Table of Contents

Electrical installations require a meticulous approach to ensure proper wiring and safety. One crucial aspect of these installations is how to connecting PVC conduit to electrical boxes. PVC conduit serves as a protective housing for electrical wiring, safeguarding it from damage and providing a neat and organized appearance. In this guide, we will explore the significance of connecting PVC conduit to electrical boxes and provide you with a step-by-step process to accomplish this task effectively.

Connecting PVC conduit to electrical boxes is a critical step in electrical installations for several reasons. Firstly, it provides a secure and enclosed pathway for electrical wiring, protecting it from physical damage, moisture, and other environmental factors. The conduit acts as a barrier, shielding the wires from potential hazards and reducing the risk of electrical shocks or short circuits.

Secondly, connecting PVC conduit to electrical boxes ensures proper organization and management of electrical wiring. It allows for a structured and systematic approach, making troubleshooting, repairs, and upgrades easier in the future. By neatly routing the wires within the conduit and connecting them to the appropriate electrical boxes, you create a tidy and accessible electrical system.

Lastly, connecting PVC conduit to electrical boxes aligns with electrical codes and regulations. These codes are designed to promote safety standards and ensure that electrical installations are carried out in a compliant manner. Properly connecting conduit to electrical boxes is an essential part of meeting these requirements and maintaining a safe electrical environment.

In this guide, we will delve into the process of connecting PVC conduit to electrical boxes. We will explore various types of electrical boxes commonly used in installations, including junction boxes, switch boxes, and outlet boxes. Additionally, we will consider factors such as the type of conduit (rigid or flexible) and the materials used in the construction of the boxes (metallic or nonmetallic).

By following the step-by-step instructions provided, you will gain the necessary knowledge and skills to connect PVC conduit to electrical boxes confidently. Whether you are a DIY enthusiast or a professional electrician, understanding this process is vital for ensuring a secure and reliable electrical system.

There are many different types of electrical boxes, and the method of connecting PVC conduit to them. Here are some of the common used electrical box types.

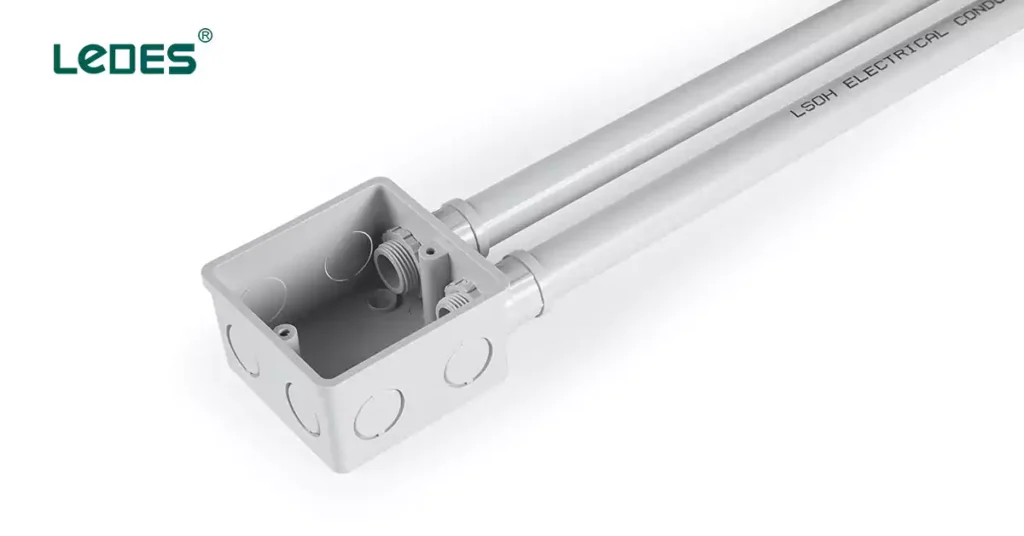

Junction boxes, also called terminal boxes or J-boxes, are protective enclosures that house and shield electrical wiring connections and wire splices from environmental factors and accidental contact. They are commonly installed in roofs, walls, and concrete plaster. It acts as a central hub where multiple wires can be securely joined together. Junction boxes are crucial for ensuring electrical safety, organizing wires, and complying with codes and regulations.

When connecting PVC conduit to junction boxes, 3 factors should be considered:

Conduit size and compatibility: Ensure that the size of the PVC conduit matches the knockout holes or openings on the junction box. Use connectors or fittings specifically designed for PVC conduit to establish a secure connection.

Grounding: Follow electrical codes and regulations to ensure proper grounding. For metal junction boxes, connect the grounding wire securely to the box. This helps prevent electrical hazards and ensures compliance with safety standards.

Protection and sealing: Use appropriate grommets or bushings where the PVC conduit enters the junction box to protect the conduit from abrasion or damage. Consider sealing the conduit-to-box connection using sealing compounds or gaskets for added protection against moisture and contaminants.

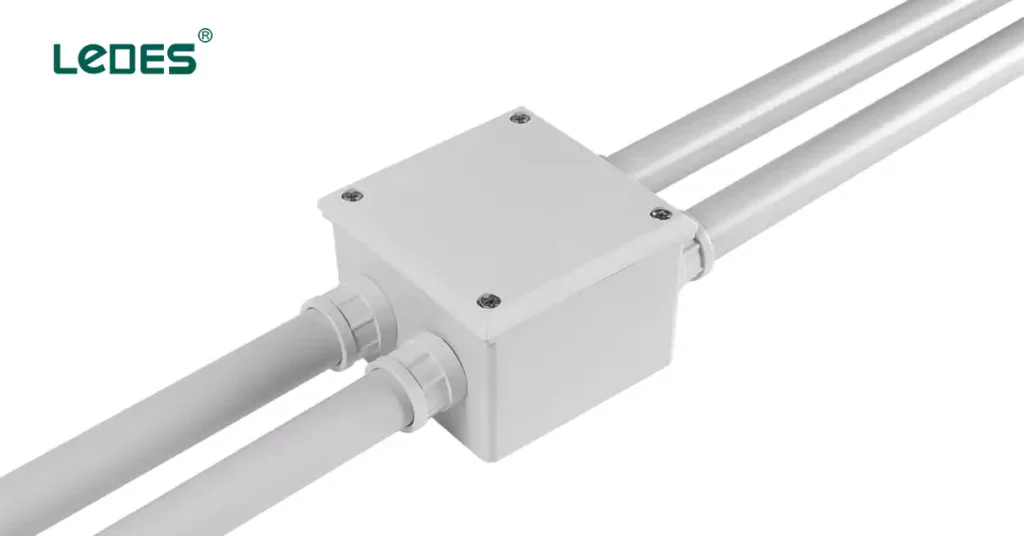

An adaptable box, also known as an adaptable junction box or adaptable enclosure, is a type of electrical box designed to accommodate various types of conduits, cables, and wiring connections. These boxes offer flexibility and versatility in terms of the types and sizes of conduits they can accommodate, making them suitable for a wide range of electrical installations.

Adaptable boxes are commonly used in residential, commercial, and industrial electrical applications where multiple conduits or cables need to be connected or where future modifications or additions may be required. They provide a convenient solution for routing and protecting electrical wiring.

A conduit body is a connector that links protective raceways, allowing the passage of electrical wires between locations. It comes in various types, each with its unique wire redirection function. It serves as an intermediary point where conduits can be joined, directionally changed, and accessed for maintenance or wire pulling purposes. Conduit bodies play a vital role in ensuring proper conduit management, facilitating wire routing, and maintaining compliance with electrical codes and regulations.

A switch box is a metal or plastic electrical enclosure, installed inside walls, that houses the working parts of a light switch. These boxes provide a safe and organized enclosure for electrical connections associated with switches and outlets.

Switch boxes come in various designs to accommodate different installation needs:

Single-gang switch boxes: These boxes are the most common and are used for mounting a single switch or outlet. They provide a compact solution for basic installations.

Multi-gang switch boxes: Used when multiple switches or outlets need to be installed side by side, multi-gang switch boxes have separate compartments for each device. They ensure a neat and organized appearance and simplify wiring management.

An outlet box is a protective enclosure within an electrical system where wires are housed and connected to devices like switches and appliances. These boxes provide protection to the electrical connections and facilitate easy installation and maintenance of outlets.

Single-gang outlet boxes: These boxes are commonly used for mounting a single outlet or receptacle. They offer a compact and efficient solution for basic installations.

Double-gang outlet boxes: Larger in size, double-gang boxes are used when multiple outlets or receptacles need to be installed side by side. They provide separate compartments for each outlet, ensuring a neat and organized appearance.

A gang box is an electrical enclosure, usually plastic or metal, that mounts to a surface to hold and protect a group of electrical devices like switches and outlets. It provides a safe and organized enclosure for electrical wiring and connections, protecting them from damage and providing a means for easy access for maintenance or modifications.

Connecting PVC conduit to an electrical box requires careful attention to ensure a secure and reliable connection. We list three different ways of connection for rigid conduit and flexible conduit, You can follow these steps to connect PVC conduit to an electrical box:

Gather the necessary tools and materials:

- PVC conduit and appropriate connectors

- Locknuts, bushings, threaded connectors, compression fittings, or push-fit connectors

Screwdriver, wrench, or suitable tools

- Thread compound or tape (if using threaded connections)

Ensure the electrical box is properly installed and grounded:

- Ensure that the electrical box is securely mounted and properly grounded according to the applicable electrical codes and regulations.

- Check that the box is suitable for the intended use and compatible with PVC conduit connections.

Verify size and type:

- Ensure that the PVC conduit diameter matches the knockout holes or connectors on the electrical box.

- Confirm that the electrical box is designed for the specific type of PVC conduit being used (rigid or flexible).

Boxes that commonly designed with knockout holes are usually used with rigid PVC conduit. Such as adaptable boxes and switch boxes. For these boxes, here is a general guideline for connecting them with PVC conduit:

- Gather the necessary materials: You will need PVC conduit, PVC connectors, PVC cement, a hacksaw or PVC cutter, a utility knife, a screwdriver, and a switch box.

- Measure and cut the PVC conduit: Measure the length of conduit needed to connect the switch box to the desired location. Use a hacksaw or PVC cutter to cut the conduit to the appropriate length. Ensure the cut is straight and clean.

- Prepare the conduit ends: Use a utility knife to remove any burrs or rough edges from the cut ends of the conduit. This will ensure a proper fit when connecting the conduit to the switch box.

- Attach the PVC connectors: Slide PVC connectors (such as adapters) onto each end of the conduit. The connectors should fit snugly over the conduit ends.

- Apply PVC cement: Apply PVC cement to the inside of each connector and the outside of the conduit ends. Make sure to follow the instructions on the PVC cement regarding drying time and application.

- Insert the conduit into the switch box: Locate the knockout hole on the switch box that aligns with the conduit. Gently insert one end of the conduit into the knockout hole. Push it in firmly until it is fully seated in the box.

- Secure the conduit: Inside the switch box, use a screwdriver to tighten the screws on the PVC connectors. This will secure the conduit in place and provide a tight seal.

- Repeat for additional conduit connections: If you need to connect multiple conduits to the switch box, repeat steps 2-7 for each conduit.

- Test the connection: Once all the conduit connections are made, double-check that they are secure and properly seated in the switch box. Ensure there are no loose parts or gaps.

- Follow up with wiring: With the conduit securely connected to the switch box, you can proceed with wiring as needed, following electrical codes and regulations.

Electrical Boxes such as junction boxes and conduit bodies that designed with hubs on the box, can directly connect with rigid PVC conduit using only PVC solvent cement, here are the steps of the connection.

- Measure and cut the PVC conduit: Measure and cut the PVC conduit to the desired length using a hacksaw or PVC cutter. Ensure that the conduit is cut squarely to create a clean and straight end.

- Remove any burrs: Use a utility knife or a deburring tool to remove any burrs or rough edges from the cut end of the conduit. This will help ensure a proper fit and a secure connection.

- Clean the conduit and box: Wipe the exterior of the conduit and the interior of the electrical box (such as junction box and conduit body), using a clean cloth to remove any dirt, dust, or debris. This will help ensure a clean surface for the PVC cement to bond effectively.

- Apply PVC primer (if required): Some PVC cement manufacturers recommend applying a PVC primer to both the conduit and the box before applying the cement. The primer helps clean and prepare the surfaces for better adhesion. Check the manufacturer’s instructions to determine if primer application is necessary.

- Apply PVC cement: Apply a generous amount of PVC cement to the exterior of the conduit end, covering approximately 2 to 3 inches of the conduit’s length. Also, apply PVC cement to the interior of the hub opening on the box.

- Insert the conduit into the box: Firmly insert the conduit into the hub opening of the box, ensuring a tight and secure fit. Rotate the conduit slightly to evenly distribute the cement and create a strong bond between the conduit and the body.

- Hold in place: Hold the conduit in place for a few seconds to allow the PVC cement to set and create a strong connection. Follow the manufacturer’s recommended curing time for the PVC cement.

- Repeat for additional conduit connections: If connecting multiple conduits to the same conduit body, repeat steps 1 to 7 for each conduit.

- Allow for proper curing: After completing the connections, allow sufficient time for the PVC cement to fully cure according to the manufacturer’s recommendations before subjecting the installation to stress or pulling on the conduits.

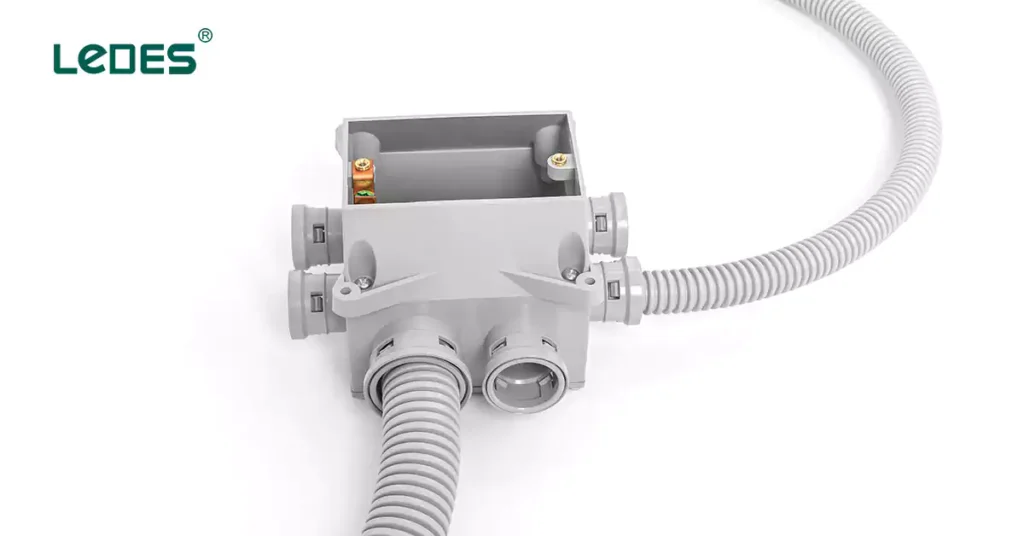

For these electrical boxes that designed with tabs, such as gang boxes, ceiling boxes, are normally connecting with flexible and corrugated conduit, these boxes’ connection require no additional tools or connectors. Here is a general guideline for connecting them to PVC flexible conduits and tubes.

- Prepare the corrugated conduit: Measure and cut the corrugated conduit to the desired length using a hacksaw or conduit cutter. Ensure that the conduit is cut squarely to create a clean and straight end.

- Inspect the electrical box: Check the box ( such as gang boxes and ceilings) for any damage or defects. Ensure that the tabs or connectors on the box are intact and in good condition for a proper connection.

- Align the conduit with the box: Hold the cut end of the corrugated conduit against the tabs or connectors on the box. Ensure that the conduit is aligned properly to fit securely onto the box.

- Push the conduit onto the box: Apply firm and even pressure to push the conduit onto the tabs or connectors of the box. It should slide or snap into place, creating a secure connection.

- Check the connection: Inspect the connection to ensure that the conduit is securely attached to the box. Verify that the tabs or connectors have engaged with the corrugations of the conduit, providing a tight and reliable connection.

- Repeat for additional conduit connections: If connecting multiple conduits to the same box, repeat steps 1 to 5 for each conduit.

- Ensure proper alignment and seating: Confirm that all the conduits are properly aligned and seated on the tabs or connectors of the box. This will help ensure a secure and reliable connection for the entire installation.

By following these steps, you can successfully connect PVC conduit to an electrical box, ensuring a safe and reliable electrical installation. It’s important to follow electrical codes and regulations and consult the manufacturer’s instructions for the specific conduit box and corrugated conduit you are using. If you are unsure or inexperienced with electrical work, it is recommended to seek assistance from a qualified electrician.

Plastic and metal electrical boxes each have their appropriate applications. Romex wire and plastic junction boxes are commonly paired, particularly for indoor receptacles, although metal enclosures may also be suitable depending on the project. Using metal conduit with plastic boxes is generally unsafe and against electrical codes.

While PVC can melt when overheated, it does not conduct electricity like metal. Use plastic boxes when non-metallic cables lead in or out of the box, as metal-sheathed wiring requires bonding with a metal electric box for grounding and should not be used in plastic boxes.

Let’s explore the scenarios where plastic or metal electrical boxes are commonly used and discuss their pros and cons.

Plastic electrical boxes, typically made of PVC or polycarbonate, offer several benefits that make them suitable for various installations

Pros:

Non-Conductive: Plastic boxes are non-conductive, which means they don’t conduct electricity. This property makes them ideal for situations where conductivity needs to be minimized, such as in damp or corrosive environments.

Ease of Installation: Plastic boxes are lightweight and easy to work with. They can be quickly installed using nails, screws, or adhesive. Their flexibility allows for straightforward adjustments and modifications.

Cost-Effective: Plastic boxes are generally less expensive than their metal counterparts. This affordability makes them a popular choice for residential applications and projects with budget constraints.

Corrosion Resistance: Plastic is resistant to corrosion, making plastic electrical boxes suitable for outdoor installations or areas exposed to moisture.

Cons:

Limited Strength: Plastic boxes may not be as sturdy as metal boxes, which can affect their suitability for heavy-duty applications or locations prone to physical impact.

Limited Heat Resistance: Plastic may not withstand high temperatures as well as metal. Therefore, plastic boxes are generally not recommended for installations that involve high wattage or heat-producing devices.

Metal electrical boxes, typically made of steel or aluminum, offer distinct advantages that make them suitable for specific applications:

Pros:

Durability and Strength: Metal boxes are highly durable and provide excellent protection for electrical connections. They are less prone to damage from impacts, making them suitable for industrial or commercial settings.

Heat Resistance: Metal boxes can handle higher temperatures better than plastic boxes, making them suitable for applications involving heat-producing devices or high-wattage circuits.

Grounding Capability: Metal boxes provide inherent grounding capabilities due to their conductive nature. This makes them necessary for grounding requirements in certain installations.

Cons:

Conductivity: Metal boxes conduct electricity, which can pose safety risks if not properly grounded. Care must be taken to ensure the box is grounded correctly to prevent electrical shocks.

Corrosion Potential: If exposed to moisture or corrosive elements, metal boxes can rust or corrode over time. Proper protective measures, such as using corrosion-resistant coatings or stainless steel boxes, should be considered for outdoor or damp environments.

Cost: Metal boxes are generally more expensive than plastic boxes due to the material and manufacturing processes involved.

In summary, here are some common scenarios where plastic or metal electrical boxes are typically used:

Plastic Electrical Boxes: Residential applications, dry indoor environments, cost-sensitive projects, non-conductive requirements, and installations where corrosion resistance is essential.

Metal Electrical Boxes: Commercial or industrial applications, outdoor installations, high-heat environments, grounding requirements, and locations that demand increased durability and impact resistance.

When choosing between plastic and metal electrical boxes, consider the specific installation requirements, budget, environmental conditions, and the electrical load involved. Always adhere to local electrical codes and regulations to ensure a safe and compliant installation.

When working with electrical systems, safety should be the top priority. Electrical installations involve inherent risks, and taking the necessary precautions is crucial for the well-being of both the installer and the occupants of the building. Here are some key safety considerations to keep in mind:

Working with electricity carries inherent dangers, including electric shock, burns, and fire hazards. It is essential to be aware of these risks and take appropriate safety precautions throughout the installation process. Some important safety measures to follow include:

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, such as insulated gloves, safety glasses, and protective clothing, to protect against electrical hazards.

- Ensure Competence: Electrical work should be carried out by individuals who are knowledgeable, trained, and experienced in electrical installations. If you are unsure about any aspect of the work, consult a qualified electrician.

- Maintain a Safe Working Environment: Keep the work area clean, organized, and free from potential hazards. Avoid working near water sources or in wet conditions.

- Use Proper Tools and Equipment: Utilize insulated tools specifically designed for electrical work. Inspect tools regularly for any damage and replace them if necessary.

Before making any connections to electrical boxes, it is critical to turn off the power supply to the circuit or area where the work will be performed. This precaution is essential to prevent electrical shocks and injuries. Follow these steps when shutting down the power supply:

- Identify the correct circuit breaker or fuse that controls the power to the specific area where the work will be done.

- Switch off the circuit breaker or remove the fuse, ensuring that the power is completely disconnected.

- Use a voltage tester to verify that there is no electrical voltage present in the circuit or wires before proceeding with any work.

To ensure the safety and compliance of electrical installations, it is vital to follow local electrical codes and regulations. These codes provide guidelines for proper installation, grounding, and other safety measures. Here are some key points to consider:

- Familiarize yourself with the applicable electrical codes and regulations in your area. These codes may vary depending on the jurisdiction.

- Adhere to the guidelines for the selection and installation of electrical boxes, conduit, connectors, and other components.

- Ensure proper grounding of electrical boxes as per the requirements outlined in the electrical codes. Improper grounding can lead to electrical hazards and equipment damage.

- Regularly inspect and maintain electrical installations to ensure they remain in compliance with the latest codes and regulations.

In conclusion, electrical boxes are everywhere and essential in electrical installations, there are many different types of electrical box, and each type may have different installation requirements, so proper installation of electrical boxes is crucial for the safety and functionality of electrical systems. Whether using plastic or metal electrical boxes, understanding their advantages, limitations, and appropriate applications is essential. By following the recommended guidelines and safety precautions, and also follow your local regulations, you can ensure a successful installation and minimize the risk of electrical hazards.

Any questions about electrical system solution, please contact us at any time.