Table of Contents

Introduction

Electrical conduits play a crucial role in safeguarding and organizing electrical wiring systems. Among the popular options available, rigid PVC conduit and flexible PVC conduit are widely used. In this article, we will provide an in-depth comparison of these two types of conduits, covering their characteristics, applications, installation considerations, and their performance requirements as specified by relevant standards. Key aspects such as impact resistance, crush resistance, temperature range, strength, bending capabilities, flexibility, flammability, and more will be discussed.

What are Flexible Conduits?

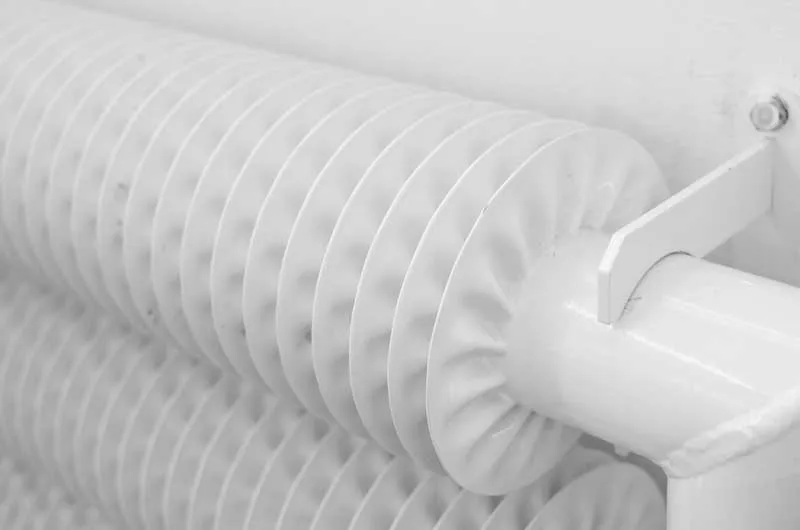

Flexible conduits, such as flexible PVC conduit, are designed to provide a pliable and easily bendable option for routing electrical wires in curved or irregular paths. They are made of flexible materials, like PVC, that allow for easy bending by hand without the need for specialized tools. Flexible conduits comply with applicable standards, such as UL1653 for ENT, and are tested for factors like impact resistance, crush resistance, temperature range, and flexibility.

What are Rigid Conduits?

Rigid conduits, such as rigid PVC conduit, are characterized by their sturdy and inflexible structure. They are made of rigid polyvinyl chloride material, which provides excellent impact resistance and structural strength. Rigid conduits comply with standards such as UL 651 for Schedule 40 and Schedule 80 rigid PVC conduit, and are tested for factors like impact resistance, crush resistance, temperature range, and strength.

Comparison of Rigid PVC Conduit and Flexible PVC Conduit

Material and Structure:

Rigid PVC Conduit: Made of rigid PVC, this conduit is sturdy and inflexible, providing excellent protection against physical damage.

Flexible PVC Conduit: Constructed with flexible PVC material, this conduit offers pliability and can be bent easily without the need for specialized tools.

Applications:

Rigid PVC Conduit: Ideal for applications that require straight runs, such as exposed or concealed installations in residential, commercial, and industrial settings.

Flexible PVC Conduit: Suited for installations that involve curved or irregular paths, such as wiring in tight spaces, moving machinery, or areas prone to vibration.

Installation and Burial:

Rigid PVC Conduit: Requires precise measurements and fittings for straight runs, often necessitating the use of specialized bending tools. It is suitable for both above-ground and underground installations.

Flexible PVC Conduit: Offers ease of installation, as it can be bent by hand to accommodate varying angles and curves. However, it is not intended for direct burial unless specifically listed for such use.

Outdoor Use and Protection:

Rigid PVC Conduit: Provides excellent protection against moisture, sunlight, and physical damage, making it suitable for outdoor installations.

Flexible PVC Conduit: Can be used outdoors but requires additional protection, such as UV-resistant coatings or conduit sleeves, to withstand exposure to sunlight and harsh weather conditions.

Some Performance Requirements:

Rigid PVC conduit(UL651):

Impact Resistance: The conduit should withstand a 9.7-kg(Schedule 40, Type A and EB) or 34-kg(Schedule 80) weight dropped from a certain height without cracking or breaking.

Crush Resistance: The conduit should withstand a force of 850-1000 lbf without deformation or failure.

Flammability: Rigid PVC conduit shall not flame for longer than 5 seconds following any of three 60-second applications of flame, the period between applications being 30 seconds

Strength: The conduit should possess sufficient structural strength to protect electrical wiring from external forces and impacts.

Extensive reading

Purpose of Electrical Conduit:

Electrical conduit serves as a protective channel for electrical wiring, shielding it from physical damage, moisture, and external elements. It also organizes and routes the wiring system efficiently.

Burial of Flexible Conduit:

Flexible PVC conduit should not be directly buried unless it is specifically designed and labeled for underground use. Buried installations typically require rigid PVC conduit or other types of suitable conduit specifically rated for burial.

Conduit Requirements for Outdoor Electrical Wire:

Outdoor electrical wires generally need to be installed within a conduit to provide protection against moisture, mechanical damage, and UV exposure. The type of conduit required depends on the specific application and local electrical codes.

Conduit Selection for Underground Use:

For underground applications, such as burying electrical wires, it is crucial to use a conduit that is specifically designed for direct burial. This conduit is typically made of durable materials and has additional features to resist corrosion and moisture.

Tips for Installing Electrical Conduits:

Plan the conduit route carefully, considering factors like bends, access points, and future expansion.

Use appropriate fittings and connectors to ensure secure connections and maintain conduit integrity.

Follow local electrical codes and regulations regarding conduit installation, grounding, and sizing.

Bending PVC Electrical Conduit without a Bender:

While it is recommended to use a conduit bender for precise bends, PVC conduit can be bent without a bender by using gentle heat from a heat gun or hairdryer. Caution should be exercised to avoid overheating or damaging the conduit.

Can you put a PVC conduit in concrete?

Yes, PVC conduit can be installed in concrete. It is a common practice to run electrical conduits through concrete walls, floors, or foundations to protect and route electrical wiring. Here are some important considerations when installing PVC conduit in concrete:

- Conduit Type: Ensure that you are using Schedule 40 or Schedule 80 rigid PVC conduit, which is specifically designed for electrical applications. These conduits have the necessary strength and durability to withstand the concrete installation process.

- Proper Placement: Plan the conduit runs carefully before pouring concrete. Determine the optimal locations for the conduits to avoid interference with structural elements and ensure efficient wiring routing.

- Conduit Protection: To protect the PVC conduit during the concrete pour, it is advisable to use conduit sleeves. These sleeves are typically made of metal or high-density polyethylene and serve as a protective barrier around the conduit. The sleeves prevent the concrete from directly contacting the conduit, reducing the risk of damage.

- Secure Installation: Position the PVC conduit inside the conduit sleeve and secure it in place using appropriate fasteners or clamps. Ensure that the conduit is straight and aligned correctly before the concrete pour to prevent any deviations or misalignments.

- Concrete Pouring: During the concrete pouring process, take care to avoid displacing or damaging the conduit. Proper coordination between the electrician and the concrete pouring team is essential to ensure the conduit remains in its intended position.

- Concrete Encasement: Once the concrete has cured, the PVC conduit will be encased within the concrete structure. The conduit will provide protection and a pathway for electrical wiring, allowing for future access or modifications if needed.

Can flexible conduit be used outdoors?

Flexible conduit can be used outdoors, but it is important to choose a specific type that is suitable for outdoor environments. Look for conduits that are designed for outdoor use or have been rated for outdoor applications. Consider factors such as UV resistance, moisture protection, temperature range, and proper installation techniques. Following manufacturer instructions and local electrical codes ensures a safe and compliant installation. By selecting the appropriate conduit and adhering to installation guidelines, you can effectively use flexible conduit for outdoor applications.

Does an electrical PVC conduit need to be glued?

It is generally recommended to use PVC cement or glue to join electrical PVC conduit fittings and pipes together. Gluing the PVC conduit ensures a secure and watertight connection. Clean and prepare the surfaces, apply PVC cement according to the manufacturer’s instructions, assemble the conduit and fitting, and allow sufficient time for the cement to cure. Following local electrical codes and regulations is essential for a safe and compliant installation.

What is the difference between conduit and pipe?

Conduit and pipe are both used for the purpose of channeling or protecting various types of materials, but they have some key differences. Here are the main distinctions between conduit and pipe:

- Purpose and Usage: Conduit is primarily used for electrical applications, providing a protective pathway for electrical wires or cables. It is specifically designed to protect and route electrical wiring systems in residential, commercial, and industrial settings. On the other hand, pipes are typically used for the transportation of fluids, such as water, gas, oil, or other liquid or gaseous substances.

- Construction and Material: Conduit is often made of materials that offer specific properties suitable for electrical applications, such as rigid metal (e.g., steel or aluminum), rigid non-metallic (e.g., PVC or fiberglass), or flexible metal or non-metallic options. Pipes, on the other hand, are commonly constructed from materials like metal (e.g., steel, copper, or stainless steel) or various types of plastic (e.g., PVC, HDPE, or PEX).

- Size and Dimension Standardization: Conduit is typically available in standardized sizes based on the trade sizes specified by electrical codes. These sizes are measured based on the internal diameter of the conduit and are commonly expressed in inches (e.g., 1/2″, 3/4″, 1″). Pipes, on the other hand, can vary significantly in size and are usually designated by their nominal pipe size (NPS) or outside diameter (OD) in inches or millimeters.

- Installation and Fittings: Conduit installation involves specific techniques and fittings designed for electrical applications, such as connectors, couplings, elbows, and junction boxes. It often requires adherence to electrical codes and regulations. Pipe installation, on the other hand, follows plumbing or industrial standards and involves fittings and connectors specific to fluid transportation, such as valves, tees, elbows, and flanges.

- Code Compliance: Conduit installation is governed by electrical codes and regulations to ensure proper electrical wiring practices, safety, and fire protection. These codes specify requirements for conduit sizing, installation methods, grounding, and other electrical considerations. Pipes, on the other hand, are regulated by plumbing codes and industry standards that focus on proper fluid flow, pressure, and material compatibility.

Conclusion

Considering the specific requirements of an electrical project is crucial when choosing between rigid PVC conduit and flexible PVC conduit. Rigid PVC conduit provides robust protection for straight runs, while flexible PVC conduit offers flexibility for curved or irregular paths. By adhering to relevant standards such as UL 651, UL 1653,and other standards, these conduits ensure reliable protection and organization of electrical wiring systems. Additionally, understanding the purpose of electrical conduits and relative information will empower professionals and DIY enthusiasts to make informed decisions when selecting the most suitable conduit for electrical installations.

Contact

If you still have questions, you can simply submit the contact form or send an email to us today.