helps maintain the safety and reliability of the electrical installations as it minimizes the risk of using substandard or non-compliant conduit systems.

Self-testing may involve subjecting the conduit to various tests, including impact resistance and tensile strength evaluations, as per the applicable standards such as UL651, CSA C22.2 NO.211.2, and UL1653. Manufacturers can use specialized testing equipment and procedures to simulate real-world conditions and ensure that the conduit systems meet the required performance criteria.

4 Factors Impacting Electrical Conduit Lifespan

The longevity of electrical conduit systems in the field depends on several factors. Understanding and addressing these factors are essential for ensuring the long-term safety and reliability of the installations.

환경적 요인: Conduit systems are exposed to various environmental conditions, such as temperature fluctuations, moisture, UV radiation, and chemical exposure. These factors can degrade the materials over time, affecting the impact resistance and tensile strength of the conduit. Proper selection of materials with suitable resistance to environmental factors can contribute to improved longevity.

Mechanical Stresses: In the field, conduit systems may experience mechanical stresses due to factors like vibrations, movements, or accidental impacts. These stresses can gradually weaken the conduit or cause damage if not properly addressed. Adequate support, secure fastening, and proper routing can help minimize the impact of mechanical stresses and extend the longevity of the conduit systems.

Installation Quality: The quality of the installation process plays a vital role in the longevity of electrical conduit systems. Improper installation practices, such as inadequate bending radii, insufficient fastening, or improper sealing, can compromise the conduit’s integrity and performance. Following manufacturer guidelines and industry best practices during installation ensures that the conduit systems are installed correctly, reducing the risk of premature failures.

Maintenance and Inspections: Regular maintenance and inspections are crucial for identifying any issues or signs of deterioration in the conduit systems. Periodic inspections can help detect early warning signs of damage or degradation, allowing for timely repairs or replacements. Implementing a maintenance schedule and conducting inspections in accordance with industry standards can significantly contribute to the longevity and reliability of the conduit systems.

6 Best Practices of Electrical Conduit Installation

Proper installation practices are paramount for ensuring the safety, performance, and longevity of electrical conduit systems. Adhering to the following installation practices is essential:

- 표준 준수: Installers should follow the relevant standards, such as local electrical codes and manufacturer guidelines, to ensure proper installation. These standards provide specifications for conduit sizing, routing, fastening, bonding, sealing, and other critical aspects.

- Suitable Conduit Selection: Choosing the appropriate conduit material and type for the specific application is crucial. Factors such as the environment, anticipated mechanical stresses, and electrical requirements should be considered during the selection process.

- Adequate Bending Radii: Bends in the conduit should be made with proper bending radii to prevent kinking or excessive stress on the conduit. Following the recommended bending radii specified by the manufacturer helps maintain the conduit’s structural integrity and prevents performance issues.

- Secure Fastening: Conduit systems should be securely fastened to prevent movement, vibrations, or dislodgment. Proper use of supports, clamps, brackets, and other fastening methods ensures the conduit remains in place during normal operation and external forces.

- Effective Sealing: Depending on the application and environmental conditions, proper sealing may be required to protect the enclosed wiring from moisture, dust, or other contaminants. Using appropriate sealing methods, such as gaskets, fittings, or sealants, helps maintain the integrity of the conduit system.

- Professional Installation: Employing qualified and experienced professionals for conduit installation is crucial. Professional installers possess the necessary knowledge and expertise to ensure proper installation practices, minimizing the risk of errors or oversights.

- By adhering to proper installation practices, installers can enhance the safety and reliability of electrical conduit systems, maximizing their longevity and minimizing the potential for failures or performance issues.

Electrical Conduit Buying Guide

When purchasing electrical conduit for your installations, it is crucial to prioritize products that have been certified by standards such as UL, CSA, and AS/NZS. Buying conduit with these certifications offers several important benefits:

- Assurance of Quality and Performance:

Conduit certified by recognized standards ensures that the product has undergone rigorous testing and evaluation to meet specific requirements. These certifications serve as a mark of quality and provide assurance that the conduit possesses the necessary impact resistance and tensile strength for reliable performance.

Certified conduit undergoes comprehensive testing to validate its structural integrity and ability to withstand pulling forces, impacts, and other stressors. By purchasing certified conduit, you can have confidence in its quality and performance, reducing the risk of premature failures or safety hazards.

- Compliance with Regulatory Requirements:

Electrical installations are subject to various regulatory requirements and codes that aim to ensure safety and reliability. Buying conduit certified by recognized standards helps ensure compliance with these regulations.

Certified conduit has been tested and evaluated according to industry-accepted criteria, aligning with the requirements set forth by regulatory bodies. This compliance reduces the potential for non-compliance issues during inspections or audits, saving time, and avoiding costly rework.

- Enhanced Safety for Personnel and Equipment:

Electrical conduit systems play a crucial role in protecting electrical wiring and preventing hazards such as electrical shocks, fires, and equipment damage. Conduit certified by standards emphasizes safety considerations, ensuring that the product is designed and manufactured to meet stringent safety requirements.

Certified conduit undergoes testing to verify its ability to withstand impacts, pulling forces, and other mechanical stresses. This validation helps safeguard personnel and equipment by reducing the risk of conduit failure, which could lead to electrical faults, short circuits, or compromised insulation.

- Long-Term Reliability and Cost Savings:

Investing in certified conduit translates into long-term reliability and cost savings. Certified products are designed to withstand the challenges posed by various environmental conditions, mechanical stresses, and installation requirements.

By purchasing conduit that meets the specified impact resistance and tensile strength requirements, you can be confident in its durability and longevity. This reduces the need for costly repairs, replacements, and maintenance, ultimately saving both time and money over the lifespan of the electrical installation.

- Confidence in Manufacturer’s Integrity:

Choosing conduit certified by recognized standards also reflects the manufacturer’s commitment to quality and integrity. Manufacturers who subject their products to testing and certification demonstrate their dedication to producing reliable and safe conduit systems.

By purchasing conduit from reputable manufacturers that adhere to industry standards, you can have confidence in the integrity of the product and the manufacturer’s commitment to delivering high-quality solutions.

결론

In conclusion, understanding the mechanical properties of electrical conduit systems is crucial for ensuring both safety and performance in electrical installations. The impact resistance and tensile strength of conduit play a significant role in protecting wiring, minimizing the risk of electrical faults, and maintaining the integrity of the entire system.

The importance of conduit’s mechanical properties cannot be overstated. considering the mechanical properties of conduit, emphasizing proper conduit selection, and prioritizing certified products are vital steps to ensure the safety, reliability, and long-term performance of electrical installations. By understanding the impact resistance and tensile strength requirements and following best practices, electrical professionals can create installations that meet the highest standards of safety and efficiency.

Any questions or requirements for certified electrical conduit, 언제든지 저희에게 연락하세요.

참고문헌

UL 651 Standard Eighth Edition from UL Solutions

UL1653 Standard Second Edition from UL Solutions

CSA C22.2 No.211.0 and CSA C22.2 No.211.2 from CSA Group

AS/NZS 2053.1:2001 Standard from standards Australia