Inhaltsverzeichnis

Clear PVC pipes and clear PVC conduits are integral components in plumbing and electrical systems, offering versatile solutions for fluid transport and electrical wiring protection. PVC, a synthetic plastic polymer, exhibits exceptional durability, corrosion resistance, and affordability, making it a popular choice in construction and infrastructure projects worldwide

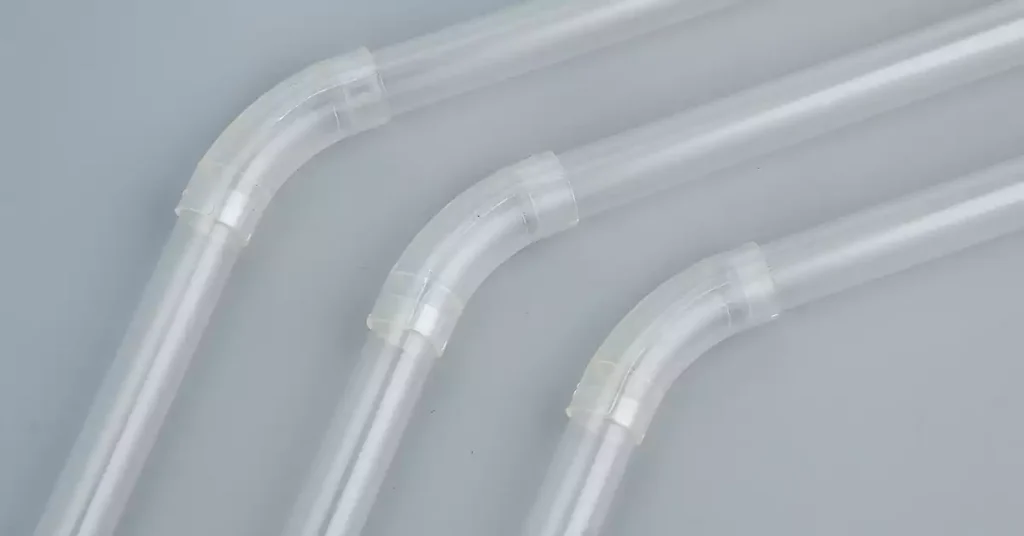

Clear PVC pipe and PVC conduit play crucial roles in modern plumbing and electrical systems due to their unique properties and benefits. Clear PVC pipe, with its transparent composition, allows for visual inspection of fluid flow, facilitating maintenance and monitoring processes in plumbing applications. Clear PVC conduits, on the other hand, are transparent tubes used for protecting electrical wiring in residential, commercial, and industrial settings. The transparency of clear PVC conduits enables easy visual inspection of the enclosed wiring, facilitating maintenance and troubleshooting. Clear PVC conduits come in standard sizes suitable for various electrical wiring installations and are commonly installed using fittings and connectors designed specifically for electrical applications. They offer good chemical resistance and provide a protective housing for wires, safeguarding them against environmental elements and damage.

This article aims to provide a comprehensive understanding of the differences between transparent PVC pipe and clear PVC conduit, highlighting their respective characteristics, uses, advantages, and disadvantages. By exploring the applications, performance characteristics, and practical considerations associated with these materials, readers will gain insights into selecting the most suitable option for their plumbing and electrical needs. Followed by a comparative analysis to help readers make informed decisions based on their specific requirements.

What is Clear PVC Pipe?

Definition

Clear PVC pipe, a specialized variant of polyvinyl chloride (PVC) pipe, stands out for its transparent composition, enabling visual inspection of fluid flow within the system. This unique feature distinguishes it from conventional opaque PVC pipes, offering enhanced functionality for a variety of applications. The composition of clear PVC pipe is predominantly based on polyvinyl chloride (PVC), a thermoplastic polymer known for its chemical resistance, durability, and ease of fabrication. The transparency of clear PVC pipe and tubing is achieved through the addition of specific additives and processing techniques that maintain the material’s structural integrity while providing clarity for visual inspection purposes.

3 Types of Clear PVC Pipe:

Clear PVC pipe is available in various types, primarily classified into Schedule 40 and Schedule 80 based on their wall thickness and pressure ratings.

Schedule 40 Clear PVC Pipe: This type features a thinner wall construction compared to Schedule 80, making it suitable for low-pressure applications such as drainage systems, irrigation lines, and general fluid transport where high pressure is not a primary concern. Clear Sch 40 PVC pipe offers a balance between affordability and functionality, making it a versatile choice for a range of plumbing applications.

Schedule 80 Clear PVC Pipe: With a thicker wall construction and higher-pressure ratings, clear PVC Sch 80 pipe is designed for applications that require enhanced strength and durability. It is commonly used in industrial settings, water mains, and processes where elevated pressure demands necessitate a more robust piping solution. Schedule 80 clear PVC pipe provides added reliability in demanding environments where structural integrity is paramount.

Clear PVC Tubing: Clear PVC tubing is a transparent, flexible tubing made from polyvinyl chloride (PVC) material. This type of tubing is commonly used in various applications where visibility of the fluid flow is important or where a flexible and durable tubing solution is required.

What are Clear PVC Pipe Used for?

Clear PVC pipe, with its unique transparent composition, finds widespread utility across diverse industries and applications where visibility of fluid flow is crucial. The distinct properties of clear PVC pipe make it a preferred choice in various settings, offering advantages in monitoring, maintenance, and quality control processes. Below are some key uses and applications of clear PVC pipe:

- Aquarium Systems

- Water Treatment Plants

- Chemical Processing Facilities

- Hospital Use

- Laboratory Applications

- Food & Beverage Processing

- Residential Plumbing

- Irrigation Systems

- Visual Test Equipment

Clear PVC pipe’s applications extend beyond these examples, demonstrating its versatility and value in environments where visual monitoring and operational efficiency are paramount.

Pros of Clear PVC Pipe

Transparency and Visibility:

The transparency of clear PVC pipe allows for easy visual inspection of fluid flow within the system. Operators can quickly identify blockages, air pockets, or contaminants, enabling prompt corrective actions and ensuring smooth operation.

Corrosion Resistance and Durability:

Clear PVC pipe is highly resistant to corrosion, ensuring longevity and minimal maintenance requirements. Its durability makes it a reliable choice for various applications, particularly in environments prone to chemical exposure or abrasive conditions.

Chemische Resistenz:

PVC transparent pipe exhibits excellent chemical resistance, making it suitable for handling a wide range of liquids and gases without degradation. This property is crucial in industries where exposure to corrosive substances is common.

Einfache Installation:

Clear PVC pipe is lightweight and easy to handle, simplifying the installation process. Its compatibility with standard PVC fittings and connectors streamlines assembly, reducing labor time and costs associated with piping projects.

Leicht:

The lightweight nature of clear PVC tubing makes it easy to transport, maneuver, and install, especially in overhead or complex piping configurations. This feature enhances convenience during construction or maintenance tasks.

Clear PVC pipe offers a host of advantages that cater to diverse industrial and commercial needs. Its transparency allows for efficient monitoring, while its corrosion resistance, chemical durability, ease of installation, and lightweight nature contribute to its widespread adoption in various applications, ensuring reliability, longevity, and operational efficiency.

Cons of Clear PVC Pipe

UV Degradation:

Clear PVC pipe is prone to UV degradation when exposed to sunlight over extended periods. This can lead to discoloration, brittleness, and reduced structural integrity, especially in outdoor or UV-exposed installations.

Temperaturbeschränkungen:

Clear PVC pipe and tubing may have limitations in extreme temperature conditions. High temperatures can affect its structural integrity, while low temperatures may cause the material to become more brittle, impacting its overall performance.

Cost Considerations:

Transparent PVC pipe tends to be more expensive than standard opaque PVC piping due to the additional processes required to achieve transparency. This cost factor may influence budget considerations for some projects.

Standards and Performance Requirements

Code-Konformität:

ASTM D1784: This standard covers the specifications for rigid PVC compounds used for manufacturing clear PVC pipes. It ensures that the PVC material used meets certain requirements for strength, durability, and chemical resistance.

ASTM D1785: ASTM D1785 is the standard specification for PVC plastic pipe, fittings, and joints used in pressure applications. Both Schedule 40 and Schedule 80 clear PVC pipes adhere to this standard, which defines the dimensions, material properties, and performance requirements for PVC pipes.

NSF/ANSI 61: NSF/ANSI 61 is a standard that establishes requirements for the safety of materials in contact with drinking water. Clear PVC pipes that are intended for use in potable water systems often carry NSF/ANSI 61 certification to ensure they meet health and safety standards.

ASTM D638: ASTM D638 provides a standardized procedure for determining the tensile properties of plastic materials under defined conditions. This test method helps assess the material’s behavior under tension, which is crucial for understanding its mechanical strength and deformation characteristics.

ASTM D648: ASTM D648 is used to measure the temperature at which a plastic material deforms under a specified load, providing valuable information about its thermal performance and ability to withstand elevated temperatures without excessive deformation.

ASTM D-2466: ASTM D2466 is a standard specification that covers requirements for PVC plastic pipe fittings used in pressure applications, particularly those conforming to Schedule 40 dimensions. This standard outlines the material properties, dimensions, performance characteristics, and testing procedures for PVC fittings used in residential and commercial plumbing systems.

Performance Requirements

Tensile Strength: When testing according to ASTM D638, clear PVC pipe normally should have a tensile strength of 6100 psi.

Pressure Rating: Both Schedule 40 and Schedule 80 clear PVC pipes are designed to withstand different levels of pressure. Here are some typical pressuring ratings you can find on the market for Schedule 40 and Schedule 80 clear PVC pipe:

MAX. W.P. PSI

Sizes (Inch) | Schedule 40 Clear PVC Pipe | Schedule 80 Clear PVC Pipe |

1/2 | 300 | 420 |

3/4 | 240 | 340 |

1 | 220 | 320 |

1-1/4 | 180 | 260 |

1-1/2 | 170 | 240 |

2 | 140 | 200 |

2-1/2 | 150 | / |

3 | 130 | 190 |

3-1/2 | 120 | / |

4 | 110 | 160 |

6 | 90 | 140 |

8 | 80 | / |

Deflection Temperature: Clear PVC Pipe can withstand a testing temperature of 150°F according to ASTM D648 without deforming.

Chemische Resistenz: Clear PVC pipes should exhibit resistance to a wide range of chemicals to ensure they can be used safely in various industrial and commercial applications.

Impact Strength: The pipes must demonstrate good impact strength to withstand handling during installation and potential external forces.

Operating Temperature: Clear PVC pipes should be able to withstand a range of temperatures without compromising their structural integrity or performance. The maximum service temperature for clear PVC is 140 °F.

Smooth Interior Surface: A smooth interior surface is essential to ensure efficient fluid flow, reduce pressure loss, and minimize the risk of clogs or build-up inside the pipe.

What is Clear PVC Conduit?

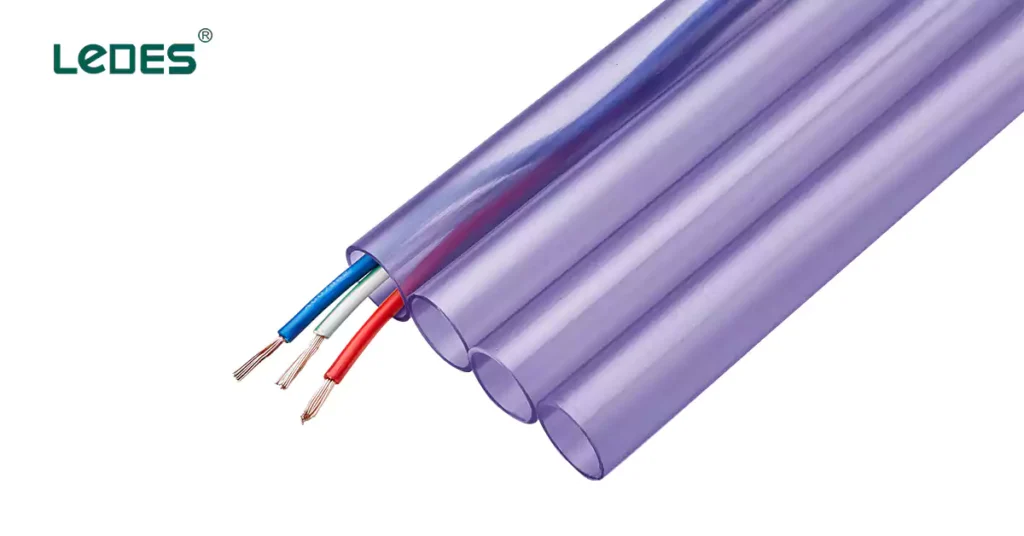

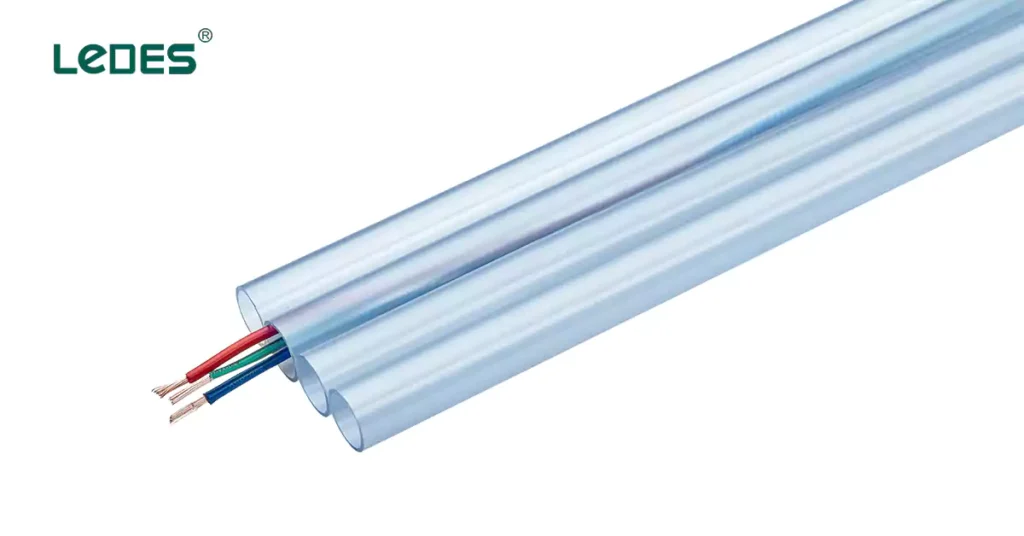

Clear PVC conduit is a type of conduit made from transparent PVC material. Unlike traditional solid PVC conduits that are opaque, its see-through nature provides visibility to the wires within, making it easier to detect any potential issues and allowing for quick troubleshooting. Clear PVC conduit offers the same protective benefits as traditional PVC conduit while offering the added advantage of visual inspection.

2 Types of Clear PVC Conduit:

Schedule 40 Clear PVC Conduit: Schedule 40 clear PVC conduit is a lightweight and cost-effective option commonly used in residential and light commercial electrical installations. It is suitable for applications where moderate mechanical stress is expected. Schedule 40 conduit is known for its ease of handling and installation.

Schedule 80 Clear PVC Conduit: Schedule 80 clear PVC conduit is a heavier-duty option designed for more demanding applications where increased mechanical protection is required. It is thicker and stronger than transparent Schedule 40 conduit, offering enhanced resistance to impact, crushing, and bending. Schedule 80 transparent conduit is often used in industrial settings and areas where the conduit may be exposed to harsh conditions.

Applications of Clear PVC Conduit

- Hausverkabelung

- Gewerbebauten

- Outdoor Installations

- Underground Wiring

- Industrial Applications

- Temporary Installations

- Specialty Applications where aesthetic considerations or unique requirements necessitate the visibility of wiring, such as in art installations, display lighting, and architectural features.

Transparent PVC conduit is a versatile solution for applications that demand visibility, ease of inspection, and reliable protection for electrical wiring. Its transparency enhances safety, facilitates maintenance, and adds a practical and aesthetic dimension to a variety of electrical projects across different sectors.

Pros and Cons of Transparent PVC Conduit

Vorteile:

Sichtweite: The primary advantage of transparent PVC conduit is its see-through design, allowing for easy visual inspection of the wiring inside without the need to disassemble the conduit. This visibility can aid in troubleshooting, maintenance, and monitoring of the electrical system.

Aesthetics: Clear PVC conduit provides a clean and modern look compared to traditional opaque conduits. It can be particularly appealing in applications where the wiring needs to be displayed or integrated into the overall design.

Sicherheit: The ability to see the wires inside the conduit can help identify potential issues such as loose connections, damage, or overheating, enhancing overall safety and reducing the risk of electrical hazards.

Korrosionsbeständigkeit: Like traditional PVC conduit, clear PVC conduit is resistant to corrosion, making it a durable option for installations in various environments, including damp or corrosive settings.

Feuerbeständigkeit: Transparent PVC conduit can be formulated to be fire-resistant, helping to prevent the spread of fire and providing an additional layer of safety in electrical installations.

Einfache Installation: Transparent PVC conduit is typically as easy to install as traditional PVC conduit, offering the same benefits of flexibility, lightweight construction, and compatibility with standard fittings and accessories.

Elektrische Isolierung: PVC is a good insulator, providing electrical insulation to protect wires and cables from external factors and preventing electrical hazards.

Chemische Resistenz: Clear PVC conduit is resistant to many chemicals, making it suitable for installations where exposure to chemicals is a concern.

Nachteile:

UV-Beständigkeit: The UV resistance of transparent PVC conduit is inferior to that of grey PVC conduit. Prolonged outdoor use can lead to accelerated aging and yellowing, impacting visibility of internal wiring and diminishing the conduit’s appearance.

Kosten: Transparent PVC conduit can be more expensive than standard opaque PVC conduit due to the specialized manufacturing process required to maintain clarity while retaining the conduit’s structural integrity.

Scratches and Damage: Clear PVC conduit is more susceptible to visible scratches and damage compared to opaque conduit, which may affect its aesthetic appeal over time. Care must be taken during handling and installation to prevent surface damage.

Storage Challenges: Due to its transparent nature, clear PVC conduit requires careful handling during storage and transportation to prevent scratches that may compromise its appearance. Monitoring warehouse conditions, including temperature and UV exposure, is essential to prevent premature aging and maintain quality, contributing to its higher cost compared to opaque conduits.

Hitzebeständigkeit: Clear PVC conduit may have slightly different heat resistance properties compared to standard PVC conduit, which could be a consideration in high-temperature applications.

Standards and Performance Requirements

Code Compliance for Clear PVC Conduit:

Clear PVC conduit is typically manufactured to comply with industry standards that govern PVC conduits in general. These standards ensure that the conduit meets certain quality and performance requirements. Here are some of the common standards that may be applicable to clear PVC conduit:

ASTM D1784: ASTM D1784 establishes the specifications for PVC (polyvinyl chloride) materials used in the manufacture of pipes, fittings, and conduits. This standard ensures that PVC used in conduit production meets specific requirements for chemical composition, physical properties, and performance characteristics.

UL 651: UL 651 is a standard published by Underwriters Laboratories that covers Schedule 40, 80, and 120 PVC electrical conduit. UL 651 certification indicates that the PVC conduit has been tested and meets safety and performance standards for electrical applications, ensuring compliance with industry regulations.

ASTM D635-18: ASTM D635-18 specifies a test method for determining the burning characteristics of plastics in a horizontal position. This standard could be relevant for assessing the fire resistance and burning behavior of PVC materials used in conduits.

ASTM D638-14: ASTM D638-14 outlines a test method for evaluating the tensile properties of plastics, including their strength, elongation, and modulus. This standard could be applicable for assessing the mechanical strength and durability of PVC materials used in conduit construction.

ASTM D256-10: ASTM D256-10 provides test methods for determining the impact resistance of plastics using the Izod pendulum method. This standard could be relevant for evaluating the impact resistance and toughness of PVC materials in conduit applications.

ASTM E1252-98(2013): This standard outlines a practice for calibrating equipment used in flammability testing to measure the buoyancy loss of materials. While not directly related to PVC conduit, this standard could be significant for assessing the flammability properties of PVC materials used in conduit manufacturing.

Performance Requirements for Clear PVC Conduit

When considering the performance requirements for clear PVC conduit, it’s essential to ensure that the conduit meets industry standards and specifications to guarantee safety, durability, and reliability in electrical installations. Here are some key performance requirements that clear PVC conduit (take Schedule 40 & 80 Clear PVC Conduit as example) should ideally meet and Ledes Clear PVC Conduits are manufactured with same criteria and requirements.

Tensile Strength: Schedule 40 & 80 clear PVC conduit have high tensile strength for not less than 5000 psi.

Resistance to Impact: UL651 require the Schedule 40 & 80 rigid PVC conduit be subjected to the impact test and show no crack or tear that longer than 0.8mm on the conduit. For Schedule 40, the impact weight should be 9.1 kg and the cylinder should have a diameter of 2 inches (51mm). For Schedule 80, the weight should be 34 kg. And the cylinder should be dropped from a certain height for different conduit sizes.

Dropping Height of the Weight | ||||

Handelsgröße | Anhang 40 | Schedule 80 | ||

feet | meter | feet | meter | |

1/2 | 2-1/2 | 0.762 | 1-1/4 | 0.457 |

3/4 | 4 | 1.22 | 1-1/4 | 0.610 |

1 | 5 | 1.52 | 2 | 1.22 |

1-1/4 | 6 | 1.83 | 2-1/4 | 1.83 |

1-1/2 | 7-1/2 | 2.29 | 2-1/2 | 2.29 |

2 | 9-1/2 | 2.90 | 4 | 2.90 |

2-1/2 | 10-1/2 | 3.20 | 5 | 3.20 |

3 – 6 | 11 | 3.35 | 7 | 3.35 |

Resistance to Crushing: According to UL651, rigid PVC conduit’s inside diameter should not be less than 70 percent of the inside diameter of the conduit measured before loading. Here are the load requirements of UL651:

Load for Crushing | ||||

Handelsgröße | Anhang 40 | Schedule 80 | ||

lbf | N | lbf | N | |

1/2 | 1000 | 4450 |

2000 for all sizes |

8896 for all sizes |

3/4 | 1000 | 4450 | ||

1 | 1000 | 4450 | ||

1-1/4 | 1000 | 4450 | ||

1-1/2 | 750 | 3336 | ||

2 | 700 | 3113 | ||

2-1/2 | 1000 | 4450 | ||

3 | 1000 | 4450 | ||

3-1/2 | 1000 | 4450 | ||

4 | 900 | 4003 | ||

5 | 850 | 3780 | ||

6 | 850 | 3780 | ||

Flame Resistance: Clear PVC conduit should be fire resistant, and Ledes’ clear PVC conduit are V-0 rated for flame propagation, will be self-extinguishing within 5 seconds.

UV-Beständigkeit: For PVC conduit intended for outdoor use, resistance to ultraviolet (UV) radiation may be a crucial requirement to prevent degradation and ensure longevity when exposed to sunlight.

Comparison of Clear PVC Pipe and PVC Conduit

When comparing clear PVC pipe to clear PVC conduit, several factors come into play, including material composition, dimensions, pressure handling, and cost considerations etc.

1. Materialzusammensetzung

Clear PVC pipe and clear PVC conduit are both made from polyvinyl chloride (PVC), a durable and versatile thermoplastic material.

2. Sch. 40 and 80 Dimensions

Clear Sch. 40 and 80 PVC Pipe: Clear PVC pipe is available in Schedule 40 and Schedule 80 dimensions, with varying wall thicknesses to accommodate different pressure ratings. Schedule 40 is commonly used for low-pressure applications, while Schedule 80 is suitable for higher pressures.

Clear PVC Conduit: PVC conduit also comes in Schedule 40 and Schedule 80 dimensions, with variations in wall thickness to provide mechanical protection for electrical wiring.

Größe | Sch. 40 Clear Conduit (Inches) | Sch. 40 Clear Pipe (Inches) | ||||

Ave. OD | Min Ave. ID | Min. T | Ave. OD | Ave. ID | Min. T | |

1/2 | 0.840 | 0.578 | 0.109 | 0.840 | 0.608 | 0.109 |

3/4 | 1.050 | 0.780 | 0.113 | 1.050 | 0.810 | 0.113 |

1 | 1.315 | 1.004 | 0.133 | 1.315 | 1.033 | 0.133 |

1-1/4 | 1.660 | 1.335 | 0.140 | 1.660 | 1.364 | 0.140 |

1-1/2 | 1.900 | 1.564 | 0.145 | 1.900 | 1.592 | 0.145 |

2 | 2.375 | 2.021 | 0.154 | 2.375 | 2.049 | 0.154 |

2-1/2 | 2.875 | 2.414 | 0.203 | 2.875 | 2.445 | 0.203 |

3 | 3.500 | 3.008 | 0.216 | 3.500 | 3.042 | 0.216 |

3-1/2 | 4.000 | 3.486 | 0.226 | 4.000 | 3.520 | 0.226 |

4 | 4.500 | 3.961 | 0.237 | 4.500 | 3.998 | 0.237 |

5 | 5.563 | 4.975 | 0.258 | / | / | / |

6 | 6.625 | 5.986 | 0.280 | 6.625 | 6.031 | 0.280 |

Größe | Sch. 80 Clear Conduit (Inches) | Sch. 80 Clear Pipe (Inches) | ||||

Ave. OD | Min Ave. ID | Min. T | Ave. OD | Ave. ID | Min. T | |

1/2 | 0.840 | 0.502 | 0.147 | 0.840 | 0.528 | 0.147 |

3/4 | 1.050 | 0.698 | 0.154 | 1.050 | 0.724 | 0.154 |

1 | 1.315 | 0.910 | 0.179 | 1.315 | 0.935 | 0.179 |

1-1/4 | 1.660 | 1.227 | 0.191 | 1.660 | 1.256 | 0.191 |

1-1/2 | 1.900 | 1.446 | 0.200 | 1.900 | 1.476 | 0.200 |

2 | 2.375 | 1.881 | 0.218 | 2.375 | 1.913 | 0.218 |

2-1/2 | 2.875 | 2.250 | 0.276 | 2.875 | 2.290 | 0.276 |

3 | 3.500 | 2.820 | 0.300 | 3.500 | 2.864 | 0.300 |

3-1/2 | 4.000 | 3.280 | 0.318 | 4.000 | / | / |

4 | 4.500 | 3.737 | 0.337 | 4.500 | 3.786 | 0.337 |

5 | 5.563 | 4.713 | 0.375 | / | / | / |

6 | 6.625 | 5.646 | 0.432 | 6.625 | 5.709 | 0.432 |

3. Pressure Handling and Stiffness Variations

Clear PVC Pipe: Transparent PVC pipe is primarily used for fluid handling applications and is designed to handle specific pressure ratings based on the schedule and diameter.

Clear PVC Conduit: Transparent PVC conduits are not typically rated for pressure, as their primary function is to protect electrical wiring.

4. Chemical Resistance

Both clear PVC pipe and clear PVC conduit exhibit good chemical resistance to a variety of substances, making them suitable for different environments.

5. Installation:

Clear PVC pipes are typically joined using solvent cement or threaded fittings.

Clear PVC conduits are commonly installed using fittings and connectors designed for electrical applications.

6. Cost Analysis

Cost can vary depending on the size, length, and manufacturer of both clear PVC pipe and clear PVC conduit. But Clear PVC may be more expensive due to the clarity of the material and its specialized applications compared to traditional grey PVC conduit and pipe.

Abschluss

In conclusion, while both clear PVC pipe and clear PVC conduit share the characteristic of transparency, they serve distinct functions within different contexts. Clear PVC pipes excel in fluid and gas conveyance applications, while clear PVC conduits are essential for safeguarding electrical wiring systems.

Understanding the unique features and applications of clear PVC pipe and clear PVC conduit, such as application, size range, pressure rating, chemical resistance, installation requirements, and cost is crucial for selecting the appropriate material for specific projects and ensuring optimal performance and durability.

Any questions about conduit and pipe, contact us at any time.