Inhaltsverzeichnis

When it comes to electrical installations, choosing the right type of conduit is crucial for ensuring safety, durability, and compliance with local codes. Among the various options available, DB120 conduit and Schedule 40 PVC conduit are two popular choices in North America, each with its unique properties and applications. This article explores these two types of conduits, helping you understand their differences and making the right choice for your project.

Was ist ein DB120-Conduit?

DB120 conduit is a rigid, non-metallic conduit made from PVC, specifically designed for direct burial applications, allowing it to be installed underground without the need for concrete encasement. It is classified as non-metallic and is governed by standards from organizations like the National Electrical Manufacturers Association (NEMA), ensuring compliance with safety and performance requirements for underground installations.

Standards: NEMA TC 6 & 8, ASTM F-512

What is Schedule 40 PVC Conduit?

PVC-Rohr nach Schedule 40, made from PVC, is utilized primarily for underground and above-ground electrical applications. It is classified based on its wall thickness, providing a robust option for protecting electrical wiring. Schedule 40 adheres to standards set by the UL and ASTM (American Society for Testing and Materials) and the National Electrical Code (NEC), making it a reliable choice for various installations. Understanding these definitions and compliance standards is essential for determining the appropriate application of each conduit type in a project.

Standards: UL651, NEMA TC -2

What are the Differences Between DB120 Conduit and Schedule 40 PVC?

While both DB120 and Schedule 40 PVC conduits serve the primary purpose of protecting electrical wiring, but their material composition, properties, and specific applications can significantly influence the decision on which to use.

Materialien

Schedule 40 conduit: Schedule 40 conduit is essentially classified as Rigid PVC conduit. According to Section 4.1 of UL 651, 8th Edition, its raw material standard is certified under ASTM D 1784. Additionally, all raw materials must be managed and certified in accordance with UL 746D standards. Regarding recycled materials, manufacturers are only permitted to use reprocessed materials from their own production.

DB120 Conduit: On the other hand, DB120 duct, as described in Section 3.1 of NEMA TC 6 & 8, 2013 Edition, must also comply with ASTM D 1784 certification. It addresses the issue of recycled materials as well, but unlike UL 651, it does not restrict manufacturers to using only recycled materials from their own production lines; it simply requires compliance with the relevant standards.

However, in ASTM F512, 2019 Edition, Section 5.2, the requirements for using recycled materials are largely consistent with those of UL 651, stipulating that manufacturers may only use recycled materials from their own production lines.

At Ledes, we proudly do not utilize any recycled materials, ensuring 100% compliance with UL, NEMA, and ASTM standards. For more information, you can read our previous content: “How We Manufacture Conduits.”

Anwendungen

Schedule 40 Conduit: Based on the description in Section 1.2 of the 8th edition of UL651, Schedule 40 PVC conduit are versatile and can be used for both above-ground and underground applications. It can be installed indoors or outdoors, exposed to sunlight and weather conditions. And it is suitable for direct burial or encasement in concrete.

DB 120 Conduit/ Duct: According to Section 1.1 of NEMA TC 6&8, DB and EB series conduits can only be used for direct burial and concrete encased applications.

Farben

According to UL requirements and industry standards, Schedule 40 conduit is generally gery, and only Schedule 40 pipe is white, distinguished by their different usages. In other words, electrical conduits are generally gray, while water pipes are white.

DB120 PVC duct, according to NEMA TC 6 & 8, 3.2, can be gery or white, and other colors are also acceptable.

Dimensions and Length

According to UL651 and NEMA TC 6&8, the dimension comparison between Schedule 40 conduit and DB120 duct is as follows:

DB120 Vs. Schedule 40 PVC Dimensions

Handelsgröße | Schedule 40 (Inches) | DB120 (Inches) | |||

Ave. OD | Min. T | Ave.OD | Min. T1 | Min. T2 | |

1/2 | 0.084 | 0.109 | / | / | / |

3/4 | 1.050 | 0.113 | / | / | / |

1 | 1.315 | 0.133 | 1.315 | 0.060 | 0.060 |

1-1/4 | 1.660 | 0.140 | / | / | / |

1-1/2 | 1.900 | 0.145 | 1.900 | 0.065 | 0.060 |

2 | 2.375 | 0.154 | 2.375 | 0.083 | 0.077 |

2-1/2 | 2.875 | 0.203 | / | / | / |

3 | 3.500 | 0.216 | 3.500 | 0.127 | 0.118 |

3-1/2 | 4.000 | 0.226 | 4.000 | 0.147 | 0.136 |

4 | 4.500 | 0.237 | 4.500 | 0.166 | 0.154 |

5 | 5.563 | 0.258 | 5.563 | 0.205 | 0.191 |

6 | 6.625 | 0.280 | 6.625 | 0.244 | 0.227 |

Length: In terms of length, the Schedule 40 is 10ft or 20ft, while the DB series, according to the description in NEMA 3.3.2, requires a length of 20 ft + 1 in. (6.10 m + 25 mm – 0 mm). In addition, ASTM F512 Section 6.2.3 directly states that the DB conduit can be 20ft or 25ft, with a tolerance of ±1 in. (±25 mm).

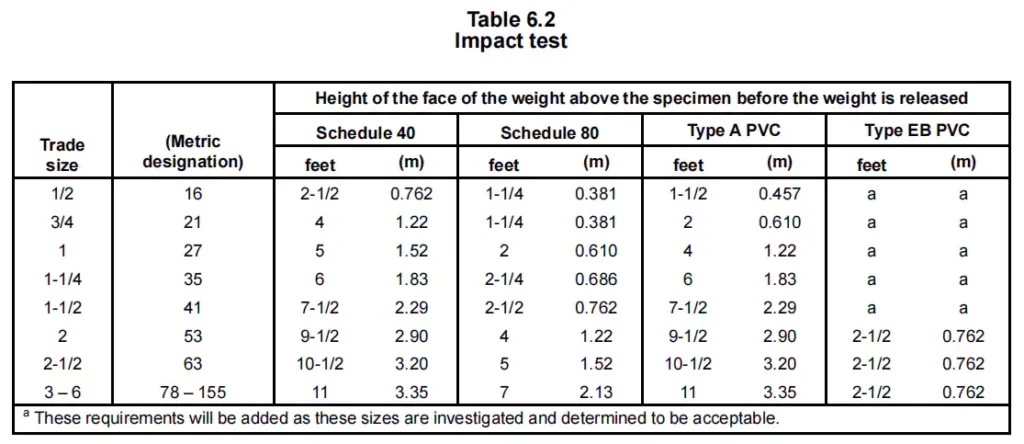

Widerstandsfähigkeit gegen Stöße

Schedule 40 Conduit: According to the relevant test standards in UL 651, the rigid PVC conduit shall not crack or tear longer than 1/32 inch (0.8 mm) along the outer surface of more than three of the ten specimens.

And UL has clear requirements on sample length, test temperature, etc. Samples should be 6-inch long, and to be conditioned in air at a temperature of 23.0 ±2.0° C (73.4 ±3.6° F) for a minimum period of 4 hours before being tested.

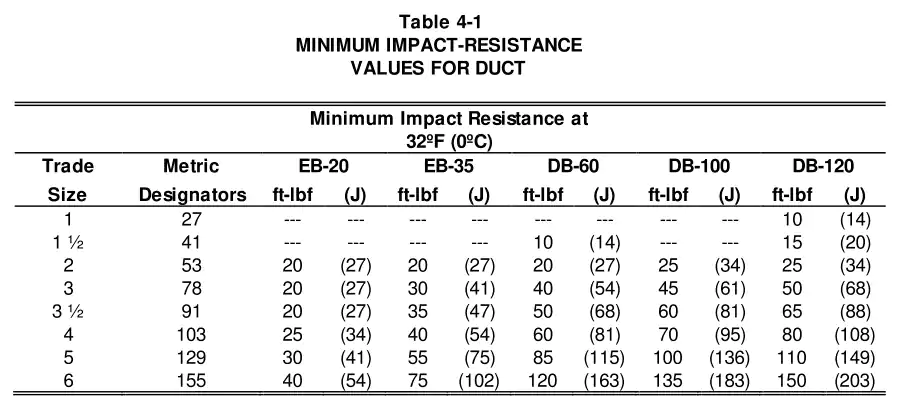

DB120 Duct: According to the description in Section 4.2.4 NEMA TC 6&8, the minimum drop-weight impact test values must meet the following requirements:

Conduit Stiffness

Schedule 40 Conduit: According to the description in section 6.12.3, UL 651:

Schedule 40, and Schedule 80 rigid PVC conduit that is intended for directional boring use shall have a minimum pipe stiffness of 120 psi (827 kPa) at 10 percent deflection when determined in accordance with the Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading, ASTM D 2412.

DB120 Duct: In NEMA TC 6 & 8, the stiffness value of DB120 conduit is consistent with that of schedule 40 conduit, it’s also 120 psi (827 kPa), but unlike UL 651, it does not mention the content of ASTM D 2412.

Markierungen

According to Section 8.1.3 of UL 651, the requirements for conduit printing are as follows:

The product, package, or label marking shall include:

- a) Der Ausdruck „starres PVC-Rohr“,

- b) Die Handelsgröße des Conduit-Produkts,

- c) Der Name oder die Marke des Herstellers oder jede andere Kennzeichnung, mit der

Die für das Produkt verantwortliche Organisation kann leicht identifiziert werden und

- d) Das Herstellungsdatum oder ein anderer Datierungszeitraum, der drei aufeinanderfolgende Monate nicht überschreiten darf.

Bei einem Winkelstück ist als Herstellungsdatum das Datum zu verstehen, an dem:

1) Das Rohr wird extrudiert, wenn sowohl Extrusion als auch Biegung an der gleichen Stelle erfolgen oder

2) Der Bogen wurde geformt, indem das Schutzrohr an einer anderen Stelle herausgepresst wird.

The description in Section 6.1 of NEMA TC 6 & 8 is as follows:

AII required markings shall be legible and so applied as to remain legible under normal handling and installation practices.

These markings shall be repeated at uniform intervals and shall appear at least every 10 feet or every 3.05 m,but not less than once,on each straight length of duct with the following:

- a) Manufacturer’s name or trademark

- b) Trade Size (Metric Designator)

- c) PVC cell classification: PVC11254,for example

- d) “NEMA TC 6&TC 8”

- e) Type:EB-20,for example

- f) Any additional marking deemed necessary by the manufacturer

By comparison, it can be found that NEMA does not require printing production time, and the requirements of UL are more detailed.

6 Things You Need to Know Before Choose PVC Conduit?

Selecting the right PVC conduit is essential for ensuring a safe and efficient electrical installation. With various options available, it’s crucial to consider several factors before making a decision. Here are six key things to keep in mind when choosing PVC conduit.

1. Understanding the Different Types of PVC Conduit

PVC conduit comes in various types, each designed for specific applications. The most common types include rigid PVC conduit, which provides excellent protection for electrical wiring, and flexible PVC conduit, which allows for easier installation in tight spaces. And DB series duct, which allows for direct burial for electrical installations. There are also low-voltage conduits designed specifically for lower voltage applications. Understanding the differences will help you select the conduit that best meets your project’s requirements.

2. Size Requirements

Choosing the correct size for your PVC conduit is critical for accommodating the number and type of wires you plan to install. Conduit sizing is often guided by the National Electrical Code (NEC), which outlines minimum fill requirements to prevent overheating and ensure easy installation. Proper sizing not only ensures compliance but also promotes safety and efficiency in the electrical system.

3. Installation Environments

The installation environment significantly influences your choice of PVC conduit. Rigid PVC conduit is ideal for both above-ground and underground applications, providing strong protection against physical damage. And DB duct is for direct burial installations. And you need to consider environmental factors such as moisture, chemicals, and temperature extremes when selecting the appropriate conduit type. Such as some conduits are rated for wet location and UV resistant, but some are not.

4. Evaluate Cost and Availability

While cost is always a consideration, it’s essential to evaluate the long-term value of your conduit choice. Rigid PVC conduit may have a higher upfront cost, but its durability can lead to lower maintenance and replacement costs over time. Additionally, check local availability; some types may be easier to source than others, impacting project timelines and budgets.

5. Code Compliance

Adhering to local and national electrical codes is crucial when selecting PVC conduit. Compliance with standards such as the NEC and ASTM not only ensures safety but also protects against potential legal issues. Before making a purchase, familiarize yourself with the specific codes relevant to your project and verify that the conduit meets these requirements.

6. Consult with Professionals

When in doubt, consulting with industry professionals can provide valuable insights. Electrical engineers, contractors, and Lieferanten für elektrische Leitungsrohre can offer guidance on the best conduit options based on your specific needs. They can help you navigate complex code requirements and ensure that your installation meets all safety standards.

How to Sourcing PVC Conduit Supplier?

Finding a reliable PVC conduit supplier is crucial for ensuring quality materials for your electrical projects. Here are some effective ways to help you identify a trustworthy supplier. For more details, you can refer to our previous article for 8 strategies to sourcing reliable supplier.

1. Online Search

The internet is a valuable resource for finding PVC conduit suppliers. Use search engines to look for manufacturers and distributors in your area or globally. Websites like Alibaba or ThomasNet can provide lists of suppliers along with their product offerings and customer reviews. Additionally, visiting supplier websites can give you insights into their capabilities, certifications, and product specifications.

2. Industry Directories

Utilizing industry-specific directories can streamline your search for reputable suppliers. Directories like the National Electrical Manufacturers Association (NEMA) or local trade associations often have comprehensive listings of suppliers. These resources can help you find suppliers that specialize in PVC conduit and are known for their reliability and quality.

3. Trade Shows and Exhibitions

Attending trade shows and industry exhibitions is an excellent way to meet potential suppliers face-to-face. These events allow you to view product offerings, ask questions, and build relationships with manufacturers and distributors. Networking at these events can also provide insights into industry trends and recommendations for suppliers from peers.

4. Referrals and Recommendations

Word-of-mouth referrals from colleagues, contractors, or industry contacts can be invaluable. Ask for recommendations from professionals who have experience sourcing PVC conduits. Their firsthand experiences can guide you toward reliable suppliers and help you avoid potential pitfalls.

5. Yellow Pages and Local Listings

Traditional resources like the Yellow Pages or local business directories can still be effective. Many suppliers list their services in these directories, making it easy to find local PVC conduit suppliers. This option can also help you discover businesses that may not have a strong online presence.

6. Social Media and Online Forums

Engaging in industry-specific social media groups and online forums can provide insights into suppliers. Platforms like LinkedIn, Facebook, or specialized forums allow you to connect with other professionals who can share their experiences and recommendations for reliable suppliers.

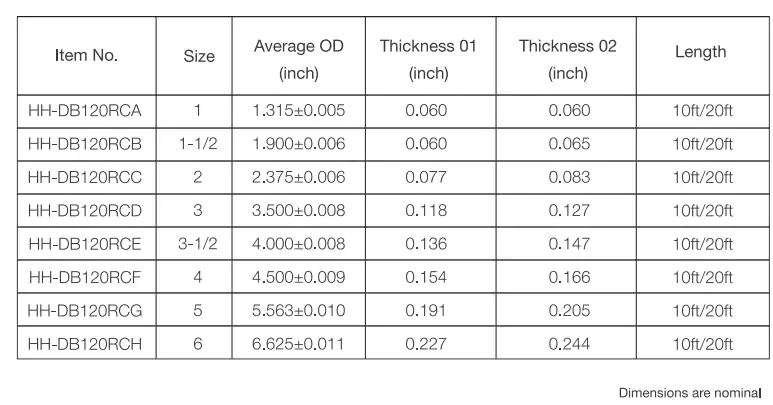

DB120 Conduit and Schedule 40 Conduit Size Chart

DB120 Duct and Schedule 40 Conduit are widely used in North America, they come in various sizes to accommodate different needs. Here are the sizes available from Ledes:

DB120 PVC Utilities Duct Size Chart:

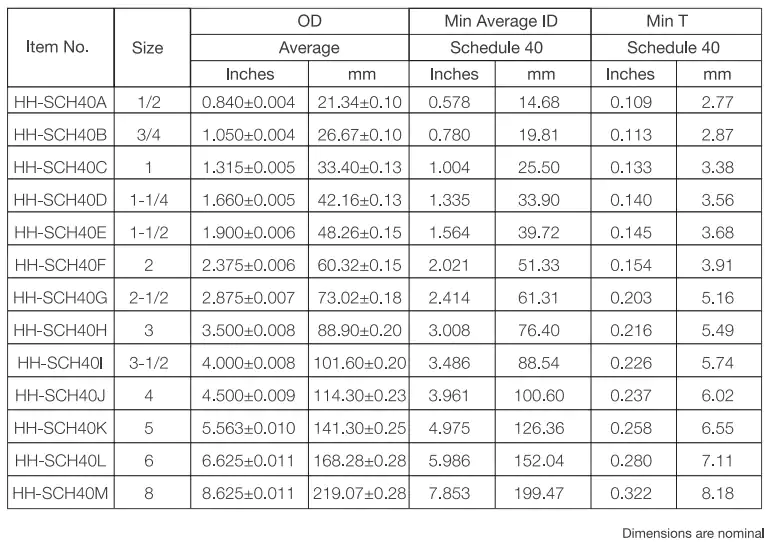

Schedule 40 Rigid PVC Conduit Size Chart:

Abschluss

For DB120 duct and Schedule 40 PVC conduit, the right choice ultimately depends on your specific project requirements and application needs. DB120 duct excels in direct burial scenarios, providing a lightweight and durable option for underground installations without the need for concrete encasement. While Schedule 40 PVC conduit offers robust protection for above-ground and underground applications, making it ideal for routing and safeguarding electrical wiring.

By understanding the distinct characteristics, advantages, and compliance standards of each option, you can make an informed decision that prioritizes safety, efficiency, and long-term performance. Whether you’re focused on installation ease, environmental conditions, or regulatory compliance, both DB120 and Schedule 40 PVC conduits have unique benefits that can support a wide range of electrical and plumbing applications. Ultimately, selecting the right conduit will enhance the integrity of your installations and ensure they stand the test of time.