Table of Contents

Electrical safety is a cornerstone of modern infrastructure, ensuring that homes, businesses, and industries remain protected from hazards. Each year, electrical failures contribute to over 1,400 fires across Canada, causing $200 million in property damage. These alarming figures highlight the importance of strict safety regulations – and at the forefront of this effort is the Canadian Electrical Code (CEC).

The CEC is not just a regulatory document; it is a living standard that evolves to keep pace with technological advancements, safety innovations, and emerging risks. From wiring methods in residential projects to electrical installations in industrial facilities, the CEC serves as the foundation of safe, compliant, and reliable electrical systems.

Why This Guide Matters

For professionals in the electrical industry, navigating the CEC can be complex. The code is reflecting advancements in electrical technology, renewable energy integration, and improved safety standards. Staying informed about these updates is crucial for:

- Ensuring compliance with legal and safety requirements

• Avoiding costly mistakes and project delays

• Enhancing the safety of electrical systems

• Improving efficiency in electrical design and installation

This ultimate guide aims to break down the key aspects of the CEC, making it easier to understand and apply. Whether you’re a seasoned electrician or a newcomer to electrical installations, this guide will provide clear insights into the structure, requirements, and applications of the CEC in real-world scenarios.

What Is the Canadian Electrical Code (CEC)?

The Canadian Electrical Code (CEC), also referred to as CE Code or CSA C22.1, is a national standard published by the Canadian Standards Association (CSA Group). It governs the installation and maintenance of electrical equipment across Canada, ensuring safety, efficiency, and compliance with modern electrical practices.

The CEC serves as the foundation for electrical wiring regulations in Canada, providing a prescriptive model that details acceptable wiring methods. While the Code allows for alternative safe installation methods, such approaches must be approved by the local enforcement authority.

History & Evolution of the CEC

The Canadian Electrical Code (CEC) has been a critical part of Canada’s electrical safety framework for nearly a century. First introduced in 1927, the CEC was developed to establish uniform electrical safety standards across the country. Over the decades, as electrical technology advanced, so did the CEC – adapting to new challenges, innovations, and regulatory requirements.

The Canadian Standards Association (CSA Group), an independent, non-profit organization, has been responsible for developing and maintaining the CEC. The CSA updates the code every three years, ensuring that it reflects emerging safety concerns, advancements in electrical engineering, and evolving industry needs.

Over the decades, each edition has contributed to safer installations and reduced risks associated with electrical work。

- 1927: The first edition of the CEC was introduced, setting the groundwork for safe electrical practices.

- Mid-20th Century: Several revisions were made to incorporate evolving technologies and better practices.

- 2024: The recent edition – 26th edition, released in 2024, includes significant updates that reflect the latest in electrical safety technology and practices, including changes in wiring methods and updated standards for new equipment.

Development of the CEC is a collaborative effort involving volunteers from industry, government bodies, and electrical safety organizations. Over the decades, the Code has expanded to address new challenges, including:

- Grounding and bonding advancements to enhance electrical safety

- Arc-fault and ground-fault protection to mitigate electrical fire hazards

- Energy efficiency requirements for modern electrical systems

- Guidelines for renewable energy integration, including solar power and electric vehicle (EV) charging infrastructure

The Code continues to evolve, adapting to the increasing complexity of electrical systems and sustainable energy solutions.

Governing Bodies: Who Regulates the CEC?

While the CSA Group is responsible for publishing and maintaining the CEC, each Canadian province and territory independently adopts and enforces the Code, often with region-specific amendments.

Provincial and Territorial Adoption

Electrical safety is regulated at the provincial and territorial levels. Some regions may:

- Implement the latest CEC edition immediately.

- Introduce administrative or technical amendments based on local needs.

- Operate under a slightly modified version of the CEC to align with specific provincial requirements.

For example:

- Quebec follows the Code de construction du Québec, Chapitre V – Électricité, which closely mirrors the CEC but includes provincial modifications.

- Ontario and British Columbia may apply additional fire protection and safety measures.

Alignment with the National Building Code

The CEC works in conjunction with the National Building Code of Canada (NBC). The NBC covers structural, fire, and energy efficiency requirements, while the CEC ensures that all electrical installations meet strict safety and performance standards. This alignment helps create a cohesive national framework for electrical and construction safety.

Impact on Industry Safety

The CEC has played a crucial role in reducing electrical hazards across Canada by:

- Standardizing wiring and grounding practices to prevent faults.

- Requiring advanced protection mechanisms (e.g., arc-fault and ground-fault circuit interrupters).

- Enhancing regulations for electrical equipment to ensure safety and durability.

- Addressing emerging technologies such as EV charging stations and renewable energy.

By maintaining strict compliance with the CEC, electricians, contractors, and engineers contribute to one of the safest electrical infrastructures in the world.

Key Sections of the CEC Every Professional Must Know

Overview of CEC Parts

The Canadian Electrical Code (CEC) is divided into multiple parts to address the diverse requirements of electrical installations. Among these, certain sections are particularly relevant to electrical wiring and conduit applications.

Part I: Safety Standard for Electrical Installations

This section sets the fundamental guidelines for the safe installation, operation, and maintenance of electrical equipment. It includes comprehensive requirements for wiring methods, grounding, over-current protection, and safety protocols to ensure compliance with national electrical safety standards.

Part II & III: Product-Specific Standards and Specialized Equipment Guidelines

These sections cover detailed technical specifications for electrical products and specialized installations. They provide guidance for specific applications such as electric signs, industrial machinery, and hazardous area wiring, ensuring that products meet safety and performance standards.

Key Sections of CSA C22.1:24

Several sections within the CEC focus specifically on electrical wiring, conduits, and installation practices for residential, commercial, and industrial applications:

Section 12: Wiring Methods and Raceways

This section provides detailed requirements for different types of conduits and raceways, including:

- Conduit installations – Different kind of installation scenarios such as underground installations, wiring in plenum chambers, under raised floors etc. (Notes: Learn more about electrical conduit installation tips for our last post)

- Raceways of wiring – Specifies the raceways of wiring, including the use of PVC, metal, and liquid-tight conduits based on environmental conditions. And cable trays to support wiring.

Sections 18-24: Commercial and Industrial Wiring

These sections outline critical installation requirements for challenging environments, including:

- Hazardous Locations (Section 18) – Classification of explosive atmospheres and conduit sealing requirements to prevent ignition.

- Gasoline Dispensing and Service Stations (Section 20) – Wiring methods for fuel-handling areas, emphasizing corrosion-resistant conduit materials.

- Industrial Facilities (Section 22) – Electrical installations in areas with corrosive liquids, vapors, and excessive moisture.

- Patient Care Areas (Section 24) – Special grounding and isolation requirements for electrical systems in hospitals and healthcare facilities.

Section 64: Renewable Energy Systems

As renewable energy adoption grows, this section provides essential guidelines for:

- Solar Photovoltaic (PV) Installations – Wiring and conduit requirements for rooftop and ground-mounted solar panels.

- Wind Energy Systems – Safe routing of electrical conduits in wind turbine installations.

- Battery Storage Systems – Compliance standards for integrating energy storage solutions with electrical infrastructure.

These sections ensure that electrical professionals comply with CEC standards while installing safe, reliable, and code-compliant electrical wiring and conduit systems. In the following sections, we will explore each of these topics in detail.

Deep Dive into the Key Sections of CEC Code

CEC code sets all aspects of electrical related requirements, here we will just introduce some of the important information that related to electrical wiring, raceways of conduit, and installations.

Wiring Methods and Raceways (Section 12):

Section 12 of the Canadian Electrical Code (CEC) outlines the general requirements for wiring methods to ensure safe and reliable electrical installations. These requirements encompass the selection, installation, and support of various wiring systems.

General Requirements for Wiring Methods:

Conductor Insulation:

Conductors must have insulation suitable for the system’s voltage and the specific environmental conditions of the installation. For instance, conductors used in ungrounded or impedance-grounded systems should comply with specific insulation thickness requirements to ensure safety.

Protection Against Mechanical Injury:

Wiring methods should be selected and installed to protect conductors from mechanical damage. This includes using appropriate raceways or conduits in areas where conductors are exposed to potential harm.

Support and Securement:

Conductors and raceways must be securely fastened and supported at intervals specified by the code to prevent sagging, physical damage, or undue strain on terminations.

Spacing:

When installing conductors, conduits or cables in cable trays, proper spacing must be maintained based on the size of adjacent conductors. This ensures adequate ventilation and reduces the risk of overheating.

Underground Installation Requirements

There are many wiring methods introduced in the CEC, one is underground installation that we often use. And here are some key requirements for this installation methods:

- Minimum Cover Requirements:

Direct buried cables or raceways must adhere to the minimum cover depths specified in Table 53 of the CEC. These depths vary depending on factors such as the type of wiring method employed and the specific installation conditions.

- Ampacity Considerations:

When conductors and cables transition from underground to above-ground installations for termination at electrical equipment, their ampacity must be determined based on the 75°C columns of Tables 1–4. This ensures compliance with the rules of CEC.

- Separation Requirements:

Rule 12-012 mandates specific separation requirements for underground installations of cables or conductors in raceways. This rule ensures that installations maintain adequate spacing to prevent potential hazards.

- Marking of Underground Installations:

All underground wiring installations must be adequately marked to indicate their presence. Common practices include burying an electrical warning marker tape halfway above the electrical wiring in the trench or using permanent above-ground markers, such as printed signs.

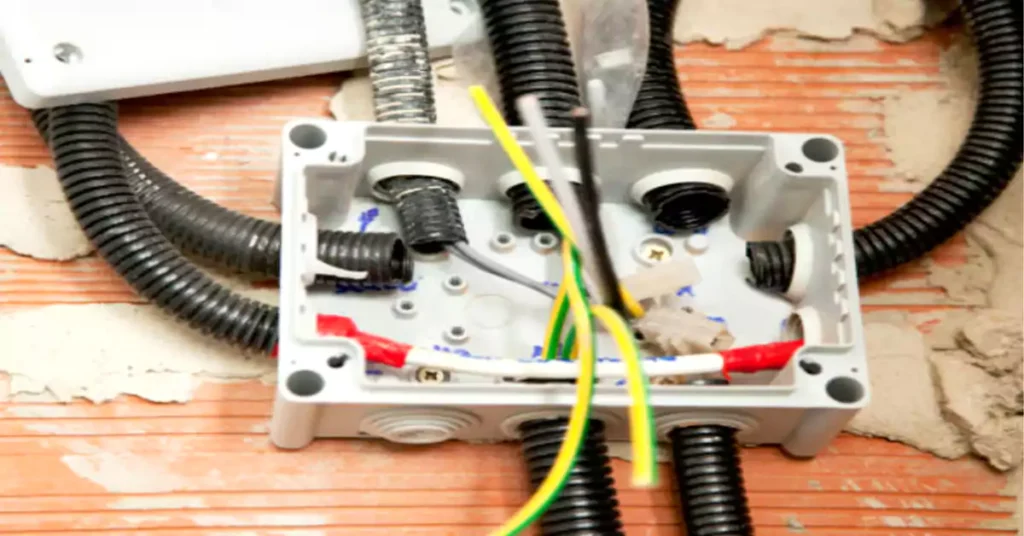

Requirements for Specific Types of Conduits:

Uses and Restrictions: Rigid PVC conduit is suitable for various installations, such as exposed work, above and underground. But it has specific restrictions outlined in the CEC, like installation enclosed in thermal insulation.

Temperature Limitations: PVC conduits must not be subjected to temperatures exceeding 75°C to maintain their structural integrity.

Number of Conductors: The CEC rule 12-1120 specifies the maximum number of conductors allowed within PVC conduits to prevent overheating and ensure safety.

Fittings and Support: Proper fittings must be used to ensure a secure and safe installation. The CEC also outlines maximum spacing for conduit supports to maintain mechanical stability.

Bonding: Provisions for bonding continuity are specified to ensure electrical safety throughout the installation.

Rigid Types EB1 and DB2/ES2 PVC Conduit:

Uses and Restrictions: These conduit types are designed for underground installations, with DB2/ES2 suitable for direct burial and EB1 intended for encased burial in concrete.

Temperature Limitations: The CEC specifies temperature limitations to ensure these conduits function correctly without degradation.

Mechanical Protection: Requirements for mechanical protection are outlined to safeguard the conduits from physical damage. The conduits should have enough mechanical strength of impact resistance, tensile resistance, crushing resistance etc.

Installation Methods: Rule 12-1162 specified the method of installing these direct burial conduit types, and together with fittings such as couplings, bends, adapters to complete the installation.

High-Density Polyethylene (HDPE) Conduit:

Uses and Restrictions: HDPE conduit is permitted for specific applications, particularly in underground installations where flexibility and corrosion resistance are advantageous.

Temperature Limitations: The CEC outlines temperature limitations for HDPE conduits to ensure they operate safely under various conditions.

Installation Methods: Specific methods of installation are prescribed in rule 12-1254 to maintain the integrity and safety of HDPE conduit systems.

Electrical Non-metallic Tubing:

Uses: Electrical nonmetallic tubing is permitted in underground when in accordance with Rule 12-012, and in exposed or concealed locations. But should not be used in locations where subjected to damage unless provided with mechanical protection.

Temperature Limitations: ENT is designed to withstand specific temperature ranges. Installers must ensure that the ambient temperature does not exceed the tubing’s rated capacity 75°C to maintain its structural integrity and safety.

Support and Securement: ENT must be securely supported and fastened at intervals by straps. Additionally, supports should be placed within 1m of every outlet box, junction box, device box, cabinet, or fitting to prevent sagging and maintain alignment. And the spacing between supports should be not more than 1m.

Number of Conductors: The number of conductors installed within ENT must not exceed the fill capacities specified in CEC Rule 12-910. It provides the maximum number of conductors of various sizes that can be safely installed to prevent overheating and ensure ease of installation.

Fittings and Connections: Only fittings specifically designed and listed for use with ENT should be utilized. These fittings ensure proper connections and maintain the integrity of the raceway system. Solvent cement or other approved methods should be used to join fittings, ensuring a secure and continuous pathway for conductors.

Commercial and Industrial Systems (Section 18-24):

Sections 18-24 of the Canadian Electrical Code (CEC), CSA C22.1:21, provide critical guidelines for ensuring the safety and functionality of electrical installations in commercial and industrial environments. These sections cover essential aspects related to hazardous locations, flammable liquid handling, environments with corrosive materials, and patient care areas.

Key information and requirements include:

Hazardous Locations (Section 18):

Classification of Hazardous Locations: Defines Class I (flammable gases or vapors), Class II (combustible dust), and Class III (flammable fibers or flyings) locations.

Wiring Methods: Requires explosion-proof enclosures, sealed conduit systems, and intrinsically safe circuits to prevent ignition.

Temperature Limitations: Specifies maximum surface temperatures for electrical equipment to avoid ignition in explosive atmospheres.

Bonding and Grounding: Essential to prevent static discharge and control potential differences.

Flammable Liquid Handling and Storage Facilities (Section 20):

Guidelines for electrical systems in fuel stations, bulk storage plants, service stations, garages, finishing processes, and aircraft hangars.

Service Stations, Garages, Bulk Storage Plants, and Aircraft Hangars: Mandates the use of sealed conduit systems and explosion-proof lighting and devices.

Ventilation and Control Systems: Requires proper ventilation and emergency shut-off systems to prevent fire and explosion hazards.

Grounding and Bonding: Ensures proper grounding of tanks, piping, and electrical equipment to prevent static discharge.

Corrosive and Moisture-Prone Environments (Section 22):

Protection of electrical systems in locations exposed to corrosive liquids, vapors, and excessive moisture. This involves using corrosion-resistant materials, sealing systems against moisture ingress, and ensuring proper grounding and bonding.

Material Selection: Requires the use of corrosion-resistant conduits (e.g., PVC rigid conduit, HDPE conduit, and non-metallic tubing) and enclosures.

Sealing and Insulation: Prevents moisture ingress through sealed fittings and junction boxes.

Support and Bonding: Specifies proper conduit support spacing and bonding for electrical continuity and protection against deterioration.

Patient Care Areas (Section 24):

Special requirements for electrical installations in healthcare facilities to ensure the safety of patients and medical equipment.

Isolated Power Systems: Reduces the risk of electric shock by isolating circuits and monitoring ground faults.

Redundant Grounding and Equipment Bonding: Ensures continuous protection for sensitive medical equipment.

Use of Hospital-Grade Devices: Specifies hospital-grade receptacles, wiring methods, and electromagnetic interference protection.

By adhering to these guidelines, commercial and industrial facilities can mitigate the risks associated with hazardous materials, flammable environments, corrosive conditions, and sensitive medical areas. Compliance with these sections is vital for safeguarding personnel, equipment, and infrastructure while meeting regulatory standards and enhancing overall safety.

Renewable Energy Systems (Section 64):

Section 64 of the Canadian Electrical Code (CEC), CSA C22.1:24, establishes the requirements for the safe installation and operation of renewable energy systems, energy production systems, and energy storage systems. This section is essential for ensuring electrical safety, efficiency, and compliance with modern energy technologies.

Key Information and Requirements:

- Renewable Energy Systems:

Solar Photovoltaic (PV) Systems, Wind Turbines, and Hydro Systems: Guidelines for proper wiring methods, grounding, and protection against overcurrent and fault conditions.

Inverter and Power Conditioning Equipment: Requirements for safe integration with utility power and grid-tied systems.

Disconnecting Means and Safety Controls: Ensures the ability to isolate renewable energy sources during maintenance or emergencies.

- Energy Production Systems:

Distributed Generation Systems: Regulations for small-scale power generation and microgrids.

Connection to Utility Grid: Standards for interconnection, metering, and synchronization with the electrical grid.

Protection Against Backfeed and Fault Current: Prevents hazards related to reverse power flow and system instability.

- Energy Storage Systems (ESS):

Battery Storage Systems (Lithium-ion, Lead-acid, and Flow Batteries): Installation requirements for safe handling, ventilation, and thermal management.

Inverter and Charge Controller Compatibility: Ensures proper charging and discharging control.

Emergency Shutdown and Fire Protection: Provides measures to prevent thermal runaway and ensure safe shutdown in critical situations.

Additional Critical Factors:

- Grounding and Bonding Requirements: Prevents electrical shock and ensures system stability.

- Protection Against Overvoltage and Overcurrent: Safeguards the electrical system and connected equipment.

- Inspection and Maintenance Protocols: Regular inspections and monitoring to ensure long-term performance and compliance.

Compliance with Section 64 is vital for supporting the transition to clean energy while maintaining the safety and reliability of electrical systems.

Compliance & Enforcement Across Canadian Jurisdictions

Ensuring electrical safety across Canada relies on the effective adoption and enforcement of the Canadian Electrical Code (CEC). While the CEC provides a national framework, each province and territory tailors its implementation to address local needs and conditions.

A. Provincial & Territorial Adoption

The CEC is a voluntary standard developed by the Canadian Standards Association (CSA), intended for adoption by regulatory authorities. Each province and territory decides how to integrate the CEC into its regulations, often with specific amendments to suit regional requirements.

- Ontario: The Ontario Electrical Safety Code (OESC) incorporates the CEC with modifications to address local safety concerns and environmental conditions.

- Alberta: Alberta Municipal Affairs adopts the CEC and may supplement it with additional regulations to meet the province’s unique industrial and residential needs.

These adaptations ensure that while the CEC provides a common safety baseline, each region can enforce additional measures where necessary.

B. Regulatory Enforcement

Enforcement of the CEC is managed by local inspection authorities and regulatory bodies within each province and territory. Their responsibilities include:

- Inspections: Conducting regular assessments to verify compliance with the Code.

- Permitting: Ensuring that electrical installations have the necessary permits before work begins.

- Amendment Enforcement: Implementing and overseeing local amendments to address regional safety challenges.

Regulatory authorities actively participate in the development of the CEC, with representation on the Canadian Electrical Code, Part I Committee from all provinces and territories, as well as major municipalities like Winnipeg, Calgary, and Vancouver.

C. Adoption Variations

The timing and edition of CEC adoption can vary across jurisdictions. For instance, as of December 2021, Alberta adopted the 2021 edition of the CEC, effective February 1, 2022, while British Columbia’s adoption took effect on October 1, 2022.

D. Expert Insights

Industry experts emphasize that regional adaptations of the CEC are crucial for addressing local challenges. The combination of a robust national standard with regional amendments results in installations that are both safe and tailored to local needs.

Case Study

In Ontario, the integration of the Canadian Electrical Code (CEC) with provincial amendments ensures that electrical installations meet both national and local safety standards. A notable example is the rigorous enforcement of the Ontario Electrical Safety Code (OESC), which incorporates the CEC with specific modifications to address regional conditions.

While specific case studies detailing the implementation of the OESC in multi-residential buildings are not readily available, the Electrical Safety Authority (ESA) emphasizes the importance of proactive maintenance and compliance with updated codes to prevent system failures in aging multi-unit residential buildings.

In summary, while the CEC provides a national framework for electrical safety, its effective implementation relies on provincial and territorial authorities adapting and enforcing the Code to meet local conditions and requirements.

Navigating CEC Compliance: A Step-by-Step Guide

Achieving full compliance with the Canadian Electrical Code (CEC) is not just about following national standards but also understanding the unique requirements of each province and territory. By integrating key CEC sections – such as wiring protection, hazardous locations, fire prevention, and installation standards – electricians and contractors can ensure safe and code-compliant electrical installations. Here’s a practical 4-step guide:

Step 1: Understand Provincial Amendments

Since the CEC serves as a national standard, each province and territory has the flexibility to implement its own amendments to meet local safety and environmental needs. Understanding these regional variations is crucial for compliance:

Ontario: The Electrical Safety Authority (ESA) mandates AFCI (Arc Fault Circuit Interrupter) protection for all bedroom circuits to prevent electrical fires.

Quebec: The Régie du bâtiment du Québec (RBQ) enforces bilingual labeling for electrical panels to ensure safety for both French and English speakers.

British Columbia: Contractors must submit a “Declaration of Compliance” form to Technical Safety BC before final inspections.

Section 12 (Wiring Methods) and Section 26 (Installation of Electrical Equipment) address proper AFCI protection and labeling practices. Following these guidelines not only meets local amendments but also enhances fire prevention and wiring protection.

Step 2: Conduct Risk Assessments and Inspections

A thorough risk assessment helps identify potential code violations before installation. Using modern compliance tools can streamline this process:

- CSA’s “CEC Quick Check” App allows contractors to quickly identify code gaps and potential hazards.

- Evaluating Hazardous Locations: Sections like 18 and 20 of the CEC provide guidelines for installations in areas with explosive gas atmospheres or flammable liquids. Proper classification of these zones is vital to mitigate risks.

- Fire Protection Standards (CEC Section 22): For areas exposed to combustible fibers or dust, selecting the right conduit and equipment prevents overheating and sparks.

- Assessing Wiring Methods: Section 12 outlines acceptable wiring methods, ensuring that installations meet safety standards and are appropriate for the specific environment.

Case Study: A Winnipeg hospital successfully reduced rework costs by 30% by hiring third-party inspectors for pre-approval inspections, identifying non-compliance issues in hazardous areas before final installation.

Step 3: Certify with Local Authorities

Proper documentation and certification are critical to proving compliance with the CEC. Each province has specific requirements:

In British Columbia, contractors must submit the “Declaration of Compliance” form to Technical Safety BC.

In Ontario, securing an ESA inspection report is necessary before energizing any installation.

Section 24 (Patient Care Areas) ensures electrical safety in healthcare facilities, while Section 32 covers installations in emergency systems, such as fire alarms and exit lighting.

Step 4: Leverage Educational Resources and Training

Staying updated with the latest CEC revisions and best practices is essential for long-term compliance:

ESA’s “Code Coach” Webinars provide expert guidance on common compliance mistakes.

CSA’s CEC Handbook offers detailed commentary from code drafters and practical installation tips.

Online Training Portals: Access to training modules and certification programs keeps professionals updated on code changes and best practices.

Expert Tip from an Electrical Engineer:

“A common compliance pitfall is improper cable protection in high-vibration environments or wet locations. By following CEC Section 12 for conduit selection and Section 18 for hazardous location installation, contractors can avoid costly rework and safety risks.”

By following this structured 4-step approach and integrating key CEC sections, electrical professionals can ensure compliance with both national standards and provincial amendments. This not only enhances safety in wiring protection, hazardous environments, and fire prevention but also reduces installation errors and project delays.

2024 CEC Updates: What's New?

The Canadian Electrical Code (CEC) undergoes regular revisions to address emerging technologies, enhance safety protocols, and improve clarity in electrical installations. The 2024 edition introduces several notable changes that professionals in the electrical industry should be aware of.

Renewable and Energy Storage Systems

Lithium Battery Integration: The previous restrictions on lithium battery usage in residential energy storage systems have been lifted, allowing for more flexible and efficient energy solutions.

Photovoltaic Systems: New rapid shutdown requirements have been implemented for photovoltaic installations to enhance firefighter safety during emergencies.

Improved Safety for Pools, Tubs, and Spas

Bonding Requirements: Revisions aim to mitigate voltage gradients around pools and portable hot tubs, reducing the risk of electric shock.

Disconnecting Means: Enhanced guidelines have been introduced to improve maintenance safety for these installations.

Health Care Facilities

Tamper-Resistant Receptacles: The code now mandates the use of tamper-resistant receptacles in areas designated for child care and diagnostics to enhance patient safety.

Wiring Methods

Non-Metallic Jacketed Cables: A new subsection addresses requirements for non-metallic jacketed cables, such as TC and LVT types, detailing guidelines for their support and bonding.

Overhead Installations: There are updated rules concerning cable supports, bonding conductors, and span limits to ensure structural integrity and safety.

Conductors

AWG and IEC Metric Alignment: A new table aligns American Wire Gauge (AWG) sizes with International Electrotechnical Commission (IEC) metric sizes, simplifying conductor selection.

Voltage Drop Calculations: The methodology for calculating voltage drops has been revised to ensure more accurate conductor sizing, promoting efficiency and safety.

Bonding and Grounding

Simplified Grounding Criteria: The code introduces simplified criteria for grounding alternating current (AC) systems, reintroduces isolated bonding conductors, and clarifies bonding requirements for non-electrical equipment like gas piping.

Electric Vehicles (EVs)

Load Calculations: Clarifications have been made regarding load calculations when using EV energy management systems, facilitating the integration of EV infrastructure.

Tips: If you would like to compare with NEC code for EV charging infrastructure, you can read our last post for NEC Code Compliance for EV Charging.

Case Study: A Toronto Contractor's Experience Adopting 2024 Updates

In Toronto, a local electrical contractor undertook a project to install EV charging stations in a commercial building. By adhering to the 2024 CEC updates, particularly the clarified load calculation methods for EV energy management systems, the contractor optimized the building’s electrical load without necessitating extensive infrastructure upgrades. This approach resulted in cost savings and ensured compliance with the latest safety standards.

The 2024 updates to the Canadian Electrical Code reflect a commitment to safety, efficiency, and adaptability in the face of evolving technologies and industry practices. Professionals should familiarize themselves with these changes to ensure compliance and to promote best practices in all electrical installations.

Common CEC Violations and How to Avoid Them

Compliance with the 2024 Canadian Electrical Code (CEC) is crucial to ensuring the safety, reliability, and efficiency of electrical installations. However, even experienced electricians and contractors can sometimes overlook critical requirements, leading to violations that result in fines, project delays, and even voided insurance policies.

Understanding the most common CEC violations and how to prevent them will not only help avoid unnecessary risks but also improve the overall quality of your electrical projects.

1. Improper Grounding and Bonding

Violation: Failure to properly ground electrical panels, equipment, and metal conduit systems is one of the most frequent code violations, especially in older installations and retrofitting projects.

Why it happens: Often due to the incorrect use of bonding jumpers or missing ground electrodes.

2024 CEC Update Impact: The new code simplifies bonding requirements for non-electrical equipment, such as gas piping, and reintroduces isolated bonding conductors for AC systems.

How to avoid it:

Use CEC-approved grounding conductors and bonding clamps.

Install isolated bonding conductors for AC systems.

Choose PVC rigid conduit or HDPE corrugated conduit to prevent corrosion in high-moisture environments.

2. Overloaded Circuits in Residential Upgrades

Violation: Adding new loads to existing circuits without calculating the updated current demand.

Home renovations, such as adding EV charging stations or HVAC systems, often exceed the original circuit capacity.

CEC Update Impact: New rules for load calculation in EV energy management systems allow electricians to exclude the EV charger load under controlled management systems.

How to avoid it:

Conduct accurate load calculations before upgrades.

Use dedicated circuits for high-load devices like Level 2 EV chargers.

Upgrade to larger gauge conductors based on the new CEC voltage drop calculation method

Use CEC-compliant conduit systems like Schedule 40 PVC or DB2 duct to safely handle additional wiring capacity.

3. Non-Compliant Wiring in Agricultural Facilities

Violation: Improper installation of wiring methods in barns, greenhouses, and grain handling facilities.

Why it happens: Use of standard residential wiring methods in high-moisture or corrosive environments.

CEC Update Impact: Enhanced requirements for non-metallic jacketed cables (such as TC-type cables) and better bonding and support rules for overhead installations.

How to avoid it:

Use corrosion-resistant conduit systems, such as PVC rigid conduit or HDPE corrugated conduit, for agricultural environments.

Ensure proper bonding and grounding in wet locations.

Follow the CEC’s revised voltage drop calculation to size conductors accurately over long distances.

4. Incorrect GFCI Protection in Outdoor and Wet Locations

Violation: Lack of proper Ground Fault Circuit Interrupter (GFCI) protection for outdoor circuits or temporary power setups.

Why it happens: Often overlooked on construction sites and outdoor events like film sets or festivals.

CEC Update Impact: New GFCI protection requirements for portable extension cords and stricter rules for single-conductor cable labeling.

How to avoid it:

Install GFCI outlets or breakers for all outdoor circuits and temporary power systems.

Use CEC-compliant extension cords with built-in GFCI protection.

Follow updated labeling standards for safe cable identification.

Ensure proper conduit protection for temporary power distribution, such as liquid-tight flexible conduit (LFMC).

5. Improper Conduit Installation and Support

Violation: Using incorrect conduit types or failing to secure conduit supports in overhead installations.

Why it happens: Lack of knowledge about the new CEC wiring methods section for conduit systems.

CEC Update Impact: Added rules for support spacing, bonding conductors, and cable span limits.

Improved sealing methods for outdoor installations.

How to avoid it:

Use Schedule 40 PVC conduit for above-ground installations.

Choose DB2 PVC duct for direct burial applications. (Pro Tips: You can read our last post for 6 types and DB duct and buying guide.)

Install Ledes Solar Conduit and Fittings for renewable energy systems.

6. Incorrect Voltage Drop Calculation for Large-Scale Projects

Violation: Undersized conductors due to incorrect voltage drop estimation in long-distance wiring.

Why it happens: Traditional voltage drop formulas often lead to miscalculations.

CEC Update Impact: New voltage drop calculation table with AWG and IEC metric sizes.

Improved conductor sizing methodology for accurate long-distance runs.

How to avoid it:

Use larger gauge conductors based on the new table.

Install conduit with high thermal resistance

Select high-performance conductors, such as copper-clad aluminum or HDPE conduit systems for long-distance runs.

7. Failure to Meet New Fire Safety Standards

Violation: Using non-fire-rated conduit and junction boxes in high-rise residential and commercial buildings.

CEC Update Impact: New fire-resistant conduit system requirements for multi-unit dwellings.

Mandates Low Smoke Halogen-Free (LSZH) conduit and fittings for emergency circuits.

How to Avoid It:

Install LSZH conduit and fittings for fire protection.

Use low-voltage conduit solutions that meet UL94 V-0 and 5VA flammability ratings.

Follow the CEC’s revised installation methods for fire-rated walls and ceilings.

CEC vs. NEC: Key Differences for Cross-Border Projects

Navigating electrical installations across the United States and Canada requires a comprehensive understanding of both the National Electrical Code (NEC) and the Canadian Electrical Code (CEC). While both codes aim to ensure safety and standardization, they exhibit distinct differences that professionals must recognize to ensure compliance in cross-border projects.

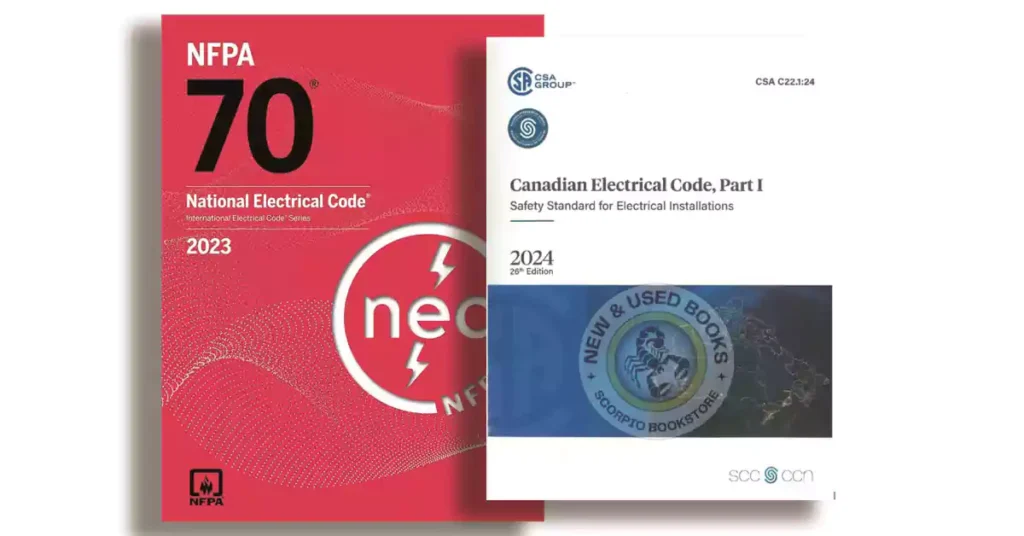

Overview of NEC and CEC

The National Electrical Code (NEC), developed by the National Fire Protection Association (NFPA), serves as the benchmark for safe electrical design, installation, and inspection in the United States. It undergoes revisions every three years to incorporate technological advancements and emerging safety concerns.

Conversely, the Canadian Electrical Code (CEC), published by the Canadian Standards Association (CSA), governs electrical installations in Canada. Similar to the NEC, the CEC is updated triennially, with its latest 26th edition released in March 2024.

8 Differences Between NEC and CEC

While both codes share foundational safety principles, several key differences exist:

Voltage and Frequency Standards

NEC: Standard residential voltage: 120/240V single-phase and 60Hz.

Three-phase systems: 208V, 240V, 480V.

CEC: Uses the same 120/240V and 60Hz standard

Three-phase systems: 120/208V, 347/600V (common in Canadian industrial settings).

Hazardous Location Classification

Both the NEC and CEC allow two classification methods for hazardous locations: Class and Division and Class and Zone. However, a key distinction is that the CEC mandates the use of the Class and Zone system for all new installations, while the NEC still permits the Class and Division system as an alternative. This shift in the CEC aligns with international IEC standards, improving compatibility with global electrical systems.

Circuit Breaker Limitation

The NEC restricts the number of overcurrent protection devices to a maximum of 42 within a single panelboard, aiming to prevent potential catastrophic failures due to sudden overload surges. The CEC, however, imposes no such limit, trusting that a properly installed system minimizes the risk of all breakers tripping simultaneously. This flexibility allows for more extensive electrical systems without additional panelboards in Canadian installations.

Ampacity Tables and Temperature Derating

NEC Approach: The NEC provides extensive ampacity tables, with separate sections for medium voltage and low voltage conductors. It also allows for temperature derating factors greater than 1 when ambient temperatures are cooler than reference values, enabling an increase in conductor ampacity.

CEC Approach: The CEC simplifies ampacity considerations by providing a single ampacity table for both low and medium voltage conductors above ground. However, it restricts temperature derating factors to a maximum of 1, meaning improvements in ampacity beyond CEC tables are not permitted.

Grounding and Bonding

NEC: Specifies standardized grounding methods and materials, emphasizing uniformity and safety.

CEC: Offers more flexibility in grounding methods, allowing adaptation to local practices as long as safety criteria are met. This flexibility can reduce installation costs and adapt to specific environmental conditions in Canada.

Conduit and Wiring Methods

NEC: Provides more options for conduit types and installation methods, including the use of flexible metal conduits in certain areas.

CEC: Places stricter requirements on conduit installations, especially in areas with high moisture or extreme temperatures, to ensure long-term durability and fire resistance.

Arc and Ground Fault Protection

NEC: Requires Arc Fault Circuit Interrupter (AFCI) protection for all bedroom circuits and certain living spaces.

CEC: Enforces similar requirements but extends AFCI protection to additional residential circuits, including kitchens and laundry rooms, for enhanced fire prevention.

Product Certification and Approval

NEC: Accepts equipment certified by UL (Underwriters Laboratories) or other nationally recognized testing laboratories.

CEC: Requires certification by CSA (Canadian Standards Association) or equivalent Canadian-recognized approval bodies.

Comparison Table: NEC vs. CEC

Comparison Table: NEC vs. CEC Code

Aspects | NEC (USA) | CEC (Canada) |

Voltages & Frequency | 120/240V, 60Hz | 120/240V, 60Hz |

Hazardous Location | Class & Division or Class & Zone (optional) | Class &Zone (mandatory for new installations) |

Circuit Breaker Limit | Max 42 devices per panel board | No limit |

Ampacity | Separate for low and medium voltage | One table for both |

Temperature Derating | Greater than 1 allowed | Limited to 1 |

Grounding & Bonding | Standardized methods | Flexible methods |

Arc Fault Protection | Bedrooms & some living spaces | Extended to kitchens and laundry rooms |

Product Certification | UL | CSA |

Case Study: A U.S.-Canada Joint Venture Navigating Dual Compliance

A multinational data center project between a U.S. contractor and a Canadian electrical engineering firm faced challenges in meeting both NEC and CEC standards. The Canadian side required flexible grounding methods and stricter conduit installation for cold-weather environments, while the U.S. team focused on meeting NEC’s arc fault protection and circuit breaker limitations. By conducting pre-installation risk assessments, the teams successfully integrated CEC-compliant non-metallic conduits and NEC-standard AFCI devices, ensuring compliance with both codes and avoiding costly rework.

Practical Applications for Electrical Contractors & Manufacturers

A. Best Practices for Installation

1.Integrating Conduit Systems in Line with CEC Standards

- Use Approved Materials: Source wiring, conduits, and fittings that meet the CEC’s strict requirements to ensure compliance and enhance durability.

- Follow Updated Wiring Methods: Implement modern wiring techniques as outlined in the latest CEC edition to accommodate increased load demands and reduce fire hazards.

- Regular Training & Certification: Ensure technicians undergo continuous training and certification updates to stay informed about the latest CEC revisions.

- Documentation and Record Keeping: Maintain detailed documentation of all installations, permits, and inspection reports for regulatory compliance and future maintenance.

2. Importance of Using Approved Materials and Methods

- Certified Conduits and Fittings: Use CSA-certified rigid PVC conduits, EMT, or liquid-tight flexible conduits depending on the application.

- Proper Installation Techniques: Maintain appropriate clearances and secure conduit runs to prevent mechanical damage and corrosion.

- Regular Inspections and Testing: Conduct periodic testing for grounding resistance and insulation integrity.

B. Tools & Resources

1. Recommended Checklists and Guidelines

CEC Compliance Checklist for Electrical Installations

Conduit Sizing and Ampacity Calculation Tools

Grounding and Bonding Best Practice Guide

2.Downloadable Resources

Digital Checklists aligned with CEC standards

Mobile apps for quick reference to CEC guidelines

Online training courses from CSA and other accredited institutions

3. Online Platforms and Forums

Canadian Electrical Contractors Association (CECA)

Electrical Safety Authority (ESA) Resources

CEC Code Update Webinars

C. Real-World Examples

1. Case Study: Delta Conduit Manufacturing

Integrated the latest CEC guidelines into production processes.

Achieved a 15% reduction in installation errors.

Improved customer satisfaction due to enhanced product safety and durability.

“By aligning our manufacturing process with the latest CEC standards, we not only ensured safety but also gained a competitive edge in the market,” remarked Sarah Nguyen, Quality Assurance Manager at Delta Conduit Manufacturing.

2. Industrial Manufacturing Plant Upgrade

Upgraded electrical infrastructure using CSA-certified PVC conduit systems

Implemented flexible grounding methods to comply with CEC requirements.

Enhanced fire prevention with advanced AFCI protection.

3. Renewable Energy Solar Farm Project

Deployed heavy-duty corrugated conduits for underground cable routing.

Integrated proper bonding techniques for lightning protection.

Improved efficiency and safety with temperature-compliant ampacity calculations.

D. Video/Testimonial Section

Expert Interviews

Electrical engineers discussing successful CEC-compliant projects.

Insights from CSA certification experts on selecting approved materials.

Contractor Testimonials

Testimonials from contractors who achieved safety improvements and efficiency gains.

Demonstrations of proper conduit installation and grounding techniques.

Visual Demonstrations

Time-lapse footage of conduit system installations.

Safety inspections and testing procedures in action.

The Future of the CEC Code

A. Product Design

Material Innovation: Development of flame-retardant conduits, low smoke halogen-free materials, and corrosion-resistant coatings to meet evolving CEC standards.

Sustainable Solutions: Incorporating eco-friendly and recyclable materials to align with green building initiatives.

Durability and Flexibility: Improved materials that withstand extreme temperatures and mechanical stress.

Sustainable Solutions: Eco-friendly materials that align with green building standards.

B. Testing & Certification

CSA/UL Certification Processes: Ensuring compliance with rigorous testing for fire resistance, mechanical strength, and electrical insulation.

Advanced Testing Facilities: Utilizing high-voltage labs to simulate extreme conditions for medium and high-voltage conduit systems.

Continuous Audits and Quality Control: Regular inspections and material traceability to meet CEC’s evolving safety requirements.

C. Marketing Edges

Enhanced Product Credibility: Showcasing CEC compliance in product documentation.

Customer Assurance: Building trust with contractors and end-users through verified safety standards.

Global Market Access: Meeting international standards for export opportunities.

D. Emerging Applications

EV Charging Infrastructure: Designing high-durability conduit systems for Level 2 and DC fast chargers that meet CEC’s strict grounding and bonding requirements.

AI Data Centers: Implementing fire-resistant conduits and advanced cable management solutions to support high-power computing environments.

Smart Conduit Solutions: Integration of real-time monitoring and predictive maintenance capabilities.

How Ledes Provides Safety and Compliance Solutions

About Ledes

Ledes is a global supplier of manufacturing electrical conduit systems and fittings that meet the highest safety and compliance standards. With a strong focus on innovation and quality, Ledes products are widely used across various industries, including renewable energy, data centers, and infrastructure projects. By adhering to both the Canadian Electrical Code (CEC) and the National Electrical Code (NEC), Ledes ensures optimal performance, durability, and safety in electrical installations.

Products that Compliant with CEC and NEC

CSA – approved rigid PVC conduit, DB2 rigid PVC conduit for direct burial applications, electrical non-metallic tubing, elbows and bends, couplings and other fittings.

UL – Listed Schedule 40 & 80 rigid PVC conduit, DB100, DB120 rigid PVC conduit, ENT, elbows, couplings, adapters, and electrical boxes such as slab boxes, wall boxes, gang boxes and conduit bodies etc.

Heavy duty and medium duty low smoke halogen free rigid conduit, corrugated conduit, fittings and electrical boxes.

Meet CEC and NEC fire safety standards.

Suitable for high-risk environments such as tunnels, transportation systems, and data centers.

Solar rigid PVC conduit, corrugated conduit, fittings and boxes.

Designed for high-voltage photovoltaic systems.

Meets both NEC grounding and bonding requirements and CEC flexibility standards.

Advantages of Ledes Products

CEC and NEC Dual Compliance: Ensuring compatibility for cross-border projects.

High Durability and Performance: Resistant to extreme temperatures, corrosion, and mechanical stress.

Advanced Fire Safety Features: LSZH materials minimize toxic emissions and prevent fire hazards.

Flexible Installation Solutions: Suitable for both aboveground and underground applications.

Sustainable and Eco-Friendly Materials: Supporting green energy initiatives and reducing carbon footprints.

Joint Projects

Metro Tunnel Project (Melbourne and Victoria, Australia)

The Metro Tunnel, formerly known as Melbourne Metro Rail (MMR), is an underground rapid transit project currently under construction in Melbourne, Victoria, Australia. The project involves the construction of twin 9-kilometre (5.6 mi) rail tunnels between South Kensington and South Yarra with five new underground stations. It aims to connect the Pakenham and Cranbourne lines with the Sunbury line, creating a new high-frequency cross-city line that bypasses Flinders Street station and the City Loop. The Metro Tunnel is equipped with high-capacity signaling and platform screen doors, a first for Melbourne.

Ledes’ Low Smoke Halogen-Free (LSZH) conduit and fittings were selected for this project to enhance fire safety and ensure durability in the challenging underground environment. These conduits provide superior protection against fire hazards and reduce toxic emissions, aligning with the project’s high safety standards.

CHPE Project (New York to Canada)

The Champlain Hudson Power Express (CHPE) is a high-voltage direct current (HVDC) underwater and underground power cable project linking Quebec to the New York City neighborhood of Astoria, Queens. Developed by Transmission Developers Inc. (TDI), a Blackstone Group portfolio company, the project aims to carry clean energy, including hydropower and wind power from eastern Canada, directly to the New York City electricity market. Construction began in 2022, with completion expected by 2026. The estimated total cost is $4.5 billion USD.

Ledes’ Schedule 40 PVC conduit and fittings were utilized in the CHPE project to protect electrical wiring and ensure long-term performance in the underground sections. The rigid PVC conduit’s durability, corrosion resistance, and compliance with NEC and CEC standards made it an ideal choice for this critical infrastructure project.

Customer Feedback

Electrical Contractors 1: “Ledes’ LSZH conduit systems significantly improved our project’s safety compliance and reduced installation time. Their products are fully certified for both Canadian and U.S. markets.”

Electrical Contractors 2: “We achieved seamless installation of solar conduits for our renewable energy project thanks to Ledes’ superior quality and compliance with CEC guidelines.”

Conclusion

The Canadian Electrical Code (CEC) serves as a cornerstone for electrical safety and innovation in Canada. By establishing rigorous standards for electrical installations, the CEC ensures enhanced fire protection, system reliability, and energy efficiency across various sectors. From material specifications to testing and certification processes, the CEC plays a vital role in maintaining compliance and protecting lives and property. As industries evolve with the integration of electric vehicles and AI data centers, the CEC continues to adapt, driving technological advancements while prioritizing safety.

To further enhance your knowledge and compliance with the CEC, download the official CEC checklist or reach out to the Canadian Standards Association (CSA) for specialized training and certification programs.

Frequently Asked Questions (FAQs):

How often is the CEC updated?

The Canadian Electrical Code (CEC) is updated every three years to reflect advancements in technology, safety standards, and industry best practices. The latest edition is 26 edition published in 2024 and by the Canadian Standards Association (CSA).

How does my province adopt the CEC?

Each province or territory in Canada adopts the CEC in its own way, often with specific amendments to meet local safety regulations and environmental conditions. For instance, British Columbia enforces the BC Electrical Code, which is based on the CEC but includes additional rules for seismic safety due to the region’s earthquake risk. Similarly, Quebec adopts the Quebec Construction Code, which integrates CEC standards with local French-language requirements and regional electrical practices.

How can electrical contractors ensure compliance?

Electrical contractors can ensure compliance with the Canadian Electrical Code (CEC) by following these steps:

- Stay Updated: Regularly review the latest version of the CEC and understand any provincial amendments.

- Obtain Proper Training: Complete CSA-certified training programs to fully understand CEC requirements.

- Use Certified Materials: Install only CEC-compliant electrical conduits, fittings, and components that meet safety standards.

- Conduct Regular Inspections: Perform thorough inspections during and after installation to ensure code compliance.

- Work with Licensed Electricians: Hire certified professionals who are familiar with the CEC and local regulations.

- Maintain Proper Documentation: Keep accurate records of installation procedures and inspection reports for future reference.

- Consult Local Authorities: Communicate with electrical inspectors or regulatory bodies for clarification on specific code requirements.