Tabla de contenido

Electrical systems are complex networks that require meticulous attention to detail during installation. One critical aspect of this process is the installation of PVC electrical conduit. PVC conduit serves as a protective housing for electrical wires, shielding them from potential damage and providing a secure pathway for their safe operation.

The importance of proper installation for PVC electrical conduit cannot be emphasized enough. This is especially true when working with PVC (polyvinyl chloride) electrical conduit. Installing PVC conduit correctly is crucial for ensuring the safety, efficiency, and longevity of your electrical system. In this article, we will explore the significance of proper installation practices for PVC electrical conduit and delve into the essential steps involved. By understanding the importance of proper installation, you will be equipped with the knowledge to carry out successful PVC conduit installations that meet safety standards and provide reliable electrical infrastructure.

Pre-installation Considerations:

Electrical installations are complex undertakings that demand careful attention to detail. When it comes to installing PVC (polyvinyl chloride) electrical conduit, there are several crucial factors to consider before diving into the installation process. Understanding and addressing these considerations is essential to ensure a safe and efficient electrical system.

▲Understanding electrical codes and regulations

Compliance with electrical codes and regulations is vital when installing PVC (polyvinyl chloride) electrical conduit. These codes and regulations establish industry standards to ensure the safe and proper installation of electrical systems.

Electrical codes and regulations provide guidelines for various aspects of conduit installation, including spacing, support, grounding, and wiring methods. Adhering to these standards not only ensures the safety of the electrical system but also helps prevent code violations, potential accidents, and operational inefficiencies.

1. National Electrical Code (NEC):

The National Electrical Code (NEC) is a widely recognized standard in the United States that governs electrical installations. It covers a broad range of topics related to electrical systems, including conduit installation. Some relevant sections of the NEC include:

Article 352: Rigid Polyvinyl Chloride Conduit (PVC)

Article 358: Electrical Metallic Tubing (EMT)

Article 362: Electrical Nonmetallic Tubing (ENT)

Article 376: Metal Wireways

Article 390: Underfloor Raceways

Article 352: Rigid Polyvinyl Chloride Conduit (PVC):

This article covers the requirements for rigid PVC conduit, including installation practices and permitted uses.

It specifies that PVC conduit should be securely fastened and supported at intervals for certain lengths of different size conduits.

It outlines the maximum fill capacities for PVC conduit based on the size and type of conductors being installed.

It provides guidelines for burial depths when PVC conduit is used underground.

2. Local Electrical Codes:

▲Planning conduit routes and sizes

Before conducting the installation, two things need to be planned.

Conduit Routes:

- Accessibility: Ensure that conduit routes are easily accessible for installation, maintenance, and future modifications.

- Obstacles: Identify and work around any existing infrastructure or structural elements that may hinder the conduit installation.

- Environmental Considerations: Choose conduit materials suitable for the environmental conditions, such as temperature, moisture, or corrosive substances.

- Cable Pulling: Minimize sharp bends and tight turns in the conduit route to facilitate smooth cable pulling during installation.

Conduit Sizes:

- Wire Capacity: Determine the number and size of wires the conduit needs to accommodate, considering future expansion needs.

- Fill Ratios: Adhere to electrical codes and standards to determine the maximum fill ratio allowed for PVC conduit.

- Voltage Drop: Select conduit sizes that minimize voltage drop, especially for long conduit runs or high-current applications.

- Bend Radius: Ensure the selected conduit size allows for proper bending radius to avoid wire damage during installation.

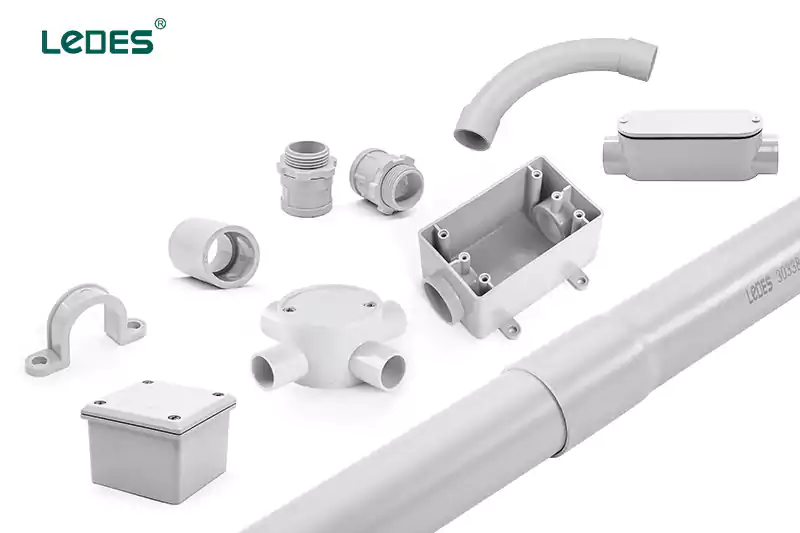

▲Selecting appropriate conduit fittings and accessories

Before installing PVC electrical conduit, consider the selection of appropriate conduit fittings and accessories. These components play a vital role in ensuring a secure and functional conduit system. Consider the following aspects when selecting conduit fittings and accessories:

- Type and Size: Choose fittings that are compatible with PVC conduit and match the conduit size being used (e.g., elbows, couplings, connectors).

- Material: Ensure that the fittings are made from corrosion-resistant and durable materials suitable for the intended environment.

- Thread Type: Verify that the fittings have the appropriate thread type (e.g., NPT – National Pipe Thread) for a secure connection.

- Conduit Joint Type: Consider the joint type required for your installation, such as solvent-welded joints or compression fittings, and select fittings accordingly.

- Accessibility: If the installation requires future access for maintenance or wire pulling, select fittings that allow for easy disassembly and reassembly.

- Conduit Supports: Choose appropriate supports, such as straps, hangers, or clamps, to securely fasten and support the conduit at regular intervals.

- Bushings and Grommets: Use bushings or grommets to protect wires from abrasion and damage at entry or exit points of conduit runs.

- Conduit Bodies: Select conduit bodies (e.g., LB, LL, LR, T) to facilitate changes in direction, provide access points, or accommodate wire splices within the conduit system.

- Grounding and Bonding: Consider grounding bushings, bonding jumpers, or grounding clamps to ensure proper grounding and bonding of the conduit system.

- Expansion Joints: In cases where conduit runs are subject to temperature variations, select expansion joints to accommodate thermal expansion and contraction.

Essential Tools for Installation:

To successfully install PVC electrical conduit, you will need the following essential tools:

1. Conduit Bending Tool

A conduit bending like heat gun, is used to create bends in the conduit, allowing for smooth routing and avoiding sharp angles or kinks.

2. Conduit Cutter

A conduit cutter is used to accurately cut the PVC conduit to the desired length. It ensures clean and precise cuts.

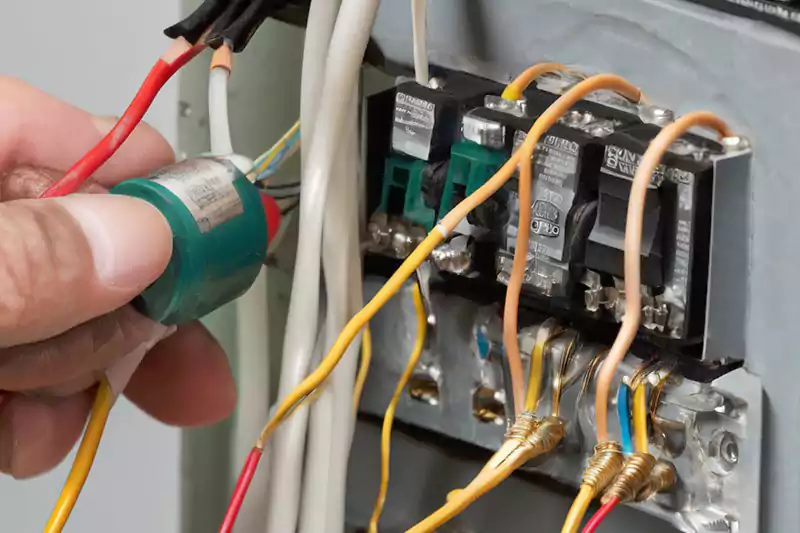

3. Screwdriver

A screwdriver is needed to tighten conduit fittings, secure conduit clamps, and perform other fastening tasks during installation.

4. Fish Tape

A fish tape, also known as a draw wire, is used to guide wires through the conduit. It helps with cable pulling and routing.

5. Level

A level is useful for ensuring that the conduit is installed horizontally or vertically, maintaining a neat and professional appearance.

6. Tape Measure

A tape measure is essential for accurately measuring conduit lengths, bend angles, and ensuring proper spacing between supports.

7. Pliers

Pliers are versatile tools that can be used for gripping, twisting, and cutting wires during the conduit installation process.

8. Hacksaw or PVC Pipe Cutter

If a conduit cutter is not available, a hacksaw or PVC pipe cutter can be used to cut the PVC conduit.

9. Drill and Bits

A drill is necessary for creating holes for conduit straps, mounting brackets, and other necessary attachments.

These tools will help you effectively install PVC electrical conduit, ensuring proper routing, secure connections, and neatness in the installation.

Conduit Installation Steps:

Step 1: Mark Conduit Placement:

Using a measuring tape, mark the locations where the conduit will be installed, including entry and exit points, bends, junction boxes, and supports.

Ensure the marked areas align with your planned conduit route.

Step 2: Cut and Prepare Conduit:

Measure the required length for each conduit section based on your markings.

Use a conduit cutter or hacksaw to make clean, straight cuts on the conduit.

Remove any burrs or sharp edges using a deburring tool.

Step 3: Install Conduit Fittings:

Attach the appropriate conduit fittings, such as elbows, couplings, or connectors, to the conduit sections.

Make sure the fittings are securely fastened to provide a tight and reliable connection.

Step 4: Mount Conduit Supports:

Install conduit straps or clamps at regular intervals along the conduit route.

Use screws or anchors to secure the supports to the mounting surface, such as walls or ceilings.

Step 5: Assemble the Conduit System:

Connect the conduit sections and fittings together, ensuring a snug fit.

Apply PVC conduit cement or glue to the inside of the fittings before joining them to ensure a watertight seal.

Follow the manufacturer’s instructions for cement or glue application and drying time.

Step 6: Pull Wires:

Attach a fish tape or draw wire to the starting point of the conduit system.

Carefully feed the fish tape through the conduit, pulling it along the desired path.

Use lubrication, if necessary, to ease the wire pulling process.

Attach the wires to the fish tape and pull them through the conduit, ensuring they are not strained or damaged.

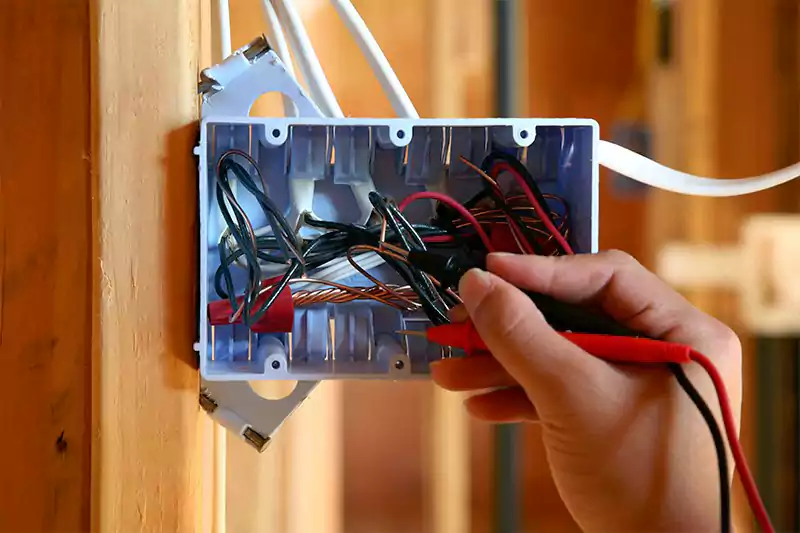

Step 7: Install Conduit Accessories:

Install conduit bodies, junction boxes, or other accessories as needed for wire splices, changes in direction, or access points.

Securely fasten the accessories to the conduit using appropriate fittings and hardware.

Step 8: Verify and Secure Connections:

Double-check all connections, ensuring they are properly aligned, secure, and free from any gaps or looseness.

Use a screwdriver or appropriate tool to tighten any loose fittings or fasteners.

Step 9: Conduct Final Inspection:

Inspect the entire conduit system to ensure it is properly aligned, securely mounted, and meets safety standards.

Check for any visible defects, such as misalignments or damaged conduit.

Verify that the wiring is neatly arranged and properly supported within the conduit.

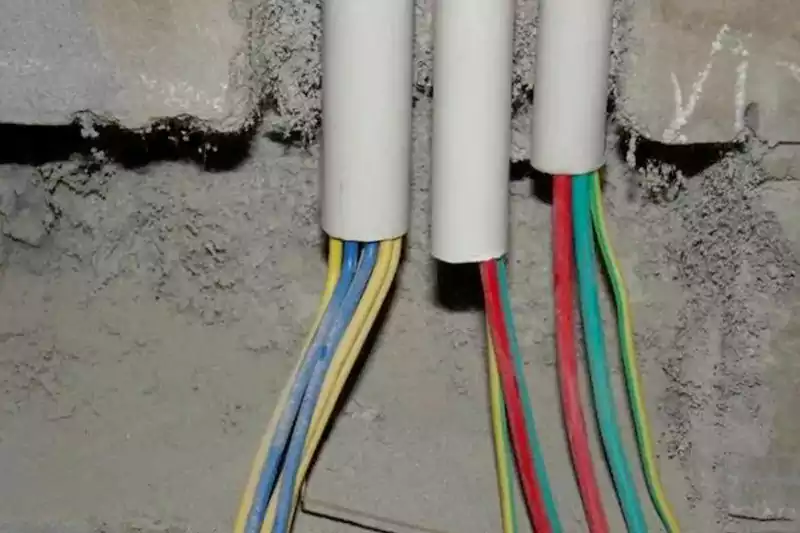

Wiring and Pulling Cables:

In the installation of PVC electrical conduit, the step of “Wiring and Pulling Cables” includes the following main aspects:

1. Preparing cables for conduit installation:

Before installing the conduit, the cables need to be prepared. This involves stripping the outer insulation of the cables to expose the individual conductors. The ends of the conductors may also need to be stripped to ensure proper electrical connections.

2. Techniques for pulling cables through conduit:

Pulling cables through the conduit can be a challenging task, especially if the conduit is long or has multiple bends. Here are some techniques to facilitate the process:

- Lubrication: Applying a suitable lubricant to the cables can reduce friction and make pulling easier.

- Proper bending radius: Ensure that the cables are not bent beyond their recommended bending radius to avoid damaging the insulation or conductors.

- Pulling tools: Various tools, such as cable pulling grips or fish tapes, can be used to assist in pulling the cables through the conduit.

- Proper cable grouping: Grouping the cables together before pulling can make the process smoother and prevent tangles.

3. Ensuring proper cable management within conduit systems:

It is essential to maintain proper cable management within the conduit systems to ensure safety and ease of maintenance. Here are some considerations:

- Adequate conduit size: The conduit should have enough space to accommodate the cables without causing excessive compression or bending.

- Cable spacing: Proper spacing between cables should be maintained within the conduit to prevent overheating and interference.

- Securing cables: Cables should be securely fastened within the conduit using appropriate supports or clamps to prevent excessive movement or strain.

- Labeling: It is recommended to label the cables at both ends to facilitate identification and troubleshooting in the future.

Conduit Bends, Junctions, and Transitions:

Proper use of fittings and connections is crucial in the installation of PVC electrical conduit. They play an important role in the installation process.

1. Conduit Bends:

Creating accurate conduit bends using bending tools is essential to ensure proper cable routing and installation. Bending tools, such as conduit benders or heat guns, are used to bend the conduit at the desired angle without damaging its structure or integrity. Accurate bends help ensure smooth cable pulling and prevent excessive strain or sharp bends that could damage the cables. Or directly use fittings such as elbows and bends.

2. Conduit Junction Boxes:

Proper installation of conduit junction boxes is crucial for electrical safety and convenient access to the wiring connections. Junction boxes are used to provide a secure enclosure for wire splices, connections, or terminations. When installing junction boxes, it is important to ensure they are properly sized for the number and size of cables, and that they are securely fastened to the wall or structure. Adequate sealing or gasketing may be required to maintain the integrity of the electrical installation.

3. Transitioning between different conduit sizes or types:

In some installations, it may be necessary to transition between different conduit sizes or types. This can occur when connecting conduits of different diameters or when transitioning from PVC conduit to metal conduit, for example. Transition fittings or adapters are used to facilitate these changes. These fittings are designed to provide a secure and smooth transition between the different conduit sizes or materials, ensuring proper cable routing and maintaining the integrity of the electrical installation.

Conexión a tierra y unión:

Understanding the importance of grounding in conduit systems:

Grounding is a fundamental aspect of electrical systems that ensures safety by providing a path for electrical faults to be safely discharged to the ground. In conduit systems, grounding serves multiple purposes, such as protecting against electrical shocks, reducing the risk of electrical fires, and maintaining proper functioning of electrical equipment. Grounding also helps to mitigate electromagnetic interference.

Proper grounding techniques for PVC conduit:

While PVC conduit itself is non-conductive, it is important to ensure proper grounding for the electrical equipment and systems connected to the conduit. This is typically achieved by grounding the metal components associated with the electrical system, such as junction boxes, enclosures, and grounding electrodes. Copper or aluminum grounding conductors are used to establish a low-resistance path to the grounding system. Grounding techniques for PVC conduit may involve:

- Connecting metal fittings, junction boxes, and enclosures to the grounding conductor using grounding screws or bonding jumpers.

- Properly sizing the grounding conductors based on the electrical load and following local electrical codes and standards.

- Ensuring a continuous and low-resistance grounding path throughout the conduit system.

Bonding conduit to ensure electrical continuity:

Bonding is the process of connecting metallic conduit sections together to ensure electrical continuity and to establish a reliable ground path. It helps to prevent voltage potential differences between metallic components and reduces the risk of electrical hazards. Bonding techniques may involve using bonding bushings, bonding jumpers, or bonding straps to establish a continuous metallic path throughout the conduit system.

By understanding the importance of grounding in conduit systems, implementing proper grounding techniques for PVC conduit, and ensuring effective bonding, you can enhance electrical safety, protect against electrical faults, and promote the efficient operation of electrical systems.

Troubleshooting Common Installation Issues:

In the installation of PVC electrical conduit, it is important to be aware of common issues that may arise and know how to troubleshoot them. Some common installation issues include:

Identifying and addressing conduit obstruction or blockage:

Sometimes, during the installation process, the conduit may become obstructed or blocked, making it difficult to pull the cables through. This can happen due to construction debris, improper cable management, or incorrect installation of fittings. To address this issue, the following steps can be taken:

- Inspect the conduit for any obstructions or blockages.

- Clear the conduit by removing any debris or foreign objects.

- Ensure proper cable management within the conduit to prevent future blockages.

Dealing with conduit damage or misalignment:

Conduit may get damaged or misaligned during installation, which can affect the integrity and functionality of the electrical system. Common causes include accidental impact, improper handling, or inadequate support. To resolve these issues:

- Inspect the conduit for any visible damage or misalignment.

- Replace any damaged sections of conduit.

- Straighten or realign misaligned sections, if possible.

- Ensure proper support for the conduit to prevent future damage or misalignment.

Resolving issues with improper conduit fittings or connections:

Improper installation or selection of conduit fittings and connections can lead to various issues, such as poor electrical continuity, loose connections, or difficulty in cable pulling. To address these problems:

- Inspect the fittings and connections for any signs of improper installation or damage.

- Replace any faulty or incorrectly installed fittings.

- Ensure proper tightening of connections to maintain electrical continuity.

- Use appropriate fittings and connectors that are compatible with the conduit and electrical system.

Additional troubleshooting steps may be required depending on the specific issues encountered during the installation process. It is important to consult relevant electrical codes, standards, and seek professional assistance if needed to ensure a safe and reliable installation of PVC electrical conduit.

Tips for Different Scenarios:

There are could be many situations and scenarios during the electrical installations, here are some tips for different scenarios:

1. Above ground runs vs buried installations:

- Above ground runs: When installing PVC conduit above ground, it is important to consider factors such as exposure to sunlight, temperature variations, and mechanical protection. UV-resistant PVC conduit or conduit with suitable UV-resistant coatings can be used to protect against sunlight degradation. Adequate supports and fastening should be used to secure the conduit in place.

- Buried installations: For buried PVC conduit installations, it is crucial to follow local building codes and regulations. The conduit should be buried at the appropriate depth to protect it from damage and meet the required burial depth specifications. Additionally, using schedule 80 PVC conduit, which is more rigid and durable, can provide added protection against external pressures and potential impact.

2. Organizing multi-branch circuits:

- Plan the layout: Before installing PVC conduit for multi-branch circuits, carefully plan the layout to ensure efficient cable routing and organization. Consider the number of circuits, their distribution, and the location of junction boxes or panels.

- Use separate conduits: Depending on the complexity of the circuitry, it may be beneficial to use separate conduits for different branches or circuits. This allows for easier identification, troubleshooting, and future modifications.

- Etiquetado: Properly label the conduits, junction boxes, and cables to ensure clear identification of circuits and simplify maintenance or repairs.

3. Fireproofing requirements:

- Consult local codes: Fireproofing requirements for PVC conduit installations may vary depending on local building codes and regulations. It is important to consult and adhere to these requirements to ensure compliance and safety.

- Use fire-rated materials: In areas where fireproofing is necessary, such as fire-rated walls or ceilings, use fire-rated PVC conduit and associated fittings. These materials are specifically designed to withstand high temperatures and prevent the spread of fire.

- Firestopping: In some cases, firestopping materials or techniques may be required at conduit penetrations through fire-rated barriers. These materials help maintain the fire resistance of the barrier by sealing gaps and preventing the passage of flames or smoke.

Remember to consult local regulations, electrical codes, and seek professional advice when dealing with specific scenarios or requirements. This will ensure that the installation of PVC electrical conduit is done safely and in compliance with applicable standards.

Safety Considerations:

In the installation of PVC electrical conduit, several safety considerations should be followed to ensure a safe working environment. These include:

Importance of following safety guidelines during installation:

– Adhering to safety guidelines and procedures is crucial to prevent accidents, injuries, and electrical hazards during conduit installation.

– Familiarize yourself with local electrical codes, regulations, and safety standards specific to conduit installations.

– Follow manufacturer instructions and recommended practices for handling and installing PVC conduit and associated materials.

Electrical safety precautions when working with conduit systems:

– Prior to starting any work, ensure that the electrical power is turned off and the circuit is de-energized to prevent electrical shocks or accidents.

– Use voltage detectors or other appropriate testing equipment to verify that the circuit is de-energized before working on conduit systems.

– Avoid working in wet or damp conditions to minimize the risk of electrical shock.

– Keep all tools and equipment properly insulated and in good working condition.

– Take precautions to prevent accidental contact with live electrical parts or conductors.

Personal protective equipment (PPE) recommendations:

– Wear appropriate personal protective equipment (PPE) to minimize the risk of injuries or exposure to hazardous substances.

– Common PPE for conduit installation may include safety glasses or goggles, gloves, and protective clothing.

– Consider using respiratory protection, such as dust masks, when working in environments with potential airborne contaminants, such as when cutting or drilling conduit.

Additional safety considerations:

– Ensure proper lighting in the work area to enhance visibility and reduce the risk of accidents or mistakes.

– Use proper lifting techniques when handling heavy conduit or equipment to prevent strains or injuries.

– Maintain a clean and organized work area to minimize trip hazards and facilitate safe movement.

Remember to prioritize safety throughout the entire installation process. If you are unsure about any aspect of the installation or encounter unfamiliar situations, consult with a qualified electrician or relevant professionals for assistance.

Maintenance and Long-Term Care:

The final step for PVC conduit installation involves maintenance and long-term care of the conduit system. Here are some considerations for this step:

Inspecting conduit installations for wear or damage:

- Regularly inspect the conduit system for any signs of wear, damage, or deterioration. This includes checking for cracks, breaks, or deformation in the conduit, as well as inspecting fittings, connections, and junction boxes.

- Pay attention to areas where the conduit is exposed to environmental factors, such as sunlight, moisture, or extreme temperatures, as these conditions can accelerate wear and deterioration.

- Promptly address any identified issues to prevent further damage and ensure the integrity of the electrical system.

Cleaning and maintaining conduit systems:

- Keep the conduit system clean and free from debris, dirt, or other contaminants. Regularly remove any accumulated dirt or debris both inside and outside the conduit.

- Avoid using abrasive or corrosive cleaners that may damage the conduit or its fittings. Instead, use mild detergents or specialized cleaning solutions recommended by the conduit manufacturer.

- Inspect and clean conduit openings, such as junction boxes or enclosures, to ensure unobstructed access and proper functioning.

Addressing potential issues proactively to prevent future problems:

- Proactively address any potential issues that may arise in the conduit system. This includes identifying and addressing factors that may contribute to wear, damage, or malfunctions, such as excessive cable tension, inadequate support, or environmental conditions.

- Regularly review and update cable management practices to ensure cables are properly organized and secured within the conduit system.

- Stay informed about changes in electrical codes, regulations, or industry standards that may impact the maintenance or care of the conduit system. Implement necessary updates or modifications accordingly.

By regularly inspecting, cleaning, and maintaining the conduit system, as well as addressing potential issues proactively, you can ensure the longevity and reliable performance of the PVC electrical conduit installation. Additionally, following manufacturer recommendations and consulting with qualified professionals can provide valuable guidance for long-term care and maintenance.

Conclusión

In summary, the installation of PVC electrical conduit involves various intricate details that need to be understood thoroughly in order to ensure compliance with installation regulations and requirements. It is crucial to follow these guidelines and perform the installation correctly to guarantee the safety and long-term stability of the electrical system. Ledes is a manufacturer that specializing in PVC electrical conduit, knowing well about the installation requirements. If you have any questions, don’t hesitate to contact us.