Tabla de contenido

When planning electrical installations, choosing the right conduit is a critical decision that can significantly impact the durability, safety, and efficiency of your project. Among the many factors to consider, understanding the differences between heavy-duty and medium-duty conduits is essential, especially when adhering to standards such as the Australian Standard (AS).

This article provides a comprehensive guide to help you make an informed choice. We will explore the key parameters, specifications, and applications of heavy-duty and medium-duty conduits as defined in the AS standard. Furthermore, we’ll discuss how these specifications apply to different types of conduits, including rigid PVC conduit, corrugated conduit, flexible conduit, and solar conduit. A dedicated section will cover the unique requirements for solar applications, offering insights into conduit selection for sustainable energy systems.

After reading this article, you’ll gain a clear understanding of:

- The primary differences between heavy-duty and medium-duty conduits

- Different conduit types and their uses

- Benefits of using PVC conduit

- The different requirements of AS/NZS 2053 and IEC 61386 for conduits

- Factors you need to consider to choose the appropriate conduit

Electrical conduits are protective ducts designed to house and safeguard electrical and communication cables. These conduits provide critical protection against physical damage, environmental exposure, and mechanical stress, ensuring the integrity and safety of underground or exposed wiring systems.

PVC conduits, a popular choice, are manufactured from durable, non-corrosive plastic and are commonly available in sizes ranging from 16mm to 200mm in diameter. The specific application often determines the size and color of the conduit, adhering to industry and authority standards. Standard colors include:

- Orange: Used for heavy-duty electrical conduits, typically for low voltage (LV) and high voltage (HV) underground installations.

- Grey: Associated with medium-duty electrical conduits, commonly used in domestic and commercial environments.

- White: Reserved for communication conduits, including telco, fibre optics, and National Broadband Network (NBN) installations.

Conduits are integral to diverse industries and sectors, providing safe and reliable pathways for electrical and communication wiring. Common applications include:

- Telecommunications: Safeguarding cables for fibre optic and broadband networks.

- Electrical Power: Supporting LV and HV installations in residential, commercial, and industrial settings.

- Infrastructure Projects: Used in roads, railways, and other public works.

- Defence and Security: Providing robust solutions for secure installations.

- Renewable Energy: Especially important in solar and other sustainable energy systems, where environmental resilience is crucial.

Australian standards classify conduits into light-duty, medium-duty, and heavy-duty categories, depending on their wall thickness and mechanical performance. This classification determines their suitability for different environments and applications:

- Heavy-Duty Conduit: Identified by its greater wall thickness and superior compressive and impact strength, heavy-duty conduit is predominantly orange and is ideal for underground electrical installations.

- Medium-Duty Conduit: A versatile choice, typically grey, used for domestic and commercial installations.

- Light-Duty Conduit: Primarily for non-critical, low-impact applications, often orange in color for underground LV and HV systems.

- Communication Conduit: Generally white, available in both medium- and heavy-duty variations, designed for telco and fibre optic networks.

These classifications provide a standardized approach to conduit selection, helping ensure proper functionality, durability, and compliance in diverse installation scenarios.

Solar Conduits

Solar conduits are a specialized type of conduit designed to meet the unique demands of photovoltaic (PV) systems. These conduits provide robust protection for wiring exposed to harsh environmental conditions, such as intense sunlight, temperature fluctuations, and moisture. Key characteristics of solar conduits include:

- Resistencia a los rayos UV: To prevent degradation from prolonged sun exposure.

- Thermal Stability: Ensures consistent performance in high-temperature environments.

- Weatherproofing: Protects against rain, wind, and dust in outdoor installations.

- Compliance Standards: Solar conduits adhere to specific guidelines for renewable energy applications, ensuring they meet performance and safety criteria.

Solar conduits are critical for ensuring the longevity and reliability of solar installations, safeguarding the wiring that connects PV panels, inverters, and storage systems. Available in rigid and corrugated forms, solar conduits cater to both above-ground and underground installations, providing flexibility and durability as required.

Conduits are categorized not only by their duty classifications (heavy, medium, or light) but also by the materials used in their construction. Material selection is crucial because it determines the conduit’s durability, application range, environmental performance, and compliance with standards. According to AS/NZS 2053.1, Clause 5, conduits are classified into four primary material categories:

- Metal

- Insulating

- Composite

- Fibre-Reinforced Concrete

This section provides an overview of these materials, focusing on their properties, applications, and suitability for different installation environments.

Metal conduits are robust and reliable, often used in applications requiring high mechanical protection or fire resistance. Common types include:

Tubería Metálica Eléctrica (EMT):

Lightweight steel conduit often used in commercial and industrial environments. It offers minimal protection against impact but is easy to install.

Conducto metálico rígido (RMC):

A thicker, galvanized steel conduit with superior durability and corrosion resistance, suitable for outdoor and underground installations.

Conducto metálico intermedio (IMC):

Lighter than RMC but with comparable strength, making it ideal for exposed applications where weight savings are beneficial.

Conducto metálico flexible (FMC):

A corrugated, flexible metal conduit used in applications requiring frequent directional changes or vibration resistance, such as machine tools or HVAC systems.

Insulating conduits, primarily made from PVC or other plastics, are versatile and widely used. Types include:

Conducto de PVC rígido:

A durable, non-metallic conduit ideal for underground and outdoor applications, available in heavy-duty, medium-duty, and light-duty classifications.

Corrugated PVC Conduit:

Flexible and lightweight, designed for installations requiring bending or movement, such as in telecommunications or automotive wiring.

Polyethylene (PE) Conduit:

Known for its flexibility and chemical resistance, often used in fibre optic networks and underground communication systems.

Liquid-Tight Non-Metallic Conduit (LTNMC):

A specialized insulating conduit with water-tight properties, used in wet or corrosive environments.

Composite conduits combine multiple materials to offer enhanced properties. Common types include:

Aluminum-Plastic Composite Conduit:

Combines lightweight aluminum for strength with a plastic outer layer for corrosion resistance, often used in outdoor environments.

Steel-PVC Composite Conduit:

A steel conduit lined or coated with PVC for added electrical insulation and chemical resistance. Ideal for industrial settings with corrosive exposures.

Fiberglass Reinforced Plastic (FRP) Conduit:

Provides excellent corrosion resistance, lightweight construction, and strength, used in chemical plants and marine applications.

FRC conduits are highly durable and primarily used in heavy-duty infrastructure applications. Types include:

Prestressed Concrete Conduits:

Manufactured with pre-tensioned steel reinforcement for added strength, used in tunnels, bridges, and highways.

Centrifugally Cast Concrete Conduits:

Made using spinning techniques for uniform strength and density, often used in underground applications requiring extreme compressive strength.

Polymer Concrete Conduits:

A blend of resin and aggregate, offering improved chemical resistance and lighter weight compared to traditional concrete conduits, used in industrial and energy projects.

Distinguishing between heavy-duty and medium-duty conduits is crucial for ensuring safety, regulatory compliance, and long-term performance across a variety of installations. Different applications, environmental conditions, and regional standards necessitate the careful selection of conduit duty levels. Here are the primary reasons why this distinction matters:

Different countries and regions enforce unique standards and requirements for conduit usage based on their environmental conditions and infrastructure needs.

Urban vs. Rural Settings: Urban areas often have dense underground utility networks requiring heavy-duty conduits to handle traffic loads and minimize risk of damage. In rural settings, medium-duty conduits may suffice due to lighter loads.

Industry-Specific Applications: Sectors like renewable energy, rail infrastructure, and heavy manufacturing demand heavy-duty conduits for enhanced mechanical protection, whereas commercial and residential buildings typically rely on medium-duty solutions.

Conduits must protect wiring and cables from environmental threats, and the duty classification determines their ability to withstand these challenges.

Harsh Conditions: Heavy-duty conduits are better suited for environments exposed to heavy soil pressure, water immersion, or corrosive chemicals.

Controlled Environments: Medium-duty conduits provide adequate protection in less demanding conditions, such as indoor installations or sheltered outdoor areas.

The type of conduit directly impacts its ability to withstand mechanical loads.

Cargas pesadas: Underground installations in high-traffic areas, such as highways or industrial zones, demand the compressive strength of heavy-duty conduits.

Moderate Loads: Areas with lower traffic or mechanical stresses can utilize medium-duty conduits, reducing costs without compromising performance.

Compliance with AS/NZS 2053.1 and other standards ensures that installations are safe and fit for purpose. Each duty classification has specific guidelines that must be followed for mechanical strength, impact resistance, and durability.

Avoiding Over-Specification: Using heavy-duty conduits in low-stress environments can unnecessarily increase costs.

Preventing Under-Specification: Medium-duty or light-duty conduits used in high-stress areas risk failure, potentially causing system outages or safety hazards.

Selecting the appropriate conduit duty helps balance performance and budget.

Heavy-Duty for Critical Areas: Investing in heavy-duty conduits for critical installations ensures long-term reliability and reduced maintenance costs.

Medium-Duty for General Use: For less demanding applications, medium-duty conduits offer cost-effective solutions without over-engineering the system.

When selecting conduit for electrical installations, understanding the differences between heavy-duty and medium-duty conduit is essential for ensuring the right performance and durability. The key differences in size, color, thickness, performance, weight, price, application scenarios, and marking are based on the standards outlined in AS/NZS 2053.1, AS/NZS 2053.2, and AS/NZS 2053.5. This section compares these two types of conduit, helping you determine which is the best fit for your needs.

There are Rigid Plain Conduit and Corrugated Conduit, both available in light, medium and heavy-duty and other types, each with specific size and thickness requirements. Below is an overview of the dimensions according to AS/NZS 2053.1, AS/NZS 2053.2, and AS/NZS 2053.5.

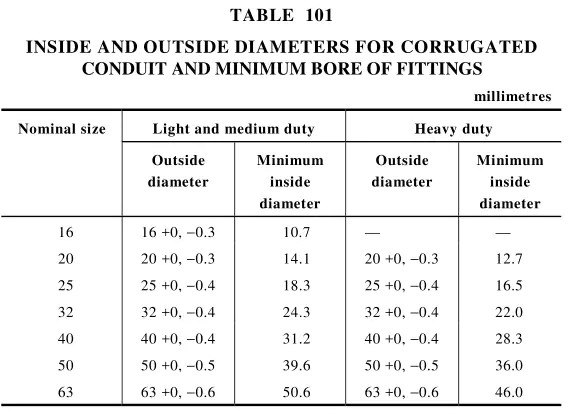

Corrugated Conduit Dimensions (AS/NZS 2053.5)

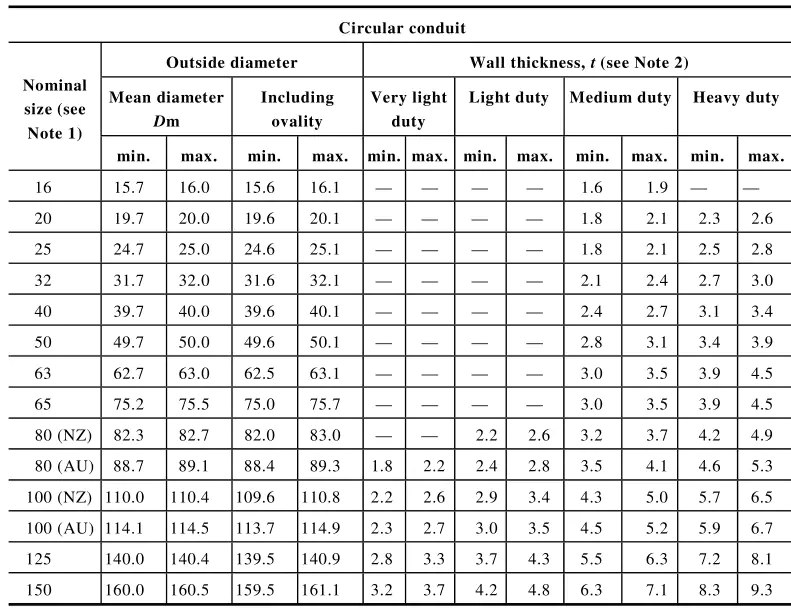

Rigid Plain Conduit Dimensions (AS/NZS 2053.2 TABLE 101)

Heavy Duty Conduit:

Heavy-duty conduits are typically orange in color, as specified in AS/NZS 2053.1. The bright orange color makes them easily identifiable, which is important for safety and compliance in power installations, both for low voltage (LV) and high voltage (HV) systems. The color also helps differentiate power-related conduits from those used for telecommunications.

Medium Duty Conduit:

Medium-duty conduits are often grey or white, depending on the application. Grey is the standard for electrical installations in commercial or residential environments, while white is commonly used for telecommunications and fiber optic cables. These colors help identify the conduit’s purpose and ensure safe handling during installation and maintenance.

In distinguishing heavy-duty and medium-duty conduits, their performance under stress is crucial. The AS/NZS 2053.1 standard provides clear guidelines for evaluating conduit performance, particularly in terms of compression resistance, impact strength, and collapse resistance. These tests ensure conduits can withstand the mechanical stresses they may encounter during installation and operation.

- Compression Test

The compression test assesses a conduit’s ability to resist deformation under load. According to AS/NZS 2053.1, conduits are subjected to a uniform load distributed over a defined area. This test ensures the conduit can maintain its shape and protect enclosed cables when exposed to external forces.

Compression Strength Criteria in AS/NZS 2053.1

Conducto | Test Load (N) | Deformation Limit |

HD Rigid Conduit | 1250 N | ≤ 10% deformation |

MD Rigid Conduit | 750 N | ≤ 10% deformation |

HD Corrugated Conduit | 1250 N | ≤ 25% deformation |

MD Corrugated Conduit | 750 N | ≤ 25% deformation |

- Impact Test

The impact test evaluates a conduit’s ability to withstand sudden mechanical shocks, such as drops, collisions, or accidental strikes. And the conduit should show no cracks or disintegration when subjected to the following weight and height. This test is crucial for ensuring the conduit’s integrity during handling and installation.

Hammer Weight and Fall Height in AS/NZS 2053.1

Conduit Duty | Weight of the hammer kg | Fall height mm |

Medio | 2.0 | 100±1 |

Pesado | 2.0 | 300±1 |

- Collapse Test

The collapse test is a critical evaluation method outlined in AS/NZS 2053 standards to ensure conduits maintain their structural integrity under mechanical and environmental stresses. This test assesses whether a conduit can retain its internal diameter and functional shape when exposed to bending forces and prolonged high temperatures.

The process begins by bending the conduit test piece at room temperature through a specific angle, typically 90°, using a bending device with a standardized radius.

Criterios de aceptación: The gauge must pass through the conduit without obstruction or excessive deformation.

Conducto rígido: According to AS/NZS 2053.2, only conduits of diameter less than 32mm and medium, or light duty conduit should be tested for collapse, heavy duty conduits do not need to be tested. When tested with a bending device, the conduit should pass the diameter check.

Corrugated Conduit: All sizes are applicable. (AS/NZS 2053.5)

Heavy Duty Conduit:

Due to their thicker walls and stronger materials, heavy-duty conduits are heavier than their medium-duty counterparts. This added weight provides greater mechanical protection, but it also means that heavy-duty conduits can be more difficult to handle and install, particularly for large-scale projects. The added weight is a trade-off for their durability and strength in harsh environments.

Medium Duty Conduit:

Medium-duty conduits are lighter in comparison, making them easier to handle and install, especially in areas where heavy-duty conduit would be overkill. The lighter weight makes them ideal for residential wiring, office installations, and other non-heavy-duty applications.

Heavy Duty Conduit:

Heavy-duty conduits are generally more expensive than medium-duty conduits due to their higher material costs, thicker walls, and enhanced performance features. While the upfront cost is higher, these conduits provide long-term value in environments where durability and reliability are critical. For example, in power transmission systems, where conduit failure could lead to costly repairs and safety hazards, the higher price of heavy-duty conduit is justified.

Medium Duty Conduit:

Medium-duty conduits are more cost-effective than heavy-duty options, making them an ideal choice for general-purpose applications such as residential, light commercial, and telecommunications installations. The lower cost is a significant factor when the conduit’s mechanical protection needs are less stringent.

Heavy Duty Conduit:

Heavy-duty conduits are designed for high-stress applications and environments where external forces are significant. Typical uses include:

Underground Power Installations: In areas with heavy traffic, such as roads or industrial zones.

Heavy Industrial Environments: Where impact and compression resistance are vital.

Renewable Energy Projects: Such as solar farms or wind turbines, where conduit must withstand harsh weather and environmental conditions.

High-Voltage Systems: Used in both low-voltage (LV) and high-voltage (HV) electrical installations.

Medium Duty Conduit:

Medium-duty conduits are suited for low to moderate stress environments. Common applications include:

Cableado residencial: Used for general electrical wiring in homes and buildings.

Commercial Installations: Ideal for wiring in offices, shopping centers, and schools.

Telecommunication and Fiber Optic Installations: Used for the protection of telecommunications cables in controlled environments.

The AS/NZS 2053 standards outline precise marking requirements for all conduit types, ensuring clear identification of their specifications and intended use. Key marking components:

- Manufacturer Identification

- Tamaño nominal

- Application Designation: The word “ELECTRICAL” must be included

- Duty Classification: Clearly marked with “ MEDIUM DUTY (MD)” or “HEAVY DUTY (HD)

- Special Properties (Optional): Such as Halogen-Free (HF) and UV protection “T”

- Rango de temperatura

PVC conduit is a popular choice for electrical installations due to its unique properties and advantages compared to metal conduits. Its lightweight nature, durability, and versatility make it a go-to option for residential, commercial, and industrial applications. Below are the key benefits of PVC conduit:

PVC conduits are more affordable than metal conduits due to lower material and manufacturing costs. Additionally, their lightweight nature reduces labor expenses, making them highly economical for large-scale projects.

Unlike metal conduits, PVC is inherently resistant to corrosion, making it ideal for humid or underground environments where moisture could deteriorate metal over time.

PVC conduits are significantly lighter than metal conduits, facilitating easier transportation and installation. This benefit reduces installation time and labor efforts, particularly in overhead or complex layouts.

PVC is a non-conductive material, providing built-in insulation for cables. This eliminates the need for additional grounding, unlike metal conduits, which require grounding to prevent electrical hazards.

Available in various types, sizes, and duty classifications (light, medium, and heavy-duty), PVC conduits can be customized to suit different environments, including underground, outdoor, and even solar installations.

PVC conduits are self-extinguishing, meaning they do not propagate flames, enhancing safety in case of a fire.

PVC Vs. Metal Conduit

Característica | Conducto de PVC | Metal Conduit |

Costo | Bajo | Alto |

Resistencia a la corrosión | Excellent | Prone to rust unless treated/coated |

Peso | Ligero | Pesado |

Electrical Insulation | Built-in | Requires additional grounding |

Facilidad de instalación | Easy | Labor-intensive |

Resistencia al fuego | Self-extinguishing | Conductive, may require extra measures |

Strength | Relatively lower than Metal | Alto |

The standards AS/NZS 2053 and IEC 61386 are both internationally recognized frameworks governing the design, testing, and application of electrical conduits. While they share similarities in ensuring safety and performance, the standards diverge in structure, scope, and testing requirements due to regional priorities and regulatory needs.

AS/Nueva Zelanda 2053

- Region: Australia and New Zealand.

- Scope: Focuses on rigid and flexible conduits for electrical applications, tailored to local environmental and industry requirements.

- Primary Concerns: Durability, UV resistance, and performance under extreme Australian and New Zealand conditions, including temperature fluctuations and heavy mechanical loads.

CEI 61386

- Region: European Union and internationally.

- Scope: Covers conduit systems for cable management in diverse settings, from industrial to residential.

- Primary Concerns: Comprehensive classification based on mechanical and electrical characteristics, emphasizing uniformity across European markets.

These two has similar requirements for conduits, they both divided the conduit into same 5 classifications: Very Light, Light, Medium, Heavy, Very Heavy. The test forces for their mechanical performance also the same. But there some differences in certain testing conditions, acceptance criteria etc. And part of the test items also different, here are the comparison of some key tests:

Tests | AS/Nueva Zelanda 2053 | CEI 61386 | ||

Conditions | Criterios de aceptación | Conditions | Criterios de aceptación | |

Compresión | Test pieces should be conditioned at 20 ±1°C for at least 10 h | OD difference≤ 10% for rigid conduit; OD difference≤ 25% for corrugated conduit;

| test at (23 ± 2) ºC | OD difference≤25%, 60s after removing force |

Impact | Condition temperatures are specified by manufacturer. | No signs of disintegration or cracks at least 9 of 12 test pieces | Condition temperatures are specified in Table 1 of the standard for 2 hours. | No signs of disintegration or cracks at least 9 of 12 test pieces |

Collapse | Condition temperatures are specified by manufacturer. | The gauge must pass through the conduit without obstruction or excessive deformation.

| Rigid conduit should condition according to Table of IEC 61386-1; Flexible conduit is not applicable for this test. | Should be possible to pass the appropriate gauge. |

Resistencia a la tracción | Not specified | Not specified | Subject to the tensile force in Table 6 of IEC 61386-1 at 23℃ | No damage visible to normal or corrected vision without magnification |

Carga suspendida | Not specified | Not specified | Sujeto a carga suspendida de la Tabla 7 y mantenido a temperaturas de la Tabla 2 | No hay grietas visibles a la vista normal o corregida sin aumento |

Comprender estas diferencias garantiza la selección adecuada de conductos según los requisitos específicos de la región, mejorando el rendimiento y el cumplimiento de las regulaciones locales.

Seleccionar el tipo de conducto adecuado es fundamental para garantizar un rendimiento confiable, seguridad y cumplimiento normativo. Al decidir entre clasificaciones como conductos para trabajos livianos, medianos y pesados (tanto rígidos como corrugados), es esencial considerar varios factores clave.

Si necesita una guía más completa sobre conductos de PVC, incluida una guía de compra, haga clic aquí para leer La guía definitiva sobre conductos de PVC.

El tipo de conducto que elija debe estar acorde con los requisitos de carga específicos de su proyecto:

Trabajo ligero: Ideal para instalaciones interiores con baja tensión mecánica, como el cableado residencial.

Servicio medio: Adecuado para aplicaciones de estrés moderado, como configuraciones comerciales e industriales ligeras.

Trabajo pesado: Requerido para escenarios de alto impacto, como instalaciones al aire libre, cableado subterráneo y proyectos de infraestructura.

Los factores ambientales como las temperaturas extremas y la humedad influyen en gran medida en la elección del conducto:

Conductos rígidos: Funciona bien en entornos estables como paredes subterráneas o empotradas.

Conductos corrugados: Opciones flexibles para configuraciones dinámicas y curvas cerradas.

El diámetro del conducto y el espesor de la pared deben coincidir con los cables y el escenario de aplicación:

Los conductos para trabajos livianos son más delgados y livianos, adecuados para cables más pequeños y entornos menos exigentes.

Los conductos para servicio mediano y pesado presentan un mayor espesor de pared y están disponibles en diámetros más grandes para soportar cargas más elevadas e instalaciones de cables más extensas.

Considere las propiedades mecánicas del conducto:

Resistencia a la compresión y al impacto: Los conductos de servicio pesado están diseñados para soportar mayores fuerzas de compresión e impacto en comparación con los tipos de servicio mediano o liviano.

Resistencia térmica: Los conductos deben resistir deformaciones o fallas bajo temperaturas altas o bajas, especialmente en aplicaciones exteriores o industriales.

Asegúrese de utilizar un producto compatible y de cumplir con los estándares requeridos, como AS/NZS 2053, IEC 61383 y EN 61386.

Las consideraciones de costos son esenciales, especialmente para proyectos de gran escala:

Los conductos para trabajos livianos son más rentables, pero es posible que sea necesario reemplazarlos antes en condiciones exigentes.

Los conductos de alta resistencia son una inversión que proporciona durabilidad a largo plazo y menores costos de mantenimiento.

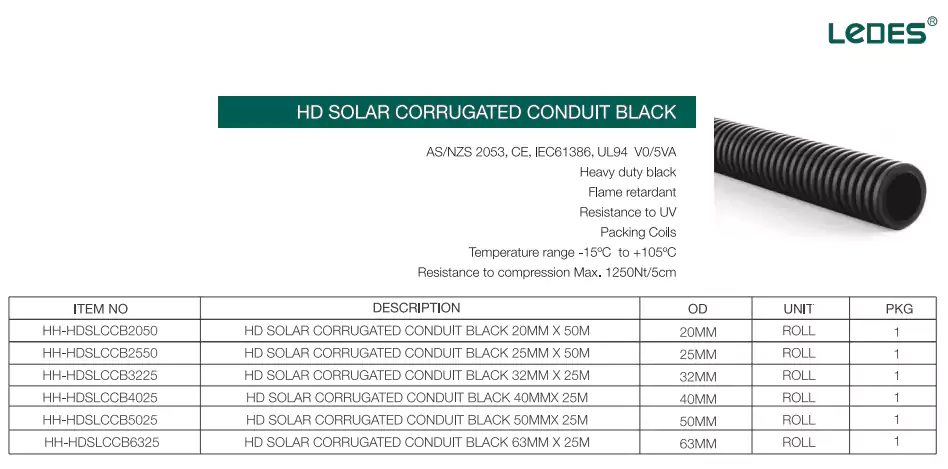

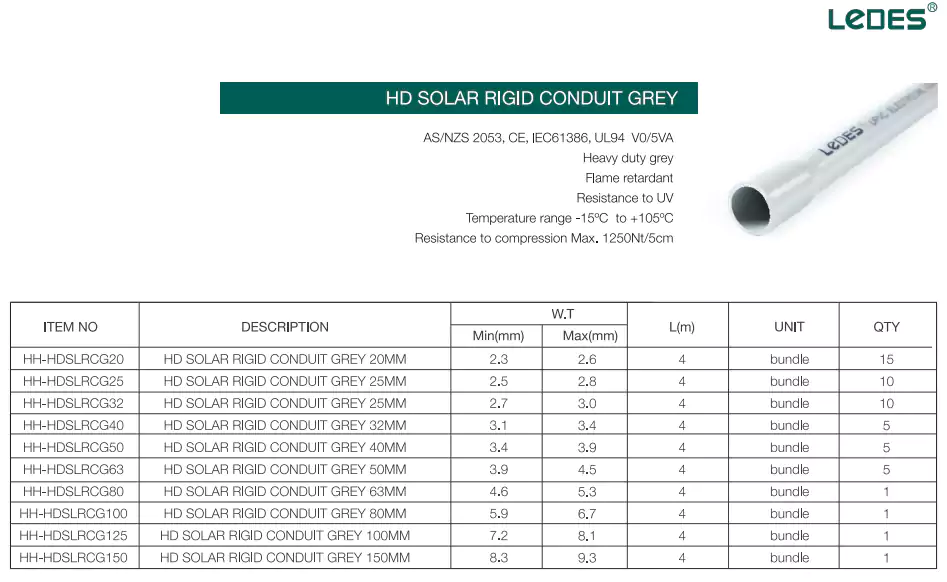

Proyectos como las instalaciones solares requieren conductos con características específicas:

Resistencia UV: Para uso en exteriores.

Flexibilidad: Los conductos solares corrugados funcionan bien en entornos dinámicos.

Tolerancia a la temperatura: importante para instalaciones de energía renovable expuestas a condiciones climáticas extremas.

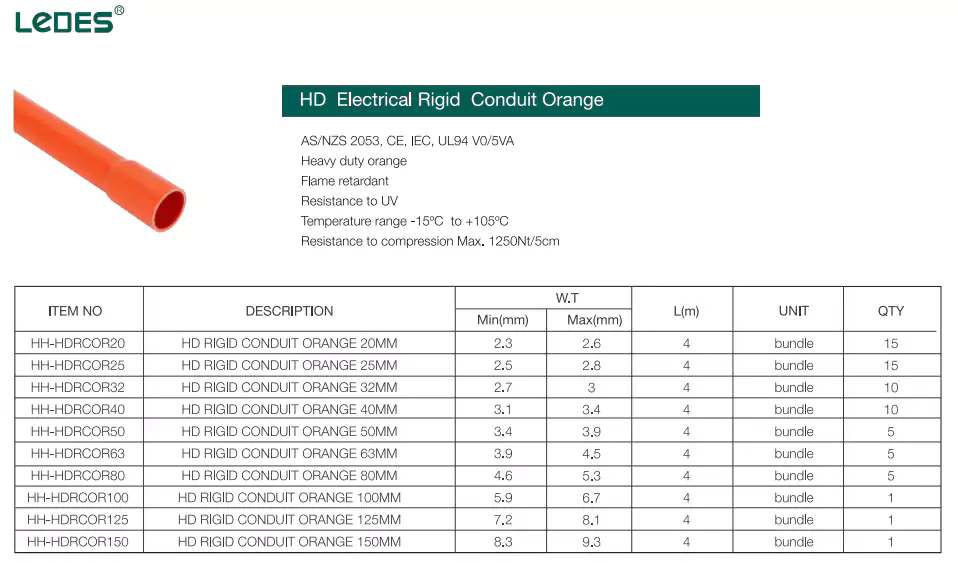

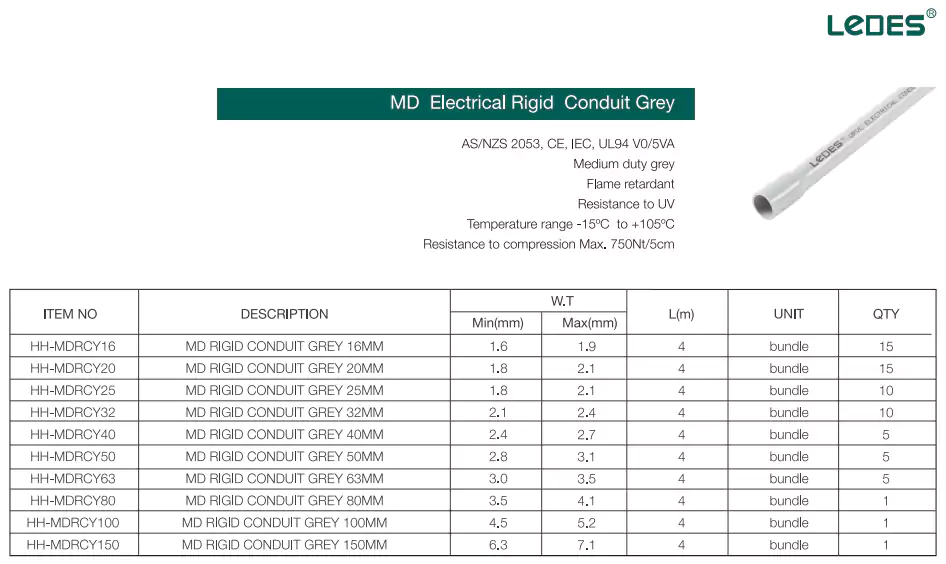

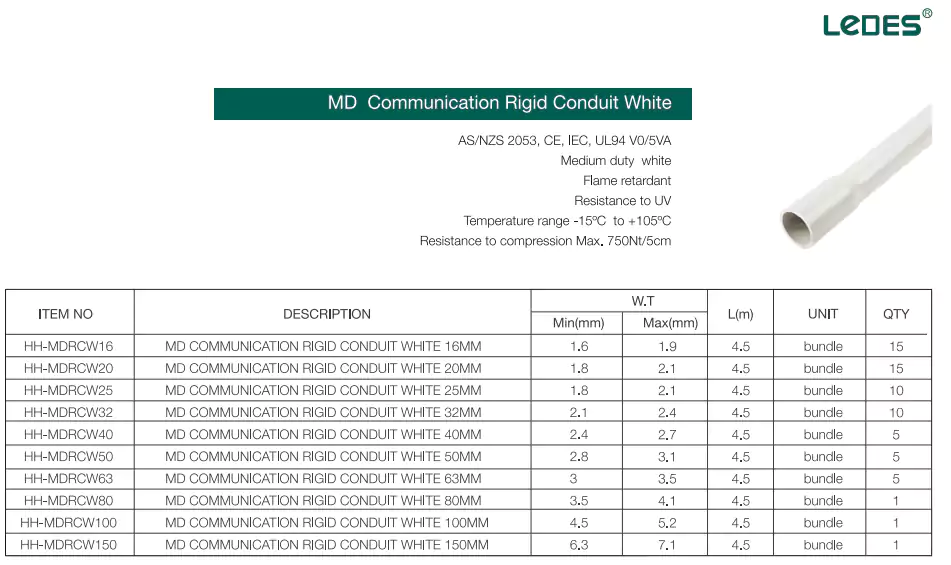

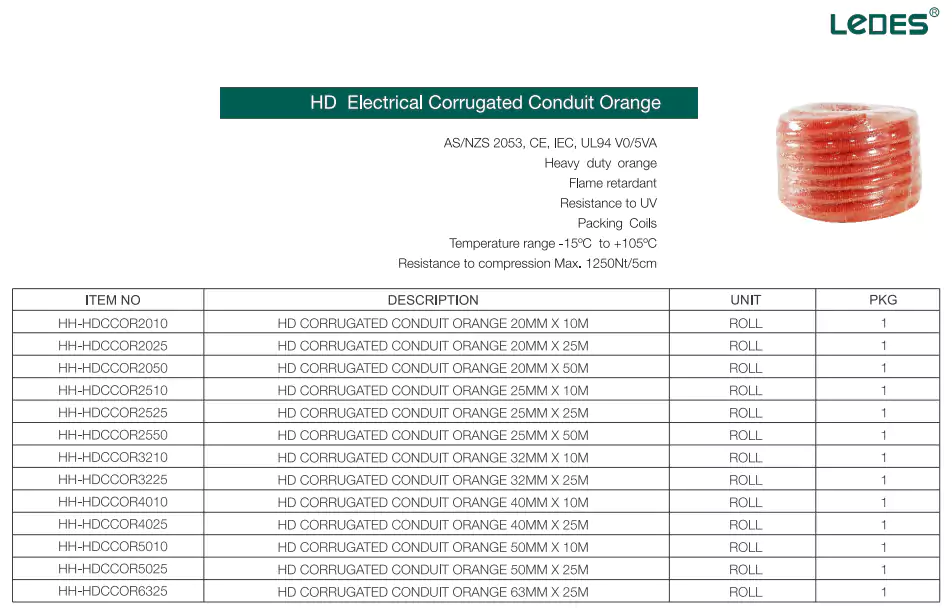

Ledes ofrece una gama completa de conductos rígidos y corrugados que cumplen con las normas AS/NZS 2053, lo que garantiza que satisfagan las demandas de diversas aplicaciones.

Tipos disponibles:

Conducto rígido HD/MD, conducto rígido de comunicación MD

Conducto corrugado HD/MD, conducto corrugado para comunicaciones MD

Los conductos de la serie AS de Ledes están diseñados para el mercado de Australia y Nueva Zelanda, se destacan por su:

- Versatilidad:Disponible en clasificaciones de servicio liviano, medio y pesado, tanto para tipos rígidos como corrugados.

- DurabilidadDiseñado para resistencia a altos impactos y rendimiento duradero.

Además de los conductos de la serie AS/NZS, Ledes ofrece conductos solares especialmente para instalaciones fotovoltaicas. También cumplen con la norma AS/NZS 2053 y las normas IEC y CE. Su excelente Resistente a los rayos UV Las propiedades de estos conductos los convierten en una opción popular para muchos proyectos solares. Estas son las especificaciones de los conductos solares Ledes:

Los sistemas de conductos no están completos sin los accesorios adecuados, que garantizan conexiones perfectas, instalaciones seguras y un rendimiento óptimo. Los accesorios vienen en varias formas, tamaños y tipos, adaptados a aplicaciones de conductos específicas. Estos son algunos de los accesorios que ofrece Ledes:

Curva de barrido:Una curva larga y suave ideal para proteger los cables de curvas cerradas.

Curva estándar:Una curva de uso general para aplicaciones estándar.

Codo sólido:Un codo pequeño de 90 grados que ofrece conexiones robustas en escenarios de ángulo fijo.

Codo de 90 grados:Diseñado para curvas cerradas en ángulos rectos, manteniendo la integridad del conducto y la protección del cable.

Codo de 45 grados:Se utiliza para ángulos menos agudos, proporcionando una ruta más suave para el cableado.

Codo de inspección:Incluye una cubierta extraíble, que permite un fácil acceso a los cables para mantenimiento o inspección.

Enganche: Une conductos rígidos de extremo a extremo para recorridos prolongados.

Adaptador de rosca simple a rosca:Convierte conductos de extremo liso en conductos roscados.

Adaptador de corrugado a tornillo:Conecta conductos corrugados a conexiones roscadas, garantizando transiciones seguras y flexibles.

Caja adaptable:Un gabinete versátil adecuado para una variedad de instalaciones.

Caja de conexiones:Facilita las conexiones entre múltiples conductos, garantizando una gestión ordenada y segura de los cables.

Camiseta estándar:Permite conexiones simples de tres vías.

Tee de inspección:Viene con una cubierta extraíble para facilitar el acceso a los cables y el mantenimiento.

Clips en U: Los clips en U son sujetadores que se utilizan para asegurar conductos a paredes, techos u otras superficies.

Accesorios para conductos solares

Para los sistemas de conductos solares, los accesorios deben soportar duras condiciones exteriores:

Resistencia a los rayos UV: Los accesorios como acoplamientos solares, codos y adaptadores están tratados para una exposición prolongada a la luz solar.

Weatherproofing: Diseñado para soportar fluctuaciones de temperatura, lluvia y polvo en aplicaciones de energía renovable.

Ledes ofrece una amplia gama de accesorios diseñados para aplicaciones solares, entre los que se incluyen:

- Codos, curvas y acoplamientos resistentes a los rayos UV.

- Cajas de conexiones de grado solar y cajas adaptables para conexiones seguras y duraderas.

- Adaptadores de terminales y accesorios de inspección diseñados para instalaciones solares.

¿Existen beneficios al utilizar tuberías de PVC de color negro?

Sí, las tuberías de PVC de color negro ofrecen varias ventajas:

Resistencia a los rayos UV: Las tuberías de PVC negro a menudo se tratan con aditivos como el negro de carbón, lo que las hace altamente resistentes a la radiación UV y adecuadas para aplicaciones en exteriores.

Durabilidad: Estas tuberías son más resistentes a la decoloración, el agrietamiento y la degradación causados por la exposición prolongada a la luz solar.

Atractivo estético: Las tuberías de color negro son visualmente discretas en ciertos entornos, como aplicaciones exteriores o de paisajismo.

¿Cuál es la diferencia entre los conductos de PVC y LSZH?

Composición del material: Los conductos de PVC (cloruro de polivinilo) están hechos de un material plástico resistente, mientras que los conductos LSZH (baja emisión de humo y cero halógenos) están formulados para emitir un mínimo de humo y ningún gas halógeno dañino durante un incendio.

Aplicaciones: Los conductos de PVC se utilizan ampliamente para instalaciones eléctricas generales, mientras que los conductos LSZH son ideales para áreas cerradas o de alto riesgo como centros de datos, centros de transporte y túneles.

Seguridad contra incendios: Los conductos LSZH se prefieren cuando la seguridad contra incendios es fundamental, ya que reducen las emisiones tóxicas y mejoran la visibilidad para la evacuación durante un incendio.

¿Cuál es el significado de conducto de comunicación?

El conducto de comunicación se refiere a una vía de protección diseñada específicamente para albergar y proteger cables de comunicación, como cables de fibra óptica, telefónicos o de datos.

Aplicaciones: Estos conductos se utilizan en redes de telecomunicaciones, infraestructura de Internet y sistemas de cableado estructurado.

Estándares: En regiones como Australia, los conductos de comunicación cumplen con estándares de servicio mediano o pesado, generalmente marcados en blanco para su identificación.

¿Se puede pegar PVC negro a PVC blanco?

Sí, puedes pegar PVC negro sobre PVC blanco, siempre que sean del mismo tipo de material (por ejemplo, ambos sean de PVC). Para ello:

Utilice el adhesivo adecuado: Se recomienda cemento para PVC, específicamente formulado para unir materiales de PVC.

Preparación de la superficie: Asegúrese de que ambas superficies estén limpias y secas antes de aplicar el adhesivo.

Solicitud: Aplique imprimación y cemento de acuerdo con las instrucciones del fabricante para lograr una unión segura.

Compatibilidad: Verifique que la tubería de PVC negro no sea una tubería de CPVC (PVC clorado), ya que el CPVC puede requerir un adhesivo diferente.

Elegir el tipo correcto de conducto es una decisión crítica que afecta la seguridad, la eficiencia y la longevidad de los sistemas eléctricos y de comunicación. En este artículo, se han analizado las diferencias entre los conductos de servicio pesado y de servicio medio, así como los beneficios de utilizar PVC en lugar de alternativas de metal. También se han proporcionado conocimientos sobre normas importantes como AS/NZS 2053 y EN 61386, accesorios comunes y los factores que se deben tener en cuenta al seleccionar el conducto más adecuado para su proyecto.

Comprender las diferencias entre materiales, aplicaciones y rendimiento es fundamental para cumplir con los requisitos específicos de instalación. Ya sea para un proyecto residencial, comercial o solar, garantizar el cumplimiento de los estándares de la industria es clave para ofrecer soluciones duraderas y de alta calidad.

Ledes ofrece una amplia gama de conductos para diferentes aplicaciones, si tiene alguna duda contáctenos en cualquier momento.