Tabla de contenido

Los conductos eléctricos son sistemas de tubos protectores que se utilizan para alojar y proteger el cableado eléctrico. Cumplen múltiples propósitos, entre ellos, proteger los cables de daños físicos, exposición ambiental e interferencias electromagnéticas. Los conductos son esenciales para garantizar la seguridad y la longevidad de las instalaciones eléctricas. Se utilizan en diversas aplicaciones. En este artículo, exploraremos los conductos que se utilizan para automóviles y los Principales fabricantes de conductos para automóviles en EE. UU..

Los conductos automotrices son tubos o carcasas protectoras que se utilizan para revestir y proteger el cableado y los componentes eléctricos de los vehículos. Actúan como barrera contra daños físicos, condiciones ambientales e interferencias eléctricas. Estos conductos son fundamentales para mantener la integridad de los sistemas eléctricos y garantizar un rendimiento confiable en los vehículos. Se utilizan tanto en vehículos convencionales como en vehículos eléctricos (VE), donde la gestión eficiente de los sistemas eléctricos es primordial debido a la creciente complejidad de las tecnologías automotrices modernas.

El uso de conductos automotrices ofrece varias ventajas, entre ellas:

- Protección contra riesgos medioambientales: Los conductos automotrices protegen el cableado de la humedad, los productos químicos, las abrasiones y las temperaturas extremas, lo que garantiza longevidad y confiabilidad.

- Seguridad mejorada: Al evitar cortocircuitos y fallas eléctricas, los conductos contribuyen a la seguridad general del vehículo.

- Organización: Los conductos ayudan a agilizar el enrutamiento de cables y alambres, reduciendo el desorden y simplificando el mantenimiento.

- Flexibilidad y adaptabilidad: Muchos conductos automotrices están diseñados para ser flexibles, lo que facilita la instalación en espacios reducidos o configuraciones de cableado complejas.

- Cumplimiento de normas: Los conductos automotrices están diseñados para cumplir con los estándares de la industria, garantizando que puedan soportar los rigores de los entornos automotrices.

Los conductos para automóviles están disponibles en varias formas, cada una diseñada para satisfacer requisitos de protección específicos dentro de los vehículos. Los tipos más comunes incluyen:

- Conductos flexibles no metálicos: Fabricados con materiales como PVC o nailon, estos conductos son ligeros, flexibles y resistentes a la humedad y a los productos químicos, adecuados para espacios reducidos y áreas de mucho movimiento.

- RMC (Conducto metálico rígido): Fabricado en acero galvanizado o aluminio de alta resistencia, el RMC proporciona una protección mecánica superior y es muy duradero. Se utiliza normalmente en zonas expuestas a fuertes impactos o que requieren una seguridad física sólida, como los bajos del vehículo y los compartimentos del motor.

- EMT (Tubería Metálica Eléctrica): Más liviano que el RMC, pero aún metálico, el EMT se usa a menudo en aplicaciones donde se necesita resistencia pero las limitaciones de espacio son un problema. Generalmente se prefiere para la protección del cableado estructurado en entornos menos hostiles dentro del vehículo.

- Conductos libres de halógenos y con baja emisión de humo (LSHF): Estos conductos emiten un mínimo de humo y gases tóxicos si se exponen al fuego, lo que los hace ideales para aplicaciones de vehículos eléctricos donde la seguridad de los pasajeros es fundamental.

Los sistemas de conductos para automóviles se utilizan estratégicamente en vehículos eléctricos y tradicionales para proteger el cableado y optimizar el rendimiento. Las aplicaciones comunes incluyen:

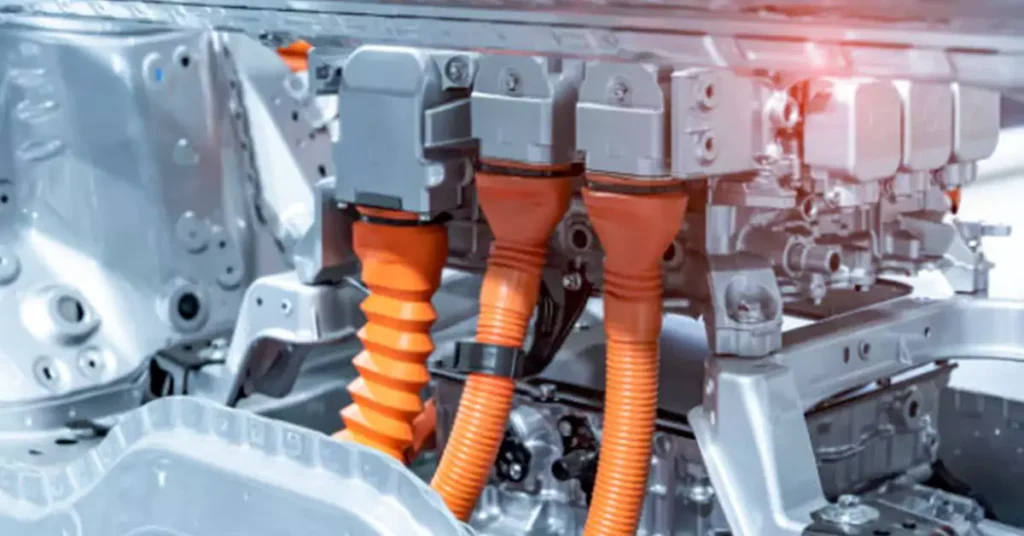

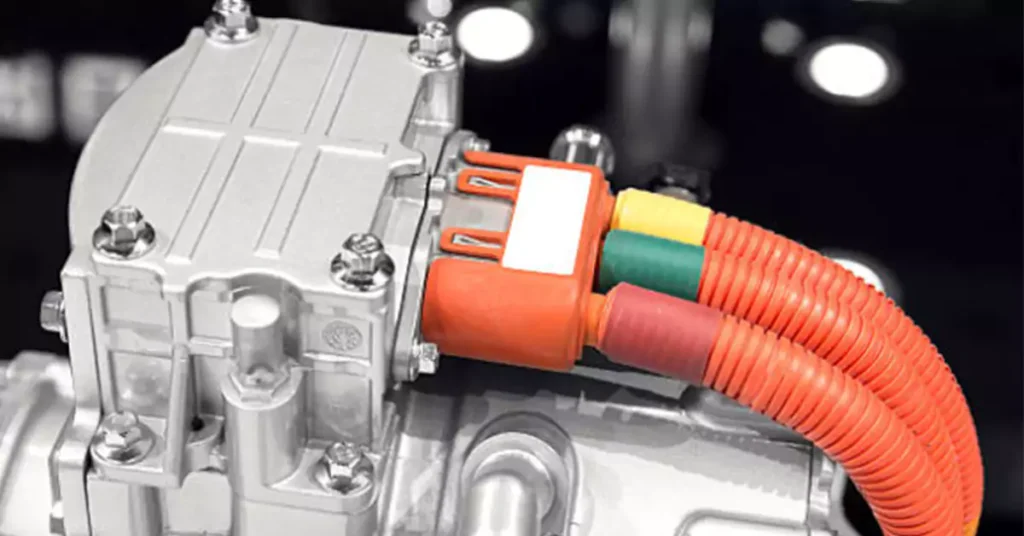

Protección del cableado de la batería: Especialmente cruciales en los vehículos eléctricos, los conductos protegen los cables de alto voltaje contra daños y previenen fallas eléctricas, extendiéndose desde la batería hasta el motor y los sistemas de distribución de energía.

Protección de bajos: Los conductos utilizados a lo largo de la parte inferior de la carrocería protegen el cableado de los residuos de la carretera, la humedad y la exposición a productos químicos, lo que garantiza la confiabilidad y reduce la corrosión en condiciones de conducción difíciles.

Motor y tren motriz: Tanto en los vehículos eléctricos como en los convencionales, el compartimento del motor es una zona de alta temperatura y alta vibración. Los conductos RMC y EMT se utilizan habitualmente en esta zona debido a su resistencia a la temperatura y a los impactos.

Cableado de cabina: Los conductos utilizados dentro de la cabina del vehículo organizan y protegen los sistemas eléctricos contra interferencias, garantizando el buen funcionamiento de los controles, pantallas y sistemas de información y entretenimiento.

Puertos de carga e infraestructura para vehículos eléctricos: Los conductos herméticos y de HDPE a menudo se aplican cerca de los componentes de carga y la infraestructura de los vehículos eléctricos para evitar la humedad, lo que es vital para la seguridad y el rendimiento eléctricos a largo plazo.

Los conductos para automóviles deben cumplir con las normas de la industria para garantizar la seguridad y la confiabilidad. Las normas clave incluyen:

Normas SAE: La Sociedad de Ingenieros Automotrices (SAE) proporciona especificaciones para materiales y métodos de prueba relacionados con componentes automotrices.

Normas ISO: La Organización Internacional de Normalización (ISO) establece estándares globales que los fabricantes deben seguir en materia de calidad y seguridad.

Normas UL: Underwriters Laboratories (UL) establece estándares de seguridad para componentes eléctricos, garantizando que cumplan con rigurosos requisitos de pruebas.

Estos tipos de conductos automotrices, junto con el cumplimiento de los estándares de la industria, son fundamentales para el avance de soluciones eléctricas seguras y de alto rendimiento en toda la industria automotriz. A medida que avanza la tecnología de vehículos eléctricos, estos conductos seguirán desempeñando un papel fundamental en la seguridad, la eficiencia y la longevidad de los sistemas eléctricos de los vehículos.

Los conductos para automóviles son componentes fundamentales que protegen el cableado del vehículo del calor, la vibración, la humedad y otros peligros ambientales. A medida que los vehículos eléctricos (VE) y las tecnologías automotrices avanzadas se vuelven más comunes, estos conductos desempeñan un papel esencial para garantizar la seguridad y la confiabilidad. A continuación, se enumeran los diez principales proveedores de conductos para automóviles en los EE. UU., cada uno de los cuales ofrece soluciones especializadas para satisfacer las estrictas demandas del sector automotriz.

Descripción general de la empresa

El Grupo ABB, con sede en Zúrich y una fuerte presencia en Estados Unidos, es una potencia en soluciones de energía y automatización. Conocida por su experiencia tecnológica y su amplia cartera de productos, la división de conductos de ABB es muy valorada por su rendimiento en aplicaciones automotrices críticas, especialmente en sistemas de alto voltaje y sistemas de propulsión de vehículos eléctricos.

Enfoque en innovación y tecnología

Los conductos flexibles PMA de ABB utilizan polímeros de última generación diseñados para ofrecer una gran flexibilidad y durabilidad. Estos conductos se utilizan a menudo en los compartimentos de las baterías de los vehículos eléctricos, donde protegen el cableado de alta tensión del calor y la tensión mecánica. ABB también está a la vanguardia del desarrollo de materiales resistentes a la temperatura que abordan necesidades específicas de los sistemas de vehículos eléctricos, como la gestión térmica de los compartimentos de las baterías.

Productos clave:

- Conductos PMA: Durable y flexible, ideal para cableado de vehículos eléctricos de alto voltaje y compartimentos de motor.

- Conductos estancos a líquidos: Diseñado para áreas expuestas a la humedad, sal y otros contaminantes, garantizando una protección confiable.

- Conductos de alta temperatura: Adecuados para el compartimiento del motor, estos conductos están diseñados para soportar temperaturas extremas.

Ventajas

La ventaja de ABB reside en su investigación y desarrollo globales y en sus soluciones basadas en tecnología que se someten a pruebas rigurosas para cumplir con los estándares de la industria automotriz. Sus productos PMA son reconocidos por su confiabilidad y se utilizan comúnmente en aplicaciones de vehículos eléctricos.

Compromiso de sostenibilidad

ABB concede una gran importancia a la sostenibilidad. Las iniciativas medioambientales de la empresa incluyen el desarrollo de materiales reciclables y la producción de conductos con un impacto medioambiental mínimo, en consonancia con el creciente interés de la industria automovilística por los componentes ecológicos. Los conductos de ABB también están diseñados para un desmontaje sencillo, lo que facilita el reciclaje al final del ciclo de vida de un vehículo.

Reconocimiento y alianzas con la industria

ABB colabora estrechamente con los principales fabricantes de equipos originales de la industria automotriz para garantizar que sus conductos cumplan con los estrictos requisitos de los sistemas híbridos y de vehículos eléctricos. Con una reputación de durabilidad e ingeniería de alta calidad, ABB suele ser un proveedor preferido para los fabricantes que buscan soluciones de conductos confiables y duraderas.

Descripción general de la empresa

Lapp Group USA, la filial estadounidense del grupo alemán Lapp, tiene una sólida reputación en el suministro de sistemas de gestión de cables y conductos de alta calidad. Sus raíces en la ingeniería alemana enfatizan la precisión y la confiabilidad, con productos diseñados para cumplir con los estrictos estándares automotrices.

Gama de productos:

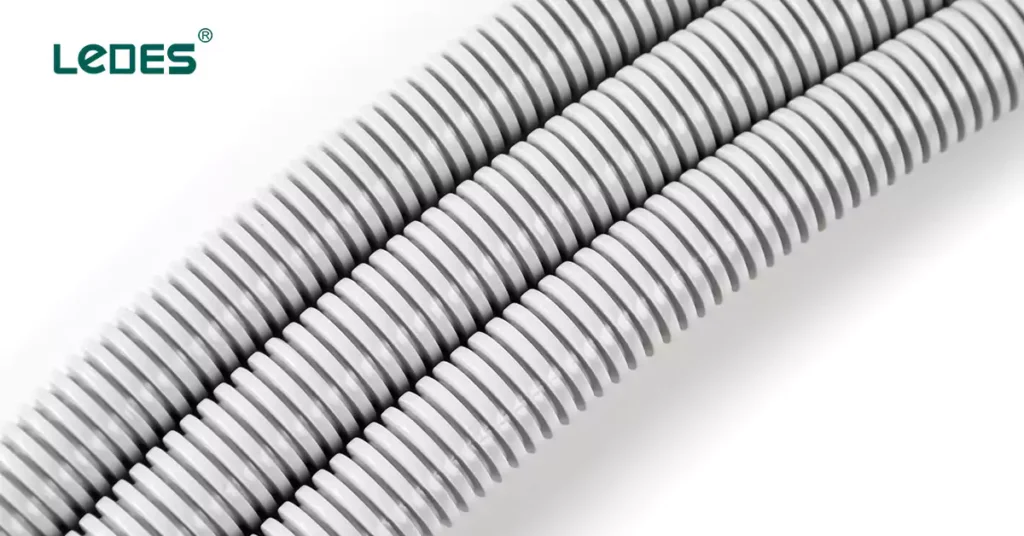

- Conductos corrugados flexibles:Estos conductos proporcionan flexibilidad y resistencia, lo que los hace ideales para áreas de alta vibración dentro de los vehículos.

- Conductos libres de halógenos y con baja emisión de humo (LSHF): Utilizados en vehículos eléctricos, estos conductos reducen las emisiones tóxicas en caso de incendio.

- Prensaestopas de protección: Los prensaestopas de Lapp aseguran los extremos de los conductos y protegen contra factores estresantes externos como el agua y el polvo.

Especialización de productos

De Lapp Conductos libres de halógenos y con baja emisión de humo (LSHF) Son una oferta destacada, especialmente adecuada para aplicaciones de vehículos eléctricos donde la seguridad contra incendios es fundamental. Estos conductos producen un humo tóxico mínimo en caso de incendio, lo que los hace muy adecuados para sistemas de baterías densamente compactas y cableado de vehículos eléctricos. Este enfoque de producto aborda directamente las preocupaciones de seguridad asociadas con los sistemas de alto voltaje en los vehículos modernos.

Fabricación sostenible

Lapp se dedica a la producción ecológica, incorporando materiales reciclables y procesos energéticamente eficientes en sus instalaciones. Al minimizar los desechos y las emisiones, Lapp se posiciona como una opción sustentable para las empresas automotrices que priorizan las cadenas de suministro responsables con el medio ambiente.

Soporte de ingeniería y personalización

El enfoque de Lapp está centrado en el cliente y ofrece soluciones de conductos a medida para aplicaciones automotrices específicas. El equipo de ingeniería de la empresa trabaja en estrecha colaboración con los clientes para desarrollar conductos que se ajusten a especificaciones particulares, desde ajustes dimensionales hasta mejoras de rendimiento según los requisitos de uso final.

Descripción general

Ledes Conduit es un fabricante líder de conductos para automoción y soluciones de protección eléctrica, que se centra en la innovación y la calidad de su gama de productos. Con una amplia experiencia en la industria, Ledes se ha convertido en un nombre de confianza en la industria de la protección eléctrica.

Amplia gama de productos

Ledes ofrece una amplia gama de productos diseñados a medida para diversas necesidades industriales y de automoción. Entre sus productos se incluyen conductos de PVC Schedule 40 y Schedule 80, que se utilizan ampliamente debido a su durabilidad, propiedades de ligereza y resistencia a la corrosión. La empresa también ofrece conductos ENT (tubos eléctricos no metálicos) y solares diseñados específicamente para proteger el cableado en aplicaciones de energía renovable, así como opciones de conductos flexibles y rígidos adecuados para instalaciones automotrices complejas. Sus conductos sin halógenos y con baja emisión de humo son especialmente críticos en aplicaciones de vehículos eléctricos, donde la seguridad contra incendios es primordial, ya que minimizan las emisiones de humo tóxico en caso de combustión.

Productos clave

- Conductos de PVC Schedule 40 y Schedule 80: Ideal para aplicaciones automotrices generales, brinda protección resistente a la corrosión.

- Conductos ORL: Conducto flexible de PVC y fácil de instalar, adecuado para rutas de cableado complejas.

- Conductos solares: Diseñado para aplicaciones de energía renovable, proporciona resistencia a los rayos UV y a la intemperie.

- Conductos libres de halógenos y con baja emisión de humo: Reduce las emisiones de humo tóxico, mejorando la seguridad en vehículos eléctricos y aplicaciones de cableado de alta densidad.

- Conductos flexibles y rígidos: Ofrece versatilidad Conductos para diversos entornos automotrices.

- Productos personalizados: Soluciones personalizadas basadas en necesidades específicas del cliente.

Compromiso con la calidad y el cumplimiento

Ledes cumple con estrictos estándares de seguridad y rendimiento, y sus productos están certificados por organizaciones líderes como UL, CSA, AS/NZS e IEC. Estas certificaciones garantizan que los conductos Ledes cumplen con los estándares internacionales, lo que brinda a los clientes confianza en la confiabilidad y el cumplimiento de sus soluciones de conductos. La dedicación de la empresa a la calidad la ha convertido en la opción preferida de los fabricantes de equipos originales de la industria automotriz que buscan cumplir con las estrictas regulaciones de la industria.

Centrarse en la personalización y la satisfacción del cliente

Ledes pone un gran énfasis en la satisfacción del cliente y ofrece productos de conductos personalizados que cumplen con los requisitos específicos de la industria automotriz. Ya sea que los clientes necesiten dimensiones de conductos especiales o características mejoradas para aplicaciones únicas, Ledes ofrece soluciones personalizadas para satisfacer diversas necesidades, lo que garantiza que cada producto brinde un rendimiento óptimo en entornos desafiantes.

Descripción general de la empresa

Con sede en Illinois, Panduit es un proveedor líder de soluciones eléctricas y de infraestructura, con un enfoque importante en sistemas de conductos que satisfacen las necesidades industriales y automotrices. Panduit, conocida por su innovación, invierte con frecuencia en investigación para mejorar la durabilidad y la adaptabilidad de sus productos en entornos hostiles.

Soluciones resistentes al calor para aplicaciones de vehículos eléctricos

Panduit ha desarrollado una gama de conductos diseñados específicamente para entornos con altas temperaturas, como los paquetes de baterías de vehículos eléctricos y los compartimentos del motor. Estos conductos pueden soportar el estrés térmico asociado a los sistemas de alto voltaje, lo que los convierte en una opción adecuada para los vehículos eléctricos de próxima generación. Su revestimiento resistente al calor es especialmente valorado por los fabricantes de vehículos eléctricos que buscan soluciones duraderas para proteger el cableado delicado.

Productos clave:

- Conductos corrugados de alto rendimiento: Diseñado para áreas de alta vibración, adecuado para sistemas de cableado complejos en vehículos eléctricos.

- Manguito resistente al calor: Ideal para compartimentos de motor, donde los cables necesitan protección adicional contra el calor extremo.

- Conductos estancos a líquidos: Adecuado para cableado debajo de la carrocería expuesto a la humedad y contaminantes de la carretera.

Reputación y alcance del mercado

Panduit se ha ganado una sólida reputación en el sector automotriz por sus soluciones confiables y duraderas. Es un nombre reconocido por los clientes que buscan sistemas de conductos que funcionen de manera constante en condiciones extremas, como compartimentos de motor con alta vibración o compartimentos de baterías con altas temperaturas.

Descripción general

Anamet Electrical, con sede en Illinois, se especializa en conductos flexibles metálicos y no metálicos diseñados para aplicaciones de alta durabilidad. Sus productos se utilizan ampliamente en entornos automotrices que requieren tanto flexibilidad como resistencia, como compartimentos de motor y sistemas de cableado debajo de la carrocería.

Productos clave:

- Conducto flexible hermético a líquidos: Se utiliza en áreas con alta humedad, como compartimentos de baterías de vehículos eléctricos.

- Conductos de alta abrasión: Proporciona una protección robusta en áreas propensas a daños mecánicos.

- Conductos resistentes a la corrosión: Diseñado para áreas expuestas a fluidos automotrices y sales de la carretera.

Personalización y durabilidad

Anamet es conocida por sus conductos metálicos de alta resistencia a la abrasión y conductos resistentes a la corrosión que ofrecen una protección excepcional contra el desgaste mecánico y la exposición a sustancias químicas. La empresa es experta en personalizar soluciones de conductos para cumplir con requisitos automotrices específicos, como recubrimientos de resistencia extra a la abrasión o aleaciones especializadas para la seguridad del sistema de combustible.

Reconocimiento del mercado para aplicaciones robustas

La reputación de Anamet en cuanto a su resistencia la ha convertido en la opción preferida entre los fabricantes de equipos originales y los clientes del sector automotor que buscan sistemas de conductos robustos que puedan soportar condiciones extremas. Sus productos son especialmente valorados en áreas que son muy susceptibles a sufrir daños por residuos de la carretera, productos químicos y fluctuaciones de temperatura.

Descripción general de la empresa

Electri-Flex, con sede en Illinois, se especializa en soluciones de conductos flexibles con altos niveles de resistencia a la abrasión y al medio ambiente. Conocidos por su enfoque en la calidad, los productos Electri-Flex son ideales para aplicaciones automotrices donde la flexibilidad y la resistencia son esenciales.

Productos clave:

- Conductos herméticos a líquidos y resistentes a la corrosión: Perfecto para ambientes corrosivos y con alta humedad.

- Conductos extraflexibles: Ideal para espacios reducidos dentro de los arneses de cableado del vehículo.

- Conductos de baja emisión de humo: Reduce las emisiones peligrosas en caso de incendio, proporcionando una medida de seguridad adicional.

Enfoque ambiental

Electri-Flex se centra en la producción de conductos flexibles herméticos que protegen el cableado de la humedad, el polvo y otros contaminantes ambientales. Estos productos son ideales para vehículos eléctricos y otras aplicaciones automotrices que requieren protección del cableado contra la exposición al agua.

Reputación y reconocimiento en el mercado

Electri-Flex es ampliamente reconocido en el sector automotriz por sus productos confiables y adaptables. Numerosos fabricantes de automóviles utilizan sus conductos debido a su calidad y facilidad de instalación en espacios difíciles.

Descripción general de la empresa

Hellermann Tyton es líder mundial en productos de protección y gestión de cables, con un fuerte enfoque en soluciones para la industria automotriz. Las operaciones de la empresa en Estados Unidos producen una gama de sistemas de conductos innovadores, con opciones diseñadas específicamente para vehículos eléctricos y entornos de cableado de alta densidad.

Innovación en protección de cables

Hellermann Tyton es conocida por desarrollar conductos con opciones de sujeción integradas, que simplifican la instalación y brindan mayor seguridad para los sistemas de cableado automotriz. Una de las innovaciones de Hellermann Tyton es su Soluciones de conductos con clip, que simplifican la instalación del cableado al incorporar características de sujeción que fijan el cableado en su lugar. Estas soluciones son particularmente valiosas para áreas con alta vibración donde la integridad del cableado es fundamental.

Productos clave:

- Sistemas de conductos con clip: Simplifica la instalación del cableado, garantizando una fijación segura en áreas de alta vibración.

- Conductos resistentes a la abrasión: Ideal para cableado sujeto a movimiento frecuente.

- Prensaestopas integrados: Proporciona protección confiable contra el polvo y la humedad, cruciales en los vehículos eléctricos.

Prácticas de sostenibilidad

Hellermann Tyton integra prácticas ecológicas en su fabricación, centrándose en la reducción de residuos y emisiones. Este enfoque lo convierte en una opción atractiva para los fabricantes de automóviles con iniciativas de sostenibilidad, ya que ofrece soluciones de conductos ecológicas y confiables.

Descripción general

Cantex Inc. es un importante fabricante de conductos y accesorios eléctricos de PVC con sede en EE. UU. que atiende a una amplia gama de industrias, incluida la automotriz. Fundada en 1982, la empresa se ha ganado una sólida reputación por la calidad, la confiabilidad y la innovación en sus ofertas de productos.

Especialización en Conductos de PVC

Cantex se especializa en la producción de conductos de PVC Schedule 40 y Schedule 80, que son livianos, resistentes a la corrosión y muy duraderos. Estos conductos son particularmente adecuados para aplicaciones automotrices donde la protección contra factores ambientales como la humedad, los productos químicos y la exposición a los rayos UV es fundamental. Sus conductos son ideales para enrutar cableado en áreas donde los conductos de metal serían propensos a oxidarse o corroerse.

Productos clave

- Conductos de PVC: Ligero y resistente a la corrosión, ideal para diversas aplicaciones automotrices.

- Accesorios eléctricos: Compatible con sus conductos, garantizando instalaciones seguras y confiables.

- Soluciones personalizadas: Productos de conductos personalizados para satisfacer necesidades automotrices específicas.

Compromiso con la calidad y el cumplimiento

Cantex hace hincapié en el estricto cumplimiento de las normas de la industria, incluido el cumplimiento de las certificaciones del Código Eléctrico Nacional (NEC) y de Underwriters Laboratories (UL). Este compromiso con la calidad garantiza que sus conductos cumplan con los rigurosos estándares de seguridad y rendimiento que exigen los fabricantes de automóviles.

Reconocimiento del mercado y alianzas

Cantex ha ganado reconocimiento como proveedor confiable en la industria automotriz, particularmente entre los fabricantes de equipos originales y los proveedores de repuestos. Su extensa red de distribución permite una entrega eficiente, asegurando que los clientes reciban productos de alta calidad con prontitud.

Descripción general

Teaflex USA es un actor emergente en el mercado de conductos para automóviles, conocido por su enfoque innovador en soluciones de conductos flexibles. La empresa se especializa en proporcionar productos de conductos personalizados diseñados para enfrentar los desafíos únicos de la industria automotriz, particularmente en aplicaciones de vehículos eléctricos.

Innovación en conductos flexibles

Teaflex se centra en el desarrollo de conductos altamente flexibles que puedan soportar temperaturas extremas y estrés mecánico. Sus productos están diseñados para brindar una protección excepcional para los mazos de cables, especialmente en vehículos eléctricos, donde la reducción de peso y la flexibilidad son cruciales. El uso de materiales avanzados permite que sus conductos mantengan el rendimiento en entornos automotrices exigentes.

Productos clave

- Conductos flexibles: Diseñado para espacios reducidos y entornos de alto estrés, ideal para cableado de vehículos eléctricos.

- Productos de aislamiento térmico: Protege el cableado del calor en los compartimentos del motor y otras áreas de alta temperatura.

- Soluciones personalizables: Conductos adaptados a los requisitos y desafíos específicos de la automoción.

Sostenibilidad y enfoque medioambiental

Teaflex está comprometido con las prácticas de fabricación sostenibles, utilizando materiales reciclables y procesos energéticamente eficientes. Este enfoque en la sostenibilidad tiene una buena acogida entre los fabricantes de automóviles que buscan reducir su huella ambiental y cumplir con las crecientes demandas regulatorias de componentes ecológicos.

Enfoque centrado en el cliente

Teaflex se enorgullece de su enfoque centrado en el cliente, que ofrece un servicio personalizado y tiempos de respuesta rápidos. La empresa trabaja en estrecha colaboración con los clientes para desarrollar soluciones de conductos que se adapten a sus aplicaciones automotrices específicas, mejorando la colaboración y la innovación.

Descripción general

LEONI Cable Inc. es líder mundial en el campo de los sistemas de cableado y cables, y ofrece soluciones de conductos innovadoras para la industria automotriz. Con un fuerte enfoque en la investigación y el desarrollo, LEONI se dedica a proporcionar productos de alta calidad que satisfagan las necesidades cambiantes del mercado automotriz, particularmente en el contexto de la electrificación.

Centrarse en la gestión de cables de alto rendimiento

LEONI se especializa en sistemas de conductos avanzados que garantizan una protección confiable para el cableado de los vehículos eléctricos. Sus sistemas de cableado de alto voltaje están diseñados para satisfacer las demandas de la tecnología EV, brindando seguridad y rendimiento en entornos de alto estrés. El uso de materiales innovadores garantiza que sus conductos mantengan la flexibilidad y la durabilidad incluso en condiciones extremas.

Productos clave

- Conductos de alto voltaje: diseñados específicamente para aplicaciones de vehículos eléctricos, garantizando seguridad y rendimiento.

- Sistemas de cableado: Soluciones integrales para la gestión completa de cables en entornos automotrices.

- Soluciones personalizadas: Soluciones de conductos y cableado a medida para satisfacer las necesidades específicas del fabricante.

Compromiso con la Innovación y la Sostenibilidad

LEONI pone un gran énfasis en la sostenibilidad y la reducción del impacto medioambiental mediante procesos de fabricación innovadores. La empresa trabaja activamente en el desarrollo de materiales ecológicos y métodos de producción energéticamente eficientes, en línea con la transición de la industria automotriz hacia tecnologías más ecológicas.

Reconocimiento del mercado y alcance global

LEONI es reconocida por su experiencia técnica y ha establecido una fuerte presencia en el sector automotriz. Los principales fabricantes de automóviles confían en sus productos, lo que los convierte en un socio confiable en el desarrollo de vehículos eléctricos e híbridos.

La industria automotriz está evolucionando rápidamente, y los vehículos eléctricos lideran el camino hacia tecnologías más innovadoras y sostenibles. Estos proveedores y fabricantes que mencionamos en el artículo y muchas otras empresas famosas están a la vanguardia de esta transformación. Cada empresa aporta puntos fuertes únicos, innovaciones de productos y compromiso con la sostenibilidad, lo que garantiza que seguirán siendo socios vitales en el futuro de las soluciones de cableado y conductos para automóviles.

A medida que los fabricantes de automóviles buscan mejorar la seguridad, el rendimiento y la sostenibilidad, el papel de estos fabricantes de conductos será crucial. Con sus diversas ofertas y su dedicación a la calidad, estas empresas están bien equipadas para apoyar a la industria automotriz mientras enfrenta los desafíos y las oportunidades de la electrificación y las tecnologías avanzadas para vehículos.