جدول المحتويات

In the modern digital age, communication conduit plays a crucial role in establishing reliable and efficient connectivity. Whether it’s for transmitting data, voice communications, or multimedia signals, comms conduit serves as the backbone of our interconnected world. This article aims to provide a comprehensive understanding of communication conduit, covering its definition, purpose, and the pivotal role it plays in modern infrastructure.

Definition and Purpose of Communication Conduit:

Communication conduit refers to a protective pathway or channel designed to house and safeguard communication cables. It provides a secure and organized means of routing cables, ensuring efficient transmission and minimizing signal interference. Communication conduit serves as a conduit system, guiding various types of telecommunication cables, including metallic, non-metallic, and fiber optic cables.

The primary purpose of comms conduit is to protect cables from physical damage, environmental factors, and electromagnetic interference. By enclosing cables within a conduit, they are shielded from external elements such as moisture, dust, impact, and exposure to harsh conditions. Additionally, conduit helps maintain the integrity and performance of communication cables, prolonging their lifespan and reducing the risk of signal degradation.

Importance of Communication Conduit in Modern Infrastructure:

In today’s interconnected world, reliable and fast communication is essential for businesses, industries, and individuals. Communication conduit plays a pivotal role in ensuring the seamless flow of information and maintaining the integrity of communication networks. Here are a few key reasons why comms conduit is of utmost importance in modern infrastructure:

1. الحماية والسلامة:

Telecommunications conduit safeguards critical communication cables from physical damage, such as accidental impacts, construction activities, and environmental factors like moisture and extreme temperatures. This protection ensures uninterrupted communication services and reduces the risk of costly downtime.

2. Signal Integrity:

By minimizing electromagnetic interference, conduit telecommunications helps maintain the integrity of signals transmitted through communication cables. It prevents crosstalk, signal degradation, and other interference issues, ensuring reliable and high-quality communication.

3. Cable Organization and Management:

Communication conduit provides a structured and organized pathway for routing cables. It allows for neat and efficient cable management, simplifying installation, maintenance, and future upgrades. Proper cable organization within conduit systems also facilitates troubleshooting and reduces the time required for repairs or modifications.

4. Future-Proofing Infrastructure:

With the rapid advancements in communication technology, infrastructure needs to adapt and support future requirements. Comms conduit offers flexibility and scalability, enabling the integration of new technologies and ensuring the longevity of communication systems. It allows for the seamless addition or replacement of cables as technology evolves.

Types of Comms Conduit:

Telecommunication conduit comes in various types, each designed to meet specific requirements and accommodate different types of communication cables. Understanding the characteristics and applications of these conduit types is essential for selecting the right conduit system for a given infrastructure. The following are the three primary types of telecommunication conduit:

▲ Metallic Conduit:

Overview and Characteristics:

Metallic conduit, typically made of steel or aluminum, offers robust protection for communication cables. It provides excellent durability, resistance to impact, and mechanical strength. Metallic conduit comes in different forms, such as rigid metal conduit (RMC), intermediate metal conduit (IMC), and flexible metal conduit (FMC). RMC is the most rigid and provides the highest level of physical protection, while FMC offers greater flexibility for installations that require bending and maneuvering.

Applications and Benefits:

Metallic conduit is commonly used in industrial environments, commercial buildings, and outdoor applications. Its strength and durability make it suitable for installations where cables may be exposed to harsh conditions, such as heavy machinery areas or outdoor infrastructure. Metallic conduit also provides enhanced protection against electromagnetic interference (EMI) and acts as a grounding path for electrical systems.

Limitations and Considerations:

Metallic conduit can be more challenging to install compared to other types due to its rigidity. Additionally, it requires proper grounding to ensure electrical safety. The conductive nature of metallic conduit may also pose challenges when routing fiber optic cables, as they require non-conductive pathways to prevent signal loss.

▲ Non-Metallic Conduit:

Overview and Characteristics:

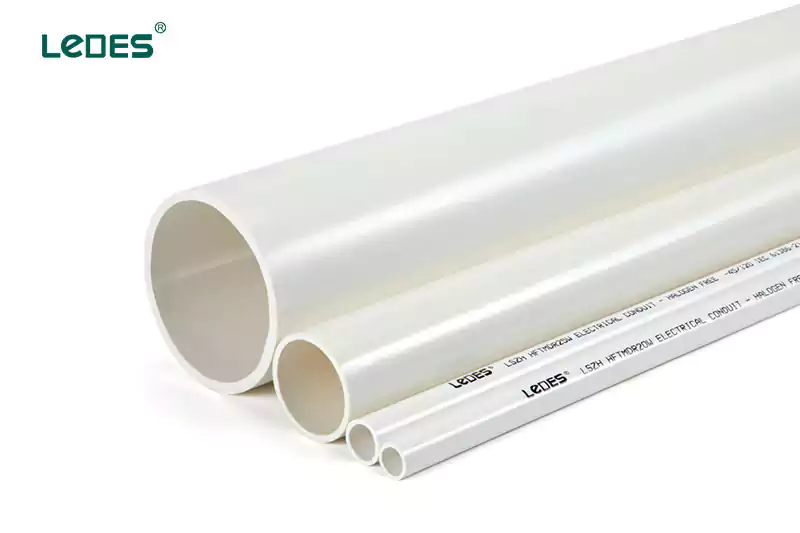

Non-metallic conduit, also known as plastic conduit, is made of PVC (polyvinyl chloride) or other non-metallic materials. It is lightweight, flexible, and easy to work with, making it suitable for a wide range of applications. Non-metallic conduit is available in different forms, such as rigid non-metallic conduit (RNC) and flexible non-metallic conduit (FNC).

Applications and Benefits:

Non-metallic conduit is commonly used in residential, commercial, and indoor installations. It is ideal for applications that require moderate protection and flexibility, such as wiring in homes, offices, and low-voltage systems. Non-metallic conduit is resistant to corrosion, moisture, and chemicals, making it suitable for both indoor and outdoor environments.

Limitations and Considerations:

While non-metallic conduit offers flexibility, it may not provide the same level of physical protection as metallic conduit. It is more susceptible to impact and crushing compared to its metallic counterpart. Non-metallic conduit also has lower resistance to heat, so it may not be suitable for installations where high-temperature conditions are present.

▲ Fiber Optic Conduit:

Overview and Characteristics:

Fiber optic conduit is specifically designed to protect and route fiber optic cables. It is typically constructed with non-metallic materials, such as PVC or high-density polyethylene (HDPE), to provide a non-conductive pathway for the delicate fiber optic cables.

Applications and Benefits:

Fiber optic conduit is used extensively in telecommunications, data centers, and high-speed internet infrastructure. It offers superior protection against EMI and provides a dedicated pathway for fiber optic cables, ensuring optimal signal transmission. Fiber optic conduit also allows for easy cable installation, maintenance, and future upgrades.

Limitations and Considerations:

Fiber optic conduit requires careful handling during installation to prevent signal loss and damage to the delicate fiber optic cables. It is essential to follow proper bending radius guidelines and avoid excessive pulling or twisting of the cables. Additionally, fiber optic conduit may have specific requirements for sealing and protecting against moisture ingress.

Benefits and Advantages of Communication Conduit:

Comm conduit offers a range of benefits and advantages that contribute to the efficiency, reliability, and longevity of communication infrastructure. The following are some key benefits of using communication conduit:

Protection and Safety:

1. Shielding from Physical Damage:

Communication conduit provides a protective barrier that shields communication cables from physical damage caused by external factors such as accidental impacts, construction activities, or environmental conditions. It helps prevent cable crushing, cutting, or bending, ensuring uninterrupted communication services.

2. Fire Resistance:

Many types of comms conduit are designed to be fire-resistant. In the event of a fire, the conduit acts as a barrier, preventing the spread of flames and providing additional time for evacuation and firefighting efforts. Fire-resistant conduit enhances the overall safety of the infrastructure.

3. Environmental Protection:

Telecommunication conduit helps safeguard cables against environmental factors like moisture, dust, chemicals, and extreme temperatures. By providing a sealed enclosure, it minimizes the risk of water ingress, corrosion, and other environmental damage that can compromise the performance and longevity of communication cables.

Cable Organization and Management:

1. Neat and Efficient Cable Routing:

Communication conduit allows for organized cable routing, ensuring a neat and aesthetic appearance. Proper cable organization within the conduit simplifies identification, maintenance, and troubleshooting processes. It also reduces the risk of cable entanglement, which can impede access and lead to signal interference.

2. Easy Access for Maintenance and Upgrades:

Conduit systems enable easy access to communication cables, facilitating maintenance and upgrades. When cables are neatly organized within conduits, technicians can quickly identify and address any issues or make necessary modifications without disrupting the entire infrastructure. This ease of access saves time and effort, minimizing downtime.

3. Minimizing Signal Interference:

Comms conduit helps minimize signal interference by providing separation between different cables and shielding them from external electromagnetic sources. This separation reduces crosstalk and ensures optimal signal integrity, resulting in reliable and high-quality communication.

Future-Proof Infrastructure:

1. Scalability and Flexibility:

Conduit telecommunications offers scalability and flexibility, allowing for the addition or replacement of cables as infrastructure needs evolve. By providing a modular and adaptable pathway, conduit systems can accommodate new technologies and changing communication requirements without the need for extensive infrastructure modifications.

2. Supporting Technological Advancements:

As communication technologies continue to advance, infrastructure needs to keep pace. Communication conduit offers the flexibility to incorporate new technologies, such as higher bandwidth fiber optic cables or emerging communication protocols. This adaptability ensures that infrastructure remains compatible with future advancements.

3. Longevity of Comms Systems:

By protecting cables from physical damage, environmental factors, and signal interference, communication conduit contributes to the longevity of communication systems. Well-protected cables within conduit systems are less prone to degradation, reducing the need for frequent repairs or replacements. This results in cost savings and ensures the reliability of communication services over an extended period.

Installation Process and Considerations

Installing communication conduit requires careful planning and adherence to industry best practices. Following a systematic installation process and considering key factors can help ensure a successful conduit installation that meets the infrastructure’s communication needs.

التخطيط والتصميم:

Assess Communication Requirements:

Determine the specific communication requirements of the infrastructure, including the types of cables to be installed, the number of conduits needed, and the locations where conduit runs are required. Consider factors such as cable capacity, future expansion needs, and compatibility with existing infrastructure.

تخطيط الطريق:

Plan the routes for conduit installation, considering the shortest distance, accessibility for maintenance, and avoidance of potential obstacles or hazards. Take into account any building codes, regulations, or permits required for the installation.

تحجيم القناة:

Select appropriate conduit sizes based on the number and type of cables to be installed. Consider factors such as cable diameter, future cable additions, and any potential temperature or expansion-related considerations.

Installation Process:

1. Marking and Clearing:

Mark the conduit installation paths on the infrastructure, ensuring they are clear of obstructions such as existing utilities, structural elements, or other underground services. Excavate or clear the areas as necessary.

2. Conduit Placement:

Lay the conduit sections along the planned routes, ensuring proper alignment and support. Connect conduit sections using suitable couplings or fittings according to the conduit type. Maintain proper bend radius and avoid excessive pulling or twisting of the conduit during installation.

3. Securing and Support:

Secure the conduit to the infrastructure using appropriate clamps, brackets, or fasteners. Ensure that the conduit is adequately supported to prevent sagging or stress on the cables. Consider expansion joints or flexible connectors for installations that may experience temperature-related expansion or movement.

4. Cable Pulling:

Pull or install the communication cables through the conduit using appropriate cable pulling techniques and tools. Follow recommended cable pulling tensions and avoid exceeding the maximum limits to prevent cable damage or signal loss.

5. Sealing and Termination:

Seal the conduit openings and junction points to prevent moisture ingress. Properly terminate and label the cables at both ends, ensuring clear identification for future maintenance or troubleshooting purposes.

الاعتبارات:

● Safety:

Prioritize safety during the installation process. Adhere to safety guidelines, use appropriate personal protective equipment (PPE), and follow proper electrical and construction safety practices. Take precautions to avoid accidentally damaging existing utilities or infrastructure.

● Compliance with Codes and Regulations:

Ensure compliance with relevant local, national, or industry-specific codes and regulations governing conduit installation, grounding, bonding, and safety practices. Familiarize yourself with the specific requirements and obtain any necessary permits or approvals.

● Collaboration and Expertise:

If needed, consult with professionals or contractors experienced in conduit installation to ensure adherence to best practices and industry standards. Collaborate with other stakeholders, such as electricians or network engineers, to address specific requirements or integration considerations.

● Documentation and Record-Keeping:

Maintain detailed documentation of the conduit installation process, including route plans, cable specifications, installation dates, and any modifications made during the process. Proper record-keeping facilitates future maintenance, upgrades, and troubleshooting activities.

الصيانة واستكشاف الأخطاء وإصلاحها

Routine Maintenance Practices:

Inspection and Cleaning:

Regular inspections of the comms conduit system are crucial to identify any signs of damage, wear, or blockages. Inspect the conduit openings, junction points, and cable pathways for any physical damage, loose fittings, or obstructions. Clean the conduit openings and junction points to remove debris, dust, or any potential obstructions that could hinder cable movement or signal transmission.

Repairing or Replacing Damaged Conduit:

In the event of damaged conduit, such as cracks, breaks, or deteriorated sections, it is important to repair or replace them promptly. Damaged conduit can compromise the integrity of the communication system, leading to signal loss, interference, or even cable damage. Repair the damaged sections using appropriate methods, such as splicing or using couplings, or replace the conduit if necessary.

Troubleshooting Common Issues:

1. Identifying and Resolving Blockages:

Blockages within the communication conduit can impede cable installation, movement, or future cable additions. If blockages are detected, use tools such as conduit snakes or fish tapes to clear the obstruction. In cases where the blockage is severe or inaccessible, it may be necessary to remove and replace the affected section of the conduit.

2. Dealing with Signal Loss or Interference:

Signal loss or interference can occur due to various factors, including cable damage, poor connections, or external electromagnetic interference. Troubleshooting steps for signal issues include:

- Inspect the affected cable for physical damage, such as cuts or pinches, and repair or replace the damaged section.

- Check the connections at both ends of the cable to ensure they are secure and properly terminated.

- Verify that the cables carrying different signals are adequately separated within the conduit to minimize electromagnetic interference.

- Assess the surrounding environment for potential sources of interference, such as electrical equipment or nearby power lines, and take necessary measures to mitigate their effects.

It is important to maintain accurate documentation of all maintenance activities and troubleshooting measures undertaken, including the identified issues, repairs made, and any modifications to the communication conduit system.

Codes and Regulations for Comms Conduit

National and International Standards:

Different countries have their own national standards that govern the installation, materials, and usage of communication conduit systems. These standards ensure consistency, safety, and interoperability. For example:

In the United States, Telecommunications conduit installations must comply with the applicable National Electrical Code (NEC) requirements. The NEC sets baseline safety standards adopted by most local jurisdictions. Specific articles cover communication raceways, cable installation methods, termination practices and more. Key NEC code sections relevant to communication conduit include:

Article 800 on Communication Circuits covers wiring methods, cable installation and protection for voice/data circuits.

Articles 770 and 820 specify requirements for CATV and broadband coax infrastructure including cable type approvals.

Article 345 outlines usage and installation practices for rigid metal conduit (RMC/IMC), an commonly used material for data centers and industrial applications.

In the United Kingdom, the British Standards Institution (BSI) publishes standards like BS 6701, which covers the installation and operation of telecommunications equipment and cabling within buildings.

In Canada, there is CSA standard for comm conduit and in Australia there is AS/NZS 2053 standard. Inernational standards such as IEC and ISO also provide guidelines for the planning and installation of communication cabling infrastructure. Different countries have different standards requirements, it’s very important to consult professionals for conduit installation.

Compliance and Permitting Requirements:

امتثال:

Compliance with codes and regulations is crucial to ensure the safety, reliability, and performance of communication conduit systems. Contractors, installers, and building owners must adhere to these requirements during the design, installation, and maintenance phases. Compliance helps prevent hazards, ensures interoperability, and meets legal obligations.

Permitting Requirements:

Many jurisdictions require permits for the installation of communication conduit systems. Permitting processes typically involve submitting plans, specifications, and other necessary documents to the local authorities. Obtaining permits ensures that the installation complies with local regulations and undergoes inspections as required by the authorities.

It is important to consult the specific standards, building codes, electrical regulations, and permitting requirements of your country or region when planning and implementing communication conduit systems. Adhering to these codes and regulations ensures the proper installation, safety, and compliance of the conduit system, contributing to the overall reliability and efficiency of communication networks.

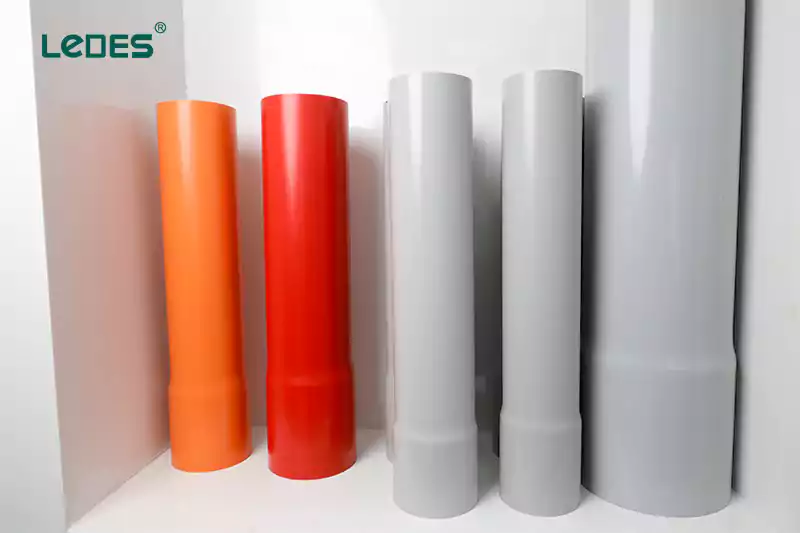

Telecommunications Conduit Colors and Identification:

Conduit Colors:

Communication conduit can be made in different colors according to different needs, could be in gray, white, black, orange, blue, green, and red etc. But the standard color of communication conduit is orange.

Importance of Proper Conduit Identification:

Easy Identification:

Proper identification of conduits helps technicians, installers, and maintenance personnel quickly identify the type of conduit and its purpose. This facilitates accurate and efficient troubleshooting, repairs, and modifications.

Preventing Cross-Connections:

Conduit identification prevents cross-connections, where cables or wires are mistakenly connected to the wrong conduit. Proper identification reduces the risk of signal interference, electrical hazards, or data transmission issues.

Compliance with Regulations:

تتطلب العديد من القوانين واللوائح تحديدًا صحيحًا للمواسير. ويؤدي الالتزام بهذه المتطلبات إلى تعزيز السلامة والامتثال وتسهيل عمليات التفتيش والتدقيق.

الاتجاهات والابتكارات المستقبلية:

أنظمة الأنابيب الذكية:

دمج إنترنت الأشياء والبنية التحتية للاتصالات:

مع استمرار توسع إنترنت الأشياء، ظهرت أنظمة توصيل ذكية لدمج أجهزة إنترنت الأشياء بسلاسة. توفر أنظمة التوصيل هذه مسارات وإمكانية اتصال لمجموعة واسعة من أجهزة إنترنت الأشياء، مما يتيح نقل البيانات بكفاءة وإدارة الطاقة والتحكم.

قدرات المراقبة والتحكم:

تتضمن أنظمة التوصيل الذكية أجهزة استشعار وأجهزة مراقبة وآليات تحكم لتمكين مراقبة وإدارة البنية التحتية للاتصالات في الوقت الفعلي. يمكن لهذه الأنظمة اكتشاف الأعطال وقياس مقاييس الأداء وتحسين الشبكة لتحسين الكفاءة والموثوقية.

حلول الأنابيب المستدامة:

المواد والتصنيع الصديق للبيئة:

مع تزايد المخاوف البيئية، يتزايد التركيز على تطوير حلول قنوات الاتصال التي تستخدم مواد وعمليات تصنيع صديقة للبيئة. ويشمل ذلك استخدام المواد المعاد تدويرها والبوليمرات القائمة على المواد الحيوية والحد من التأثير البيئي الإجمالي للإنتاج.

كفاءة الطاقة والمبادرات الخضراء:

وستركز أنظمة التوصيل المستقبلية على كفاءة الطاقة من خلال دمج التقنيات المبتكرة، مثل أجهزة الاستشعار منخفضة الطاقة، وإدارة الطاقة الذكية، وتوجيه الكابلات بشكل محسن. بالإضافة إلى ذلك، سيكون هناك تركيز أكبر على تنفيذ المبادرات الخضراء، مثل مصادر الطاقة المتجددة لتشغيل البنية التحتية للاتصالات.

تعكس هذه الاتجاهات والابتكارات في أنظمة قنوات الاتصالات التطور المستمر للتكنولوجيا والتزام الصناعة بالاستدامة والكفاءة. ومع انتشار أجهزة إنترنت الأشياء وتزايد المخاوف البيئية، ستلعب أنظمة القنوات الذكية والحلول المستدامة دورًا حاسمًا في تشكيل مستقبل البنية التحتية للاتصالات.

ما هو عدد الكابلات المسموح بها في قناة الاتصالات؟

يعتمد عدد الكابلات المسموح بها في قناة الاتصالات على عوامل مختلفة، بما في ذلك حجم القناة وقطر الكابل والرموز واللوائح المعمول بها. من المهم اتباع رموز البناء المحلية ومعايير الصناعة لتحديد سعة التعبئة المسموح بها لحجم قناة معينة.

غالبًا ما توفر هذه الرموز إرشادات وحسابات لتحديد نسبة التعبئة القصوى أو النسبة المئوية التي لا ينبغي تجاوزها. تأخذ نسبة التعبئة عادةً في الاعتبار عوامل مثل قطر الكابلات والقناة، بالإضافة إلى نوع الكابلات التي يتم تركيبها (على سبيل المثال، كابلات الطاقة، وكابلات البيانات، وكابلات الألياف الضوئية).

هل يجب أن يكون كابل الألياف الضوئية في قناة؟

في كثير من الحالات، لا يلزم بالضرورة تركيب كابلات الألياف الضوئية داخل أنبوب توصيل. تم تصميم كابلات الألياف الضوئية لتكون متينة ومقاومة للعوامل البيئية، مثل الرطوبة وتغيرات درجات الحرارة والتداخل الكهرومغناطيسي. ويمكن دفنها مباشرة في الأرض، أو تركيبها جواً على أعمدة، أو وضعها في قنوات داخلية (قنوات فرعية) دون الحاجة إلى أنبوب توصيل إضافي.

ومع ذلك، هناك مواقف حيث يكون استخدام الأنابيب مع كابلات الألياف الضوئية مفضلًا أو مطلوبًا. تتضمن بعض أسباب استخدام الأنابيب مع كابلات الألياف الضوئية ما يلي:

حماية: يوفر الموصل طبقة إضافية من الحماية المادية لكابل الألياف الضوئية ضد التلف العرضي أو القوى الخارجية أثناء التثبيت أو الصيانة أو أنشطة البناء.

سهولة الوصول: يمكن أن تسهل الأنابيب الوصول إلى كابل الألياف الضوئية لإجراء الإصلاحات أو الاستبدالات أو الترقيات في المستقبل. كما تسمح بإدارة الكابلات بشكل منظم وتقلل من الحاجة إلى أعمال حفر مكثفة أو أنشطة مزعجة.

التوسع المستقبلي: يتيح تركيب كابلات الألياف الضوئية في الأنابيب إمكانية التوسع في المستقبل أو إضافة كابلات جديدة بسهولة أكبر. كما يوفر المرونة ويسهل تركيب ألياف إضافية أو أنواع مختلفة من الكابلات دون الحاجة إلى تعديلات كبيرة في البنية التحتية.

امتثال: في بعض الحالات، قد تلزم قوانين البناء المحلية أو معايير الصناعة أو متطلبات المشروع المحددة استخدام الأنابيب لتركيبات كابلات الألياف الضوئية

خاتمة

وفي الختام، فإن قنوات الاتصال تشكل عنصراً حيوياً في البنية الأساسية للاتصالات الحديثة. فهي توفر المسارات والحماية اللازمة للكابلات والأسلاك، مما يضمن التركيب والصيانة الفعّالة لشبكات الاتصالات. والالتزام بالمعايير واللوائح، والتعريف السليم، واحتضان الاتجاهات والابتكارات المستقبلية، كلها عوامل أساسية لبناء بنية أساسية موثوقة ومستدامة للاتصالات. ومن خلال فهم أهمية قنوات الاتصالات، يمكننا خلق اتصال سلس ودعم الطلب المتزايد باستمرار في العصر الرقمي على شبكات البيانات والاتصالات.

إذا كانت لديك أي أسئلة حول قنوات الاتصال، فإن شركة Ledes، باعتبارها شركة مصنعة لقنوات الكهرباء، بما في ذلك قنوات الاتصال، لديها متخصصون لمساعدتك في حل مشاكلك، إرسال النموذج أو أرسل لنا بريدًا إلكترونيًا للحصول على مزيد من المعلومات.