Tabla de contenido

Comparta esta imagen en su sitio

Descripción general

All information is explained based on UL 651 Eighth Edition, published on Oct 25, 2011, and all interpretation rights belong to UL.

Ámbito de aplicación

Conductos y accesorios de PVC rígido extruido cédula 40 y 80, tipo EB y A. UL651 se aplica a accesorios relacionados, incluidos codos, acoplamientos, adaptadores, juntas de expansión, expansión-deflexión, deflexión y accesorios de tuberías rígidas para la construcción. Sin embargo, el material UPVC debe cumplir con los requisitos pertinentes de ASTM 1784.

Los estándares relevantes de UL 651 han cubierto los estándares relevantes en NEC (Código Eléctrico Nacional) y NFPA 70. Los conductos y accesorios de PVC rígido Schedule 40 y 80 se pueden usar para acabados interiores y exteriores o para uso en exteriores. Deben protegerse de la luz solar y de los efectos de las inclemencias del tiempo y pueden utilizarse directamente sobre el hormigón.

Conductos y accesorios de PVC rígido, cédulas 40 y 80 Se puede utilizar a una temperatura entre 50 °C (122 °F) y 75 °C (167 °F).

Funciona bien y se puede utilizar para necesidades de cableado de 90 °C (194 °F).

Detalles de dimensiones

Para materiales reciclados limpios o materiales mixtos, los fabricantes deben garantizar que se cumplan los estándares relevantes, como UL746D y los estándares relacionados con UL.

Aquí queremos expresar nuestras opiniones. Aunque por razones de protección del medio ambiente, el uso de materiales reciclados o una producción mixta puede reducir el desperdicio de materias primas, la desventaja es que conduce a una disminución del rendimiento.

Entonces habrá una situación en la que muchos productos en el mercado afirmarán estar certificados según los estándares UL pertinentes. De hecho, también cuentan con certificados de cumplimiento. Pero en términos de rendimiento, sí hay una disminución, como la resistencia al estiramiento.

Los conductos y accesorios de PVC rígido cédula 40 y 80 son resistentes a influencias corrosivas comunes, incluidos vapores y neblinas de ácido alcalino, fluorhídrico y crómico, así como al decapado y galvanoplastia, y satisfacen las necesidades de los usuarios en estos escenarios industriales.

Los conductos rígidos de PVC cédula 40 y 80 y las paredes interiores de los accesorios deben ser lisas y no debe haber riesgo de que las rebabas causen daños a los cables. Además, no debe haber astillas, ampollas, grietas, desconchones, incrustaciones, tiza u otros defectos en la superficie exterior del tubo.

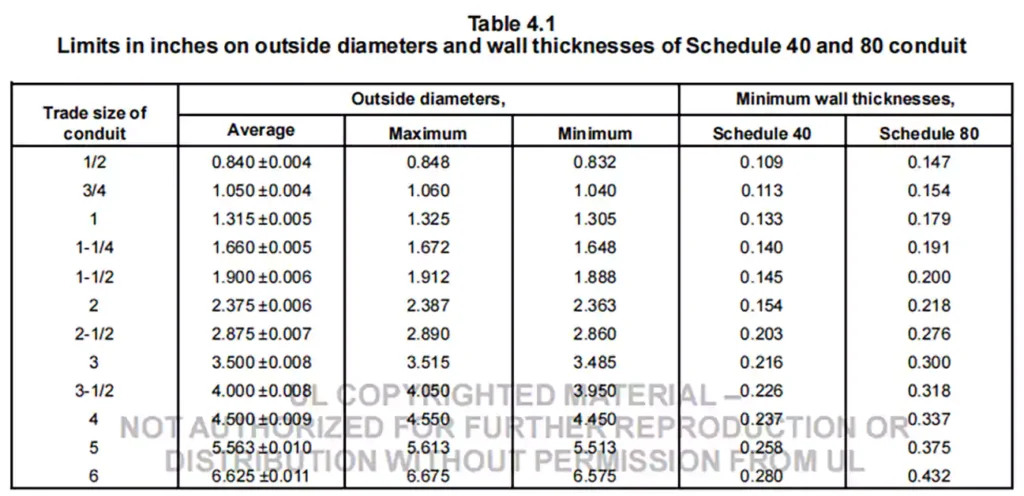

El cuerpo de la tubería debe mantener las ordenadas verticales y no tener roscas. Utilice un micrómetro o un medidor de manga cónica para medir; la escala debe tener una precisión de 0,001 pulgadas o 0,01 mm y la desviación de la precisión de la medición no debe exceder ±1%. Las dimensiones medidas deben ajustarse a las dimensiones especificadas relevantes. Los datos relevantes ya incluyen el rango de tolerancia. Las dimensiones que deben cumplirse incluyen el espesor exterior, interior y de pared. Además, al igual que los acoplamientos, es necesario medir la longitud, la profundidad del casquillo, etc.

Los requisitos de tamaño para conductos de PVC rígido cédula 40 y 80 se describen claramente en la Tabla 4.1. En términos generales, el rango de tolerancia del diámetro exterior es de ±0,004 a ±0,011 pulgadas, mientras que el diámetro interior y el espesor de la pared son valores mínimos especificados para garantizar que se alcancen los parámetros requeridos.

Para los tipos A y EB, el método básico es similar. La diferencia es que en esta versión, el diámetro exterior y el espesor de pared del Tipo EB, la descripción oficial es que "Se agregarán requisitos adicionales a medida que se determine que estos tamaños son aceptables".

Para los requisitos de calidad de los accesorios, UL651 también tiene algunas regulaciones, como una pared interior lisa y sin rebabas, que no puede afectar el movimiento de los cables. No permite residuos, ampollas, grietas, descamación, descamación, pulverización u otros defectos.

UL 651 también especifica los valores máximos y mínimos de longitud, espesor de pared, diámetro del zócalo y otros parámetros para que todos los accesorios coincidan con el conducto rígido. Por ejemplo, para acoplamientos para conductos tipo EB y A, bajo la condición de un tamaño comercial de 1/2 a 6 pulgadas, la tolerancia promedio del diámetro interior en el extremo interno del casquillo es de ±0,008 a ±0,014 pulgadas, mientras que el promedio La tolerancia del diámetro interior en la entrada del casquillo es de ±0,015 a ±0,023 pulgadas y los requisitos de tamaño se especifican en la tabla correspondiente.

También hay algunos especiales, que aquí enumeraremos brevemente. Por ejemplo, en un adaptador roscado adecuado para cables y tubos de PVC roscados, la rosca debe ser clara y limpia, y el tamaño debe cumplir con los requisitos de ASME B1.20.1-1983. Al mismo tiempo, el puerto roscado debe tener suficiente campo y superar la prueba de flexión.

Debido a que hay demasiados accesorios, no los enumeraremos aquí.

Rendimiento y pruebas

Hay hasta 19 pruebas de rendimiento en UL651, que es la prueba definitiva para el rendimiento del producto. Elegimos los siguientes elementos para alguna explicación,

- Resistencia a la tracción

- Extrusión

- Absorción de agua

- Resistencia al impacto

- Resistencia al aplastamiento

- Fuego

- Resistencia a la luz solar

- Schedule 40 and 80 for use with 90°C wire

- Permanencia de la impresión

Resistencia a la tracción

The primary goal of this test is to determine the tensile strength of both aged and unaged specimens of rigid PVC conduit. The aged specimens must retain at least 95% of the tensile strength of their unaged counterparts to meet compliance requirements.

Specimen Preparation

- Six specimens are cut from finished conduit, with specific dimensions based on the conduit type.

- Measurements, including wall thickness and diameter, are taken using precision micrometer calipers with a minimum accuracy of 0.0001 inches (0.001 mm).

- The conduit must be clean and at a controlled temperature of 23.0 ±2.0°C (73.4 ±3.6°F) before testing.

Procedimiento de prueba

- Aging Process: Three specimens are subjected to 168 hours in a circulating-air oven at 113.0 ±1.0°C (235.4 ±1.8°F), then cooled in still air.

- Tensile Testing:

- The six specimens (three aged and three unaged) are tested within 16 to 96 hours after aging.

- A metal plug is inserted to prevent crushing during testing.

- Each specimen is subjected to tensile force on a power-driven machine, with grips separating at a controlled rate of 1/2 ±1/8 inch (10.0 ±2.5 mm) per minute.

- The maximum load before failure is recorded.

Results & Evaluation

- Tensile strength is calculated by dividing the maximum load by the cross-sectional area.

- The average tensile strength of aged and unaged specimens is compared to ensure compliance with UL651 requirements:

Schedule 40 & 80: Minimum 5,000 psi (34.5 MN/m²).

Type A & EB: Minimum 4,000 psi (27.6 MN/m²).

- The aged specimens must maintain at least 95% of the unaged specimens’ tensile strength.

Extrusión

Simulate extruding PVC pipes using anhydrous acetone to observe and test for incomplete fusion. In general, whether there is a large area of peeling, cracking, and other problems after soaking, test whether the product meets the standard requirements. It is a great test for PVC catheters’ raw material quality and production process.

Absorción de agua

UL651 requiere que después de que el producto esté terminado Conducto de PVC Si se sumerge el tubo de PVC en agua destilada durante 24 horas, la tasa de absorción de agua no debe superar el 0,50% de su peso. Es muy fácil de entender. Si enterramos los tubos de PVC en el suelo, inevitablemente se verán afectados por la humedad del suelo. Si el conducto de PVC absorbe demasiada agua y se hincha, provocará que la unión del conducto se hinche y se deforme, lo que dará como resultado un sellado deficiente y el resultado es que los cables no están protegidos como deberían.

Resistencia al impacto

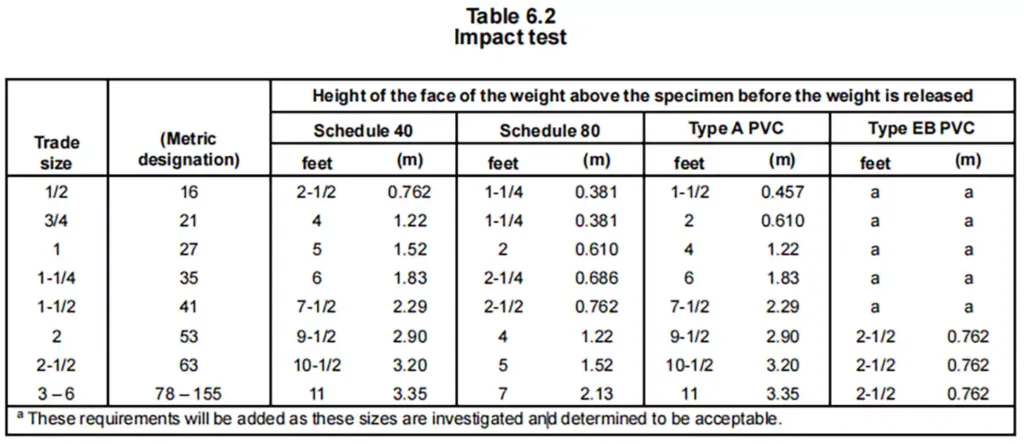

The Resistance to Impact Test outlined in UL 651 evaluates the ability of rigid PVC conduit to withstand physical impact without cracking or tearing beyond an acceptable limit. This test is crucial in assessing the durability and mechanical strength of conduit under real-world conditions, ensuring that it remains intact and functional even when subjected to sudden force or impact.

Specimen

- Ten 6-inch (150 mm) specimens are cut from finished lengths of each trade size of rigid PVC conduit.

- The specimens must be free from cracks, tears, or other imperfections before testing.

Acondicionamiento

- The specimens are conditioned in air at a temperature of 23.0 ±2.0°C (73.4 ±3.6°F) for at least 4 hours to ensure uniform testing conditions.

Impact Setup

- Each specimen is placed on a solid, flat, steel plate that is at least 1/2 inch (13 mm) thick and firmly anchored in a horizontal position.

Impact Mechanism

- A steel weight, shaped as a solid, right-circular cylinder with a flat impact face and rounded edges, is dropped onto the specimen from a specified height.

- The impact conditions depend on the conduit type:

Schedule 40, Type A, and Type EB:

Peso: 20 lbs (9.1 kg)

Cylinder diameter: 2 inches (51 mm)

Anexo 80:

Peso: 75 lbs (34 kg)

Cylinder diameter: 6 inches (150 mm)

- El flat face of the weight strikes the center of the specimen across the diameter and along the longitudinal axis, ensuring a standardized impact force.

- A mechanism is in place to ensure the weight only strikes once per test.

Pass/Fail Criteria

- The rigid PVC conduit fails the test if more than three out of ten specimens develop a crack or tear longer than 1/32 inch (0.8 mm) along the outer surface.

- If seven or more specimens remain intact or develop cracks/tears within the allowable limit, the conduit passes the test.

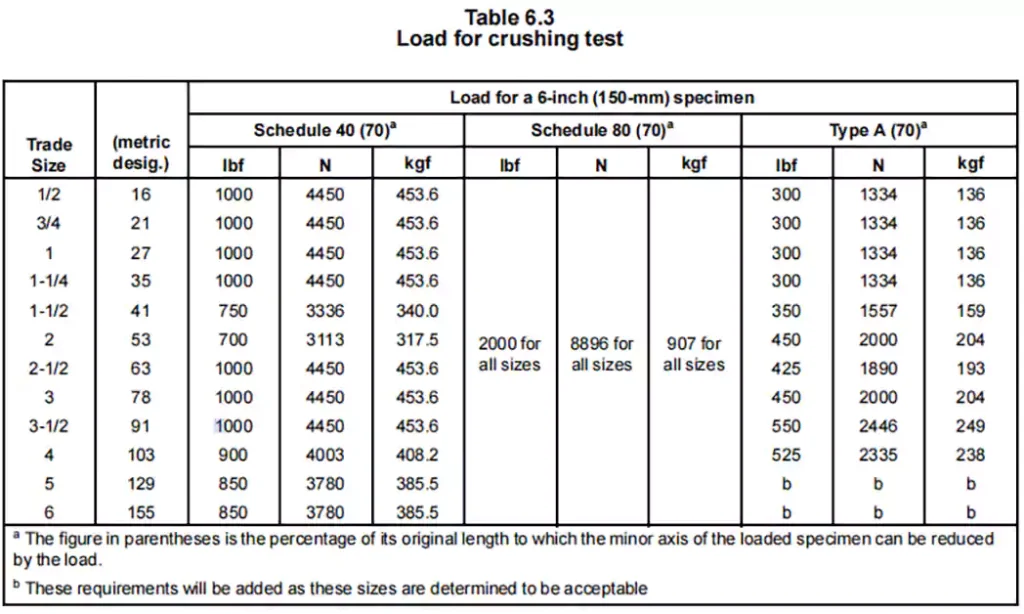

Resistencia al aplastamiento

The Resistance to Crushing Test evaluates the ability of rigid PVC conduit to withstand external pressure without significant deformation or structural failure. This test ensures that the conduit maintains its integrity under compressive forces, which is essential for its performance in underground, encased, or exposed installations where it may be subjected to heavy loads.

By simulating real-world conditions, the test verifies that the conduit does not buckle or excessively deform under specified loads. A key criterion for passing the test is that the minor axis of the inner diameter must not be reduced to less than 70% of its original measurement before loading.

Esta prueba se diferencia de la prueba de resistencia al impacto porque el conducto de PVC está incrustado en el suelo o en la pared y está bajo presión durante un largo tiempo. En este ensayo se experimenta la capacidad compresiva del conducto de PVC bajo la acción de una presión, que también afecta al mismo. Factores de longevidad.

Fuego

The Flame Test in UL 651 evaluates the fire resistance of Schedule 40 and Schedule 80 rigid PVC conduit to ensure it does not sustain or spread flames in the event of a fire. This test is designed to confirm that the conduit self-extinguishes quickly and does not contribute to igniting nearby combustible materials.

During the test, the conduit is exposed to a 60-second flame application, repeated three times, with a 30-second interval between each exposure. The conduit must cease flaming within 5 seconds after each flame application and must not release flaming particles that could ignite surrounding materials. If the conduit fails to meet these criteria, it is considered unsuitable for applications where fire safety is a concern.

Esta prueba simula si el conducto de PVC cédula 40 y 80 puede proporcionar la máxima protección ante la amenaza de un incendio. Si el conducto tiene una excelente retardancia de llama, puede garantizar que los cables del conducto estén intactos cuando se apague la llama abierta para no causar un accidente más grave.

Resistencia a la luz solar

The Sunlight Resistance Test in UL 651 evaluates the ability of Schedule 40 and Schedule 80 rigid PVC conduit to withstand prolonged exposure to UV radiation without significant degradation. Since outdoor electrical installations often expose conduits to direct sunlight, this test ensures that the material maintains its mechanical integrity and impact resistance over time.

The test involves Izod impact strength measurements on notched specimens prepared from both unaged and UV-conditioned conduit samples. These samples are exposed to UV radiation for up to 1440 hours, after which their impact strength is tested according to ASTM D 256 standards. To pass the test, the conduit must retain an acceptable level of impact resistance as specified in UL 651.

This testing process ensures that rigid PVC conduits remain durable and reliable in outdoor applications, providing long-term performance and protection against environmental factors such as UV exposure and weathering.

Conduit for Use with 90°C Wire

Among UL651 requirements, one key specification is the ability to support 90°C-rated wire, which indicates the maximum operating temperature of the conductors inside the conduit.

What Does 90°C Wire Mean and Why It Matters?

The 90°C rating refers to the maximum temperature the wire’s insulation can withstand without degrading over time. UL 651-certified PVC conduit is typically rated for 75°C conductors, but many electrical specifications now demand 90°C-rated conduit to accommodate higher-temperature wiring without requiring system derating. This higher temperature tolerance ensures that the electrical system operates at full efficiency while maintaining safety and reliability.

To achieve a 90°C rating, PVC conduit must pass additional long-term testing beyond the standard requirements for 75°C conduit. The testing process outlined in UL 651 extends over 360 days, exposing the conduit to various environmental stresses, including prolonged high temperatures, to evaluate its resistance to thermal degradation, mechanical integrity, and overall performance.

Testing Requirements

The test involves accelerated aging by placing conduit specimens in a circulating-air oven at 80°C (176°F) for up to 360 days. At specific intervals, impact tests are conducted using a steel cylinder drop method to determine impact strength retention over time. A smooth degradation curve is plotted, and the conduit must maintain at least 50% of its initial impact strength after prolonged exposure.

This rigorous evaluation ensures that Schedule 40 and 80 PVC conduits remain reliable and structurally sound when used with high-temperature wiring, providing long-term safety and performance in demanding electrical applications.

How to Tell If the PVC Conduit is Listed to the 90°C Requirements?

Compliant 90°C-rated conduit must also include permanent markings that explicitly state “maximum 90°C wire” or “max 90°C wire”. Listing agencies such as UL, ETL require these markings to confirm the conduit meets the standard.

If a conduit does not have this mandatory marking, it is not compliant with the 90°C specification, regardless of manufacturer claims. Using non-compliant conduits in systems designed for 90°C conductors can lead to serious consequences, including failed inspections, system rejection, costly replacements, and legal liabilities.

Permanencia de la impresión

Esta prueba requiere que la muestra se someta a una prueba de envejecimiento con 168 horas de anticipación, se sumerja en agua del grifo durante 24 horas y luego se frote con aceite IRM902 para comenzar la prueba. La prueba utilizará un dispositivo automático simple para permitir que la cinta entre en contacto con la parte impresa del catéter en un ciclo fijo, con un movimiento de ida y vuelta para cada ciclo, para un total de 50 ciclos.

Después de las pruebas anteriores, los caracteres impresos deben ser claramente visibles para los productos calificados.

Dado que la mayoría de los fabricantes ahora graban con láser, esta prueba no es demasiado dura. Su propósito es principalmente retener la impresión del catéter, que puede rastrear el fabricante, la fecha de producción, etc.

Marcas

La impresión habitual de tubos rígidos de PVC debe incluir lo siguiente:

1) Con las palabras 'Conducto rígido de PVC';

2) Tamaño del comercio

3) El nombre del fabricante o propietario de la marca.

4) fecha de producción

5) La información anterior debe imprimirse al menos una vez cada 10 pies.

6) Como se indica en el capítulo anterior, la impresión es permanente.

Además, existen algunos requisitos detallados para los conductos de PVC cédulas 40 y 80. Por ejemplo, la impresión debe actualizarse a conducto de PVC rígido Schedule 40 o Schedule 80 para estos dos conductos.

Algunos son aptos para cables de 90 °C (194 °F), en cuyo caso se debe marcar en la impresión el “cable apto para 90 °C como máximo”. También existen algunos requisitos especiales. Por ejemplo, si Conducto rígido Schedule 40 solo es apto para uso subterráneo, entonces debe imprimirse “Solo para uso subterráneo”.

En cuanto a la impresión de productos accesorios, debido a que la mayoría de ellos se producen mediante tecnología de moldeo por inyección, solo es necesario realizarla durante el diseño del molde y debe cumplir con los requisitos permanentes. El contenido impreso generalmente es el nombre del fabricante o la marca y el modelo del producto. Similar al conducto de PVC rígido Schedule 40 o Schedule 80, si solo se puede usar en escenarios limitados, es necesario tener en cuenta, como enterrado en el suelo, o solo es adecuado para cables de 90 °C.

Conduit Applications and Installation - NEC Article 352

NEC (National Electrical Code) has outlined the installation and usage requirements of PVC conduit, to ensure compliance with electrical safety standards. Article 352 of NEC specifies the key applications, limitations, and installation requirements, follow are some key information:

Applications for PVC Conduit:

Applications for PVC Conduit:

Uses Permitted | Uses Not Permitted |

Concealed installations within walls, floors, or ceilings | In hazardous (classified) locations unless specifically permitted |

Wet and dry locations | As a means of support for luminaries (light fixtures) |

Corrosive environments where metal conduits could deteriorate | Where subject to severe physical damage |

Underground installations, including direct burial | In areas where temperatures exceed 50°C (122°F) |

Exposed applications, provided the conduit is rated for sunlight resistance | Where it may be used as a grounding conductor |

Some Installation Considerations:

Conduit Fill: The number of conductors must comply with NEC Chapter 9.

Conduit Fill Size Chart for PVC Conduit

Número de conductores | Cross-Sectional Area (%) |

1 | 53 |

2 | 31 |

Más de 2 | 40 |

Support Requirements: Must be secured within 3 feet (900mm) of terminations and supported per NEC Table 352.30.

Expansion Fittings: Required when thermal expansions is expected to exceed 1/4 inch (6mm).

Toma de tierra: PVC conduit does not provide an equipment grounding path; a separate grounding conductor is required.

Composición del material: Must be made from non-plasticized PVC, resistant to moisture, chemicals, impact, and fire, and UV-resistant for above ground use.

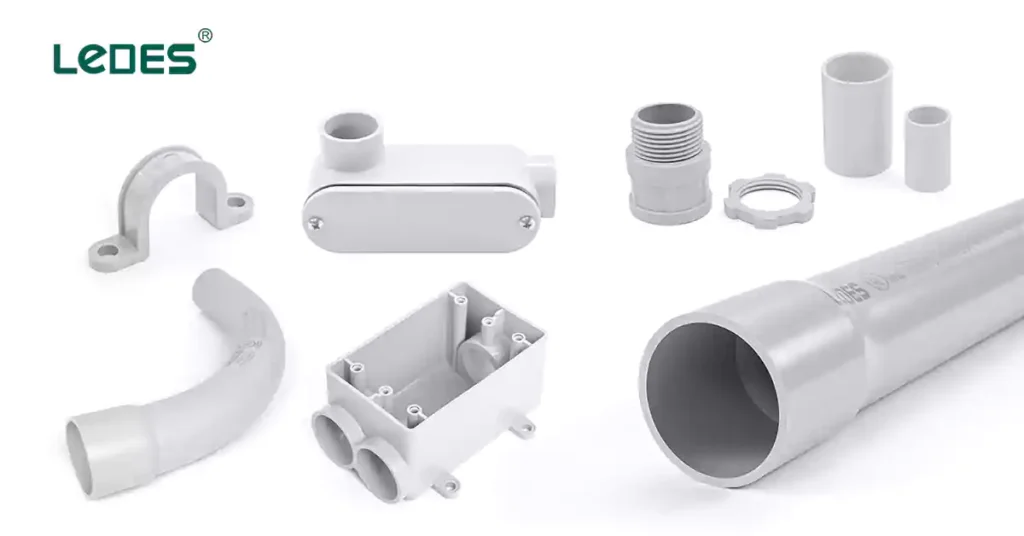

Your Reliable Electrical Solution – Ledes

Ledes is a trusted manufacturer in high-quality electrical conduit solutions, committed to delivering safe, durable, and high-performance products that meet industry standards. Our extensive range of UL-listed PVC conduits and fittings ensures compliance with the UL standard, offering superior reliability for a variety of electrical applications.

Ledes provides UL-listed PVC conduits and fittings that for use with the conduits, including:

- Conducto de PVC Schedule 40 – A versatile, lightweight option suitable for general-purpose electrical installations, both aboveground and underground.

- Schedule 80 PVC Conduit – Features a thicker wall for enhanced impact resistance, ideal for high-traffic or demanding environments.

- Elbows – Available in 45°, 90°, and other custom angles of standard elbows and special radius elbows, these elbows allow smooth directional changes in conduit runs without compromising wiring integrity.

- Couplings – Essential for joining conduit sections, ensuring a seamless and secure connection for continuous wiring runs.

- Adapters – Including Male Terminal Adapters and Female Adapters, enabling smooth transitions between different conduit types, boxes, or enclosures.

- Pipe Straps – Strong and reliable conduit supports that securely fasten Schedule 40 and 80 conduits to walls, ceilings, or other structures.

- Gang Boxes – Designed for secure mounting of electrical devices and wiring connections.

- Conduit Bodies – Ideal for providing pull points, splicing spaces, and directional changes, available in multiple styles such as Type LB, LL, LR, T, and C to suit different installation needs.

Trusted by Major Infrastructure Projects

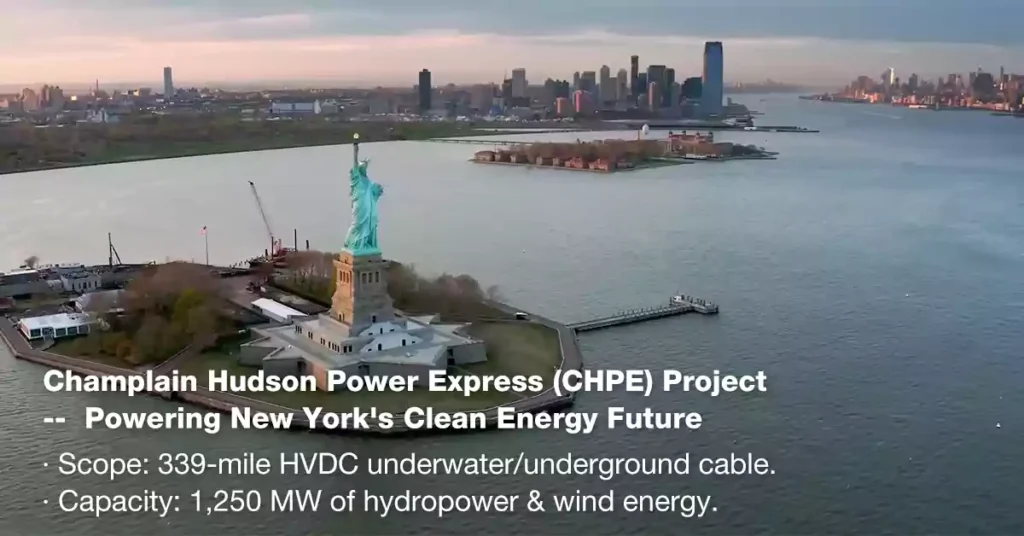

Champlain Hudson Power Express (CHPE) Project

The Champlain Hudson Power Express (CHPE) is a landmark high-voltage direct current (HVDC) transmission project, spanning 339 miles from Quebec, Canada, to New York City. This project is critical for:

- Delivering clean, renewable hydroelectric power to New York.

- Reducing carbon emissions and enhancing grid reliability.

- Creating thousands of jobs and modernizing the region’s energy infrastructure.

For this massive underground and underwater transmission line, Ledes’ UL-listed PVC conduits and fittings were selected due to their superior durability, corrosion resistance, and electrical safety. Our Schedule 40 and 80 PVC conduits provide secure cable protection over long distances, ensuring efficient energy transmission while withstanding underground conditions.

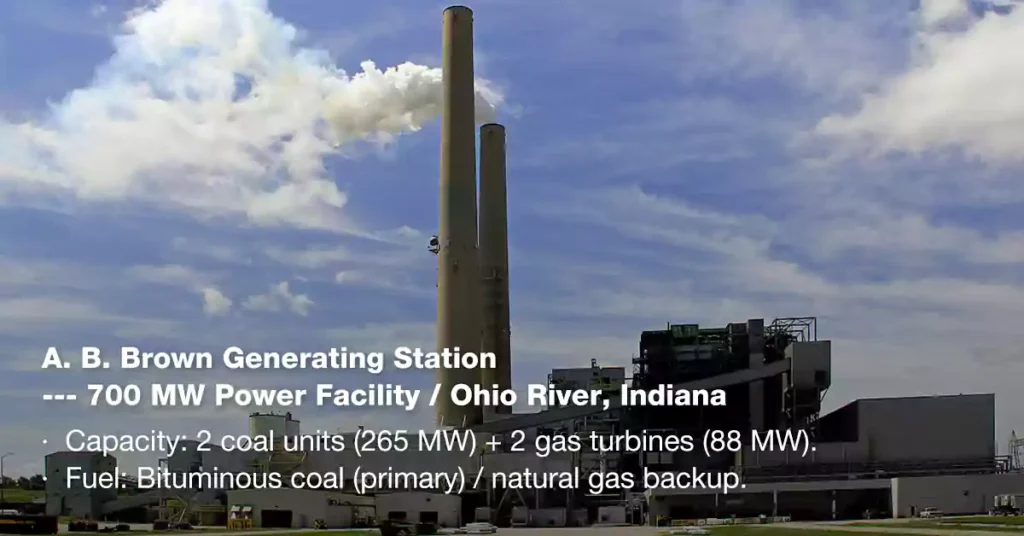

A.B. Brown Power Station Project

The A.B. Brown Generating Station is a 700-megawatt (MW) power plant located along the Ohio River in Indiana, just southwest of Evansville. This facility, owned by CenterPoint Energy (formerly Vectren), consists of:

- Two coal-fired units, each with a 265.2 MW nameplate capacity, primarily using bituminous coal with the capability to substitute natural gas.

- Two gas turbine units, each providing 88.2 MW of capacity for additional power generation.

As part of CenterPoint Energy’s modernization plan, there are ongoing infrastructure improvements and grid enhancements to support future energy needs. The company previously announced plans to retire the coal-fired units and transition to natural gas-powered generation, pending approval from the Indiana Utility Regulatory Commission.

To ensure a secure and reliable electrical system, Ledes’ UL-listed PVC conduits and fittings were selected for various electrical installations and upgrades within the A.B. Brown facility.

¿Por qué elegir Ledes?

Listado UL – Ensuring compliance with safety and performance standards.

Durable & Corrosion-Resistant – Made from high-quality PVC for long-lasting performance in harsh environments.

Fácil instalación – Lightweight and designed for quick assembly.

Versatile Applications – Suitable for residential, commercial, and industrial electrical installations.

Ledes is proud to be a supplier for critical infrastructure projects that shape the future of energy. Our innovative, high-performance conduit solutions ensure safe and efficient electrical installations in the most demanding environments.

UL vs. CSA Standard PVC Conduits

UL (Underwriters Laboratories) and CSA (Canadian Standards Association) are two leading organizations establishing safety and performance benchmarks for electrical conduits. Their standards ensure products meet rigorous requirements for durability, fire resistance, and environmental adaptability, with distinct regional and technical emphases.

- UL Standards: Primarily recognized in the United States, UL standards focus on ensuring that electrical products, including PVC conduits, are safe to use within the U.S. infrastructure. The UL standard for PVC conduit (e.g., UL 651) addresses fire safety, impact resistance, temperature ratings, and more.

- CSA Standards: These are focused on ensuring that products are safe for use within Canada. CSA standards often align with international guidelines but may have specific adjustments to reflect local safety and regulatory needs. CSA C22.2 No. 211.2 is the standard for PVC conduit in Canada, outlining similar requirements to UL but tailored for Canadian safety regulations.

Performance Requirements for UL and CSA

Performance Requirements UL651 and CSA C22.2:

Aspects | UL651 | Norma CSA C22.2 N.º 211.2 |

Temperature | Use at 50° C(122°F) or lower ambient temperatures; Use with 75° C (or maybe 90° C) wiring. | Use at a continuous operating temperature of 75° C.

|

Resistencia al impacto | Test at 23.0 ±2.0° C, with 20lbs (9.1 kg) weight for Schedule 40. | Test at –34 ± 2 °C, with 12 J impact energy for rigid conduit.

|

Resistencia a la tracción | 5,000 psi for Schedule 40 conduit | Not specified |

Resistant to Crushing | Detail required in section 6.9 | Not specified |

Compresión | Not specified | No cracks and decrease no more than 25% when subjected to certain forces. |

Fuego | 3 times of 60-seconds flame application, no more than 5s flame after each application. No flaming drops. | Not burn than 30 seconds, no flaming or glowing particles. |

Resistencia a la luz solar | Same requirements with CSA | Same requirements with UL |

El cumplimiento del Código

- Código Eléctrico Nacional (NEC): UL-certified PVC conduits are recognized for compliance with the U.S. National Electrical Code (NEC), which is the standard governing electrical installations across the United States.

- Código Eléctrico Canadiense (CEC): CSA-certified PVC conduits are recognized for compliance with the Canadian Electrical Code (CEC), ensuring that products meet the specific safety and installation standards for electrical systems in Canada.

Marking and Labeling

- UL Mark: PVC conduit that is UL-listed typically displays the UL mark, which indicates that it meets the specific UL safety standards and is approved for use in the United States.

- CSA Mark: Similarly, PVC conduit that meets CSA standards is marked with the CSA logo, indicating that it is compliant with Canadian requirements.

Both UL and CSA standards are crucial for ensuring that PVC conduits meet the necessary safety, performance, and regulatory requirements in their respective regions. While there are similarities in the testing protocols and requirements, the key difference lies in their geographic applicability and specific regulations. For projects in the United States, UL-listed PVC conduit is the ideal choice, while CSA-certified conduit is essential for Canadian installations.

Conclusión

As we’ve explored throughout this guide, UL 651 PVC conduit plays a crucial role in modern electrical installations by offering a combination of durability, fire resistance, corrosion resistance, and compliance with NEC requirements. Its classification into Schedule 40 and Schedule 80 allows for flexibility in different applications, ensuring that electricians and contractors can choose the right type based on mechanical protection needs and environmental conditions.

Whether you’re working on an underground installation, a commercial building, or an industrial facility, using UL 651-compliant PVC conduit ensures that your electrical system meets safety standards and performs reliably over time. By selecting certified conduit from reputable manufacturers, you can guarantee long-term performance while ensuring compliance with industry regulations.

As the demand for sustainable, cost-effective, and reliable electrical solutions continues to grow, UL 651 PVC conduit remains a key component in safe and efficient wiring infrastructure. Now that you have a thorough understanding of UL 651, you can confidently choose the right conduit for your next project.

Si tiene alguna pregunta o está interesado en nuestra serie de productos UL, puede contáctenos por correo electrónico o incluso What’s app, y generalmente le responderemos dentro de 1 día hábil.