Tabla de contenido

An electrical conduit is a tube used to protect and route electrical wiring in a building or structure. Electrical conduit may be made of metal, plastic, fiber, or fired clay. Most conduit is rigid, but flexible conduit is used for some purposes.

Why Use Electrical Conduit?

Regardless of the material of the wire conduit, it is to protect the wires. Not only during installation but also during later use. It can isolate bacteria, moisture, microorganisms, etc., and avoid safety problems caused by short circuits of wires.

In large equipment, especially electrical equipment, wire conduit is indispensable. For example, the Abu Dhabi UAE Al Dhafra PV2 Project participated before considering the solar panels and wire pipes need to be exposed to extremely harsh environments for a long time, requiring higher quality wire pipes. High temperatures and UV light during the day and extremely low temperatures at night will constantly erode the electrical conduits and wires, and if there is a problem, it may cause the equipment to short out and fail to be used.

Some Basics Theory

There are differences between the conducto rígido and flexible pipe, usually made of metal or plastic. For installation purposes, we must carefully evaluate your installation environment before purchasing to avoid some problems. For example, when installing in a corner, the installation is difficult due to the inability to bend the pipe.

In different countries, in addition to the different sizes and specifications, more importantly, there are corresponding installation standards. For example, the United States has NEC Code covering 50 states. It has made clear specifications for the construction details, such as the buried depth of the conduit pipe and fittings.

Whether a DIY installation or a decoration company, it must operate according to the NEC’s relevant specifications. Otherwise, it may be short-circuited, causing an electrical fire and endangering safety.

If you are not a professional electrician, we recommend leaving this work to an electrician to avoid the risk of installation errors.

Types Of Electrical Conduits

Industry classification is generally based on different materials. Different countries or standards have different requirements for the outer diameter, inner diameter, and wall thickness of electrical conduits, so there will be differences. In addition, even if the material is similar, some products will be subdivided for use, such as a Liquid-tight conduit, whose feature is that it can improve sealing and watertight performance.

Metal

Type of Metal Conduit

Conducto metálico rígido (RMC)

Rigid metal conduits are common and can be found in many commercial buildings. It is generally thick-walled, heavy-duty, and made of coated steel, stainless steel, or aluminum.

Since large-scale commercial buildings generally require high power, the diameter of the wire is thick. To increase the number of pull wires, the diameter of this type of wire tube is generally larger, and the impact resistance is stronger. At the same time, because of its large diameter and strength, it cannot bend pipes and is expensive.

Conducto rígido galvanizado (GRC)

It is also very common, generally used in commercial or industrial buildings, and the cost is cheaper than stainless steel or aluminum pipes. Galvanizing is to add an anti-rust layer, which can ensure that the rust cycle is delayed after outdoor or indoor installation.

Likewise, GRC usually has thick walls and is suitable for heavy or medium construction projects. It can provide excellent impact resistance and protect wires well.

Conducto metálico intermedio (IMC)

A metal pipe with impact strength higher than EMT but lower than RMC is not as widely used as the former two.

Tubos Metálicos Eléctricos (EMT)

Usually called Thin Wall Conduit, it is thicker but lighter than RMC, so it is usually used to replace RMC series products.

EMT is not threaded but can be connected to threaded fittings. EMT is commonly used in commercial and industrial buildings, usually produced from coated steel and aluminum.

Conducto de aluminio

Similar to the above-mentioned several metal tubes, the aluminum tube is also rigid. It is usually used in commercial or industrial buildings, especially in projects that require high corrosion resistance, such as food factories, water purification plants, etc.

Another point is that aluminum pipes cannot be directly embedded in concrete and need a protective coating before they can be used normally (such as adding a plastic coating).

Because aluminum is lighter, it has pros when installing, such as saving your labor cost.

Non-metal

Conducto de PVC

Currently, among the non-metallic conduits, the most common one is PVC wire conduit products, which is also the main product of Ledes.

Compared with metal conduits, PVC conduits’ strength and flame retardancy are worse than metal conduits, which is very obvious. At the same time, it has many advantages, such as lower cost, lightweight, easy to bend, easy to transport, not susceptible to corrosion, and so on. Moreover, in the electrical conduit market in North America, PVC conduits with different wall thicknesses have been differentiated according to current uses and have been widely accepted in the industry.

In addition, the accessories of PVC conduit are also easy to purchase, which can perfectly match the needs of different scenarios and projects.

Conducto de resina termoendurecible reforzada (RTRC)

RTRC is a fiberglass conduit with obvious advantages, such as lightweight, low manufacturing cost, and strong corrosion resistance.

Considering the main advantages of RTRC, it is widely used in outdoor and indoor projects, and its upgraded version of the low-smoke and halogen-free product series has also been applied in commercial projects.

Conducto rígido no metálico (RNC)

A non-metallic, unthreaded, smooth-walled conduit.

Tubos eléctricos no metálicos (ENT)

Thick-wall, corrugated pipe characteristics are similar to PVC conduit.

The birth of corrugated pipe is mainly to solve our needs in the corner or need to “turn.” ENT can realize the pipe bending requirements without using the bending tools, and the manufacturer has special accessories for sale, which are very convenient to use.

Flexible

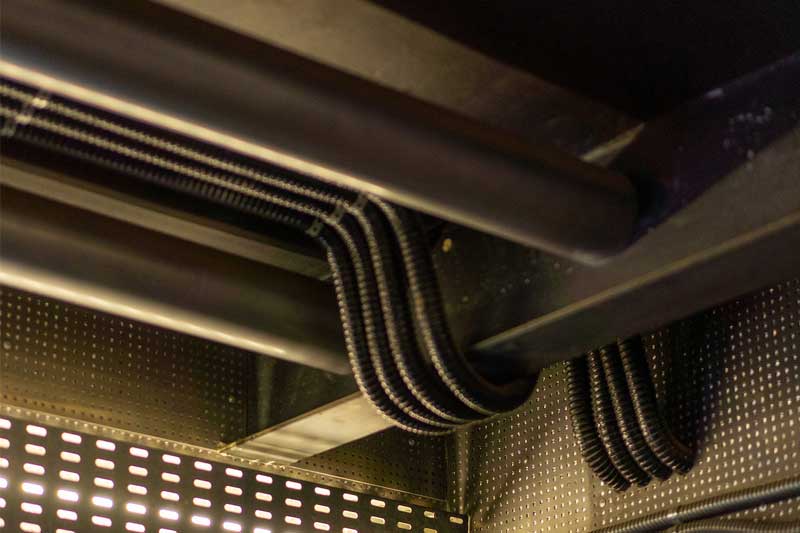

Flexible Metallic Conduit (FMC or Flex)

is made by the helical coiling of a self-interlocked ribbed strip of aluminum or steel; the hollow part in the middle can be convenient for pulling the wire.

It also makes up for the lack of EMT because it has flexibility. FMC can be applied in dry places and has enough strength to protect the wires from damage.

It is worth mentioning that because FMC can be bent, it can absorb a small vibration and accept small displacement space. Therefore, it can be applied to equipment and machinery such as water pumps and motors.

Liquid Tight Flexible Metal Conduit (LFMC)

Like FMT plus a layer of plastic Coating, this can enhance its waterproof performance.

Similarly, the accessories suitable for LFMC strengthen the waterproof performance, such as adding sealing rubber rings.

Flexible Metallic Tubing (FMT)

FMT is a raceway rather than a conduit. According to the description in NEC, It only comes in 1/2″ & 3/4″ trade sizes, whereas FMC is sized 1/2″ to 4″ trade sizes.

In practical applications, FMT is often used in short-distance exposed connections to space, such as the garbage processor cable connection and the water heater’s wire connection.

Liquid Tight Flexible Nonmetallic Conduit (LFNC)

Non-metallic conduits with flame retardancy are collectively referred to, and the inner wall of the conduit has reinforcements, which can be smooth or corrugated.

It can be applied to dry, wet, or oily scenes, such as surface laying, high voltage units, swimming pools, etc.

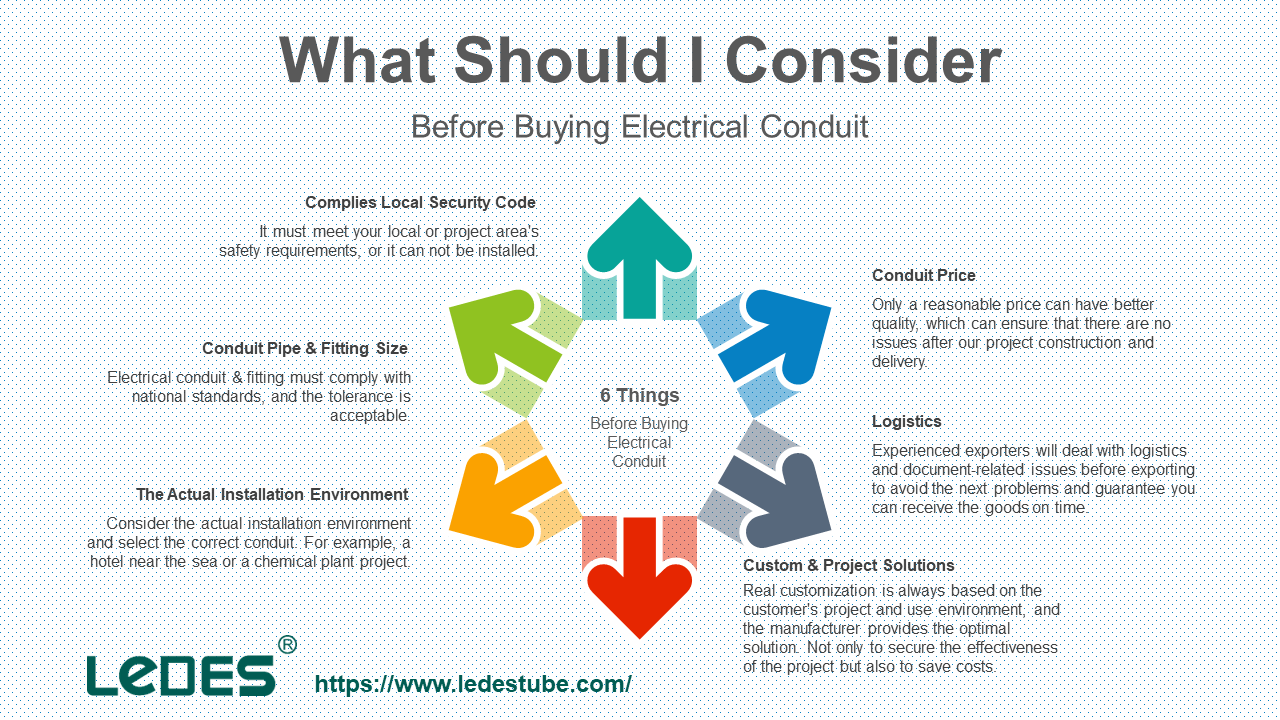

What Should I Consider Before Buying an Electrical Conduit

Whether we are individual buyers, wholesalers, or even builders, we are confused before purchasing electrical conduits: what problems should we pay attention to?

If you are buying electrical products and accessories in bulk for the first time and are also looking for buyers from foreign suppliers on the Internet, here we summarize the precautions that can help you buy the products you need.

6 Things Before Buying Electrical Conduit

Comparta esta imagen en su sitio

It Complies with Local Security Requirements

Although we are all clear that electrical wire conduit products in different countries have different sizes and specifications, it is necessary to confirm whether they meet the safety requirements of your local or project area. Otherwise, even if the product enters the construction site, it cannot be installed normally.

For this, you only need to check the relevant regulations in your area before purchasing, such as NEC code in North America.

Is the Conduit Pipe Size in Compliance?

Does it matter? It’s very simple. I consult the seller, confirm the size I need, and buy it.

For products circulating through formal channels, there is no problem. But our customers complained to us that they bought the product several times, and they were pretty sure that they bought the standard size product, but found that the size was wrong at the installation stage.

Whether it is any testing agency, such as UL, their test requirements will make requirements on the inner diameter and outer diameter of the wire tube, but within a range, the existence of allowable tolerances. However, once the tolerance of some products is out of range, it is difficult for our naked eyes to find out.

Therefore, we recommend you purchase compliant products from brand owners to avoid such problems.

Fitting Size Compliance

The PVC conduits and fittings are also very important, such as elbows, junction boxes, etc. Once the fitting is the wrong size (as we said above), then the same problem occurs, it is not working.

The Actual Installation Environment

Some projects have excessive humidity or are close to the sea, and many installation locations need to be installed on the wall or around the corner. It would help if you were extra considering the project design requirements and actual installation environment.

However, we must also balance the construction cost and difficulty. For example, if we use steel pipes, the time cost of pipe bending will increase.

And suppose it is close to the sea or a chemical product factory. In that case, metal conduits can be excluded from the selection of electrical conduits because plastic conduits are a smart choice.

Conduit Price

Undoubtedly, this is directly related to the project’s cost.

However, for products with lower prices than most brands, we must be vigilant. Just imagine that merchants still have to provide you with after-sales service and quality assurance, so how do merchants make money for products that are too cheap? The only option is to reduce the quality of the product, which is not cost-effective for buyers.

For example, in PVC conduit, merchants can use recycled materials to produce piping and sell them to buyers at a lower price. However, the quality of products produced from recycled materials is unstable. If there is a problem, the merchant will not solve it for you well because they have already paid the money.

Logistics

From the moment your product is finished, this question will be involved.

It seems pretty simple. But, from the design of the package, the way of loading the container and delivery to your warehouse by truck after arriving at the port. With such a long process, no one can guarantee no issues will happen.

Experienced brand owners with rich experience can think of and avoid problems in advance before shipment, giving you a better buying experience.

Custom & Project Solutions

Customization is actually OEM if you just change the size or wall thickness.

Customization should be a product tailored to your needs based on the customer’s project and actual usage scenarios. Raw materials, formulations, and the final product’s performance are all different, which is the experience Ledes has learned from thousands of cases.

Now, we hope to serve your projects with our experience.

Fin

That’s it. If you have other questions, welcome to enviar el formulario de contacto or send us an email, and we will answer your questions within 24 hours.

References: