Tabla de contenido

In the modern digital age, communication conduit plays a crucial role in establishing reliable and efficient connectivity. Whether it’s for transmitting data, voice communications, or multimedia signals, comms conduit serves as the backbone of our interconnected world. This article aims to provide a comprehensive understanding of communication conduit, covering its definition, purpose, and the pivotal role it plays in modern infrastructure.

Communication conduit refers to a protective pathway or channel designed to house and safeguard communication cables. It provides a secure and organized means of routing cables, ensuring efficient transmission and minimizing signal interference. Communication conduit serves as a conduit system, guiding various types of telecommunication cables, including metallic, non-metallic, and fiber optic cables.

The primary purpose of comms conduit is to protect cables from physical damage, environmental factors, and electromagnetic interference. By enclosing cables within a conduit, they are shielded from external elements such as moisture, dust, impact, and exposure to harsh conditions. Additionally, conduit helps maintain the integrity and performance of communication cables, prolonging their lifespan and reducing the risk of signal degradation.

In today’s interconnected world, reliable and fast communication is essential for businesses, industries, and individuals. Communication conduit plays a pivotal role in ensuring the seamless flow of information and maintaining the integrity of communication networks. Here are a few key reasons why comms conduit is of utmost importance in modern infrastructure:

Telecommunications conduit safeguards critical communication cables from physical damage, such as accidental impacts, construction activities, and environmental factors like moisture and extreme temperatures. This protection ensures uninterrupted communication services and reduces the risk of costly downtime.

By minimizing electromagnetic interference, conduit telecommunications helps maintain the integrity of signals transmitted through communication cables. It prevents crosstalk, signal degradation, and other interference issues, ensuring reliable and high-quality communication.

Communication conduit provides a structured and organized pathway for routing cables. It allows for neat and efficient cable management, simplifying installation, maintenance, and future upgrades. Proper cable organization within conduit systems also facilitates troubleshooting and reduces the time required for repairs or modifications.

With the rapid advancements in communication technology, infrastructure needs to adapt and support future requirements. Comms conduit offers flexibility and scalability, enabling the integration of new technologies and ensuring the longevity of communication systems. It allows for the seamless addition or replacement of cables as technology evolves.

Telecommunication conduit comes in various types, each designed to meet specific requirements and accommodate different types of communication cables. Understanding the characteristics and applications of these conduit types is essential for selecting the right conduit system for a given infrastructure. The following are the three primary types of telecommunication conduit:

Metallic conduit, typically made of steel or aluminum, offers robust protection for communication cables. It provides excellent durability, resistance to impact, and mechanical strength. Metallic conduit comes in different forms, such as rigid metal conduit (RMC), intermediate metal conduit (IMC), and flexible metal conduit (FMC). RMC is the most rigid and provides the highest level of physical protection, while FMC offers greater flexibility for installations that require bending and maneuvering.

Metallic conduit is commonly used in industrial environments, commercial buildings, and outdoor applications. Its strength and durability make it suitable for installations where cables may be exposed to harsh conditions, such as heavy machinery areas or outdoor infrastructure. Metallic conduit also provides enhanced protection against electromagnetic interference (EMI) and acts as a grounding path for electrical systems.

Metallic conduit can be more challenging to install compared to other types due to its rigidity. Additionally, it requires proper grounding to ensure electrical safety. The conductive nature of metallic conduit may also pose challenges when routing fiber optic cables, as they require non-conductive pathways to prevent signal loss.

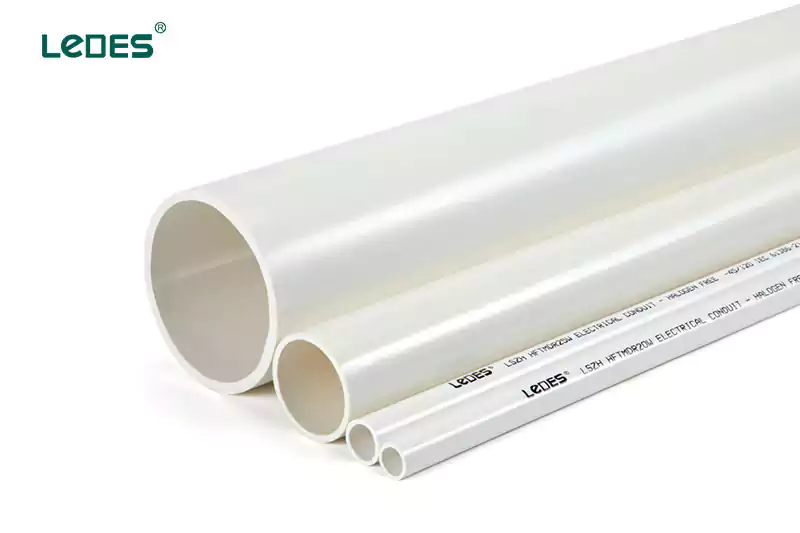

Non-metallic conduit, also known as plastic conduit, is made of PVC (polyvinyl chloride) or other non-metallic materials. It is lightweight, flexible, and easy to work with, making it suitable for a wide range of applications. Non-metallic conduit is available in different forms, such as rigid non-metallic conduit (RNC) and flexible non-metallic conduit (FNC).

Non-metallic conduit is commonly used in residential, commercial, and indoor installations. It is ideal for applications that require moderate protection and flexibility, such as wiring in homes, offices, and low-voltage systems. Non-metallic conduit is resistant to corrosion, moisture, and chemicals, making it suitable for both indoor and outdoor environments.

While non-metallic conduit offers flexibility, it may not provide the same level of physical protection as metallic conduit. It is more susceptible to impact and crushing compared to its metallic counterpart. Non-metallic conduit also has lower resistance to heat, so it may not be suitable for installations where high-temperature conditions are present.

Fiber optic conduit is specifically designed to protect and route fiber optic cables. It is typically constructed with non-metallic materials, such as PVC or high-density polyethylene (HDPE), to provide a non-conductive pathway for the delicate fiber optic cables.

Fiber optic conduit is used extensively in telecommunications, data centers, and high-speed internet infrastructure. It offers superior protection against EMI and provides a dedicated pathway for fiber optic cables, ensuring optimal signal transmission. Fiber optic conduit also allows for easy cable installation, maintenance, and future upgrades.

Fiber optic conduit requires careful handling during installation to prevent signal loss and damage to the delicate fiber optic cables. It is essential to follow proper bending radius guidelines and avoid excessive pulling or twisting of the cables. Additionally, fiber optic conduit may have specific requirements for sealing and protecting against moisture ingress.

Comm conduit offers a range of benefits and advantages that contribute to the efficiency, reliability, and longevity of communication infrastructure. The following are some key benefits of using communication conduit:

Communication conduit provides a protective barrier that shields communication cables from physical damage caused by external factors such as accidental impacts, construction activities, or environmental conditions. It helps prevent cable crushing, cutting, or bending, ensuring uninterrupted communication services.

Many types of comms conduit are designed to be fire-resistant. In the event of a fire, the conduit acts as a barrier, preventing the spread of flames and providing additional time for evacuation and firefighting efforts. Fire-resistant conduit enhances the overall safety of the infrastructure.

Telecommunication conduit helps safeguard cables against environmental factors like moisture, dust, chemicals, and extreme temperatures. By providing a sealed enclosure, it minimizes the risk of water ingress, corrosion, and other environmental damage that can compromise the performance and longevity of communication cables.

Communication conduit allows for organized cable routing, ensuring a neat and aesthetic appearance. Proper cable organization within the conduit simplifies identification, maintenance, and troubleshooting processes. It also reduces the risk of cable entanglement, which can impede access and lead to signal interference.

Conduit systems enable easy access to communication cables, facilitating maintenance and upgrades. When cables are neatly organized within conduits, technicians can quickly identify and address any issues or make necessary modifications without disrupting the entire infrastructure. This ease of access saves time and effort, minimizing downtime.

Comms conduit helps minimize signal interference by providing separation between different cables and shielding them from external electromagnetic sources. This separation reduces crosstalk and ensures optimal signal integrity, resulting in reliable and high-quality communication.

Conduit telecommunications offers scalability and flexibility, allowing for the addition or replacement of cables as infrastructure needs evolve. By providing a modular and adaptable pathway, conduit systems can accommodate new technologies and changing communication requirements without the need for extensive infrastructure modifications.

As communication technologies continue to advance, infrastructure needs to keep pace. Communication conduit offers the flexibility to incorporate new technologies, such as higher bandwidth fiber optic cables or emerging communication protocols. This adaptability ensures that infrastructure remains compatible with future advancements.

By protecting cables from physical damage, environmental factors, and signal interference, communication conduit contributes to the longevity of communication systems. Well-protected cables within conduit systems are less prone to degradation, reducing the need for frequent repairs or replacements. This results in cost savings and ensures the reliability of communication services over an extended period.

Installing communication conduit requires careful planning and adherence to industry best practices. Following a systematic installation process and considering key factors can help ensure a successful conduit installation that meets the infrastructure’s communication needs.

Determine the specific communication requirements of the infrastructure, including the types of cables to be installed, the number of conduits needed, and the locations where conduit runs are required. Consider factors such as cable capacity, future expansion needs, and compatibility with existing infrastructure.

Plan the routes for conduit installation, considering the shortest distance, accessibility for maintenance, and avoidance of potential obstacles or hazards. Take into account any building codes, regulations, or permits required for the installation.

Select appropriate conduit sizes based on the number and type of cables to be installed. Consider factors such as cable diameter, future cable additions, and any potential temperature or expansion-related considerations.

Mark the conduit installation paths on the infrastructure, ensuring they are clear of obstructions such as existing utilities, structural elements, or other underground services. Excavate or clear the areas as necessary.

Lay the conduit sections along the planned routes, ensuring proper alignment and support. Connect conduit sections using suitable couplings or fittings according to the conduit type. Maintain proper bend radius and avoid excessive pulling or twisting of the conduit during installation.

Secure the conduit to the infrastructure using appropriate clamps, brackets, or fasteners. Ensure that the conduit is adequately supported to prevent sagging or stress on the cables. Consider expansion joints or flexible connectors for installations that may experience temperature-related expansion or movement.

Pull or install the communication cables through the conduit using appropriate cable pulling techniques and tools. Follow recommended cable pulling tensions and avoid exceeding the maximum limits to prevent cable damage or signal loss.

Seal the conduit openings and junction points to prevent moisture ingress. Properly terminate and label the cables at both ends, ensuring clear identification for future maintenance or troubleshooting purposes.

Prioritize safety during the installation process. Adhere to safety guidelines, use appropriate personal protective equipment (PPE), and follow proper electrical and construction safety practices. Take precautions to avoid accidentally damaging existing utilities or infrastructure.

Ensure compliance with relevant local, national, or industry-specific codes and regulations governing conduit installation, grounding, bonding, and safety practices. Familiarize yourself with the specific requirements and obtain any necessary permits or approvals.

If needed, consult with professionals or contractors experienced in conduit installation to ensure adherence to best practices and industry standards. Collaborate with other stakeholders, such as electricians or network engineers, to address specific requirements or integration considerations.

Maintain detailed documentation of the conduit installation process, including route plans, cable specifications, installation dates, and any modifications made during the process. Proper record-keeping facilitates future maintenance, upgrades, and troubleshooting activities.

Regular inspections of the comms conduit system are crucial to identify any signs of damage, wear, or blockages. Inspect the conduit openings, junction points, and cable pathways for any physical damage, loose fittings, or obstructions. Clean the conduit openings and junction points to remove debris, dust, or any potential obstructions that could hinder cable movement or signal transmission.

In the event of damaged conduit, such as cracks, breaks, or deteriorated sections, it is important to repair or replace them promptly. Damaged conduit can compromise the integrity of the communication system, leading to signal loss, interference, or even cable damage. Repair the damaged sections using appropriate methods, such as splicing or using couplings, or replace the conduit if necessary.

Blockages within the communication conduit can impede cable installation, movement, or future cable additions. If blockages are detected, use tools such as conduit snakes or fish tapes to clear the obstruction. In cases where the blockage is severe or inaccessible, it may be necessary to remove and replace the affected section of the conduit.

Signal loss or interference can occur due to various factors, including cable damage, poor connections, or external electromagnetic interference. Troubleshooting steps for signal issues include:

- Inspect the affected cable for physical damage, such as cuts or pinches, and repair or replace the damaged section.

- Check the connections at both ends of the cable to ensure they are secure and properly terminated.

- Verify that the cables carrying different signals are adequately separated within the conduit to minimize electromagnetic interference.

- Assess the surrounding environment for potential sources of interference, such as electrical equipment or nearby power lines, and take necessary measures to mitigate their effects.

It is important to maintain accurate documentation of all maintenance activities and troubleshooting measures undertaken, including the identified issues, repairs made, and any modifications to the communication conduit system.

Different countries have their own national standards that govern the installation, materials, and usage of communication conduit systems. These standards ensure consistency, safety, and interoperability. For example:

In the United States, Telecommunications conduit installations must comply with the applicable National Electrical Code (NEC) requirements. The NEC sets baseline safety standards adopted by most local jurisdictions. Specific articles cover communication raceways, cable installation methods, termination practices and more. Key NEC code sections relevant to communication conduit include:

Article 800 on Communication Circuits covers wiring methods, cable installation and protection for voice/data circuits.

Articles 770 and 820 specify requirements for CATV and broadband coax infrastructure including cable type approvals.

Article 345 outlines usage and installation practices for rigid metal conduit (RMC/IMC), an commonly used material for data centers and industrial applications.

In the United Kingdom, the British Standards Institution (BSI) publishes standards like BS 6701, which covers the installation and operation of telecommunications equipment and cabling within buildings.

In Canada, there is CSA standard for comm conduit and in Australia there is AS/NZS 2053 standard. Inernational standards such as IEC and ISO also provide guidelines for the planning and installation of communication cabling infrastructure. Different countries have different standards requirements, it’s very important to consult professionals for conduit installation.

Compliance with codes and regulations is crucial to ensure the safety, reliability, and performance of communication conduit systems. Contractors, installers, and building owners must adhere to these requirements during the design, installation, and maintenance phases. Compliance helps prevent hazards, ensures interoperability, and meets legal obligations.

Many jurisdictions require permits for the installation of communication conduit systems. Permitting processes typically involve submitting plans, specifications, and other necessary documents to the local authorities. Obtaining permits ensures that the installation complies with local regulations and undergoes inspections as required by the authorities.

It is important to consult the specific standards, building codes, electrical regulations, and permitting requirements of your country or region when planning and implementing communication conduit systems. Adhering to these codes and regulations ensures the proper installation, safety, and compliance of the conduit system, contributing to the overall reliability and efficiency of communication networks.

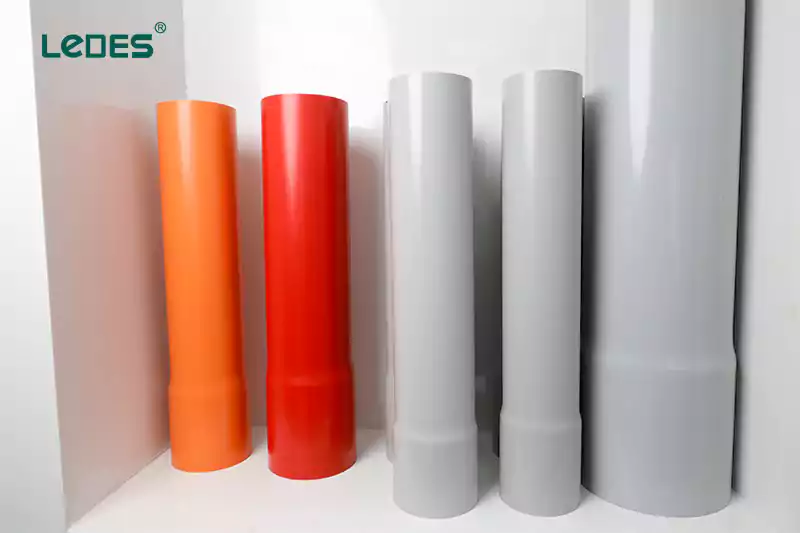

Communication conduit can be made in different colors according to different needs, could be in gray, white, black, orange, blue, green, and red etc. But the standard color of communication conduit is orange.

Proper identification of conduits helps technicians, installers, and maintenance personnel quickly identify the type of conduit and its purpose. This facilitates accurate and efficient troubleshooting, repairs, and modifications.

La identificación de conductos evita conexiones cruzadas, donde los cables o alambres se conectan por error al conducto incorrecto. Una identificación correcta reduce el riesgo de interferencias de señal, peligros eléctricos o problemas de transmisión de datos.

Muchos códigos y normativas exigen la correcta identificación de los conductos. El cumplimiento de estos requisitos promueve la seguridad y el cumplimiento normativo, y facilita las inspecciones y auditorías.

A medida que el Internet de las Cosas (IoT) continúa expandiéndose, están surgiendo sistemas de conductos inteligentes para integrar dispositivos IoT sin problemas. Estos sistemas de conductos proporcionan rutas y conectividad para una amplia gama de dispositivos IoT, lo que permite una transmisión de datos, una gestión de energía y un control eficientes.

Los sistemas de conductos inteligentes incorporan sensores, dispositivos de monitoreo y mecanismos de control para permitir la monitorización y gestión en tiempo real de la infraestructura de comunicaciones. Estos sistemas pueden detectar fallas, medir métricas de rendimiento y optimizar la red para mejorar la eficiencia y la confiabilidad.

Ante la creciente preocupación por el medio ambiente, se presta cada vez más atención al desarrollo de soluciones de comunicación que utilicen materiales y procesos de fabricación ecológicos. Esto incluye el uso de materiales reciclados, polímeros de origen biológico y la reducción del impacto ambiental general de la producción.

Los futuros sistemas de conductos priorizarán la eficiencia energética mediante la incorporación de tecnologías innovadoras, como sensores de bajo consumo, gestión inteligente de la energía y enrutamiento optimizado de cables. Además, se hará mayor hincapié en la implementación de iniciativas ecológicas, como el uso de energías renovables para la infraestructura de comunicaciones.

Estas tendencias e innovaciones en sistemas de conductos de comunicaciones reflejan la evolución continua de la tecnología y el compromiso de la industria con la sostenibilidad y la eficiencia. A medida que proliferan los dispositivos IoT y aumentan las preocupaciones ambientales, los sistemas de conductos inteligentes y las soluciones sostenibles desempeñarán un papel crucial en el futuro de la infraestructura de comunicaciones.

La cantidad de cables permitidos en un conducto de comunicación depende de varios factores, como el tamaño del conducto, el diámetro del cable y los códigos y normativas aplicables. Es importante cumplir con los códigos de construcción locales y las normas del sector para determinar la capacidad de llenado admisible para un tamaño de conducto específico.

Estos códigos suelen proporcionar directrices y cálculos para determinar la relación de llenado máxima o el porcentaje que no debe excederse. La relación de llenado generalmente considera factores como el diámetro de los cables y el conducto, así como el tipo de cables instalados (p. ej., cables de alimentación, cables de datos, cables de fibra óptica).

En muchos casos, los cables de fibra óptica no necesariamente tienen que instalarse dentro de un conducto. Están diseñados para ser duraderos y resistentes a factores ambientales como la humedad, las variaciones de temperatura y las interferencias electromagnéticas. Pueden enterrarse directamente, instalarse en postes aéreos o colocarse en conductos internos (subconductos) sin necesidad de conductos adicionales.

Sin embargo, existen situaciones en las que se prefiere o se requiere el uso de conductos para cables de fibra óptica. Algunas razones para su uso incluyen:

Protección: El conducto proporciona una capa adicional de protección física para el cable de fibra óptica contra daños accidentales o fuerzas externas durante las actividades de instalación, mantenimiento o construcción.

Facilidad de acceso: El conducto facilita el acceso al cable de fibra óptica para futuras reparaciones, reemplazos o actualizaciones. Permite una gestión organizada del cableado y reduce la necesidad de excavaciones extensas o actividades disruptivas.

Expansión futura: La instalación de cables de fibra óptica en conductos facilita futuras ampliaciones o la incorporación de nuevos cables. Ofrece flexibilidad y facilita la instalación de fibras adicionales o diferentes tipos de cables sin necesidad de realizar grandes modificaciones en la infraestructura.

Cumplimiento: En algunos casos, los códigos de construcción locales, los estándares de la industria o los requisitos específicos del proyecto pueden exigir el uso de conductos para instalaciones de cables de fibra óptica.

En conclusión, los conductos de comunicación son un componente vital de la infraestructura de comunicaciones moderna. Proporcionan las vías y la protección necesarias para cables y conductores, garantizando la instalación y el mantenimiento eficientes de las redes de comunicación. El cumplimiento de las normas y regulaciones, la correcta identificación y la adopción de las tendencias e innovaciones futuras son clave para construir una infraestructura de comunicaciones fiable y sostenible. Al comprender la importancia de los conductos de telecomunicaciones, podemos crear una conectividad fluida y satisfacer la creciente demanda de redes de datos y comunicación en la era digital.

Si tiene alguna pregunta sobre conductos de comunicación, Ledes, como fabricante de conductos eléctricos, incluidos conductos de comunicación, cuenta con profesionales para ayudarlo a resolver sus problemas, Envía el formulario o Envíenos un correo electrónico para obtener más información.