Tabla de contenido

As electric vehicles (EVs) become more prevalent worldwide, setting up safe and effective charging infrastructure is critical to support the industry’s growth. One essential component is the conduit system, which protects the wiring that supplies power to EV chargers. This article explores international standards governing EV charging infrastructure, with a specific focus on conducto eléctrico requirements for safety, compatibility, and efficiency. We’ll look at standards such as IEC 61851 (International), SAE J1772 (USA), and GB/T 20234 (China) to compare how different regions address these needs.

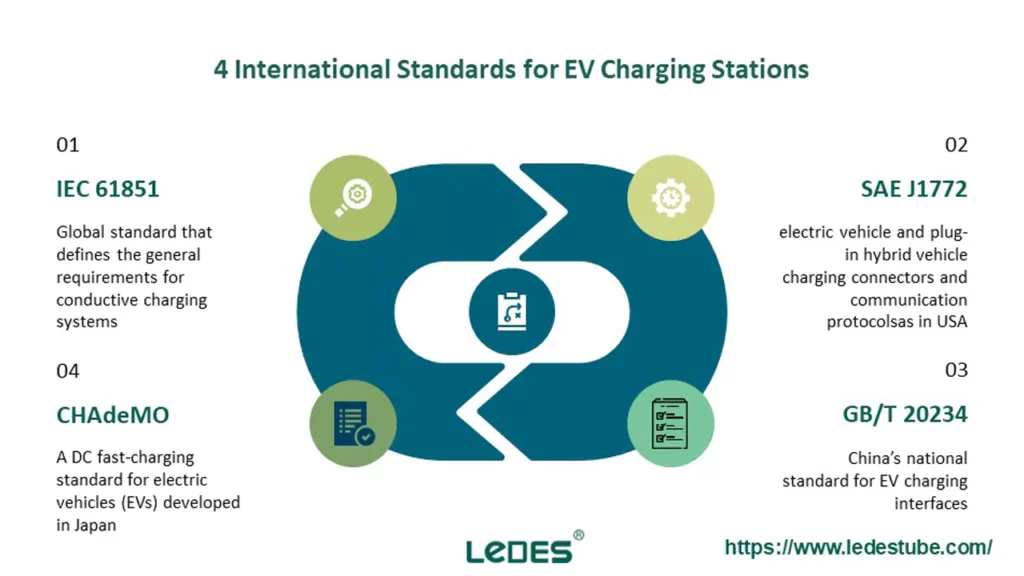

Four Key International Standards for EV Charging Stations

IEC 61851

IEC 61851 (International Electrotechnical Commission) is a global standard that defines the general requirements for conductive charging systems for electric vehicles. It sets guidelines for EV charging systems, including charging modes, cable requirements, and connector specifications.

Scope: Covers all four EV charging modes (from Mode 1 with basic AC charging to Mode 4 for fast DC charging – with a rated maximum voltage at side A of up to 1000V AC or up to 1500V DC and a rated maximum voltage at the side B up to 1500V DC).

Charging Types: Includes specifications for AC and DC charging.

Safety Requirements: Ensures protection from electric shocks, covers grounding, insulation, and temperature resistance.

SAE J1772

The SAE J1772 standard, established by the Society of Automotive Engineers in the United States, specifies requirements for electric vehicle and plug-in hybrid vehicle charging connectors and communication protocols. It primarily focuses on AC Level 1 and Level 2 charging, commonly used in the US for residential and public charging stations.

Cover: This standard covers the general physical, electrical, functional, and performance requirements to facilitate conductive charging of EV/PHEV vehicle in North America.

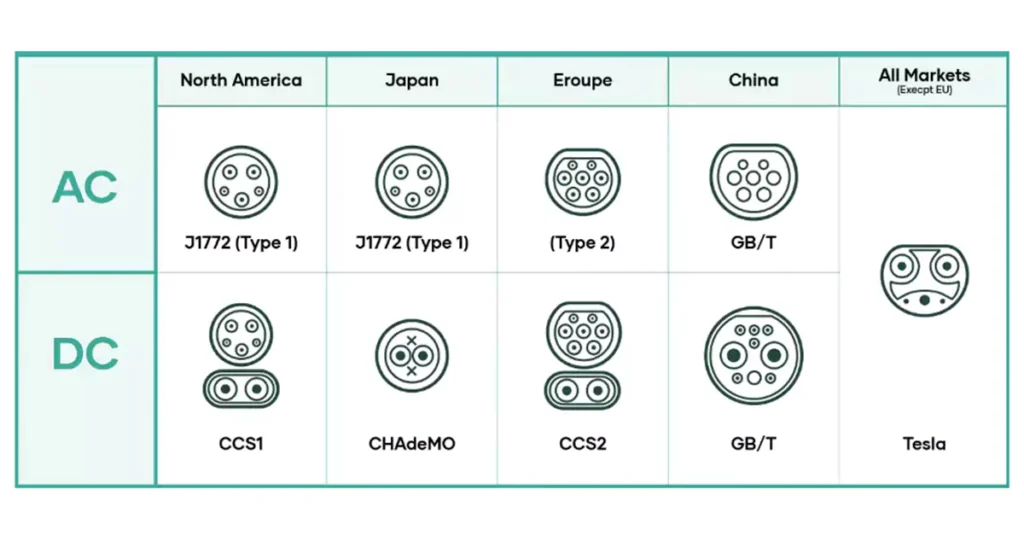

Connector Type: Standardized Type 1 connector for AC charging.

Voltage Requirements: AC Level 1 (120V) and Level 2 (240V).

Communication Protocols: Enables safe communication between the vehicle and charging equipment.

GB/T 20234

GB/T 20234 is China’s national standard for EV charging interfaces. It includes guidelines for AC and DC charging and is primarily adopted in China. Which defines the Plugs, socket-outlets, vehicle couplers and vehicle inlets for conductive charging of electric vehicles-General requirements.

Connector Type: Unique to China’s market, incompatible with IEC or SAE.

Voltage Levels: AC up to 220V for Level 2, and DC up to 750V for fast charging.

Protection Requirements: Specifies insulation resistance, ground continuity, and short-circuit protection.

CHAdeMO:

CHAdeMO (an abbreviation of “CHArge de MOve,” meaning “charge for moving”) is a DC fast-charging standard for electric vehicles (EVs) developed in Japan. It was introduced by a consortium that includes TEPCO (Tokyo Electric Power Company), Nissan, Mitsubishi, and Toyota and has become one of the most widely adopted fast-charging protocols globally. Originally designed to enable rapid DC charging, CHAdeMO has expanded significantly over the years to support high-power charging for larger vehicles, integrate bidirectional Vehicle-to-Grid (V2G) capabilities, and enhance global compatibility with other charging systems.

IEC 61851 Requirements for EV Charging Station

Key Provisions of IEC 61851

IEC 61851’s requirements span a range of important areas for EV charging stations, ensuring both safety and efficiency in real-world operation. Below are the critical sections within the IEC 61851 standard that installers, manufacturers, and regulators need to understand:

1. Charging Modes and Power Levels

IEC 61851 categorizes EV charging into four charging modes, each corresponding to specific applications, power levels, and safety requirements. The four modes help standardize the variety of EV charging speeds and setups, offering solutions suitable for both residential and commercial contexts. The following table provides a breakdown of these modes:

IEC 61851 Charging Modes Table

Mode |

Charging Type |

Current & Voltage |

Maximum Power |

Solicitud |

Safety Features |

Mode 1 | Basic AC charging | 16 A, 250V (single phase), 480V (three phases) | 3.7 kW | Residential, low power | Minimal; often lacks advanced safety |

Mode 2 | Enhanced AC charging | 32 A, 250V (single phase), 480V (three phases) | 7.4 kW | Home charging with added safety | Includes in-cable control and protection |

Mode 3 | Dedicated AC charging | 32 A, 250V (single phase), 480V (three phases) | 7.4 – 22 kW | Public stations, commercial | Grounding, RCDs, temperature control |

Mode 4 | High-power DC fast charging | 200 A, up to 400V | 50 – 400 kW | Highway fast chargers | Robust insulation, communication control |

Note: Modes 3 and 4 involve higher voltage and current levels, requiring more stringent protective measures to ensure user safety and prevent overheating.

2. Safety and Grounding Requirements

Safety is a cornerstone of IEC 61851, with emphasis on grounding and protection against electric shock. The standard requires residual current devices (RCDs) for Modes 3 and 4, designed to disconnect power in the event of a fault. For DC charging, grounding protocols are even more stringent due to the higher current levels involved. Here’s a summary of safety measures required by charging mode:

IEC 61851 Safety Required of Charging Mode

Charging Mode | Safety Measures | Protection Level |

Mode 1 | Minimal; relies on basic outlet protection | Bajo |

Mode 2 | In-cable protection, including overload protection | Moderado |

Mode 3 | RCDs, grounding, temperature monitoring | Alto |

Mode 4 | RCDs, insulation monitoring, thermal management | Very High |

3. Thermal Management and Environmental Resilience

High-power DC charging (Mode 4) generates substantial heat, and IEC 61851 specifies that stations must include adequate thermal management to prevent overheating. Additionally, the standard emphasizes UV and moisture resistance for outdoor equipment to protect against environmental degradation. The following table summarizes temperature and environmental resilience requirements:

IEC 61851 temperature & Environmental Summarizes

Environmental Factor | Requirement | Applicable Modes |

Temperature | Thermal management for temperatures over 50°C | Modes 3, 4 |

Resistencia a los rayos UV | Required for exposed outdoor conduits | Modes 2, 3, 4 |

Moisture Protection | Conduits must withstand high humidity levels | All Modes |

4. Interoperability and Communication

A unique aspect of IEC 61851 is its focus on interoperability. To ensure smooth operation across different manufacturers, the standard includes communication protocols that enable data exchange between the vehicle and charging station. These protocols cover battery status, charging rate adjustments, and other real-time parameters. This interoperability is crucial for fostering a unified charging experience, especially in public stations.

5. EMC Requirements

IEC 61851 mandates Electromagnetic Compatibility (EMC) compliance to reduce interference between EV chargers and other electronic devices, crucial in densely populated urban areas. Environmental requirements focus on durability and resilience to different weather conditions, as charging units often operate outdoors.

6. Communication Protocols

IEC 61851 emphasizes the vehicle-to-charger communication protocols that facilitate safe and controlled charging, including provisions for vehicle-to-grid (V2G) integration. The standard allows charging stations to implement ISO 15118 communication, enabling features such as:

Smart charging: Adjusting power levels based on grid capacity.

V2G support: Allows bi-directional power flow for grid stabilization.

User authentication: Facilitates secure, personalized charging sessions.

7. Connector Types and Safety Standards

IEC 61851 specifies Type 2 connectors for AC charging and Combined Charging System (CCS) Combo Type 2 for DC charging in European markets. Safety features include ground fault protection, overcurrent monitoring, and thermal management, which are critical for high-power applications.

Data Example: IEC 61851’s Mode 4 allows for ultra-fast DC charging up to 400 kW, supporting efficient high-speed charging infrastructure.

Why Compliance with IEC 61851 is Critical for EV Charging Stations

IEC 61851 is indispensable for ensuring safety, functionality, and consistency in EV charging. Compliance with IEC 61851 not only provides a standard framework for installation but also improves operational efficiency and minimizes risks associated with high-voltage electrical systems. By following this standard, manufacturers, installers, and regulatory authorities ensure that each EV charging station:

- Provides consistent, safe charging across various vehicle types and manufacturers.

- Minimizes the risk of electrical shock, overheating, and mechanical damage.

- Offers resilience against environmental factors like UV exposure, moisture, and high temperatures.

- Ensures interoperability for enhanced user convenience and universal access to charging.

SAE J1772 Requirements for EV Charging Station

SAE J1772, developed by the Society of Automotive Engineers (SAE) in the United States, is the North American standard for EV charging. Primarily used across the U.S. and Canada, SAE J1772 outlines specific requirements for connector types, charging levels, communication protocols, and safety measures. With a strong focus on residential and commercial charging, J1772 supports both AC Level 1 and Level 2 charging, as well as DC fast charging.

Key Components of SAE J1772 Requirements

The SAE J1772 standard addresses multiple technical and safety considerations to create a well-rounded charging experience for consumers. Below are the key components and specifications within the standard, accompanied by relevant tables and data.

1. Charging Connector Types and Power Levels

SAE J1772 specifies two main charging connector types for EVs: AC Level 1, AC Level 2, and DC fast charging. Each type offers different power outputs and charging speeds to meet various needs, from residential charging to high-speed public stations.

Charging Connector Types & Power Levels Date Sheet

Charging Type | Connector Type |

Voltage |

Current |

Power Output |

Uso principal |

AC Level 1 | J1772 Connector |

120V |

12-16A |

Up to 1.9 kW | Residential, overnight charging |

AC Level 2 | J1772 Connector |

240V |

Up to 80A |

Up to 19.2 kW | Residential and public |

DC Fast Charge | Combo Connector (CCS1) |

200-600V |

400A |

Up to 350kW (CCS1) | High-speed public charging |

Note: While Level 1 and Level 2 are AC charging, DC fast charging uses a Combined Charging System (CCS1) connector that combines AC and DC charging functionality for faster power delivery. SAE J1772 thus enables stations to cover a wide range of power levels, making it suitable for both private and public EV charging infrastructure.

2. Safety and Grounding Requirements

Safety is paramount in SAE J1772, with strict requirements for grounding and shock protection mechanisms. The standard includes the use of Ground Fault Circuit Interrupters (GFCIs) to automatically detect and interrupt current leakage, protecting users from electric shock. Additionally, overcurrent protection ensures that charging stations are safeguarded against excessive currents that could lead to overheating or equipment damage.

SAE J1772 Grounding Requirement

Charging Level | Required Safety Features | Protection |

AC Level 1 | GFCI, Basic grounding | Low to moderate |

AC Level 2 | GFCI, thermal management, overcurrent protection | Moderate to high |

DC Fast Charging | Grounding, insulation monitoring, robust RCDs | Alto |

Data Note: According to recent data, GFCIs used in Level 2 chargers reduce electric shock risks by up to 80% when properly installed, underscoring the importance of these protective measures in high-powered charging environments.

3. Basic Communication Protocols

Unlike IEC 61851, which supports advanced V2G capabilities, SAE J1772 is unique in its emphasis on communication between the vehicle and charging station. Through its Pilot Signal communication protocol, J1772 enables the vehicle and charging station to exchange key data regarding battery status, charging current levels, and safety checks. This feature not only facilitates efficient energy transfer but also enhances safety by allowing real-time monitoring and adjustments.

Pilot Signal Functionality:

- Allows the station to detect vehicle presence.

- Communicates charging current availability.

- Manages state-of-charge information y charging level adjustments.

SAE J1772 Communication Protocols

Pilot Signal Role | Function |

Vehicle Detection | Identifies whether an EV is connected |

Charging Level Adjustment | Adjusts current based on battery needs |

Fault Detection | Monitors for grounding or overcurrent faults |

By fostering interoperability between EVs and charging infrastructure, SAE J1772 ensures that vehicles from various manufacturers can utilize compatible stations, promoting a seamless charging experience across North America.

4. Environmental Considerations

SAE J1772 includes basic requirements for outdoor resilience, especially for high-powered Level 2 and DC fast charging, but doesn’t emphasize EMC as heavily as IEC standards. Conduits and enclosures are designed to withstand typical North American climates, with specifications for dust and moisture resistance in exposed installations.

For outdoor installations, the standard emphasizes UV resistance and moisture protection, ensuring that equipment can endure variable weather conditions without compromising safety or performance.

SAE J1772 4. Environmental Rules

Environmental Factor | Requirement | Applicable Charging Levels |

Temperature Control | Required for high-powered DC chargers | DC fast charging |

Resistencia a los rayos UV | Required for outdoor installations | All levels when used outdoors |

Moisture Protection | IP-rated enclosures for moisture exposure | Primarily for outdoor Level 2 and DC |

Importance of SAE J1772 Compliance for EV Charging Stations

SAE J1772 compliance is essential for ensuring safety, compatibility, and reliability in EV charging. Meeting these standards means that EV charging infrastructure can support a range of charging levels and vehicle types, offering both residential and commercial users a reliable and standardized charging experience. Compliance with J1772 also helps manufacturers align with North American safety standards, reducing liability risks and enhancing consumer confidence in EV technology.

GB/T 20234 Requirements for EV Charging Station

GB/T 20234 includes multiple standards that specifically govern AC and DC charging connectors, communication protocols, safety measures, and technical specifications. It is designed to accommodate China’s unique charging needs and aligns closely with the country’s push for sustainable urban transportation solutions. This introduction provides an overview of the key aspects of GB/T 20234, including data tables to illustrate the standard’s requirements for charging connectors, conduit types, power levels, and safety protocols.

Key Aspects of GB/T 20234 Requirements

The GB/T 20234 standard is composed of three primary sections, each dedicated to specific charging methods and designed to ensure a standardized approach across all EV charging systems in China.

1. Charging Connector Types and Power Levels

GB/T 20234 specifies distinct connectors for AC charging, DC charging, and DC fast charging, each tailored to suit different power demands and installation environments. The table below summarizes the key connector types and their power specifications, allowing for a versatile range of charging speeds:

GB/T 20234 Charging Connector Types & Power Levels Chart

Charging Type | Connector Type |

Voltage |

Current | Power Output | Uso principal |

AC Charging |

Type 1 GB/T |

220-240V |

10-32A |

Up to 7.7 kW | Residential, public slow charging |

DC Charging |

Type 2 GB/T |

450-750V |

Up to 80A |

Up to 60 kW | Public, high-speed charging |

DC Fast Charging | Type 3 GB/T | 450-1000V | Up to 250A | Up to 250 kW | Highway fast charging |

Note: AC charging is primarily used for residential settings or low-speed public charging stations, while DC and DC fast charging cater to high-power applications, providing rapid charging for longer travel distances.

2. Advanced Communication and SOC Monitoring

GB/T 20234 includes rigorous guidelines for communication protocols for real-time state-of-charge (SOC) monitoring and dynamic charging adjustments. Through Control Pilot Signals and Proximity Pilot Protocols, the GB/T standard enables the charging station to:

- Identify when a vehicle is connected and determine the charging current.

- Monitor and adjust the state of charge (SOC) in real-time.

- Detect faults or disconnect the power during emergency situations.

GB/T 20234 Communication and SOC Monitoring

Protocol Type | Objetivo | Functions |

Control Pilot Signal | Establishes connection and charging readiness | Vehicle detection, charging start/stop |

Proximity Pilot Protocol | Provides additional safety controls | Fault detection, emergency shutdown |

SOC Communication | Monitors battery status | Real-time SOC tracking, charging optimization |

3. Safety and Grounding Requirements

Safety protocols are critical to GB/T 20234, particularly for high-voltage DC fast charging stations. The standard specifies grounding measures, insulation monitoring, and thermal protection to ensure that users are safeguarded from electrical hazards, overheating, and potential equipment damage. This section is especially important for high-capacity chargers, which require advanced protective measures to manage significant current and voltage levels.

GB/T 20234 Grounding Requirements

Charging Type | Safety Measures | Protection Level |

AC Charging | Basic grounding, insulation checks | Low to moderate |

DC Charging | Overcurrent protection, RCDs, thermal control | Alto |

DC Fast Charging | Grounding, advanced insulation monitoring | Muy alto |

Data Note: Recent safety evaluations show that thermal control systems in DC fast chargers significantly reduce overheating incidents by up to 90% when used in conjunction with GB/T grounding requirements, indicating the effectiveness of these safety measures.

4. Environmental and Thermal Management Requirements

Thermal management is a significant focus in GB/T 20234 due to the high power output of DC fast charging stations, which can generate substantial heat. The standard mandates cooling mechanisms for chargers exceeding specific power levels and includes requirements for environmental protection, including UV resistance, moisture protection, and dust ingress prevention for outdoor equipment.

GB/T 20234 Environmental and Thermal Management

Environmental Factor | Requirement | Applicable Charging Types |

Temperature Control | Required for high-power DC charging stations | DC fast charging |

Resistencia a los rayos UV | Mandatory for exposed outdoor equipment | AC, DC, and DC fast charging |

Dust and Moisture Protection | IP54 or above-rated enclosures | All outdoor charging types |

Why GB/T 20234 Compliance is Essential for EV Charging Stations in China

Adhering to GB/T 20234 is vital for ensuring that charging infrastructure in China is safe, reliable, and compatible with a wide array of EVs. Compliance with this standard also helps reduce safety risks, improve user experience, and enable faster growth of the EV sector. For manufacturers, installers, and operators, GB/T 20234 provides a robust framework for building stations that meet China’s high standards for EV charging, allowing for:

- Uniform compatibility with all China-market EVs, ensuring ease of access for consumers.

- Enhanced safety through rigorous grounding, insulation, and temperature control.

- Durability in diverse climates, addressing UV exposure, moisture, and dust ingress.

- Optimized performance with standards for effective communication, SOC monitoring, and fault detection.

CHAdeMO Requirements for EV Charging Station

CHAdeMO has distinct technical requirements for connectors, voltage, current levels, communication protocols, and safety features, making it one of the pioneering standards in the fast-charging landscape.

Key Requirements of CHAdeMO

1. Voltage, Current, and Power Specifications

CHAdeMO’s specifications allow for efficient high-speed charging by delivering direct current (DC) directly to the vehicle’s battery. The standard initially supported a maximum of 50 kW of power, but recent versions have extended this capacity significantly, meeting the demands of next-generation EVs.

Voltage, Current, and Power Specifications for CHAdeMO

Version | Voltage Range | Current | Power Output | Aplicaciones |

CHAdeMO 1.0 | 50-500V DC | Up to 125A | Up to 50 kW | Older EV models, moderate fast charging |

CHAdeMO 2.0 | 50-1000V DC | Up to 400A | Up to 400 kW | Heavy-duty vehicles, highway fast charging |

CHAdeMO 3.0 (ChaoJi) | 200-1500V DC | Up to 600A | Up to 900 kW | Ultra-fast charging, supporting V2G |

Notable Data: CHAdeMO’s current maximum output of 900 kW (under the new ChaoJi connector version) places it among the fastest charging systems worldwide, making it suitable for heavy-duty and high-capacity EVs like buses and trucks, as well as personal EVs.

2. Connector Design and Compatibility

The CHAdeMO connector is a two-pin DC connector with an ergonomically designed interface, ensuring user safety and ease of use. The standard connector has 5 pins, two of which are dedicated to power delivery, and three are used for communication and safety checks.

The newest CHAdeMO version, CHAdeMO 3.0 (also called ChaoJi), introduces a smaller, more efficient connector that is backward compatible with CHAdeMO 2.0, ensuring existing stations can be upgraded easily. The ChaoJi connector is also compatible with CCS, providing flexibility and integration with other global standards.

3. Communication Protocols

CHAdeMO incorporates a highly reliable digital communication protocol that allows real-time monitoring and control over the charging process. This protocol manages:

- Battery monitoring: Real-time updates on the state of charge (SOC), battery health, and temperature.

- Dynamic power adjustment: Optimizes power delivery based on the vehicle’s SOC, reducing charging speed as the battery approaches full charge.

- Vehicle-to-Grid (V2G) capability: CHAdeMO was the first standard to incorporate bidirectional charging, allowing power to flow from the vehicle back to the grid, which supports energy management and grid stabilization.

4. Safety Requirements

Safety is central to the CHAdeMO standard, particularly at high-power levels. Key features include:

- Interlock Mechanism: Prevents the charging session from starting unless the connector is securely connected, reducing risks of accidental disconnection.

- Overcurrent and Overvoltage Protection: Ensures charging stops if electrical thresholds are exceeded, protecting both the EV battery and the charger.

- Thermal Management: Implements real-time monitoring of temperature to prevent overheating, particularly during high-current charging sessions.

5. CHAdeMO’s Role in Vehicle-to-Grid (V2G) Technology

CHAdeMO’s V2G capability has positioned it as a leader in bidirectional charging, which has significant implications for energy management and the adoption of renewable energy. This feature enables vehicles to:

Return power to the grid during peak demand, helping stabilize energy availability.

Support home energy needs as a backup power source in cases of outages.

The CHAdeMO protocol’s bidirectional charging is used in Japan and is being piloted in other regions as a way to make the energy grid more resilient and optimize renewable energy use.

6. Environmental and EMC Standards

CHAdeMO chargers are designed to function in diverse environmental conditions, given Japan’s climate variability. Requirements include:

- Protection from moisture, dust, and temperature fluctuations: Ensures reliable operation in both outdoor and indoor environments.

- Electromagnetic Compatibility (EMC) compliance: Reduces interference with other electronic devices, especially important in dense urban areas.

Distinctive Parts of IEC 61851, SAE J1772, and GB/T 20234 Requirements

IEC 61851, SAE J1772, and GB/T 20234 three standards all set the safety and installation requirements for EV charging stations, but there are some differences between them, here are the key differences:

IEC 61851 & SAE J1772 & GB/T 20234 Comparing

Standard | Region of Focus | Connector Type | Charging Levels Supported |

Communication | Unique Requirements |

IEC 61851 | Europe & International | IEC Type 2, CCS Combo Type 2 | Modes 1-4, including V2G | Advanced, includes ISO 15118 | Global compatibility, EMC, diverse modes, V2G |

SAE J1772 | América del norte | J1772 for AC, CCS1 for DC | AC Level 1, AC Level 2, DC Fast | Basic pilot signal, simpler protocols | Standardized connectors, high safety focus, 80A AC Level 2 |

GB/T 20234 | Porcelana | GB/T proprietary connectors | AC, DC, Ultra-Fast (up to 250kW) | Comprehensive real-time SOC monitoring | High DC capacity, robust environmental standards |

CHAdeMO | Japan, with adoption in EU and globally | CHAdeMO (2.0), ChaoJi (3.0) | Primarily DC Fast, high-power DC up to 900 kW | CAN bus, CHAdeMO-specific digital protocol | Pioneering V2G, high-power DC, backward-compatible with CCS |

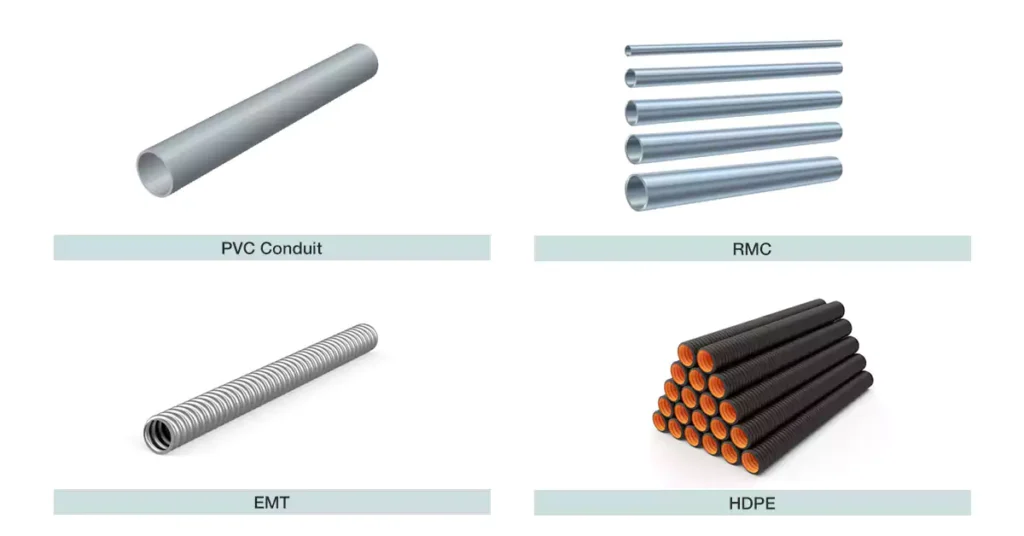

4 Commonly Used Conduit Types in EV Charging Stations

The conduit system is crucial for protecting the electrical wiring in EV charging infrastructure. Various conduit types offer different levels of protection, flexibility, and cost-effectiveness. Below is a breakdown of the most common conduit types used in EV charging stations.

Conducto de PVC

PVC conduit like Conducto Schedule 40 y Sch 80 PVC conduit are widely used due to their affordability, ease of installation, and resistance to moisture and corrosion. PVC is generally suitable for outdoor installations as well, provided it’s protected from direct sunlight.

Rigid Metallic Conduit (RMC)

RMC is a heavy-duty conduit made from galvanized steel or aluminum, offering robust protection against physical damage and excellent fire resistance. It’s ideal for high-traffic public charging stations or areas where security is a concern.

Tubos Metálicos Eléctricos (EMT)

EMT is a lightweight, thin-walled conduit made from aluminum or steel. It is easy to bend and install, making it ideal for indoor installations or areas where flexibility is required.

High-Density Polyethylene Conduit (HDPE)

HDPE conduit stands for High-Density Polyethylene conduit, a type of plastic conduit made from high-density polyethylene material, known for its flexibility, durability, and environmental resistance. It is commonly used for protecting electrical and data cables, especially in underground and outdoor applications.

4 Commonly Used Electrical Conduit in EV Charging Stations

Tipo de conducto | Material | Best Use Case | Ventajas | Contras |

PVC (Schedule 40/80) | Plastic | Underground, exposed with Schedule 80 | Lightweight, corrosion-resistant | Brittle in cold, limited heat tolerance |

CMR | Metal | Exposed outdoor areas | High durability, fire-resistant, grounding | Heavy, costly, labor-intensive |

Técnico en emergencias médicas | Metal | Indoor or protected locations | Lightweight, cost-effective for indoor use | Limited outdoor use, less impact-resistant |

HDPE | Plastic | Underground long runs | Flexible, impact-resistant, corrosion-resistant | Not suitable for high heat, limited UV resistance |

If you are interested in the NEC code compliance for electrical conduits, you can read our earlier post, ‘NEC Code Compliance for EV Charging Stations.‘

Smart Conduits: Enhancing EV Charging with Real-Time Monitoring

As the demand for EV charging infrastructure grows, so does the need for more advanced and intelligent conduit systems that go beyond basic cable protection. Smart conduit technology is emerging as a promising innovation for real-time monitoring, data analytics, and predictive maintenance, offering a range of potential benefits:

1. Real-Time Monitoring and Diagnostics

Embedded Sensors: Smart conduits can incorporate sensors to monitor conditions such as temperature, humidity, and pressure inside the conduit, offering real-time data on the environment surrounding the electrical wiring.

Electrical Monitoring: Sensors can detect voltage, current, and potential power fluctuations in the wiring. Any anomalies can be flagged immediately, preventing potential equipment failures or safety hazards.

Leak and Moisture Detection: Moisture and leak sensors can detect water ingress in underground or exposed conduits, allowing operators to address these issues before they cause cable damage or service interruptions.

2. Data Collection and Analytics

Data Aggregation: Smart conduits can continuously collect data on environmental conditions, electrical load, and system performance. This data can be aggregated and analyzed to identify trends and patterns in power usage and system health.

Predictive Analysis: With data analytics, operators can anticipate potential issues by identifying conditions that historically precede failures, enabling proactive repairs and minimizing downtime.

Usage Optimization: Data on charging patterns and power demand can help optimize energy distribution and predict peak usage times, allowing for improved resource management and efficiency.

3. Predictive Maintenance

Failure Prediction: By continuously monitoring data points like temperature spikes, abnormal electrical loads, or conduit aging, smart conduits enable predictive maintenance. This means issues can be addressed before they escalate, which reduces maintenance costs and enhances safety.

Asset Longevity: Predictive maintenance extends the service life of cables and equipment by preventing issues like overheating, which could degrade components over time.

Ahorro de costes: Early detection of wear and tear allows for timely repairs or replacements, reducing the likelihood of expensive emergency repairs and prolonged service interruptions.

4. Integration with Charging Station Management Systems

Data Sharing: Smart conduits can share real-time and historical data with EV charging station management systems, providing a comprehensive view of the station’s health and performance.

Remote Diagnostics: Integration enables remote monitoring, so station operators can troubleshoot issues without having to visit each location physically. This remote capability is especially beneficial for large networks of charging stations.

Automated Alerts: Many smart conduits can trigger automated alerts for issues like overcurrent, overheating, or moisture, allowing operators to react swiftly to minimize risks.

5. Environmental and Regulatory Compliance

Tracking Energy Consumption: Smart conduits can log energy usage, providing data that can help with regulatory compliance and reporting requirements. Accurate energy tracking supports sustainability goals and compliance with standards on energy efficiency.

Support for Data-Driven Decision Making: The insights generated by smart conduits help operators make informed decisions about capacity planning, infrastructure expansion, and maintenance scheduling.

Conclusión

International standards play a crucial role in guiding EV charging station infrastructure, with conduit systems designed to ensure safe and effective power delivery. By comparing IEC 61851, SAE J1772, and GB/T 20234, and CHAdeMO we see varying approaches to safety, conduit materials, and technical specifications based on regional priorities. When choosing a conduit for EV charging installations, factors like environmental exposure, conduit material properties, and compliance with local standards are essential for a durable, safe setup that meets the global demand for reliable EV infrastructure.