Tabla de contenido

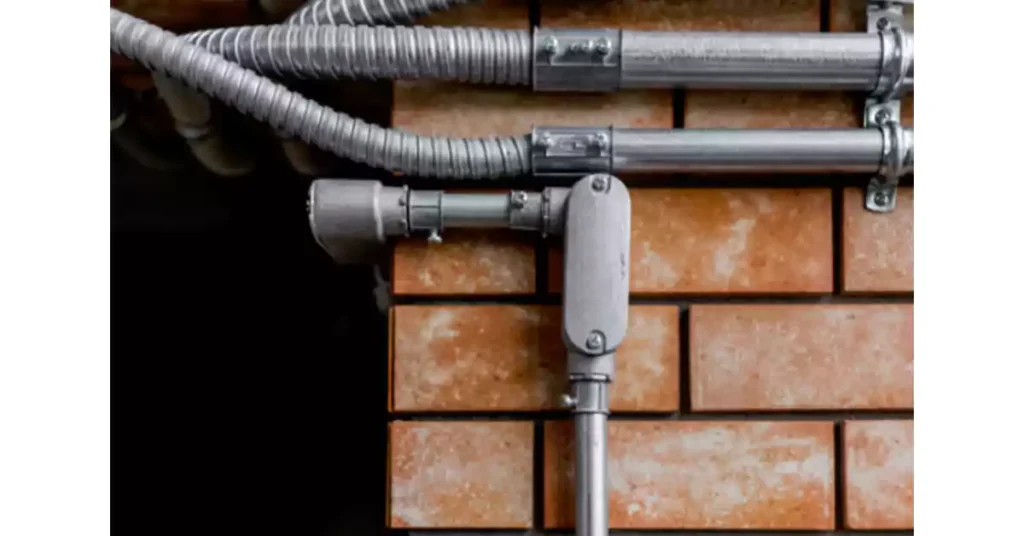

sistemas de conductos eléctricos Son la base de un cableado seguro y eficiente en edificios residenciales, comerciales e industriales. Ya sea para una nueva construcción o para la renovación de un edificio existente, los sistemas de conductos son vitales para proteger los cables eléctricos y garantizar la seguridad. En estos sistemas, un componente crucial, aunque a menudo pasado por alto, desempeña un papel fundamental: el cuerpo del conducto.

Importancia en las Instalaciones Eléctricas

En las instalaciones eléctricas, los cuerpos de conductos son vitales para brindar protección y acceso al cableado dentro de los conductos eléctricos. Su función principal es permitir a los electricistas realizar cambios de dirección o conexiones dentro del sistema de conductos, proporcionando espacio para empalmes, uniones y puntos de tracción de cables. Sin cuerpos de conductos, los sistemas eléctricos carecerían de la flexibilidad necesaria para sortear esquinas o curvas, y los cables serían más difíciles de mantener o reemplazar.

Un cuerpo de conducto también cumple una función protectora, ya que garantiza que los cables dentro del conducto estén protegidos contra daños físicos, riesgos ambientales y humedad. Esta protección es crucial para la longevidad y la seguridad del sistema, previniendo problemas como cortocircuitos o incendios. Además, los cuerpos de conducto ayudan a los electricistas a cumplir con los requisitos de cumplimiento normativo, garantizando que las instalaciones cumplan con las normas de seguridad establecidas.

Al ofrecer tanto practicidad como seguridad, los cuerpos de conductos son indispensables en las instalaciones eléctricas modernas, especialmente en sistemas de cableado complejos, como los que se utilizan en entornos industriales o comerciales.

Lo que puedes aprender de este artículo

Este artículo servirá como guía completa sobre los cuerpos de conductos, detallando sus diversos tipos, aplicaciones y cumplimiento normativo. Al finalizar el artículo, comprenderá a fondo los siguientes temas:

- ¿Qué es un cuerpo de conducto y diferentes tipos?

- Beneficios de los cuerpos de conducto

- Códigos y normas para cuerpos de conductos

- Cómo instalar cuerpos de conductos

- Aplicaciones de los cuerpos de conducto

Definición: ¿Qué es un cuerpo de conducto?

Un cuerpo de conducto es un tipo de accesorio eléctrico utilizado en sistemas de conductos, diseñado para permitir cambios de dirección, proporcionar puntos de acceso para el tendido de cables y facilitar las conexiones entre secciones de conducto. Esencialmente, es una caja o recinto que se instala en el tramo de conducto, generalmente en uniones, esquinas o puntos donde se necesita acceder al conducto para realizar tareas de mantenimiento o reparaciones.

Los cuerpos de los conductos se fabrican con diversos materiales, como aluminio, acero y plástico, según los requisitos específicos de la instalación y el entorno. Estos cuerpos alojan las conexiones de cables, proporcionan espacio para empalmes y permiten un tendido seguro y eficiente de los conductores eléctricos a través del sistema.

Propósito de los cuerpos de conducto

Los cuerpos de conducto se utilizan con mayor frecuencia con conductos rígidos de cédula 40 y cédula 80, ambos de PVC (cloruro de polivinilo). Estos tipos de conducto se eligen por su durabilidad, resistencia a la corrosión y facilidad de instalación.

Los cuerpos de conductos se utilizan principalmente en las siguientes aplicaciones:

- Cambios de dirección: Cuando un sistema de conductos requiere un giro o una curva, un cuerpo de conducto permite una transición fluida entre secciones. Admite curvas de diferentes grados (p. ej., 90°, 45°) y ayuda a mantener la alineación correcta del cableado eléctrico.

- Conexión de secciones de conducto: Los cuerpos de los conductos sirven como puntos de unión donde se unen dos o más secciones de conducto. Estos puntos de conexión son esenciales para garantizar la continuidad del sistema y que los cables puedan enrutarse de forma segura por toda la instalación.

- Acceso y tracción de cables: Una de las principales funciones de un cuerpo de conducto es proporcionar puntos de acceso donde los electricistas pueden tender, inspeccionar o instalar cables. Estos cuerpos son especialmente útiles cuando es necesario tender cables a través de tramos de conducto largos o complejos, lo que facilita la navegación e instalación de los cables.

- Empalme y terminación de cables: Los cuerpos de conductos también permiten el empalme y la terminación de cables, lo que permite realizar conexiones eléctricas dentro del sistema de conductos. Esto es especialmente útil en sistemas donde es necesario unir cables o cuando se requiere una extensión para conectar circuitos adicionales.

- Cajas para conexiones eléctricas: En algunos casos, los cuerpos de los conductos actúan como pequeñas cajas de conexiones dentro del recorrido de los conductos. Estas cajas ayudan a proteger las conexiones eléctricas de daños físicos, humedad y contaminantes, garantizando así la seguridad y la longevidad del sistema.

Tipos de cuerpos de conductos

Los cuerpos de conducto están disponibles en diversas formas y diseños, cada uno adaptado a las necesidades específicas de los sistemas de conductos eléctricos. Estos accesorios se utilizan para cambiar la dirección de los conductos, facilitar el acceso al cableado y facilitar el empalme o el mantenimiento de cables. A continuación, abordaremos los tipos estándar de cuerpos de conducto que se utilizan comúnmente en instalaciones eléctricas, así como un tipo más especializado diseñado para sistemas más grandes. Además, diferenciaremos entre cuerpos de conducto y cajas de conexiones, ya que estos dos componentes, si bien son similares en algunos aspectos, cumplen funciones diferentes.

Tipos estándar de cuerpos de conductos

Cuerpo del conducto LB (lateral posterior):

El cuerpo del conducto LB es uno de los tipos más utilizados para realizar un giro de 90 grados en el recorrido del conducto, además de proporcionar acceso para el tendido y empalme de cables. Incluye dos conectores para conductos (uno para el cableado de entrada y otro para el de salida), lo que permite al electricista pasar los cables eléctricos por una esquina. El punto de acceso del cuerpo del conducto LB se encuentra en la parte posterior, lo que lo hace ideal para pasar cables eléctricos a través de una pared o superficie.

Uso común: Ideal para situaciones en las que el conducto necesita cambiar de dirección en un ángulo de 90 grados, particularmente cuando los cables deben enrutarse desde el exterior de una estructura hacia el interior.

Cuerpo del conducto LL (lateral izquierdo):

Similar al LB, el Cuerpo del conducto LL También forma un giro de 90 grados, pero el cableado sale por el lado izquierdo del cuerpo en lugar del derecho. Esta versión incluye dos conectores de conductos: uno para la entrada de cables en la parte superior y otro para la salida de cables en el lado izquierdo. Al igual que el cuerpo LR, el cuerpo LL es útil para redirigir el cableado en el mismo plano.

Uso común: Se utiliza comúnmente en instalaciones donde es necesario dirigir el cableado hacia la izquierda después de un giro de 90 grados.

Cuerpo del conducto LR (lateral derecho):

El Cuerpo del conducto LR Es otro codo de 90 grados que permite al electricista redirigir el cableado de los conductos. Esta versión cuenta con dos conectores para conductos: uno en la parte superior para la entrada de cables y otro en el lado derecho para la salida de cables. Este diseño permite ajustar la orientación de la canalización sin cambiar de plano.

Uso común: Se utiliza cuando es necesario dirigir el cableado desde un conducto en la dirección correcta, especialmente en espacios reducidos o cuando se enruta a través del mismo plano.

Cuerpo de conducto en T (en forma de T):

El cuerpo de conducto en T es el primero de esta lista que cuenta con más de dos conectores. Forma una unión en forma de T, con un conector de conducto orientado a 90 grados, mientras que los otros dos son paralelos. Esto permite al electricista fusionar el cableado de dos ubicaciones diferentes en un solo conducto o derivarlo en dos direcciones distintas.

Uso común: Se utiliza comúnmente en situaciones donde es necesario dividir el recorrido del conducto en múltiples direcciones, como cuando se agregan nuevos circuitos a un sistema existente.

Cuerpo del conducto C (línea recta):

El cuerpo de conducto C funciona como un cuerpo de empalme recto. Conecta dos secciones de conducto en línea recta sin alterar la dirección del cableado. Está diseñado con placas extraíbles para facilitar el acceso al conducto, proporcionando un punto de servicio a lo largo de la canalización. Este tipo es ideal para conectar secciones de conducto sin necesidad de cambiar de dirección.

Uso común: Se utiliza en sistemas donde es necesario unir o extender conductos en línea recta, proporcionando puntos de acceso a lo largo del camino.

Cuerpo del conducto E (acceso final):

El cuerpo del conducto E está diseñado con un único punto de acceso en su extremo. Esto facilita la entrada y salida de cables al final del tramo. Si bien su diseño es simple, el cuerpo del conducto E es eficaz para instalaciones donde se requiere tendido de cables o mantenimiento al final de una sección del conducto.

Uso común: Se utiliza comúnmente en conductos rectos, donde solo se necesita un punto de acceso para tirar del cable o inspeccionarlo.

Cuerpo de conducto tipo TB:

El cuerpo del conducto TB está diseñado con puntos de acceso superior e inferior, además del punto de acceso posterior. Esta mayor flexibilidad facilita el tendido y empalme de cables desde múltiples direcciones, lo cual resulta especialmente útil en espacios reducidos o sistemas eléctricos complejos.

Ideal para instalaciones donde se necesitan múltiples puntos de acceso para mantenimiento, inspección o al tirar cables desde diferentes direcciones.

Cuerpo de conducto X (en forma de cruz):

El cuerpo del conducto en X es similar al cuerpo en T, pero cuenta con cuatro concentradores: dos conjuntos paralelos que forman una cruz. Esta configuración permite la entrada y salida de cableado en múltiples direcciones desde el mismo punto. El cuerpo del conducto en X es la solución ideal cuando varios tramos de conductos deben unirse en una unión central, lo que lo convierte en un componente clave para sistemas eléctricos complejos.

Uso común: Generalmente se utiliza en sistemas eléctricos comerciales o industriales a gran escala donde varios conductos deben conectarse o ramificarse desde un punto central.

Tipo especializado de cuerpo de conducto

Cuerpos de conductos Mogul

Los cuerpos de conducto Mogul son versiones más grandes y robustas de los cuerpos de conducto estándar. Están diseñados para adaptarse a conductos de mayor tamaño y se utilizan habitualmente en aplicaciones industriales o instalaciones eléctricas a gran escala donde el sistema de conductos maneja altas capacidades. Los cuerpos de conducto Mogul son ideales para situaciones donde se requieren accesorios más grandes y robustos para el cableado eléctrico.

Uso común: Se utiliza generalmente en sistemas eléctricos industriales o comerciales de alta capacidad que requieren accesorios de conductos grandes para administrar circuitos eléctricos de servicio pesado.

Cuerpo del conducto vs. caja de conexiones

Si bien tanto los cuerpos de conductos como las cajas de conexiones son parte integral de las instalaciones eléctricas, cumplen diferentes propósitos y se utilizan en diferentes contextos.

Característica | Cuerpo del conducto | Caja de conexiones |

Objetivo | Proporciona acceso, permite cambios de dirección o enruta el cableado dentro de un sistema de conductos. | Alberga y protege conexiones eléctricas, empalmes y terminaciones. |

Función primaria | Cambia la dirección del conducto, facilita el tendido de cables y crea puntos de acceso para empalmes. | Protege y encierra las conexiones eléctricas, garantizando la seguridad y el cumplimiento. |

Ubicación | Integrado en el sistema de conductos; parte de la canalización. | Colocado externamente al sistema de conductos para protección y acceso. |

Diseño | Generalmente cuenta con múltiples concentradores para conectar secciones de conductos. | Contenedor cerrado con uno o más puntos de entrada/salida para conexiones de cableado. |

Requisitos de montaje | No es necesario apoyarlo individualmente, ya que es parte de la pista de carreras. | Debe sostenerse de forma independiente, a menudo montado sobre una superficie. |

Tipos | LB, LL, LR, C, T, X, TB, E, etc. (varias formas para diferentes funciones). | Cajas cuadradas, rectangulares, redondas u ovaladas, a menudo con tapas extraíbles. |

Puntos de acceso | Proporciona acceso al cableado directamente desde el propio sistema de conductos. | Proporciona acceso a las conexiones del cableado para mantenimiento o inspección. |

Características de los cuerpos de conductos

Los cuerpos de conducto son componentes esenciales de los sistemas eléctricos y su diseño varía según la composición del material, la resistencia a la intemperie, la compatibilidad con los tipos de conducto y las necesidades específicas de la aplicación. Esta sección explorará las diferentes opciones de materiales, sus ventajas y desventajas, y las diversas características de diseño que los hacen adecuados para diversas aplicaciones.

Opciones de materiales para cuerpos de conductos

Los cuerpos de los conductos se fabrican con diversos materiales, cada uno con ventajas específicas según el entorno y los requisitos de la aplicación. Los cuatro materiales más comunes son el aluminio, el acero, el PVC y los materiales recubiertos de zinc.

Cuerpos de conductos de aluminio

Los cuerpos de conducto de aluminio son ligeros, resistentes a la corrosión y muy duraderos. Se utilizan ampliamente en aplicaciones donde el cuerpo del conducto puede estar expuesto a la humedad o a la intemperie.

Cuerpos de conductos de acero

Los cuerpos de conductos de acero son robustos y ofrecen excelente resistencia y protección para el cableado eléctrico en entornos hostiles o de alto impacto. El acero se utiliza a menudo en instalaciones industriales o comerciales donde se requiere protección mecánica adicional.

Cuerpos de conductos de PVC

Los cuerpos de conductos de PVC están hechos de un material plástico que ofrece resistencia a la corrosión y se utilizan comúnmente en aplicaciones que requieren soluciones no metálicas de bajo costo.

Cuerpos de conductos recubiertos de zinc

Los cuerpos de conductos galvanizados suelen estar hechos de acero, pero cuentan con un recubrimiento protector de zinc para mejorar la resistencia a la corrosión. Se utilizan en entornos que pueden exponer el conducto a la humedad, productos químicos u otros elementos corrosivos.

Pros y contras:

Resistente a la intemperie y a la corrosión

Una de las características clave de los cuerpos de conductos es su capacidad para resistir la intemperie, lo que los hace adecuados tanto para aplicaciones interiores como exteriores. A continuación, se detallan las propiedades de resistencia a la intemperie y a la corrosión de los diferentes materiales:

- AluminioNaturalmente resistente a la corrosión, pero puede oxidarse con el tiempo. Buen rendimiento en ambientes húmedos o salinos.

- AceroResistente y duradero, pero propenso a la oxidación a menos que esté galvanizado o revestido. Apto para entornos industriales, pero requiere mantenimiento para evitar la corrosión.

- CLORURO DE POLIVINILOExcelente resistencia a la corrosión e ideal para ambientes húmedos. Además, no es reactivo, lo que lo hace ideal para zonas expuestas a productos químicos.

- Acero recubierto de zinc:Proporciona una mayor resistencia a la corrosión, pero aún requiere mantenimiento para garantizar que el revestimiento de zinc permanezca intacto.

Al elegir el material para el cuerpo de un conducto, se deben tener en cuenta las condiciones climáticas, la exposición a la humedad y el potencial desgaste físico.

Compatibilidad con los tipos de conductos

Los cuerpos de conducto están diseñados para ser compatibles con diversos tipos de conductos eléctricos, lo que garantiza una integración perfecta en el sistema de conductos general. Algunos tipos de conductos comunes que funcionan con cuerpos de conducto incluyen:

- Conducto metálico rígido (RMC):Este es un conducto de alta resistencia utilizado en entornos industriales. Cuerpos de conducto fabricados con acero o aluminio Son ideales para sistemas RMC.

- Conducto metálico intermedio (IMC):Una alternativa más fina al RMC, acero Los cuerpos de conducto se utilizan con mayor frecuencia en sistemas IMC.

- Conducto de PVC:Para sistemas de conductos no metálicos, Cuerpos de conductos de PVC Se utilizan para garantizar la compatibilidad con el conducto y mantener la protección contra la corrosión en instalaciones húmedas o subterráneas.

Los cuerpos de los conductos deben coincidir con el tipo de conducto que están destinados a conectar, por lo que la compatibilidad es un factor clave al momento de seleccionar el tipo correcto para su proyecto.

Variaciones de diseño para aplicaciones específicas

Los cuerpos de conductos vienen en diversos diseños para satisfacer las necesidades de aplicaciones específicas. Algunas de las variaciones de diseño incluyen:

- TallasLos cuerpos de los conductos están disponibles en diferentes tamaños para adaptarse al diámetro del conducto y al número de cables que deben pasar. Elegir el tamaño correcto garantiza suficiente espacio para el tendido de cables y el mantenimiento.

- Puntos de acceso:Muchos cuerpos de conductos vienen con cubiertas extraíbles o múltiples puntos de acceso Para facilitar el tendido de cables, los empalmes y las inspecciones del sistema. La posibilidad de abrir y cerrar la caja facilita el mantenimiento a lo largo del tiempo.

- Opciones para trabajo pesado: For harsh environments, heavy-duty acero o zinc-coated conduit bodies may be used. These bodies are designed to withstand high-impact situations and offer enhanced durability.

Each type of conduit body is tailored to meet the needs of specific projects, offering versatility and flexibility in a variety of installations.

Code Compliance and Standards for Conduit Bodies

Conduit bodies must adhere to various regulatory standards to ensure they meet safety, durability, and performance requirements. In this section, we will discuss the NEC (National Electrical Code) requirements for conduit bodies, including the key codes that govern their use, UL (Underwriters Laboratories) Listing, and CSA (Canadian Standards Association) certifications. We will also cover best practices for installation to ensure compliance with these standards.

NEC (National Electrical Code) Requirements

The National Electrical Code (NEC) is a set of regulations used in the United States to ensure safe electrical installations. Several specific NEC sections apply to the use of conduit bodies in electrical systems. These sections outline the necessary safety measures, proper installation practices, and performance criteria.

NEC Article 300.15 Boxes, Conduit Bodies, or Fittings: Where Required

NEC 300.15 provides the general requirements for when a box, conduit body, or fitting is required in an electrical installation. These components are essential for providing proper access and protection for conductors at various points along the wiring system. The code outlines specific requirements for their use at outlet points, splice points, junction points, and other key locations.

General Requirement:

A box or conduit body must be installed at each outlet point, switch point, conductor splice point, conductor junction point, conductor termination point, wiring method transition point, or conductor pull point. This requirement applies when using conduit, tubing, Type AC cable, Type MC cable, Type MI cable, nonmetallic-sheathed cable, or other cables unless an exception is specifically permitted under 300.15(A) through (L).

NEC Article 314

Conduit bodies are essential components used to join, protect, and provide access to electrical conductors in various wiring installations. Under NEC Article 314, conduit bodies are classified as boxes or fittings that serve as junction points for wiring systems, enabling secure connections and ensuring accessibility for future maintenance or modification. The article provides comprehensive guidelines on the installation, sizing, and specific use cases for conduit bodies to maintain safety, efficiency, and code compliance in electrical systems.

Some key points introduced in Article 314:

Types of Conduit Bodies:

Conduit bodies come in various materials, including cast metal, sheet metal, and nonmetallic types. They serve as connection points between raceways and cables.

They must be designed and listed specifically for their intended use, ensuring safety and performance.

Volume Calculations:

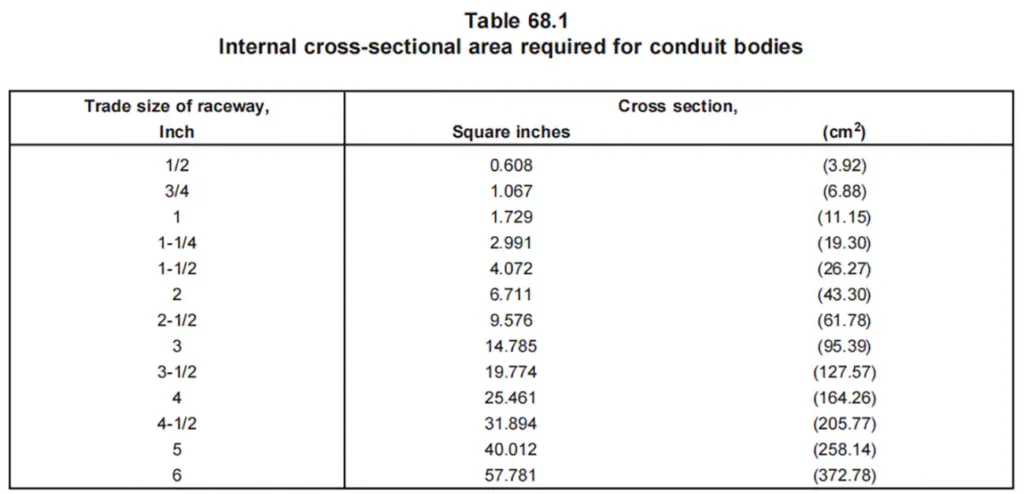

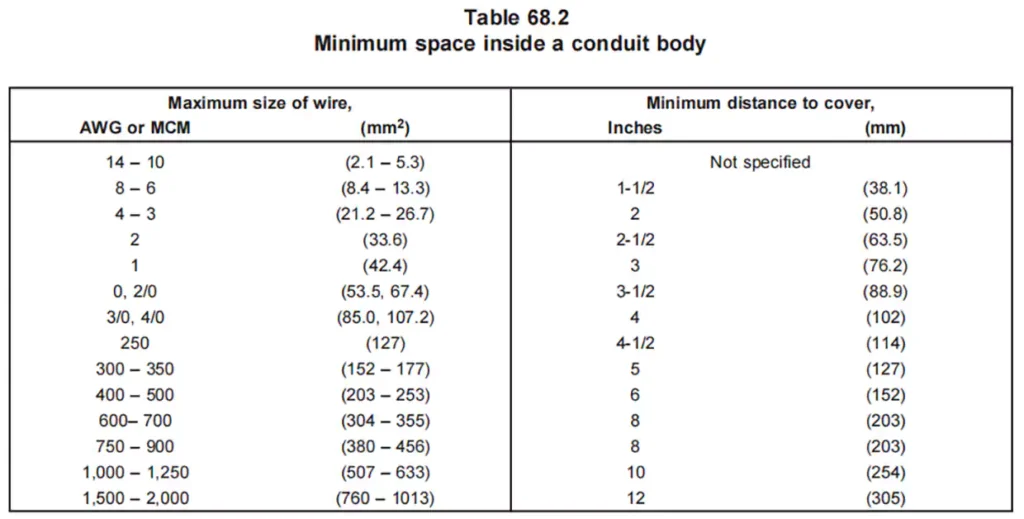

Conduit bodies must be large enough to accommodate the number and size of conductors they enclose. The volume of a conduit body must meet the requirements set in 314.16(C), ensuring there is adequate space for all conductors.

Cross-sectional area: For most conduit bodies, the cross-sectional area must be at least twice the area of the largest conduit it is attached to, ensuring that conductors can be routed safely without overcrowding.

Installation and Use:

Conduit bodies are required to be securely supported in a rigid and stable manner. This ensures they can withstand environmental stresses and maintain structural integrity over time.

Short-radius conduit bodies, like elbows, which are intended to change the direction of the conduit system, are exempt from housing splices, taps, or devices.

Damp or Wet Locations: When installed in wet locations, conduit bodies must be designed to prevent moisture from accumulating inside. Drainage openings are allowed in such installations to prevent water ingress.

Conduit Bodies with Splices or Taps:

Only those conduit bodies marked by the manufacturer with their volume are permitted to contain splices, taps, or devices. These must comply with volume requirements and be sized appropriately to handle the electrical load.

Protection and Abrasion:

Conductors entering a conduit body must be protected from abrasion. Insulating bushings should be used where metal conduit bodies are installed with unprotected conductors.

Conduit bodies are also required to have adequate fittings and closures to prevent accidental contact with live conductors and to maintain the integrity of the wiring system.

Conduit Bodies for Larger Conductors:

For installations involving conductors larger than 6 AWG, the conduit body size must be calculated based on the conductors’ total cross-sectional area. This ensures enough space for proper conductor management and heat dissipation.

Maintenance and Accessibility:

Conduit bodies must remain accessible after installation for inspection, maintenance, and potential upgrades. This is essential for ensuring safety and allowing for any future modifications or repairs without significant disruption to the wiring system.

UL Listed Conduit Bodies

The Underwriters Laboratories (UL) is an independent safety certification organization that ensures electrical products meet established safety standards. Conduit bodies are typically UL Listed, which means they have passed rigorous testing and are deemed safe for use in electrical systems. The related UL standards for conduit bodies including UL514C and UL 514B.

UL 514C – Nonmetallic Outlet Boxes, Flush Device Boxes, and Covers

UL514C sets forth the performance and testing requirements for conduit bodies. These standards are critical for ensuring that conduit bodies are safe, reliable, and durable in electrical systems. Some key performance tests and requirements under UL 514C include:

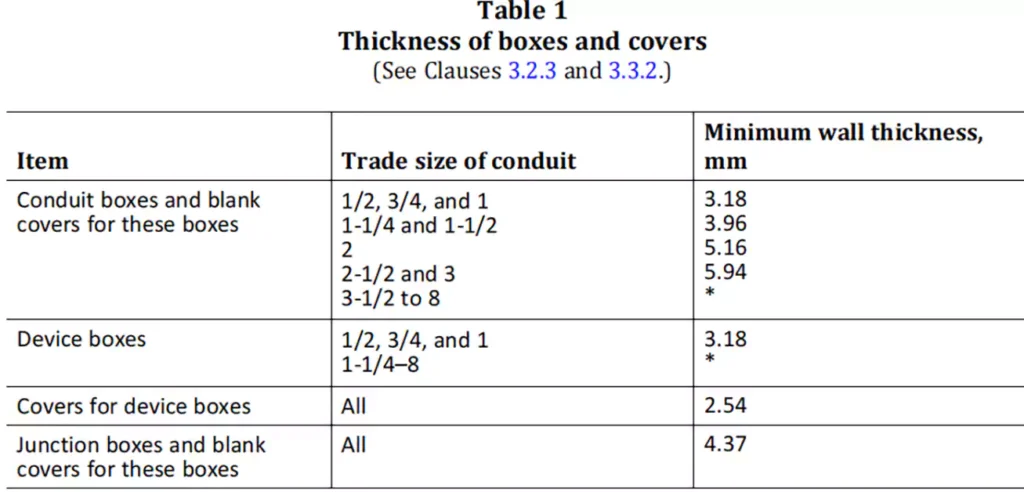

Dimensiones: UL 514C specifies the dimension requirements for conduit bodies, including their cross-sectional area requirements, inside volume etc.

Temperature Endurance: Conduit bodies must withstand elevated temperatures, 92℃ as specified in the standard, without deformation, warping, cracking, or losing their structural integrity. UL 514C tests the ability of conduit bodies to handle extreme conditions, ensuring they perform reliably in both high and low-temperature environments.

Flame Retardant: Require the conduit box do not support combustion for more than 5 seconds after the third application of the flame, and there should be no flame drops, and the box should not be completely consumed.

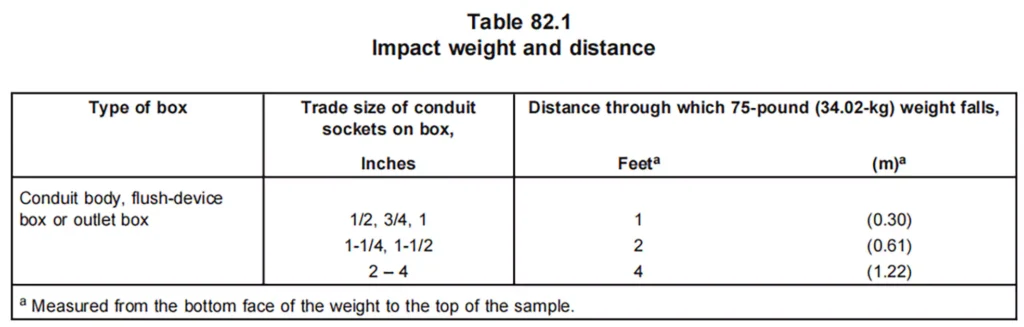

Resistencia mecánica: Conduit bodies are subject to mechanical stress testing to ensure they can resist physical impacts, vibrations, and other mechanical stresses typically encountered in electrical systems. Including the tensile test, impact test.

Resistencia a la corrosión: UL 514C requires that conduit bodies meet specific corrosion resistance standards, particularly for those used in wet or harsh environments. This ensures that the conduit body will not degrade or compromise the integrity of the wiring.

Electrical Insulation and Conductivity: For non-metallic conduit bodies, UL 514C verifies that the material is non-conductive, preventing any risk of electrical shorts or shocks. For metallic bodies, they must be properly insulated or grounded as necessary.

Protection Against Environmental Elements: Conduit bodies used in outdoor or harsh environments must be tested for weatherproofing and resistance to elements like moisture, dust, and chemicals. This ensures that electrical systems remain safe even in challenging environments.

UL 514B – Conduit, Tubing, and Cable Fittings

UL 514B is the Underwriters Laboratories standard that outlines the construction, performance, and safety requirements for conduit bodies, ensuring they are safe for use in electrical installations. This standard applies to all conduit bodies used to connect raceways and cables, including those intended for residential, commercial, and industrial applications. Below is an overview of the key requirements outlined in UL 514B regarding dimensions, construction materials, and performance standards. It covers aspects like:

Dimensions of Conduit Bodies:

UL 514B specifies precise dimensional criteria to ensure conduit bodies are suitable for housing conductors and maintaining their intended function.

Construction and Material Requirements:

The materials and construction methods used in the manufacturing of conduit bodies are crucial for their durability, performance, and safety. UL 514B specifies the following requirements for construction:

Performance Requirements:

UL 514B ensures that conduit bodies meet stringent performance standards to guarantee electrical safety, durability, and overall functionality. These include:

Physical Strength:

Resistencia al impacto: Conduit bodies must be able to withstand physical impact without cracking or failing. This is particularly important in environments subject to mechanical stresses.

Compression Strength: The material must be strong enough to resist deformation when subject to compression, ensuring the conduit body maintains its shape under load and does not collapse or become deformed under normal conditions.

Seguridad eléctrica:

Aislamiento eléctrico: For nonmetallic conduit bodies, the materials must be electrically insulating to prevent inadvertent short circuits or shock hazards. Metal conduit bodies, on the other hand, must be properly bonded and grounded to ensure that they do not carry stray electrical current that could pose a shock risk.

Moisture and Corrosion Resistance: UL 514B requires that conduit bodies have sufficient protection against moisture and corrosion, particularly when used in damp or wet environments. This includes proper sealing and the use of corrosion-resistant materials to maintain electrical safety over time.

CSA Certified - CSA C22.2 No. 85

In Canada, the Canadian Standards Association (CSA) establishes safety standards for electrical products. Conduit bodies sold in Canada must comply with CSA C22.2 No. 85, which provides the requirements for fittings for electrical conduit and tubing. Some key requirements under CSA C22.2 No. 85 include:

Material and Design Standards:

Similar to UL standards, CSA requires that conduit bodies meet specific material composition and design criteria to ensure they are suitable for safe and reliable use in electrical systems.

Dimensions of Conduit Bodies:

CSA C22.2 No. 85 sets specific dimensional criteria to ensure that conduit bodies have adequate space for wiring and can accommodate the conductors within raceways without risking overcrowding or improper installation.

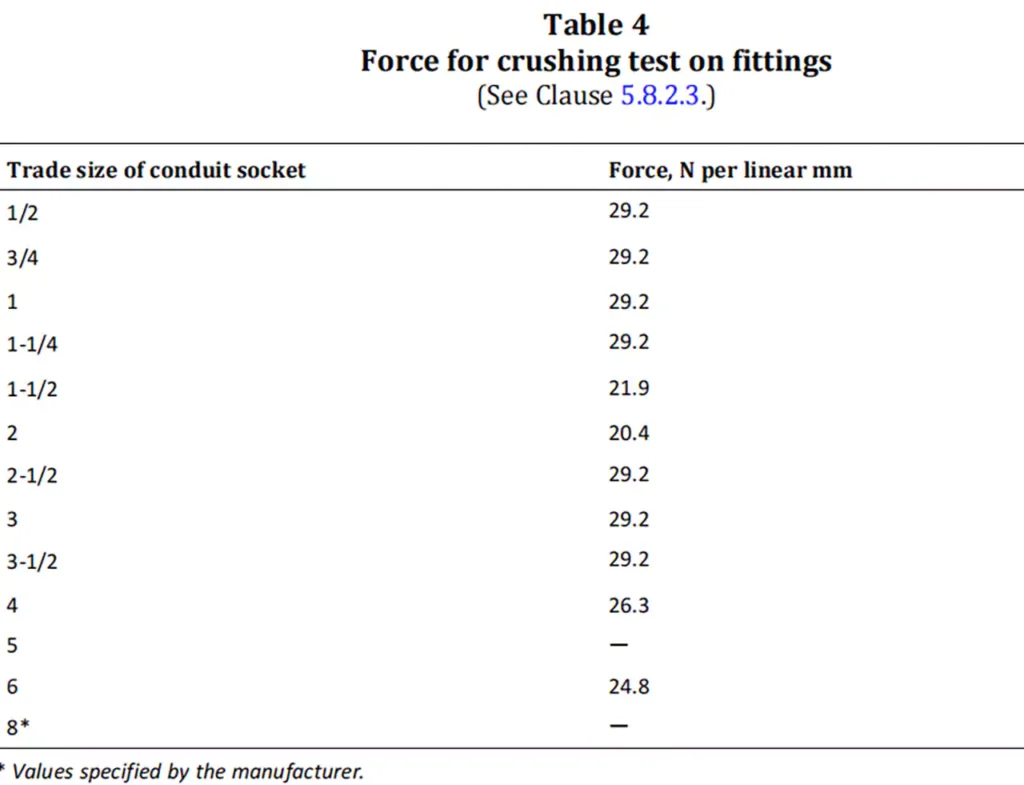

Physical Performance and Durability Requirements:

CSA C22.2 No. 85 outlines various physical and environmental performance requirements to ensure that conduit bodies can operate reliably under harsh conditions. These include resistance to heat, flame, impact at -34 Degree Celsius., and crushing.

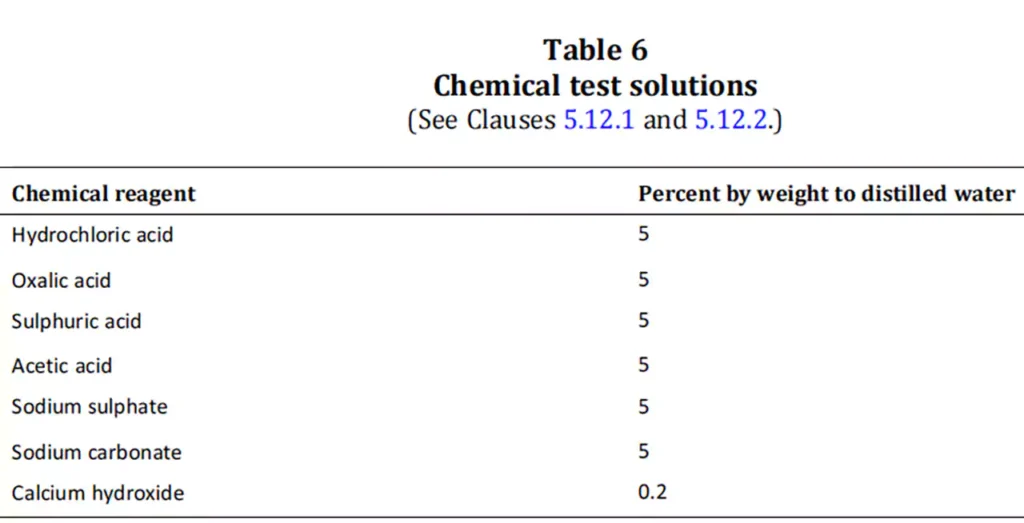

Resistencia química:

Resistencia a la corrosión: Conduit bodies, especially those used in outdoor or industrial applications, must be resistant to corrosion caused by exposure to moisture, chemicals, and pollutants. This is especially true for metallic conduit bodies, which must be treated or coated with corrosion-resistant materials to prevent rusting and deterioration.

Exposición a sustancias químicas: Nonmetallic conduit bodies must also exhibit resistance to common industrial chemicals, oils, and solvents that may be encountered in some electrical installations, ensuring they do not degrade or lose their structural integrity.

Marking and Labeling:

Conduit bodies must be clearly marked with manufacturer information, material type, voltage ratings, and CSA certification. Durable labeling ensures that conduit bodies are used properly and meet safety regulations.

Conduit Body Applications

Conduit bodies are essential components used in various electrical installations to protect and organize wiring. Their versatility makes them suitable for a wide range of applications in both residential and industrial environments. Below are some common uses for conduit bodies:

1. Residential Electrical Systems

In homes, conduit bodies are used for:

Conexiones de cableado: They provide a secure space for connecting and joining electrical wires. This ensures that wiring is well-organized and accessible for future maintenance.

Proteccion: They help protect electrical wiring from physical damage and environmental factors like moisture and heat, especially in areas like basements or kitchens.

Branch Circuits: Conduit bodies allow electrical systems to branch out and power multiple circuits, such as outlets, lights, and appliances.

2. Commercial and Industrial Applications

In businesses and factories, conduit bodies are used in:

Control Panels: They house wiring connections and provide easy access to electrical systems, ensuring smooth operations in industrial settings.

Heavy-Duty Systems: They protect wiring from physical damage in environments that involve high mechanical stress, such as factories and warehouses.

Automation Systems: Conduit bodies help route electrical wiring safely to machinery, robots, and automated equipment.

3. Wet and Damp Locations

In areas with exposure to moisture, conduit bodies are designed to meet specific standards for wet and damp locations:

Instalaciones al aire libre: Conduit bodies used outdoors—such as for street lighting, signage, or landscape lighting—are built to prevent moisture ingress and protect wiring from weather-related damage.

Damp Environments: In places like basements, parking garages, or laundry rooms, conduit bodies prevent moisture from affecting the wiring, reducing the risk of short circuits or deterioration of the electrical system.

Ubicaciones húmedas: In locations directly exposed to water, like outdoor swimming pools, fountains, or marine environments, special conduit bodies rated for wet locations provide full protection against moisture, ensuring the safety of electrical systems.

4. Data Centers and Telecommunications

In data centers and telecommunications systems, conduit bodies are used to:

Manage Cables: They keep cables organized and protected while ensuring the safe routing of electrical wiring within the infrastructure of sensitive equipment.

Provide Safety: Conduit bodies help to prevent electrical interference, protect wiring from external elements, and ensure that the electrical systems continue to function smoothly without risk to critical data and communication systems.

5. Hazardous Locations

In environments with a higher risk of fire or explosion, such as chemical plants or oil refineries, conduit bodies are designed to:

Explosion-Proof: Explosion-proof conduit bodies prevent the risk of sparks or electrical arcs from igniting flammable gases or vapors, providing safety in volatile environments.

Resistencia a la corrosión: In areas where the electrical system is exposed to harsh chemicals or corrosive elements, conduit bodies are made from corrosion-resistant materials, ensuring they maintain their protective function

4 Benefits of Using Conduit Body

Conduit bodies are not just functional components; they offer a wide range of benefits that enhance the performance, safety, and longevity of electrical installations. Below are some key advantages of using conduit bodies in electrical systems:

1. Flexibility in Conduit Layouts

One of the primary benefits of conduit bodies is the flexibility they provide in designing and modifying electrical conduit systems.

Multiple Entry Points: Conduit bodies offer various openings and configurations, allowing for easy access points at different locations within a system. This flexibility makes it easier to change or expand electrical systems without the need to completely redesign the layout.

Complex Routing: They enable complex wiring configurations, such as sharp bends, branches, or 90-degree turns, without compromising the integrity or performance of the system. This is especially important in spaces with limited access or where the wiring must follow specific paths.

Adaptability: Conduit bodies are available in many sizes and shapes, allowing them to be used in a wide variety of installations, from small residential systems to large commercial and industrial setups.

2. Simplifying Wiring Access

Conduit bodies serve as access points for wiring connections, which simplifies the maintenance, inspection, and modification of electrical systems.

Easy Maintenance: Because they are designed for easy access, conduit bodies make it much simpler to perform electrical maintenance. Technicians can easily access splices, taps, or connections housed within the conduit body without disassembling large portions of the conduit system.

Convenient Modifications: If the electrical system needs to be updated or expanded, conduit bodies provide a convenient place for adding or modifying circuits without the need to disrupt the entire installation.

Safe Access: They also provide safe and organized access to wiring, which can be important for troubleshooting or repairs, reducing the risk of accidental damage to the wiring or the system as a whole.

3. Protection of Electrical Connections

Conduit bodies play a crucial role in protecting electrical connections and ensuring the overall safety of the electrical system.

Shielding from Physical Damage: By enclosing wiring connections, conduit bodies protect them from external forces such as physical impacts, abrasion, or crushing. This is particularly important in environments where cables are at risk of being damaged by equipment, machinery, or everyday wear and tear.

Moisture and Dust Protection: In wet or damp environments, conduit bodies can be designed to prevent moisture or dust from entering the electrical connections, helping to maintain the integrity of the system and reducing the risk of electrical faults or failures.

Seguridad mejorada: Conduit bodies help maintain safe electrical systems by ensuring that connections are properly protected from environmental hazards. This contributes to reducing the risk of short circuits, sparks, and potential fire hazards.

4. Reducing Stress on Cables and Wires

Electrical cables and wires are often subjected to mechanical stresses, especially in systems with sharp bends or high traffic areas. Conduit bodies help alleviate this stress, contributing to the longevity of the wiring system.

Preventing Physical Stress: By providing a smooth path for cables and offering space for changes in direction, conduit bodies reduce the risk of kinks, tight bends, or other forms of mechanical stress on the wires. This helps prevent the potential for insulation damage and reduces the risk of wire breakage.

Minimizing Wear and Tear: Conduit bodies can also prevent direct contact between the cables and surfaces that might cause abrasion, further protecting the wiring and extending its service life.

Reducing Tension on Wires: They allow for smoother transitions and more room for wiring within the system, ensuring that wires do not experience undue tension, which can lead to failure or degradation of the cable insulation.

Conduit Body Installation Guide (7 Steps)

Installing conduit bodies correctly is essential for ensuring a safe and reliable electrical system. Proper installation not only helps maintain code compliance but also ensures the system operates efficiently and minimizes the risks of electrical faults or failures. This section provides a step-by-step guide to installing conduit bodies, highlights the tools needed, and emphasizes key considerations based on relevant codes of such as International Residential Code and NEC.

Tools Required for Installation

Before starting the installation, ensure you have the following tools:

- Measuring Tape: For accurately measuring distances and ensuring conduit bodies are placed in the right location.

- Screwdriver: To secure screws and fasteners in place.

- Wire Strippers: To prepare the conductors before they enter the conduit body.

- Hacksaw or Pipe Cutter: For cutting conduits to the required length.

- Conduit Bender: To bend the conduit to fit the installation layout if required.

- Drill: To create holes for mounting the conduit body if needed.

- Level: To ensure the conduit body is correctly aligned.

- Conduit Wrenches: For tightening connections securely.

Step-by-Step Installation Process (7 Steps)

1. Prepare the Conduit and Conductors

Measure and cut the conduit to the required lengths using a hacksaw or pipe cutter. Make sure the conduit ends are clean and free from burrs.

Strip the insulation from the conductors carefully, ensuring the exposed wires are ready for connection.

2. Position the Conduit Body

Select the appropriate location for the conduit body. Ensure that the position complies with NEC Code Section 314.17 for access and clearance, allowing space for wiring and other connections.

Mount the conduit body securely, using a level to ensure it is aligned correctly. Make sure it is placed at an accessible location for future maintenance.

3. Install the Conduit Entries

Connect the conduit to the conduit body by threading the conduit into the appropriate entry points on the conduit body. Use a conduit wrench to tighten the connections and ensure they are secure.

If using any fittings or bushings, ensure they are installed correctly to avoid damage to the conductors (NEC 300.4(G)).

4. Insert Conductors into the Conduit Body

Insert the prepared conductors into the conduit body, ensuring they pass through any openings smoothly and without damage. According to NEC, conductors entering the conduit body should be protected from abrasion. Use insulating fittings or bushings where necessary.

5. Close Any Openings

If there are unused openings in the conduit body, close them with approved plugs or covers as to prevent any exposure to moisture or dust, which could compromise the safety of the installation.

6. Secure and Seal the Conduit Body

Secure the cover or device to the conduit body, ensuring it is tightly fastened using appropriate screws. Follow manufacturer instructions for any specific sealing requirements.

Use non-corrosive, weather-resistant materials if installing in wet or damp environments.

7. Test the Installation

Once the conduit body and conductors are installed and secured, test the system for continuity and proper operation. Inspect all connections for tightness, ensuring that no part of the system is loose or improperly mounted.

5 Tips for Securing and Sealing

- Tighten Connections Properly: Always ensure that threaded connections between the conduit and the conduit body are tightened securely. Over-tightening can damage threads, while under-tightening can lead to leaks or faults in the system.

- Use Insulated Fittings: To protect the conductors from abrasion when entering the conduit body, use insulated fittings (per NEC 300.4(G)) where appropriate.

- Seal Unused Openings: Unused openings must be sealed using proper plugs or covers to prevent entry of moisture, dust, or debris. Ensure that these covers are properly secured.

- Waterproofing in Wet Locations: In wet or damp environments, be sure to use waterproof conduit bodies and ensure all connections are sealed with a gasket or other weatherproof material.

- Ensure Proper Grounding: Make sure that any metal conduit bodies are properly grounded as per the grounding requirements of the NEC (Section 250).

4 Common Mistakes to Avoid

- Incorrect Placement: Ensure that the conduit body is installed in a location that allows easy access for future maintenance and modification. Avoid placing the conduit body where it is difficult to reach or in locations with poor ventilation.

- Not Sealing Unused Openings: Leaving unused openings in the conduit body open can lead to moisture ingress, which could result in short circuits or corrosion over time.

- Failure to Follow Code: Make sure the installation adheres to the local code, including requirements like those outlined in NEC for securing, sealing, and mounting conduit bodies. Not complying with these can result in unsafe installations or costly repairs.

- Improper Support: Make sure the conduit body is properly supported, especially when mounted in areas with high vibration or movement. According to NEC, all enclosures should be securely mounted to prevent accidental dislodging.

Buying Guide for Conduit Bodies

Choosing the right conduit body is crucial for ensuring the safety, efficiency, and longevity of your electrical installations. With a variety of options available, it’s important to consider the specific requirements of your project, including environmental factors, installation conditions, and compliance with relevant standards. This guide will help you navigate the selection process and make an informed purchase decision.

5 Factors to Consider When Buying Conduit Bodies

1. Size and Capacity

Conduit bodies come in different sizes, often referred to as “trade sizes,” which relate to the diameter of the conduit. You need to pick a size that suits the number of conductors (wires) you will be using, as well as any future wiring that might need to pass through. If the conduit body is too small, it could lead to crowded wires that are difficult to manage. If it’s too large, it may be unnecessary and take up too much space.

2. Material

The material of the conduit body affects its durability and ability to handle environmental factors.

3. Environmental Conditions (Indoor vs. Outdoor Use)

The environment where the conduit body will be installed is crucial. For indoor use, plastic or aluminum is often sufficient. However, for outdoor use or areas exposed to moisture, heat, or chemicals, you’ll need a more rugged material like aluminum or steel. Make sure the conduit body is sealed properly to prevent water or dust from entering.

4. Compatibility with Existing Conduit Systems

Ensure the conduit body matches the size and type of conduit you’re using. Conduit bodies come in different styles (like LB, T, LL) and sizes, so check that the trade size of the conduit body matches your conduit, and that the style works with your wiring layout.

Choosing a conduit body from a reputable manufacturer ensures you’re getting a high-quality, durable product that meets safety standards. Trusted brands typically offer better customer service, warranties, and ensure that their products meet important certifications like UL or CSA.

Maintenance and Troubleshooting for Conduit Bodies

Proper maintenance of conduit bodies is essential to ensure the continued safety and functionality of your electrical system. Regular inspections and prompt attention to any signs of wear or damage can help you avoid costly repairs and potential electrical hazards. In this section, we’ll explore some key tips for maintaining your conduit bodies and troubleshooting common issues.

Routine Inspection Tips

Routine inspections are crucial to ensure that your conduit bodies remain in good condition. Here’s how to go about it:

- Visual Inspection: Start with a visual check to spot any obvious signs of damage or wear. Look for cracks, dents, or deformations in the conduit body. Check the cover and sealing gaskets for any signs of looseness, rust, or corrosion.

- Limpieza: Make sure that the conduit body is free from debris, dirt, or any other buildup that could block openings or impede airflow. Dust or dirt can build up over time, which might also affect the performance of the seals or cause overheating.

- Secure Connections: Ensure that all fasteners are tight and that the conduit body is securely mounted. Loose connections or poorly sealed conduit bodies can lead to moisture intrusion, which could damage the wiring inside.

- Check for Ingress: Examine the conduit body for any signs of water, dust, or other contaminants entering. This is especially important for outdoor or wet-location installations. Look for moisture buildup inside the body or at the conduit entry points, as this could indicate a compromised seal.

Identifying Signs of Wear and Damage

Identifying wear and damage early can save you from more serious problems down the line. Here are some common signs to look for:

Daño físico: Look for cracks, splits, or other physical damage to the conduit body. These can weaken the structure and compromise its protective function. Impact damage is particularly common in outdoor installations, so be sure to check for any visible dents or deformations.

Corrosión: In wet or outdoor environments, metal conduit bodies can corrode over time. If you notice rust, pitting, or any signs of oxidation, this can lead to structural weaknesses and potential failure. Corrosion can also affect the electrical grounding of the system.

Loosening or Displacement: If the conduit body cover or fittings are loose or have become misaligned, this can lead to improper sealing, exposing the internal wiring to environmental factors. Tighten any loose screws and ensure that all components are properly aligned.

Moisture or Debris Inside: If you find water, rust, or other debris inside the conduit body, it could indicate that the seal is no longer intact. Moisture is especially concerning as it can lead to short circuits or corrosion of the internal wiring.

Repair and Replacement Considerations

When a conduit body shows signs of wear, you may be faced with the decision to repair or replace it. Here are some considerations to guide your decision:

Minor Damage: If the damage is minor (such as a loose cover or a small crack), a simple repair might be sufficient. Tighten any loose fasteners or replace worn seals, gaskets, or screws. For cracks or damage in plastic conduit bodies, you might be able to apply a sealant or patch if the damage is not severe.

Corrosion or Major Damage: If the conduit body is significantly corroded or structurally compromised (such as severe cracking or rusting), it is often best to replace it entirely. Corrosion can weaken the integrity of the conduit body, making it a safety hazard. A replacement ensures that your electrical system remains secure and fully functional.

Old or Outdated Conduit Bodies: If your conduit body is outdated or no longer complies with current electrical codes, it might be worth replacing it with a newer model that meets modern standards. This is particularly true if the conduit body has been in place for a long time and shows signs of aging, such as brittle materials or outdated fittings.

Consideraciones de costo: While repairs might seem more cost-effective in the short term, it’s important to evaluate the long-term cost. In some cases, replacing a conduit body with a newer, more durable model may be a more cost-effective solution in the long run, as it will likely last longer and require fewer repairs.

FAQs:

¿Cómo se sellan los cuerpos de los conductos para uso en exteriores?

Sealing conduit bodies for outdoor use is essential to protect electrical connections from moisture, dust, and other environmental elements. Here’s how to properly seal them:

- Use Weatherproof Gaskets: When installing conduit bodies outdoors, ensure that the cover and the body are equipped with a weatherproof gasket or sealant. This will help prevent water and dirt from entering the body.

- Apply Silicone Sealant: For additional protection, you can apply silicone or polyurethane sealant around the edges of the conduit body cover before securing it. This creates a more airtight and waterproof seal.

- Use Approved Outdoor-Rated Fittings: When using conduit bodies outdoors, it’s crucial to use components specifically rated for outdoor use, such as weather-resistant covers and corrosion-resistant fittings.

- Check Seals Regularly: Over time, seals and gaskets may wear out, so it’s important to inspect and replace them periodically to ensure a continued waterproof barrier.

¿Para qué se utilizan los cuerpos de conductos?

Conduit bodies serve several functions in electrical systems:

- Junction Points: They act as connection points where different sections of conduit come together. Conduit bodies provide a safe, accessible location for splicing or joining electrical wires and cables.

- Wiring Access: They provide access to the wiring within the conduit system for future maintenance or troubleshooting. This allows electricians to work on the wiring without needing to dismantle large sections of the conduit system.

- Cornering and Bending: Conduit bodies, such as the LB, LR, and LL types, allow for smooth direction changes in the conduit system, helping to run wires around corners and bends.

- Proteccion: They offer additional protection to wiring from external elements and damage by enclosing the wires in a safe, secure box.

¿Cómo se pasa un conducto por las esquinas?

Running a conduit around corners requires either using pre-made fittings or bending the conduit manually. Here’s how to do it:

- Use Conduit Bodies: The most common method to run conduit around corners is by using a conduit body, such as the LB, LR, or LL models, which are designed for this purpose. These conduit bodies have built-in angles that allow for smooth changes in direction without the need for bends.

- Use Elbows or 90-Degree Bends: If you’re not using a conduit body, you can use elbows or pre-formed 90-degree bends. These fittings are installed directly into the conduit system to turn the conduit at the desired angle. Ensure that the bend radius meets the requirements for the type of conduit you’re using to prevent damage to the wire inside.

- Manual Bending: For metal conduit (such as EMT or RMC), you can use a conduit bender to create a custom bend around a corner. However, be mindful of the conduit’s minimum bend radius to prevent damaging the conduit or wiring.

Conclusión

In this article, we’ve explored the essential role that conduit bodies play in electrical systems, offering both functional and safety benefits. Conduit bodies are critical for providing accessible junction points, simplifying wiring layouts, protecting electrical connections, and ensuring smooth transitions in conduit systems. Whether you’re working with an LB, LR, or LL type, each conduit body is designed to meet specific needs while adhering to safety codes like NEC and CSA standards.

Understanding the types of conduit bodies, their applications, and the importance of code compliance ensures that your installations are both efficient and safe. Regular maintenance and correct installation will keep your electrical systems functioning smoothly and compliant with industry regulations.

If you’re ready to enhance your electrical systems with high-quality conduit bodies, contact us today or explore our wide selection of conduit bodies and fittings that meet the highest industry standards. Let us help you create safe, reliable, and efficient electrical systems with the right conduit solutions!