Tabla de contenido

With the rapid development of the electric vehicle industry, auto conduit has gradually entered our vision. As a traditional cable conduit supplier, we know that although plastic conduits look inconspicuous, they are very important.

In this post, we will discuss the relevant content about auto electrical conduits in detail. By reading, you can learn:

What is Auto Conduit, and How Does It Work?

Why is Auto Conduit Important for Electrical Systems?

How Do I Choose the Right Size for Auto Conduit?

And more. So, let’s get started.

An auto conduit is a pipe used to protect and route electrical wiring in a vehicle. Automotive conduits may be made of metal or plastic. Most conduit is split flexible, but rigid conduit is used for some purposes.

Auto conduit and PVC electrical conduit are designed to meet the stringent performance requirements of the automotive industry. They protect internal wires from impact, bacteria, chemicals, and other forms of corrosion, particularly in the demanding conditions of the engine compartment.

As we all know, electric vehicles often have high voltages, so once the internal wires break and cause a short circuit or instantaneous high voltage, it may cause potential risks to the car or the driver and passengers.

Auto electrical conduits are not simply tubes for carrying electrical wires. They act as protective pathways, channeling electricity safely and efficiently while safeguarding against a multitude of potential hazards. Think of them as the arteries of an electric car’s circulatory system, ensuring that vital energy reaches its destination without disruption or danger.

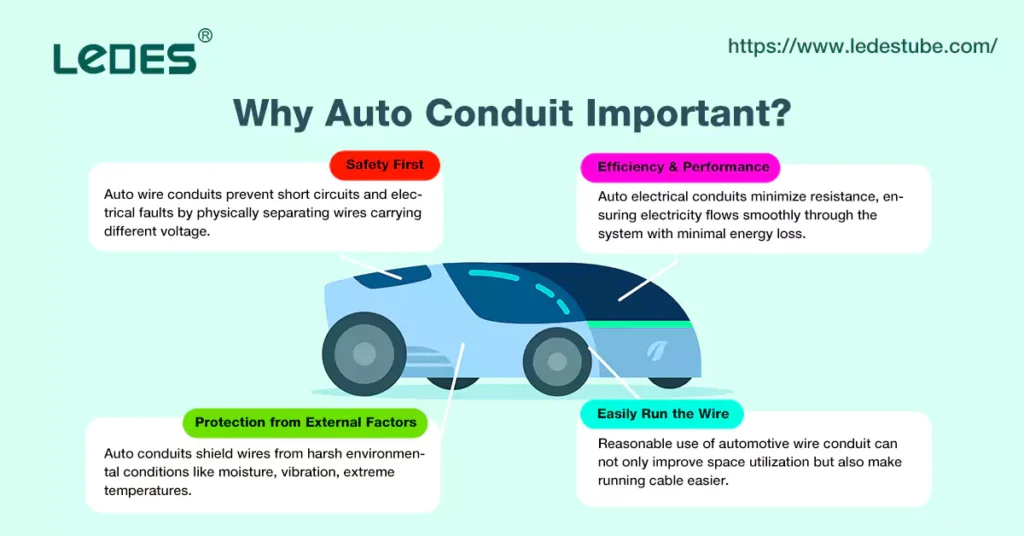

Seguridad ante todo: Auto wire conduits prevent short circuits and electrical faults by physically separating wires carrying different voltages, reducing the risk of overheating, fires, and injuries. A 2022 report by the National Highway Traffic Safety Administration (NHTSA) highlighted that faulty wiring was a contributing factor in nearly 10% of vehicle recalls related to electrical systems.

Efficiency & Performance: Auto electrical conduits minimize resistance, ensuring electricity flows smoothly through the system with minimal energy loss. This translates to improved performance and range for EVs, where every watt counts.

Protection from External Factors: Auto conduits shield wires from harsh environmental conditions like moisture, vibration, extreme temperatures, and even corrosive road debris. This durability is essential for longevity and maintaining reliable electrical performance over time.

Easily Run the Wire. The interior space of new energy vehicles is compact, especially the engine compartment or the body. Reasonable use of automotive wire conduit can not only improve space utilization but also make running cable easier. Even if there is repair or maintenance, it is easy to add or remove cables, make the wires look more beautiful and avoid potential risks.

Following a high-profile fire incident involving a Tesla Model 3 in 2019, investigations revealed that the fire originated from an underfloor battery module, potentially exacerbated by faulty wiring insulation. This case underscores the critical importance of robust conduits for containing and mitigating potential electrical hazards within EVs.

“Conduits are not just passive conduits; they actively contribute to the safety, performance, and reliability of electric vehicles,” states Dr. Emily Chen, Automotive Electrification Specialist at the Society of Automotive Engineers (SAE). “The materials used and the design principles employed in auto conduit development are crucial for ensuring a safe and efficient future of mobility.”

As EVs become increasingly complex, expect to see even more sophisticated conduits with:

Integrated sensors: For real-time monitoring and condition assessment.

EMI shielding: To protect sensitive electronic systems from electromagnetic interference.

Lightweight materials: To contribute to overall vehicle weight reduction.

The future of auto conduits is intertwined with the future of electric vehicles. Investing in research and development in this area will be crucial for driving innovation, enhancing safety, and ensuring a seamless transition to a more sustainable transportation landscape.

Selecting the right auto conduit size isn’t just about squeezing wires into a pipe; it’s about ensuring efficient power delivery, optimal performance, and above all, safety.

A poorly sized conduit can lead to overheating, reduced energy transfer, or even pose fire hazards – consequences that no vehicle owner wants to face.

Auto conduit sizing depends on several key factors:

Current Draw: The amount of electrical current flowing through the wires dictates the necessary conduit size. Higher currents require larger conduits to prevent excessive heat buildup and maintain safe operating temperatures.

Wire Gauge: The thicker (lower gauge number) the wire, the more current it can handle, influencing the required conduit diameter.

Number of Wires: Multiple wires bundled together within a conduit increase its internal volume requirements. Overcrowding leads to heat dissipation issues and reduced airflow.

Condiciones ambientales: Extreme temperatures or exposure to harsh elements necessitate larger conduits to accommodate potential expansion/contraction of wires and prevent insulation degradation.

The common size of the auto electrical pipe is from 9mm to 30 mm (1/4 inch to 1 inch), and it is used for auto inside.

Size (OD) | Typical Applications |

9 mm (1/4 in) | Low-current circuits, sensor wiring, auxiliary lights |

12 mm (3/8 in) | |

16 mm (1/2 in) | General purpose use, smaller gauge wiring harnesses, instrument panel wiring |

20mm (5/8 in) | |

24mm (3/4 in) | High-current applications, starter motor wiring, ignition systems |

30 mm (1 in) |

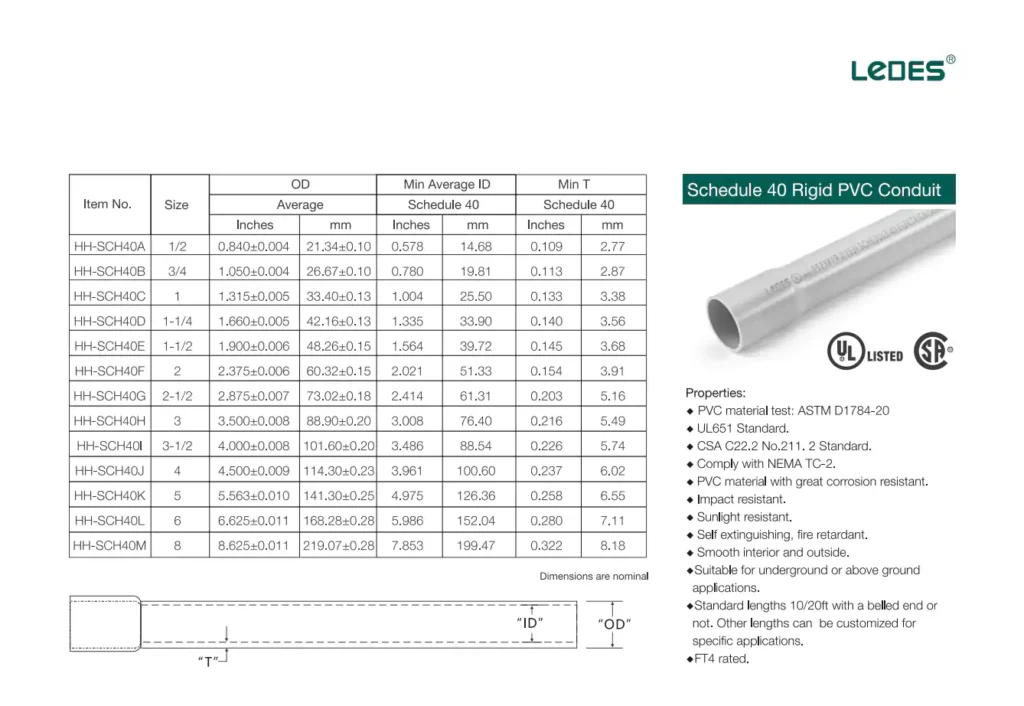

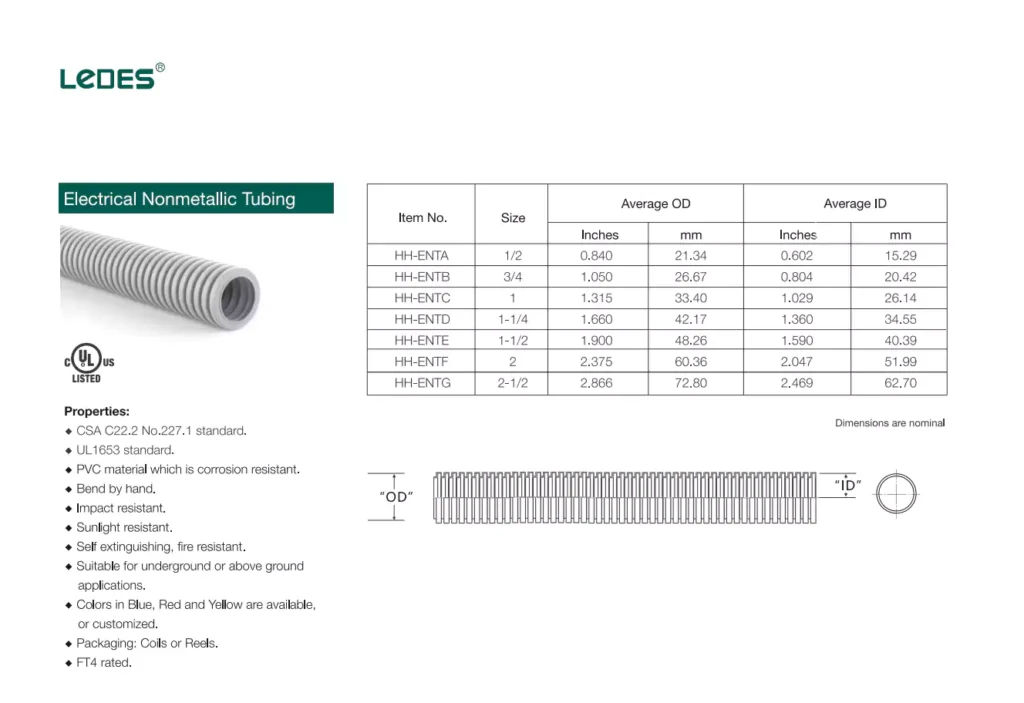

If you talk about the charging station’s electrical conduit, the size is the same as the building’s electrical conduit. Let’s take the US & Canada as an example,

Conducto Schedule 40 Trade Size (USA)

Conducto ORL Trade Size (Canada)

Undersized Conduit: Can result in overheating, insulation damage, and even fires due to excessive heat build-up. This poses a serious safety hazard and can lead to costly repairs or accidents.

Oversized Conduit: While seemingly better, it can lead to unnecessary material costs, weight increases, and potential interference within the vehicle’s design.

Tesla’s Roadster, known for its impressive performance, uses high-power charging systems requiring substantial current flow. Their engineers carefully selected conduits with appropriate diameters to handle these demanding currents without compromising safety or efficiency. Undersizing would have significantly hampered charging speed and posed a fire risk.

“Choosing the right conduit size is like finding the perfect puzzle piece,” explains John Smith, Lead Electrical Engineer at Automotive Wire Products Association (AWPA). “It’s about balancing current capacity, wire gauge, environmental factors, and overall vehicle design to ensure optimal performance and safety.”

Automotive consult resources such as:

National Electric Code (NEC):

Provides guidelines for safe electrical installations in vehicles.

SAE Standards:

Offer specific recommendations for automotive wiring and conduit sizing.

Manufacturer Specifications:

Always refer to your vehicle’s manufacturer guidelines for accurate conduit requirements.

Código local:

Wire conduit and PVC conduit are very close. Because we need to consider not only the auto wire conduit itself, but also the cable conduit installation and protection of the super fast charging station.

Let’s take North America as an example. The current UL 651 standard in the United States (applicable to Rigid PVC Conduit), or UL 1653 or CSA C22.2 NO. 227.1:19 standards for ENT conduit are all specifications that need to be followed. At the same time, fire resistance is also a factor that needs to be focused on. Then it is very necessary to have UL94 V-0 or FT4 related tests and certifications.

By understanding the factors influencing conduit size and leveraging industry standards, you can ensure your auto electrical system operates safely, efficiently, and reliably.

Under the hood of modern vehicles, a complex network of electrical systems hums with activity, powered by specialized conduits that carry vital currents safely and efficiently. But did you know these unsung heroes are crafted from a diverse range of materials, each with its own strengths and limitations?

These versatile conduits offer excellent flexibility, impact resistance, and cost-effectiveness. They are widely used for low to medium voltage applications in automotive wiring harnesses due to their ease of installation and durability.

Case Study: In classic car restorations, Conducto de PVC is often favored for its ability to mimic the original aesthetic while providing reliable insulation for electrical components.

PE conduits boast high flexibility, chemical resistance, and excellent dielectric properties. They are particularly well-suited for automotive applications requiring durability against moisture and environmental factors.

A 2021 report by Grand View Research indicates that the global polyethylene market is projected to reach $255 billion by 2030, driven in part by its widespread use in diverse industries, including automotive.

While heavier than their thermoplastic counterparts, metallic conduits offer superior electrical conductivity and shielding against electromagnetic interference (EMI). They are often used in high-voltage applications or where EMI protection is critical, such as in EV battery systems.

Case Study:

Tesla’s Model S Plaid utilizes aluminum conduit to manage the significant currents flowing within its high-performance electric drivetrain, ensuring safe and efficient power delivery.

FRP conduits combine strength, lightweight properties, and excellent corrosion resistance, making them ideal for applications exposed to harsh environments or requiring long service life.

“For EVs operating in extreme climates or off-road conditions, FRP conduits offer a robust solution that can withstand demanding environmental factors,” states David Lee, Materials Engineer at the Automotive Innovation Center.

The future of auto conduit materials will likely see:

Increased use of sustainable and recycled materials.

Development of composites with enhanced strength-to-weight ratios.

Integration of smart sensing technologies for real-time monitoring and diagnostics.

Choosing the right material for your specific application is crucial for ensuring safety, performance, and longevity. Understanding the properties and applications of each material will empower you to make informed decisions when it comes to your vehicle’s electrical infrastructure.

Auto conduits are the unsung heroes of your vehicle’s electrical system, ensuring safe and efficient power delivery. But like any vital component, improper handling or installation can lead to serious consequences.

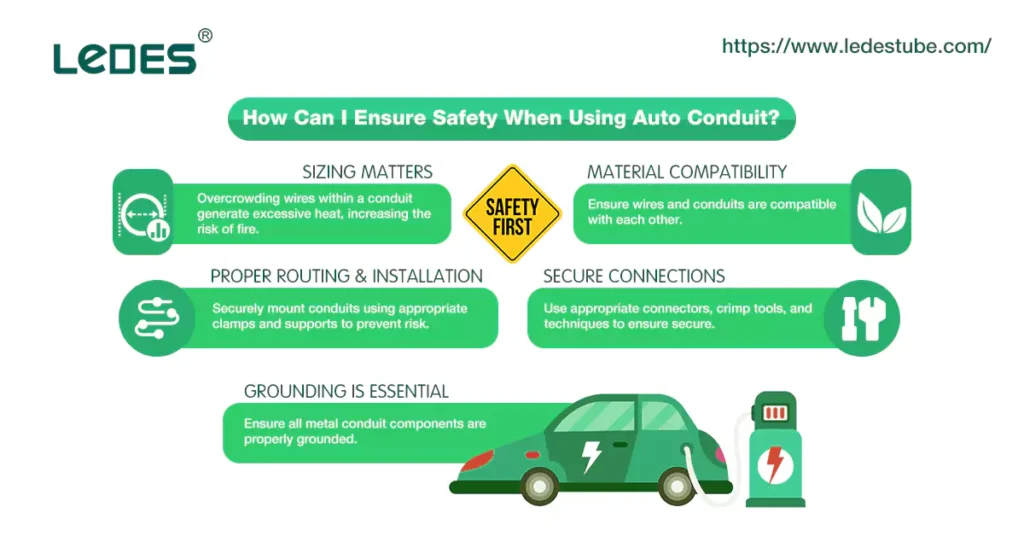

Prioritizing safety when working with auto conduits is non-negotiable. Here’s a breakdown of essential practices:

Overcrowding wires within a conduit generates excessive heat, increasing the risk of insulation failure and potential fires. Undersized conduits can also lead to overheating and damage.

According to the National Fire Protection Association (NFPA), electrical malfunctions are responsible for an estimated 46,000 home structure fires annually in the U.S., highlighting the importance of proper sizing.

Ensure wires and conduits are compatible with each other, considering factors like voltage rating, temperature resistance, and chemical compatibility.

A faulty installation involving incompatible conduit materials led to insulation breakdown in a classic car’s wiring system, resulting in a fire during operation. Always refer to manufacturer specifications for compatibility guidelines.

Use appropriate connectors, crimp tools, and techniques to ensure secure, vibration-resistant connections within the conduit. Loose connections can lead to arcing, shorts, or even complete circuit failure.

Estándar en la industria: El SAE (Society of Automotive Engineers) provides detailed standards for electrical connector design and installation practices in vehicles.

Route conduits away from heat sources, sharp edges, and areas subject to excessive vibration. Securely mount conduits using appropriate clamps and supports to prevent movement and potential damage to wires.

Ensure all metal conduit components are properly grounded to provide a safe path for fault currents, minimizing the risk of electrical shock or injury.

“Safety should always be paramount when working with auto conduits,” emphasizes Mary Johnson, Lead Electrical Engineer at the Automotive Safety Institute. “Adhering to industry standards, using appropriate materials and techniques, and prioritizing secure connections are crucial steps in preventing potential hazards.”

Regularly inspect your vehicle’s conduit system for signs of wear, damage, or loose connections.

Consult a qualified electrician for any complex wiring or conduit repairs.

By adhering to these safety practices, you can ensure your auto conduits function reliably and protect both your vehicle and yourself from electrical hazards. Remember: safety isn’t just a priority, it’s the foundation of a safe and enjoyable driving experience.

Think of your auto conduit system as the unsung hero of your vehicle’s electrical infrastructure. While often hidden beneath the hood, it plays a vital role in safely delivering power to every component. Just like any critical system, regular maintenance ensures optimal performance and longevity.

Neglecting your conduit system can lead to overheating, short circuits, malfunctions, and even fires – consequences no driver wants to face. Here’s how to keep your auto conduits running smoothly:

Regularly inspect conduits for signs of wear, damage (cracks, cuts, abrasions), loose connections, or excessive heat buildup. Early detection is crucial for preventing serious issues down the road.

Case Study: A 2019 report by the National Highway Traffic Safety Administration (NHTSA) highlighted that a frayed wiring harness, leading to exposed wires within a conduit, was a contributing factor in a vehicle fire incident.

Examine connectors for corrosion, looseness, or signs of overheating. Securely tighten any loose connections and replace damaged connectors as needed.

Estándar en la industria: The SAE (Society of Automotive Engineers) provides specific guidelines for connector installation and maintenance practices to ensure secure and reliable connections.

Inspect conduits for areas where they rub against sharp edges, moving parts, or other components. Use protective sleeves, padding, or adjust routing to minimize chafing and prevent insulation damage.

A study by the Society of Automotive Engineers (SAE) found that improper conduit routing was a common cause of wiring failures in vehicles, leading to electrical malfunctions and potential safety hazards.

Excessive heat can degrade conduit materials and insulation. Check for signs of overheating near high-current components or in areas with poor ventilation.

Expert Perspective:

“Regularly checking for temperature fluctuations around conduits is essential,” states Dr. Emily Chen, Lead Materials Engineer at the Automotive Industry Association (AIA). “High temperatures can significantly impact material lifespan and lead to premature failures.”

For complex repairs, troubleshooting electrical issues, or if you’re unsure about any aspect of conduit maintenance, consult a qualified electrician specializing in automotive systems.

Proactive Maintenance Saves You Down the Road:

By incorporating these practices into your vehicle care routine, you can prevent costly repairs, ensure safe operation, and prolong the life of your auto conduit system. Remember: a little preventative care goes a long way in keeping your ride running smoothly and safely.

Your vehicle’s auto conduit system acts as the silent guardian of its electrical network, channeling power safely and efficiently. But like any complex system, it can sometimes encounter problems. Knowing how to troubleshoot these issues can save you headaches, repair costs, and even potential hazards.

Here’s your roadmap to diagnosing and addressing common auto conduit troubles:

The first step is recognizing the signs. Look for flickering lights, blown fuses, electrical component malfunctions, or unusual noises (buzzing, crackling) near the conduits.

A study by AAA found that faulty wiring and electrical system problems account for over 20% of vehicle repair claims annually, highlighting the prevalence of conduit-related issues.

Examine conduits thoroughly for cracks, cuts, loose connections, chafing, or signs of overheating.

Case Study: A customer reported intermittent dashboard warning lights and a malfunctioning power window. Upon inspection, a technician discovered a rodent bite on an auto conduit near the engine compartment, disrupting electrical flow.

Inspect connectors for corrosion, loose wires, or damage to pins. Use a multimeter to test voltage continuity at each connection point.

Estándar en la industria: The SAE (Society of Automotive Engineers) provides detailed guidelines for connector inspection and testing procedures in their automotive wiring standards.

Ensure all metal conduit components are securely grounded using a grounding strap or bolt. Use a multimeter to check ground continuity by placing one probe on the conduit and the other on a known ground point.

Expert Perspective:

“Proper grounding is crucial for safety,” explains John Smith, Lead Electrical Engineer at the Automotive Safety Institute. “A faulty ground connection can lead to electrical shocks or even damage to electronic components.”

Carefully inspect the wiring harness within the conduit for broken strands, frayed insulation, or pinched wires. Replace any damaged sections of the harness.

For complex issues or if you’re uncomfortable diagnosing and repairing electrical problems yourself, consult a qualified automotive electrician. They have the expertise and tools to pinpoint the issue accurately and ensure a safe repair.

By following these troubleshooting steps, you can become more confident in addressing common auto conduit issues. Remember, prompt action prevents minor problems from escalating into major headaches and potential safety hazards.

When it comes to your vehicle’s electrical system, reliability is paramount. Selecting the right auto electrical conduit supplier can make all the difference between a smooth-running engine and a potential nightmare scenario.

Here’s how to navigate the market and find a supplier worthy of your trust:

Look for suppliers with a proven track record in the automotive industry. Years of experience translate to deep understanding of material properties, application-specific requirements, and evolving industry standards.

Case Study: A renowned motorsport team switched to a new conduit supplier for their racing vehicles. The switch resulted in improved conductivity and superior temperature resistance, contributing to a significant performance boost during competitive events.

Demand Assurance: Request certifications like ISO 9001 (Quality Management), AS9100 (Aerospace), or industry-specific automotive standards. These demonstrate commitment to quality control and material integrity.

A report by the American Automotive Association (AAA) highlighted that using non-compliant materials in vehicle repairs can lead to malfunctions, safety hazards, and costly repairs down the line.

Assess if the supplier offers a diverse range of conduit types (PVC, nylon, metal, etc.) and sizes to meet your specific needs.

Expert Perspective:

“A reputable supplier will understand that one size doesn’t fit all,” says Sarah Johnson, Lead Engineer at Auto Wire Solutions. “They should offer customization options for unique applications and vehicle models.”

Look for suppliers who provide prompt customer service, technical support, and readily available resources (e.g., application guides, installation manuals).

Case Study: A small repair shop praised a particular auto wire conduit supplier for their exceptional technical assistance in troubleshooting a complex wiring issue, ultimately saving them valuable time and resources.

Compare quotes from multiple suppliers while considering overall value, not just the lowest price. Factor in lead times, delivery options, and potential bulk discounts.

Choosing a reliable auto conduit supplier is an investment in your vehicle’s performance and safety. By prioritizing experience, quality, support, and customization, you set yourself up for success and long-lasting reliability on the road ahead.

The automotive industry is on the cusp of a revolution, driven by electrification, autonomous driving, and advanced connectivity. This rapid evolution necessitates a transformation in every aspect of vehicle design, including the often-overlooked world of wiring conduits.

Here’s a peek into the exciting future of auto conduits:

As vehicles strive for greater fuel efficiency and range (especially in EVs), lightweight materials like carbon fiber composites, fiberglass reinforced plastics (FRP), and even advanced polymers will become increasingly prevalent.

Case Study: Tesla’s Model S Plaid utilizes a combination of aluminum and composite materials in its wiring harnesses, significantly reducing weight without compromising strength or conductivity.

A 2023 report by Grand View Research projects the global automotive sensors market to reach $169 billion by 2030, highlighting the increasing integration of sensing technologies into vehicles.

Integration of Sensors: Future conduits could incorporate embedded sensors for real-time monitoring of temperature, pressure, vibration, and even electrical current flow. This data can help predict potential failures, optimize performance, and enable proactive maintenance.

Imagine an auto conduit that can repair minor damage autonomously! Research into self-healing materials is progressing rapidly, offering the potential for enhanced durability and extended service life.

Expert Perspective:

“The future of auto conduits lies in smart integration,” says Dr. Emily Chen, Lead Materials Engineer at the Automotive Industry Association (AIA). “Self-healing capabilities could revolutionize maintenance procedures and significantly improve safety.”

Wireless charging is already becoming commonplace in smartphones and other devices. This technology holds immense potential for vehicles, eliminating the need for physical connections between the battery and electrical components, reducing cable clutter, and improving overall efficiency.

Case Study: Companies like Local Motors are already exploring 3D printing to create custom conduits tailored to specific vehicle models and application requirements. This opens doors for greater design flexibility and on-demand manufacturing.

The future of auto conduits promises a dynamic shift towards smarter, lighter, and more resilient systems, ultimately contributing to safer, more efficient, and technologically advanced vehicles.

Thanks to the rapid development of electric vehicles, auto conduit has gone from an unnoticed conduit series to the current rapid development.

It works in harsh environments for a long time, so its performance is very important. At present, AAA has also established relevant standards. In this article, we also mentioned how to choose the right automotive electrical conduit, and type, material, etc., and how to maintain it during use.

This is all for this post. If you still have questions, you can submit a form or send an email to our experts, who will discuss specific solutions with you.